Documente Academic

Documente Profesional

Documente Cultură

Side Channel Pumps

Încărcat de

wakgeng marwahDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Side Channel Pumps

Încărcat de

wakgeng marwahDrepturi de autor:

Formate disponibile

Side Channel Pumps

Self-priming, segmental type

AKH 1101 … 6103

Technical data

Capacity: from 0,2 up to 35 m³/h

Head: from 6 up to 144 m

Speed: 1450 rpm (max. 1800 rpm)

Temperature: max. 120 °C

Casing pressure: PN 16

Shaft sealing: stuffing box or mechanical seal

Flange connections: DIN 2501 / PN 16

Direction of rotation: clockwise

(when seen from the drive end)

Application Construction

The Sterling SIHI AKH pump is a self-priming side channel Casing pressure

pump capable of handling gas along with the medium and Maximum 16 bar from -40 °C up to +120 °C.

operates at a low noise level. The AKH is suitable for trouble

free handling of clean or turbid liquids without any abrasive

particles. Please observe

Technical rules and safety regulations:

The performance curve steepness admits a precise regulation Casing pressure = inlet pressure + delivery head at minimum

of the pressure with a small change in capacity. pump capacity.

The AKH pump has been developed for a broad range of

medium duty applications in: Position of branches

• Chemical industry, Suction and discharge branch point radially upwards.

• Petro-Chemical industry,

• Oil industry,

• Machinery and automobile industry , Flanges

• Food industry,

• Building trades, The flanges correspond to DIN EN 1092-2 / PN 16.

• Plastic and rubber industry, Flange design as per DIN 2512 with groove or drilled

• Surface treatment, according to ANSI 150 or 300 lbs is basically possible.

• Ship yards.

Bearing

Either by one grease lubricated ball bearing and one liquid

Design surrouned sleeve bearing (design A) or by two grease

lubricated ball bearings (design B). The ball bearings are

Pumps of the series AKH have a segmental type construction according to DIN 625. The first grease filling is done in the

with open vane wheel impellers. The pump construction is factory.

either with one liquid surrounded slide bearing and one ball

bearing or in a more industrial construction by using a double

ball bearing design. Direction of rotation

Clockwise, when looking at the pump from the drive end.

The program comprises 6 sizes with up to 4 stages (an Anti-clockwise is possible.

extension with 5 or 6 stages is possible for certain sizes).

The performance curves of the AKH are identical for all the

material designs. Shaft sealing

The applied hydraulic components are from our Modular Side The shaft can be sealed by either a stuffing box or a standard

Channel system (interchangeability of parts). mechanical seal.

Sterling Fluid Systems Pumping Technology AKH-00 2003

Material design AKH

Cast iron

Pos Components Material design

0A 0B 0F

1060 Suction casing

1070 Discharge casing

EN-GJL-250

1090

1140 Intermediate piece

1141

2100 Shaft X 20 Cr 13

2350 Vane wheel impeller CuZn40Al2 G-X 3 CrNiMoCuN 26 6 3 3 PAEK

0241 Bearing bush EK 2203

Stainless steel and Bronze

Pos Components Material design

2H* 3B 4B 4F

1060 Suction casing

EN-GJL-250 GC-CuSn 12

1070 Discharge casing

G-X 6 CrNiMo 18 10

1090

1140 Intermediate piece G-Sn Bz 16

1141

2100 Shaft X 5 CrNiMo 17 12 2

G-Cu Sn chrome G-Cu Sn chrome

2350 Vane wheel impeller plated plated G-X 3 CrNiMoCuN 26 6 3 3 PAEK

0241 Bearing bush EK 2203

* The construction of the AKH in material 2H is conform the construction of the AKH in Cast iron (see the next page)

Casing seal General comments

The casing can be sealed with a liquid sealing compound or Side Channel pumps with the same hydraulic construction

soft Teflon. are manufactured in series as:

AOH Low duty pump with oval flanges, PN 10

Drive

CEH High duty pump, PN 40

By electric motor, type of construction IM B3. Also available with magnetic coupling

CEB Vertical tank mounted pump, PN 25 with magnetic

coupling

CEV Vertical tank mounted pump, PN 25 with mechanical

seal (replacement for CVGP)

AEH High duty pump, PN 40

Also available with magnetic coupling

Technical documents about these pump series will be readily

supplied on request.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 2 / 20

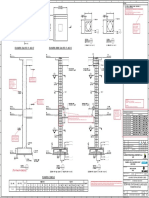

Sectional drawing and parts list AKH (typical)

AKH in Cast iron (0A, 0B, 0F, 2H)

1070 1060

2350 2100

Design A

(only for sizes 1100 up to 5100)

1140

0241 1141 1090 4330

Pos. Components

0241 Bearing bush

1060 Suction casing

1070 Discharge casing

1090 Suction intermediate piece

1140 Discharge intermediate piece

1141 Discharge intermediate piece Design B

1800 Mounting flange

2100 Shaft

2350 Vane wheel impeller

3500 Bearing housing

4330 Mechanical seal

4610 Stuffing box Stuffing box (available for all material designs)

AKH in Bronze (3B) and Stainless steel (4B and 4F)

1070 1060 2100

2350 3500

4610

1800

Design A

(only for Stainless steel in sizes 1200 up to 5100)

1141 1090

0241 1140 4330

Design B

All possible design combinations can be found in the delivery program

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 3 / 20

Performance range AKH

General conditions

Liquid: Water

Density: 1 kg/dm3

Viscosity: 1 cSt

Temperature: 20 °C

Atmospheric pressure: 1013 mbar

Characteristic tolerances

Capacity ± 10% - Delivery head ± 10% - Power + 10%

For designs with a mechanical seal or a casing seal of soft Teflon, the tolerance for the delivery head is extended by 2% each.

Measuring standard

According to ISO 5198

150 n = 1450 rpm

H

(m)

100

1100* 1200 3100 3600 4100 5100 6100

50

0

0,2 0,4 0,6 0,8 1 2 4 6 8 10 20 40

Q

* only for cast iron design (m3/h)

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 4 / 20

Dimensiom chart, Pump set drawing and Performance curves

AKH 3600 in Bronze and Stainless steel (3B, 4B and 4F)

H w

(m) 36

04 1450 rpm 146 a 189

100 40

360 4

3

80

60 3602

40 55

3601 G¼

20 m2 m1

0 f1

v e1

P w1

(kW)

5

3604 ∅18x4

4 ∅140

3603

3

3602 ∅100

2 ∅16j5

3601 118 5 DN32

1

0

NPSH 112 15 18,1

(m) h3

3 ∅13 36 d

2

1 c

4 5 6 7 Q 160 e2

(m3/h) 196 b2

General: Values are valid for water ρ = 1 kg/dm3 and ν = 1 cSt.

Characteristic tolerances: Capacity ± 5% - Delivery head ± 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head

is extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

3601 0.75 80 P241 B68 26 58 150 330 25 19 480 290 125 99 177 308 268 762 730

1.1 90S 62 820

1.5 90L P241 B68 67 330 480 290 125 820 730

3602 27 150 25 19 99 177 308 268

2.2 100L P272 B80 78 360 540 320 140 861 820

2.2 100L 82

901

3103 3 100L P272 B80 31 83 190 360 25 19 540 320 140 99 177 348 308 820

4 112M 101 922

3 100L 87 360 19 540 320 140 177 941

P272 B80 820

3604 4 112M 34 109 230 361 25 15 600 325 160 99 162 388 348 962

5.5 132S P015 B95 131 182 1038 920

* Design B - dimensions depend on the motor brand.

The weight of the pump in design A (only available in Stainless steel) will be approximately 2,7 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 14 / 20

Sterling SIHI Side Channel pumps

Sterling Fluid Systems offers an extensive Side Channel pump range under its brand name Sterling

SIHI. Sterling Fluid Systems has more than 80 years of experience in manufacturing, installation and

support of Side Channel pumps. The Sterling SIHI Side Channel pumps can be found in a wide

application range for the:

• Chemical market

• Pharmaceutical industry

• Petrochemical industry

• Food industry

• Ship yards

• LPG industry

• and many more ...

The Sterling SIHI Side Channel pump range

1000

CEH

AEH

AEHL

100 ADHL

CDHL

Delivery head (m)

AOH ASH

AKH

10 AKL

AKV

AOL

DRV

0 10 20 30 40

Capacity (m3/h)

The benefits of the Sterling SIHI Side Channel pumps

• Self priming

• Gas handling

• High-resistant materials

• Performance curve characteristics

• High efficiency

• Low NPSHR value

• Modular hydraulic system

The Sterling SIHI Side Channel pumps comply with the highest demands of our customers and

are the best solution for the handling of liquid under critical physical conditions.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 19 / 20

S-ar putea să vă placă și

- Laplace MPNI 1150Document20 paginiLaplace MPNI 1150mansyur yadi67% (3)

- Volute Casing Pumps: SupernovaDocument9 paginiVolute Casing Pumps: SupernovaP. Ernesto C. GutierrezÎncă nu există evaluări

- Pressure Controls - SaginomiyaDocument3 paginiPressure Controls - Saginomiyawakgeng marwahÎncă nu există evaluări

- TCSP10403R0Document30 paginiTCSP10403R0BADRI VENKATESHÎncă nu există evaluări

- AKH - CatalogoDocument20 paginiAKH - CatalogoSapta WaeÎncă nu există evaluări

- Bomba Agua dulceTC - FLS - SIHI - AKHA - ENDocument18 paginiBomba Agua dulceTC - FLS - SIHI - AKHA - ENOscar CaviedesÎncă nu există evaluări

- TC FLS Sihi Akhx enDocument12 paginiTC FLS Sihi Akhx enandrescaligoÎncă nu există evaluări

- Side Channel Pumps: CEH 1201 ... 6108 CEH 1202/5 ... 6108/5 CEH 1202/7 ... 6107/7Document20 paginiSide Channel Pumps: CEH 1201 ... 6108 CEH 1202/5 ... 6108/5 CEH 1202/7 ... 6107/7yecidÎncă nu există evaluări

- Data Sheet Pompa PDFDocument19 paginiData Sheet Pompa PDFamamÎncă nu există evaluări

- Samonasavaci Cerpadlo CEHDocument19 paginiSamonasavaci Cerpadlo CEHdewidewi76Încă nu există evaluări

- Ceha PDFDocument17 paginiCeha PDFMIGUELÎncă nu există evaluări

- Sihi Aeh enDocument12 paginiSihi Aeh enIrvan NouriÎncă nu există evaluări

- SIHI CEH Magnetic CouplingDocument17 paginiSIHI CEH Magnetic CouplingAde NugrahaÎncă nu există evaluări

- Pump Sterling PDFDocument18 paginiPump Sterling PDFJackÎncă nu există evaluări

- WILO SCP RangeDocument48 paginiWILO SCP RangeSaikat PurkaitÎncă nu există evaluări

- Type Zlic Brand SihiDocument8 paginiType Zlic Brand SihiArdi 4791Încă nu există evaluări

- LPG - Side Channel Pump: Technical DataDocument4 paginiLPG - Side Channel Pump: Technical DataMona NormianaÎncă nu există evaluări

- Side Channel Pumps: ADH/CDH 0801 - . - 2504 AEH 0805 - . - 0808Document10 paginiSide Channel Pumps: ADH/CDH 0801 - . - 2504 AEH 0805 - . - 0808Anonymous CMS3dL1TÎncă nu există evaluări

- LPG - Pump CatalogueDocument19 paginiLPG - Pump CataloguepomaukÎncă nu există evaluări

- CEB - E PumpDocument4 paginiCEB - E PumpJan AlsicannÎncă nu există evaluări

- Volute Pumps Sihi: SupernovaDocument10 paginiVolute Pumps Sihi: SupernovaLuis Fernando collazosÎncă nu există evaluări

- 3-Lever-Valve, BH Series: Features Shaft DesignDocument4 pagini3-Lever-Valve, BH Series: Features Shaft DesignScipp ZengÎncă nu există evaluări

- SY Actuators WEB2Document12 paginiSY Actuators WEB2vikalpsharma96Încă nu există evaluări

- Side Channel Pumps: Self-Priming, Multi-Stage TypeDocument5 paginiSide Channel Pumps: Self-Priming, Multi-Stage TypeLPG Equipment Consulting and ServicesÎncă nu există evaluări

- Evap PumpDocument21 paginiEvap PumpWest Damietta2Încă nu există evaluări

- Multistage Centrifugal Pumps HEGA 2502 ... 8009: Technical DataDocument17 paginiMultistage Centrifugal Pumps HEGA 2502 ... 8009: Technical Datajairo ardilaÎncă nu există evaluări

- Sterling PumpeDocument20 paginiSterling PumpesrdzaÎncă nu există evaluări

- TC Fls Sihi Zti en SihiDocument12 paginiTC Fls Sihi Zti en SihiArdi 4791Încă nu există evaluări

- Sihi AolDocument5 paginiSihi Aolmohsen fatemiÎncă nu există evaluări

- PU HEGA Esite GBDocument17 paginiPU HEGA Esite GBRinto SilalahiÎncă nu există evaluări

- VS6Document4 paginiVS6Arash Sotoudeh100% (1)

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 paginiCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanÎncă nu există evaluări

- Curve PompaDocument23 paginiCurve PompaacexventuraÎncă nu există evaluări

- TC FLS Sihi TKH TLH enDocument16 paginiTC FLS Sihi TKH TLH enAnonymous 24lnhhÎncă nu există evaluări

- NK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Document14 paginiNK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Geovanni MZÎncă nu există evaluări

- Grundfos - NB 50 250 254 A F2 A E BAQEDocument13 paginiGrundfos - NB 50 250 254 A F2 A E BAQEHoria AliÎncă nu există evaluări

- Series NTWH - CTWH - NBWH - CBWH - NIWH - CIWHDocument32 paginiSeries NTWH - CTWH - NBWH - CBWH - NIWH - CIWHJorge Vásquez.Încă nu există evaluări

- ZLKDocument10 paginiZLKHunter NoVaÎncă nu există evaluări

- Grundfos - NK 125 315 317 A2 F A E BAQEDocument14 paginiGrundfos - NK 125 315 317 A2 F A E BAQEMaryasa RobedÎncă nu există evaluări

- BombasDocument8 paginiBombasDiego Fernando GaviriaÎncă nu există evaluări

- KSB BEV BEV LO PDFDocument36 paginiKSB BEV BEV LO PDFBernardo Salinas GonzalezÎncă nu există evaluări

- K3VL Datasheet 21 03 11Document56 paginiK3VL Datasheet 21 03 11Muhammad AzkaÎncă nu există evaluări

- Screw Pumps Series SPF: Application Shaft SealingDocument16 paginiScrew Pumps Series SPF: Application Shaft Sealingmsh16000Încă nu există evaluări

- Brochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDocument6 paginiBrochure FSA, 50 Hz1-Dikonversi - Pdf. TerbaruDt BarusÎncă nu există evaluări

- Instrumentation Products: Ball Valves and Ball Valve ManifoldsDocument28 paginiInstrumentation Products: Ball Valves and Ball Valve ManifoldsMAHESH CHANDÎncă nu există evaluări

- Bombas SterlingDocument19 paginiBombas SterlingGenrry EchaccayaÎncă nu există evaluări

- Product Catalogue Rev 4Document202 paginiProduct Catalogue Rev 4kanbur.191Încă nu există evaluări

- Self-Priming Pumps: Type Series Booklet CTI-2100/0 2 (07-2016)Document32 paginiSelf-Priming Pumps: Type Series Booklet CTI-2100/0 2 (07-2016)mohsen aminiÎncă nu există evaluări

- GX and Baumann ValvesDocument25 paginiGX and Baumann ValvesSATHISHKUMAR RÎncă nu există evaluări

- Suppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalDocument34 paginiSuppl.B HPK-L - 1136 - 00 - 03 S2-EN - FinalJorge VillalobosÎncă nu există evaluări

- Sihi Pomp01 PDFDocument24 paginiSihi Pomp01 PDFes9857Încă nu există evaluări

- Центробежные насосы Allweiler серии ALLHEAT NTWHDocument30 paginiЦентробежные насосы Allweiler серии ALLHEAT NTWHAris Fitama ZeinauraÎncă nu există evaluări

- R - 1776 - Check Valves Side Mounted Extraction Check ValveDocument4 paginiR - 1776 - Check Valves Side Mounted Extraction Check ValvedharmendrabholeÎncă nu există evaluări

- Contavac Pumps - PIII1 PDFDocument18 paginiContavac Pumps - PIII1 PDFrakacyuÎncă nu există evaluări

- KSB B: Deep Well Turbine Pump BDocument36 paginiKSB B: Deep Well Turbine Pump BKishore Krishna0% (1)

- Brochure FSA, 60 HZDocument6 paginiBrochure FSA, 60 HZIbrahim SanusiÎncă nu există evaluări

- Heavy Duty Process Pumps According To API 610, 11 Ed. Type NCRDocument11 paginiHeavy Duty Process Pumps According To API 610, 11 Ed. Type NCRJaldhi PatelÎncă nu există evaluări

- Reactomate ValveDocument2 paginiReactomate ValveibkhiÎncă nu există evaluări

- AVKDocument2 paginiAVKpiscesguy78Încă nu există evaluări

- 84-45-003 Avk002ax Eni 432444Document3 pagini84-45-003 Avk002ax Eni 432444Gotica ManagementÎncă nu există evaluări

- CMOS Piezo Transducer Buzzer Driver CircuitDocument2 paginiCMOS Piezo Transducer Buzzer Driver Circuitwakgeng marwahÎncă nu există evaluări

- Health, Safety, Environment (Hse) Department PTDocument29 paginiHealth, Safety, Environment (Hse) Department PTwakgeng marwahÎncă nu există evaluări

- 21 Tugas Dan Tanggung Jawab HSE Manager - Safety - Safety ArticleDocument5 pagini21 Tugas Dan Tanggung Jawab HSE Manager - Safety - Safety Articlewakgeng marwahÎncă nu există evaluări

- Contoh CV (Curriculum Vitae) Terbaru 2018 Agar Cepat Di Terima Kerja - LulusandiplomaDocument11 paginiContoh CV (Curriculum Vitae) Terbaru 2018 Agar Cepat Di Terima Kerja - Lulusandiplomawakgeng marwahÎncă nu există evaluări

- Checklist Inspeksi HSEDocument2 paginiChecklist Inspeksi HSEwakgeng marwahÎncă nu există evaluări

- UL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Document7 paginiUL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Juan Jose Teodoro AguilarÎncă nu există evaluări

- Toshiba Satellite L650 12Q Laptop ManualDocument229 paginiToshiba Satellite L650 12Q Laptop ManualTasos KachpanisÎncă nu există evaluări

- Plsed309005en (Web)Document174 paginiPlsed309005en (Web)Arifin SaniÎncă nu există evaluări

- Klauke - Bi-Metal Lugs & ConnectorsDocument6 paginiKlauke - Bi-Metal Lugs & ConnectorsBiplab PaulÎncă nu există evaluări

- Schneider ElectricCahier Technique No. 199Document36 paginiSchneider ElectricCahier Technique No. 199Alda EnglandÎncă nu există evaluări

- Gad Ad2 J10k1020c27a 200a201Document1 paginăGad Ad2 J10k1020c27a 200a201AbdulÎncă nu există evaluări

- List of Accredited Service Center - ProtechDocument1 paginăList of Accredited Service Center - ProtechLarryMatiasÎncă nu există evaluări

- Gujarat Technological University: A Project Report On:-Automatic Water Purification SystemDocument11 paginiGujarat Technological University: A Project Report On:-Automatic Water Purification SystemJay KakadiyaÎncă nu există evaluări

- Irgb 4064 DPBFDocument11 paginiIrgb 4064 DPBFKrista TranÎncă nu există evaluări

- Lesson Plan - Revit Intro Lesson OverviewDocument56 paginiLesson Plan - Revit Intro Lesson Overviewlingga123Încă nu există evaluări

- Biogas Presentation PDFDocument44 paginiBiogas Presentation PDFAli Aamir100% (1)

- Geology 1Document2 paginiGeology 1Mike SantosÎncă nu există evaluări

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDocument5 pagini(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiÎncă nu există evaluări

- LogcatDocument3.139 paginiLogcatvatsavai swathiÎncă nu există evaluări

- Datasheet PDFDocument10 paginiDatasheet PDFRodrigo BarbosaÎncă nu există evaluări

- Acoustic Simulation and Analysis of Reciprocating Compressor Piping Systems IDocument20 paginiAcoustic Simulation and Analysis of Reciprocating Compressor Piping Systems IJose PradoÎncă nu există evaluări

- Lesson 3 - Equipment and FacilitiesDocument15 paginiLesson 3 - Equipment and FacilitiesRishiel Dimple BalonesÎncă nu există evaluări

- Zeal High Precision Wet Test Gas Flow Meters 2022Document5 paginiZeal High Precision Wet Test Gas Flow Meters 2022Hiran ChathurangaÎncă nu există evaluări

- Organic Chemistry 4th Edition Gorzynski Test BankDocument17 paginiOrganic Chemistry 4th Edition Gorzynski Test Bankdigonousconcrewh2zxi100% (31)

- Transfer FunctionDocument19 paginiTransfer FunctionVinay Kumar SmartyÎncă nu există evaluări

- Fastshapes - Sprocket: Typical ApplicationsDocument23 paginiFastshapes - Sprocket: Typical ApplicationsJimmy MyÎncă nu există evaluări

- Cp5151 Advanced Data Structures and AlgorithimsDocument3 paginiCp5151 Advanced Data Structures and AlgorithimsPragaDarshÎncă nu există evaluări

- 327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupDocument1 pagină327101-BJ81-C-RCC-0007 Rev.00 - Client MarkupGokulprabhuÎncă nu există evaluări

- SPE-184314-MS PVT Analysis: Validity Checks and EOS Tuning Techniques For Retrograde Gas Condensate ReservoirsDocument12 paginiSPE-184314-MS PVT Analysis: Validity Checks and EOS Tuning Techniques For Retrograde Gas Condensate ReservoirshusseinhshÎncă nu există evaluări

- CilindarDocument44 paginiCilindardjoko123Încă nu există evaluări

- C-Zone SDN BHD: Price List Effective 10 AUG 2019Document2 paginiC-Zone SDN BHD: Price List Effective 10 AUG 2019Cikgu AlÎncă nu există evaluări

- Minimal Requirements: Solaris InstallationDocument74 paginiMinimal Requirements: Solaris InstallationsrinivasÎncă nu există evaluări

- HQ Accessoriescatalogue 20142015 LRDocument28 paginiHQ Accessoriescatalogue 20142015 LRapi-36492444Încă nu există evaluări