Documente Academic

Documente Profesional

Documente Cultură

The Gamgram: No. 66 APR. 2015 Refueler Truck Design

Încărcat de

Jagadeesh KammaraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

The Gamgram: No. 66 APR. 2015 Refueler Truck Design

Încărcat de

Jagadeesh KammaraDrepturi de autor:

Formate disponibile

THE GAMGRAM

No. 66 REFUELER TRUCK DESIGN APR. 2015

This GamGram is written mostly to help people new to refueler trucks, some points that even those with experience may learn

from. This GamGram is not a complete education. Please read the manuals and other operational documentation available

from the refueler truck manufacturer, airline, oil company and other applicable standards. Do the quality control and the

preventive maintenance. Inspect the truck regularly for leaks, damage and the operation of all systems, even brake lights and

turn signals.

The #1 safety device in refueling is you. Never assume a refueler truck is safe to use, be sure. Be observant, do inspections,

check pressures, test equipment, calibrate gauges and never operate a refueler truck unless you have been completely

checked out on safety, spill and environmental concerns. See GamGram 23.

The key to safety and quality control is to be on the lookout for changes. Changes mean something may be wrong and if in

doubt, don't pump fuel. Life is too important to take chances.

A refueler truck is a vehicle with a storage tank and the needed equipment to dispense fuel safely to aircraft. We will address

hydrant carts, without storage tanks, in a future GamGram.

DESIGNED FOR SAFETY

To protect everyone, a refueler has safety systems. A primary safety system is the brake interlock, designed so that the truck

cannot be driven when it is engaged in refueling an aircraft or when the cargo tank is being loaded at the loading rack. Most

trucks have an “emergency brake override” in the cab to allow the truck to be moved in an emergency. Never bypass safety

systems.

THE FUEL STORAGE/CARGO TANK

The tank on a refueler truck is an expensive part. The weight of the fuel affects the cost of the chassis, so a large capacity adds

cost, but a small cargo tank means less refueling ability.

THE PUMP

The fuel pump is driven either from the transmission (PTO), from a “split shaft” in the middle of the drive shaft or from a

hydraulic drive. It is important to not exceed the maximum rated rpm for the pump, and to keep it lubricated properly, follow the

manual.

THE FILTER

A refueler truck may have a water absorbing (monitor type) filter or a filter separator. A water absorbing filter collects water in

the element media itself, like a baby diaper. A filter separator removes the water and this water must be drained from the vessel

sump and a sump water sensor should be present to stop flow if excessive water accumulates. See GamGrams 47, 48, 53 and

63. All filters must be rated for aviation fuel, properly maintained and contain the correct, latest Edition approved elements for

the flow rate and vessel. See GamGrams 8 and 57.

All filters are also equipped with a differential pressure (DP) gauge. An increase in the difference between inlet pressure and

outlet pressure (DP) means you have contaminated fuel. See GamGram 26. Pressure drop is caused by dirt and/or water in a

water absorbing type filter and dirt in a filter separator. The gauge should have a shutdown system to stop flow if DP is too high,

this must be tested. See the manufacturer's recommendations and GamGram 65.

Other accessories on a filter are a means to: eliminate air, relieve excessive pressure and take fuel samples from the flowing

system (standard on jet fuel and optional on avgas trucks) as well as a low point drain.

GAMMON TECHNICAL PRODUCTS INC.

2300 HIGHWAY 34 MANASQUAN, N.J. 08736

PHONE: 732-223-4600 FAX:732-223-5778 WEB: WWW.GAMMONTECH.COM

SUMPS AND STRAINERS

Checking the tank and filter sump as well as all strainers is important to look for water, dirt or anything else that should not be in

the system. (A true story, someone once found a small fish in a nozzle strainer after installing a new hose that had not been

properly stored in a shed by a creek.)

FUELING NOZZLES

Refueling overwing is similar to fueling a car and usually the flow goes into the aircraft above the wing or high on the fuel tank.

Automatic nozzles with “hold open” designs are not allowed, because there is too much spill danger from variations in the

aircraft fill connection. It is best to maintain contact between the spout and fill connection at all times.

Underwing, or single point refueling is done with a nozzle that locks onto the aircraft, usually from under the wing.

All nozzles should have a strainer as a last defense against debris getting into the aircraft and to detect deterioration of the

inside of the hose.

PRESSURE AND FLOW CONTROLS

If all you do is to fuel overwing, you only need an emergency fuel shutdown system to stop the pump and all valves, but if you

refuel underwing, you need pressure controls, a deadman control and likely a rate of flow control. These may be hydraulic,

pneumatic or electric, or a combination. See the manufacturer's instructions. Hydraulic pressure controls are defined in

GamGrams 32 and 33.

A deadman control is either a handle on an electric cord, a handle on small deadman hose(s) or the trigger on an overwing

nozzle (or similar design). It must be operated to obtain flow. NEVER bypass the deadman control. The deadman control may

have a timer control that requires you to quickly release and re-squeeze the deadman control to maintain flow. A timer-type

deadman makes “jamming the deadman” virtually impossible.

FLOW RATE

The maximum flow rate of a truck is determined by the rating of the meter and the filter, with the lowest rating being important.

The flow rate printed on the filter vessel is not important, what is important is the current rating of the vessel with the specific

elements in it. See your filter supplier for this rating.

HOSE REELS

Hose is stored on hose reels and must be wound in a neat way to prevent damage and allow the maximum capacity of hose.

Rewinding is most commonly by electrical motor, hydraulic power or air. The swivel should be properly lubricated and have a

grease vent to prevent grease getting into the fuel. Petroleum jelly (”Vaseline”) is a common lubricant to use.

REFUELING HOSE

All aircraft fueling hose must meet stringent standards. It must NEVER have a wire in it for conductivity (except lift-deck hose).

It must meet the EI-1529 standard. Inspection of the hose regularly is very important. Pull the entire hose from the reel regularly

and inspect it fully for any sign of cracking, splitting, flat spots and fabric showing through or bubbles. Turning a hose end-for-

end can extend the life of the hose. See GamGrams 35 & 49.

STATIC BONDING

To prevent sparks between the aircraft and the truck, a static cable must be provided, usually on a reel for storage. It is

important to not only keep this cable and clamp intact and conductive but use it in every refueling. Conductivity is checked

between the clamp and the frame of the truck.

BOTTOM LOADING

To fill a refueler storage tank, you need to make sure the tank is not overloaded. All trucks should have a working high level

shutoff with a test feature. This is separate from the fuel farm high level control, if present. Operate this truck mounted

“precheck” test feature regularly not only to ensure the high level control works, but to ensure the internal valve in the bottom of

the tank works.

COMPRESSED AIR SYSTEM

Most refuelers have compressed air systems that need to be maintained. See GamGram 62.

OVERALL

Do the daily, weekly and all other periodic tests required by the standard that you operate under. This may be ATA-103, IATA

JIG or other standards. Keeping the truck maintained includes pressure controls, water controls, filters, hoses, tires, air and oil

filters, chassis lube and oil changes - and much more.

Text

S-ar putea să vă placă și

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- MDLK YTVk NTUx MZK 4 MWNi ODQ0 Yj Q2 OTdk ZTY4 NGQ1 OWRl Yz Ri NGM3 YgDocument23 paginiMDLK YTVk NTUx MZK 4 MWNi ODQ0 Yj Q2 OTdk ZTY4 NGQ1 OWRl Yz Ri NGM3 Ygraihan alfathirÎncă nu există evaluări

- Aircraft Fuel SystemDocument63 paginiAircraft Fuel SystemsushantreshmaÎncă nu există evaluări

- AMWDocument14 paginiAMWSudeesh BabuÎncă nu există evaluări

- A Magnum Manual mlg25 Operating Parts PDFDocument52 paginiA Magnum Manual mlg25 Operating Parts PDFOswaldo GuevaraÎncă nu există evaluări

- 22 0 100 - NCDocument7 pagini22 0 100 - NCjussmeeeÎncă nu există evaluări

- 010-027 Charge-Air Cooler (CAC) : Preparatory StepsDocument11 pagini010-027 Charge-Air Cooler (CAC) : Preparatory StepsbejoythomasÎncă nu există evaluări

- Cf-Fa12-Dpt 154 2227 12261194719Document125 paginiCf-Fa12-Dpt 154 2227 12261194719اشرينكيل مسونكيلÎncă nu există evaluări

- Refuelinganddefuelin GDocument16 paginiRefuelinganddefuelin Guploadz upÎncă nu există evaluări

- Chapter 28-BennetDocument63 paginiChapter 28-BennetsengottaiyanÎncă nu există evaluări

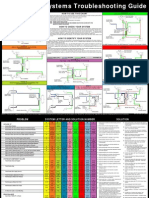

- Truck Brake Systems PDFDocument63 paginiTruck Brake Systems PDFLazarusÎncă nu există evaluări

- Lesson 2 Finals Amte 232Document16 paginiLesson 2 Finals Amte 232Bo BoÎncă nu există evaluări

- Chapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Document14 paginiChapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Juan F. MamaniÎncă nu există evaluări

- Genset Preventive MaintenanceDocument6 paginiGenset Preventive MaintenanceSatria PinanditaÎncă nu există evaluări

- Deck SealDocument7 paginiDeck SealAlamin Siddique100% (1)

- Trailer Systems Troubleshooting Guide W7NPA RadioDocument2 paginiTrailer Systems Troubleshooting Guide W7NPA RadioZeckÎncă nu există evaluări

- Chief 11ac Poh SBDocument11 paginiChief 11ac Poh SBDarien Andrew SoleimanyÎncă nu există evaluări

- IM107Document36 paginiIM107Stefano Di LuccaÎncă nu există evaluări

- Laboratory Vacuum PumpsDocument40 paginiLaboratory Vacuum PumpsPajooheshÎncă nu există evaluări

- Mercury Maintenance ManualDocument27 paginiMercury Maintenance ManualJens Adam Hedegaard HansenÎncă nu există evaluări

- Liquid Ring Pump ManualDocument25 paginiLiquid Ring Pump ManualCornelius Toni KuswandiÎncă nu există evaluări

- Generator Faults and RemediesDocument7 paginiGenerator Faults and Remediesemmahenge100% (2)

- Watchkeeping and TroubleshootingDocument16 paginiWatchkeeping and TroubleshootingAditya JoglekarÎncă nu există evaluări

- Aircraftfuelsystem 150511184932 Lva1 App6892Document16 paginiAircraftfuelsystem 150511184932 Lva1 App6892raimanchunagesh06Încă nu există evaluări

- Brake System MaintenanceDocument3 paginiBrake System MaintenancejohnribarÎncă nu există evaluări

- 0911 Maintenance-8to9 9FSDocument20 pagini0911 Maintenance-8to9 9FSLahiru Chamara JayasingheÎncă nu există evaluări

- Portable Cargo Pump TK80 Simillar To Marflex Portable PPDocument18 paginiPortable Cargo Pump TK80 Simillar To Marflex Portable PPSubramoniam MarineÎncă nu există evaluări

- Yanmar BulletinsDocument10 paginiYanmar BulletinsBill Carter100% (2)

- MaintenanceInformation 4CylVeradoDocument27 paginiMaintenanceInformation 4CylVeradocombaheeÎncă nu există evaluări

- tb9 2300 426 20Document20 paginitb9 2300 426 20Rolando DaclanÎncă nu există evaluări

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pagini2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- Difference Between 53 A B CDocument3 paginiDifference Between 53 A B CAmol PatkiÎncă nu există evaluări

- MaintenanceInformation 6CylVeradoDocument25 paginiMaintenanceInformation 6CylVeradocombaheeÎncă nu există evaluări

- Outside Vehicle: General MaintenanceDocument8 paginiOutside Vehicle: General MaintenanceTung NguyenÎncă nu există evaluări

- SEBU6965-06 Before StartDocument6 paginiSEBU6965-06 Before StartLUIZ GUSTAVOÎncă nu există evaluări

- Packer Machine (Ia)Document34 paginiPacker Machine (Ia)Chrystal Baker100% (1)

- Chapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Document75 paginiChapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1carmen solanoÎncă nu există evaluări

- General Engineering Knowledge For Marine EngineersDocument31 paginiGeneral Engineering Knowledge For Marine EngineersSrini VasanÎncă nu există evaluări

- Pilot k25p Industrial Petrol ReciprocatingDocument14 paginiPilot k25p Industrial Petrol ReciprocatingPepeÎncă nu există evaluări

- Air Brake ManualDocument94 paginiAir Brake Manualfreeemeee.now130Încă nu există evaluări

- Genset MaintenanceDocument2 paginiGenset MaintenanceRiRie RamLeeÎncă nu există evaluări

- Mech Seal System Difference 53 A B CDocument3 paginiMech Seal System Difference 53 A B CAmol PatkiÎncă nu există evaluări

- 100-00 Standart Workshop PracticesDocument34 pagini100-00 Standart Workshop PracticesFerhan SerdarogluÎncă nu există evaluări

- V8051 335 Instruction Manual 88aceDocument7 paginiV8051 335 Instruction Manual 88acecarlÎncă nu există evaluări

- May2010 PDFDocument3 paginiMay2010 PDFJULIO CESARÎncă nu există evaluări

- Sealing System Jun05Document2 paginiSealing System Jun05jrri16Încă nu există evaluări

- Safety Anchor Handling ManualDocument22 paginiSafety Anchor Handling ManualSardar Sirajul Islam100% (8)

- Zenith Service BulettinDocument5 paginiZenith Service Bulettinmike hilliardÎncă nu există evaluări

- SLJ Super Lift Jack ManualDocument10 paginiSLJ Super Lift Jack Manualaula8045040Încă nu există evaluări

- GasolineDocument9 paginiGasolinejoshua agustinÎncă nu există evaluări

- Fuel Lift PumpDocument5 paginiFuel Lift PumptattinpipeÎncă nu există evaluări

- 60d1a18b-cb42-4fc3-a01c-49c9b37f5594Document8 pagini60d1a18b-cb42-4fc3-a01c-49c9b37f5594Tarso BrasilÎncă nu există evaluări

- Compresor Tuflo 550Document6 paginiCompresor Tuflo 550Ramón José Aponte FrancoÎncă nu există evaluări

- 0911 Maintenance 15FSDocument23 pagini0911 Maintenance 15FSemilio275655Încă nu există evaluări

- Assessment Sheet: Student ID: Unit Code & NameDocument17 paginiAssessment Sheet: Student ID: Unit Code & NameheshanÎncă nu există evaluări

- Starting of Main EngineDocument5 paginiStarting of Main EngineAayush Agrawal100% (2)

- Manual Compresor Amico MateoDocument20 paginiManual Compresor Amico MateoSanchez HenriquezÎncă nu există evaluări

- Chemgaurd Bladder Tank Design and System Installation PDFDocument7 paginiChemgaurd Bladder Tank Design and System Installation PDFVignesh WaranÎncă nu există evaluări

- 23 Ijmtst020417 PDFDocument4 pagini23 Ijmtst020417 PDFJagadeesh KammaraÎncă nu există evaluări

- 31 3 1Document11 pagini31 3 1Jagadeesh KammaraÎncă nu există evaluări

- 30Document4 pagini30Jagadeesh KammaraÎncă nu există evaluări

- 21Document11 pagini21akhilesh120Încă nu există evaluări

- 17 83 86Document4 pagini17 83 86Jagadeesh KammaraÎncă nu există evaluări

- 1 DD 1Document3 pagini1 DD 1Jagadeesh KammaraÎncă nu există evaluări

- 10 1 1 691 8302 PDFDocument33 pagini10 1 1 691 8302 PDFJagadeesh KammaraÎncă nu există evaluări

- 15 02 0518 0526Document9 pagini15 02 0518 0526Jagadeesh KammaraÎncă nu există evaluări

- 17 03 0835 0841Document7 pagini17 03 0835 0841Jagadeesh KammaraÎncă nu există evaluări

- 14 A00 SC (90-98) PDFDocument9 pagini14 A00 SC (90-98) PDFJagadeesh KammaraÎncă nu există evaluări

- 10 1 1 691 8302 PDFDocument33 pagini10 1 1 691 8302 PDFJagadeesh KammaraÎncă nu există evaluări

- 419330d7-78b4-4a45-b4a1-7039f0a1d1cdDocument19 pagini419330d7-78b4-4a45-b4a1-7039f0a1d1cdJagadeesh KammaraÎncă nu există evaluări

- 14 A00 SC (90-98) PDFDocument9 pagini14 A00 SC (90-98) PDFJagadeesh KammaraÎncă nu există evaluări

- Aerospace Micro Lesson 37 Aerial RefuelingDocument7 paginiAerospace Micro Lesson 37 Aerial RefuelingJagadeesh KammaraÎncă nu există evaluări

- Aircraft Refueling PumpDocument9 paginiAircraft Refueling PumpJagadeesh KammaraÎncă nu există evaluări

- Vehicules & EquipimentsDocument29 paginiVehicules & EquipimentsMohamed OukassiÎncă nu există evaluări

- 2024 Dated Minimalist Editable Calendar by Shining MomDocument13 pagini2024 Dated Minimalist Editable Calendar by Shining Momdesau3321Încă nu există evaluări

- The White Stripes - Seven Nation Army - Cifra ClubDocument4 paginiThe White Stripes - Seven Nation Army - Cifra ClubGoveanÎncă nu există evaluări

- Mahindra Scorpio-N Review - Page 2 - Team-BHPDocument13 paginiMahindra Scorpio-N Review - Page 2 - Team-BHPRavi DhingraÎncă nu există evaluări

- Leg ExercisesDocument7 paginiLeg ExercisesChoirun Nisa Nur AiniÎncă nu există evaluări

- ACPlus Survival Mode FAQDocument11 paginiACPlus Survival Mode FAQMimeblade100% (1)

- Pankration GRADINGDocument2 paginiPankration GRADINGANGELLOPEZÎncă nu există evaluări

- HOPE-3-Quarter 2Document48 paginiHOPE-3-Quarter 2reymart100% (1)

- Evidence Based Concepts For Prevention of Knee and ACL Injuries. 2017 Guidelines of The Ligament Committee of The German Knee Society (DKG)Document11 paginiEvidence Based Concepts For Prevention of Knee and ACL Injuries. 2017 Guidelines of The Ligament Committee of The German Knee Society (DKG)lipemagalhaesÎncă nu există evaluări

- Club 420Document6 paginiClub 420rlytle875Încă nu există evaluări

- Activity 3 & 4 (Module 3)Document4 paginiActivity 3 & 4 (Module 3)Marvin GasparÎncă nu există evaluări

- Public Inquiry - Proof of Evidence ListDocument44 paginiPublic Inquiry - Proof of Evidence ListKeeping Everton In Our CityÎncă nu există evaluări

- PHYSICALEDUCATION Grade 6Document57 paginiPHYSICALEDUCATION Grade 6Jetron CambroneroÎncă nu există evaluări

- Macroscopic MorphopathologyDocument12 paginiMacroscopic MorphopathologySalsa Salaa HÎncă nu există evaluări

- Distribution - Excel & Access PackagesDocument2 paginiDistribution - Excel & Access Packagesumer plays gameÎncă nu există evaluări

- Hemoglobin (American English)Document2 paginiHemoglobin (American English)Ana MariaÎncă nu există evaluări

- Chaleco Sin MangasDocument15 paginiChaleco Sin MangasTextWG Gg100% (1)

- All Load Data For The 40 S&W Handgun CartridgeDocument12 paginiAll Load Data For The 40 S&W Handgun Cartridgeblowmeasshole1911Încă nu există evaluări

- Ready-Mix Driver and Concrete Pumping Hand SignalsDocument1 paginăReady-Mix Driver and Concrete Pumping Hand SignalsAdonis AlabiÎncă nu există evaluări

- M6044 InsDocument23 paginiM6044 InsFareeha Hasan83% (6)

- Vehicle Handover ChecklistDocument2 paginiVehicle Handover Checklistbitben17Încă nu există evaluări

- Tendonitis of The Long Head of The Biceps-Orthoinfo - AaosDocument5 paginiTendonitis of The Long Head of The Biceps-Orthoinfo - Aaosapi-228773845100% (1)

- Ppe and First AidDocument5 paginiPpe and First Aidjela rose camilonÎncă nu există evaluări

- Soulbound - Dark Industrial FantasyDocument458 paginiSoulbound - Dark Industrial FantasythhpitiÎncă nu există evaluări

- BJ Cicada: Bore: Stroke: Displacement: 0.437" (11.10mm) 0.554" (14.07mm) 0.093 Cuin (1.362cc)Document5 paginiBJ Cicada: Bore: Stroke: Displacement: 0.437" (11.10mm) 0.554" (14.07mm) 0.093 Cuin (1.362cc)antamanÎncă nu există evaluări

- VI DL JazzDrums Patch Matrix Preset v5Document42 paginiVI DL JazzDrums Patch Matrix Preset v5Nils Van der PlanckenÎncă nu există evaluări

- Catalog Lenso 2016 PDFDocument37 paginiCatalog Lenso 2016 PDFRagea GeorgeÎncă nu există evaluări

- Readme - SkyBirds 0.92BDocument15 paginiReadme - SkyBirds 0.92BKristin WattsÎncă nu există evaluări

- Hotel List 19.03.2021Document4 paginiHotel List 19.03.2021rkoticha100% (1)

- Cross-Country Olympic 3: Start List Men EliteDocument3 paginiCross-Country Olympic 3: Start List Men EliteClub de Ciclismo de Montaña PichinchaÎncă nu există evaluări

- LYCOMING O & LO-360 (76 Series) Parts Catalog PC-123 PDFDocument29 paginiLYCOMING O & LO-360 (76 Series) Parts Catalog PC-123 PDFBrunoÎncă nu există evaluări