Documente Academic

Documente Profesional

Documente Cultură

F

Încărcat de

Venkatagiri Srinivas MurthyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

F

Încărcat de

Venkatagiri Srinivas MurthyDrepturi de autor:

Formate disponibile

TECHNICAL REPORT

Calculation of Theoretical Torque and Displacement

in an Internal Gear Pump

Y. INAGUMA

This paper describes numerical determination of theoretical torque (ideal torque) and theoretical stroke volume

(pump displacement) in an internal gear pump without crescent. The design analyzed has been commonly used

for an automatic transmission and continuously variable transmission in vehicles because of its high mechanical

efficiency. For estimating the pump efficiencies accurately, determining the accurate theoretical torque and

theoretical displacement of the pump is important.

This paper presents a calculation method that takes into consideration the contact points for meshing and sealing

between the driving and driven gear for the accurate theoretical torque and displacement of an internal gear pump

without crescent such as a gerotor pump.

Key Words: hydraulic power system, hydraulic pump, internal gear pump, theoretical torque, theoretical

displacement, calculation method

calculation method to a balanced vane pump, which has

1. Introduction been previously reported4).

Internal gear pumps used in relatively low pressure

conditions have been widely used for automatic

transmissions and engines to supply oil for both

2. Nomenclature

lubrication and hydraulic control. They are used because b : Gear width

of their simple structure with fewer components and easy F 1 : Force due to pressure acting on tooth face with

assembly than other options. Currently, they have been meshing point of driven gear

used in CVT (Continuous Variable Transmission) with F 2 : Force received from driving gear on meshing point

operating pressures over 5 MPa1), 2). In the meantime, to of driven gear

improve fuel economy in vehicles, auxiliary components F 3 : Force due to pressure acting on tooth face with

including hydraulic pumps are required to increase their sealing point of driven gear

efficiencies. Currently a conventional internal gear pump F 4 : Force due to pressure acting on tooth face with

has a crescent placed between the tips of the driving and meshing point of driving gear

driven gears to separate the delivery pressure side and the F 5 : Force received from driven gear on meshing point of

suction pressure side and to prevent oil leakage from the driving gear

delivery pressure side. Now this has been replaced with F 6 Force due to pressure acting on tooth face with

:

an internal gear pump without crescent. In this design the sealing point of driving gear

sealing is performed by the tooth tips of the driving and N : Pump speed

driven gears. For improving the efficiencies of the pump, p d : Delivery pressure

it is important to determine accurately the theoretical p s : Suction pressure

torque and the displacement volume of the pump. 3p : Difference between delivery and suction pressure

Although for the internal gear pump with crescent (= p d−p s)

including an involute gear pump the calculation method r 1 : Radius from center of driven gear to meshing point

for theoretical torque and displacement has already been r 2 : Radius from center of driven gear to sealing point

proposed3), it has yet to be clarified for the internal gear r 3 : Radius from center of driving gear to meshing point

pump without crescent. r 4 : Radius from center of driving gear to sealing point

This paper presents the calculation method for the T th : Theoretical torque

theoretical torque and the theoretical displacement for V th : Theoretical displacement per revolution

internal gear pump without crescent, by using a similar z : Number of teeth on driving gear

70 JTEKT Engineering Journal English Edition No. 1001E (2006)

−Calculation of Theoretical Torque and Displacement in an Internal Gear Pump−

u : Pressure angle of tooth at meshing point In the gear pump, the meshing points of the driving

h : Rotational angle of driving gear gear and the driven gear transfer to the next teeth during

Subscript: rotation. The locus of the meshing point as well as the

R : Component in radial direction sealing point changes in the radial direction.

h : Component in circumferential direction

Driven gear

3. Structure of the Pump

First, the internal gear pump without crescent is

described below. The pump is composed of a driving

gear (an external tooth gear placed inside) and a driven

gear (an internal tooth gear placed outside). Various tooth

profiles are in use, among which the trochoidal profile and

the combined profile with hypocycloidal curves shown in

Driving gear

Fig. 1 are well known. Unlike the pump with crescent to

prevent leakage between the tips of the driving and driven

gears, shown in Fig. 2, these pumps without crescent Fig. 1 Configuration of internal gear pump without crescent

are designed so the tooth tip parts of both gears come in

contact at one point to separate suction part from delivery Driven gear

part (in practice a very small clearance is provided to

Crescent

avoid locking of the gears).

In contrast to the internal gear pump with crescent, the

internal gear pump without crescent has a larger volume

between the teeth of the driving and driven gears. This

means that the pump without crescent can have a larger

theoretical displacement when the tooth width, the tip

diameter of the driving gear and the outer diameter of Driving gear

the driven gear are the same as those of the pump with

crescent. In other words, when the tooth width and the Fig. 2 Configuration of internal gear pump with crescent

tip diameter of the driving gear are the same, the outer

diameter of the driven gear in the pump without crescent

can be smaller with the same displacement. Especially at

high-speed pump operation, it can decrease the friction

torque caused by shearing viscous oil on the sliding parts Meshing

pd point

of the gears, improving the mechanical efficiency. That Sealing

point O 0

o

is the reason why this type of gear pump has often been O' h

ps

used in the automotive automatic transmissions, including

CVTs.

In the gear pump, the meshing point between the

driving and driven gears changes depending on the

O : Center of driving gear

rotating position (angle) of the driving gear. As shown in O': Center of driven gear

Fig. 3, the teeth of both the driving gear and the driven

gear are subject to the suction pressure and/or the delivery Fig. 3 Pressure acting in internal gear pump

pressure. The tooth faces meshing with each other receive

different pressures separated at the meshing point. Also,

the tooth faces concerned with sealing receive different Driven gear

pressures separated at the sealing point. In addition,

for the gear pump without crescent the sealing point is

pd

not always on the tip of the tooth, as shown in Fig. 4. It

changes depending on the rotational angle of the driving r2

gear. This difference from the internal gear pump with r T1

Sealing

crescent makes the accurate calculation of the theoretical O'

point ps Driving gear

torque and the displacement difficult.

Fig. 4 Tip circle radius and seal radius of driven gear

JTEKT Engineering Journal English Edition No. 1001E (2006) 71

−Calculation of Theoretical Torque and Displacement in an Internal Gear Pump−

equivalent concentrated force as expressed below:

4. Calculation of Theoretical Torque and

Displacement →

│F 1h│=3pb(r 1−r T1) ⑴

4. 1 Calculation Method →

│F 3h│=3pb(r 2−r T1) ⑵

There are two calculation methods for the theoretical

displacement. One is to calculate geometrically the The radii r m1 and r m2 from the center of the driven gear

→ →

volume of the space enclosed by the teeth of the driving O' to the points acting F 1 and F 3 are expressed by the

and driven gears. The other method first requires following equations, respectively.

calculation of the theoretical torque of the pump. Then

the displacement of the pump should be calculated by r m1=(r 1+r T1)/2 ⑶

using the theoretical torque. This is based on the principle r m2=(r 2+r T1)/2 ⑷

that the hydraulic energy given to the oil by the pump

operation equals the power required to drive the pump

shaft, disregarding energy loss. The former approach used

to have a problem with accuracy because of the integral Driven gear

of the volume between the teeth of the driving and driven Tooth bottom

gears. In recent years, thanks to the spread of CAD, the

p

calculation has become relatively easier. Nevertheless,

it still requires drawings of the driving and driven gears

Tooth face

for each minute change of rotational angle. To avoid this

trouble with accurate calculation when calculating the Tooth tips of driven gear

theoretical torque, the latter method was selected and

described below. Y

In this calculation method, the torque to rotate −f1 f1

−f2 f2

−f3 f3

the driving gear is considered against the difference −f4 p

f4

−f5 f5

between the suction pressure and the delivery pressure. −f6 f6

−f7 f7

These pressures act on the tooth face in the direction −f8 f8

−f9 f9 X

X

perpendicular to it. However, for the calculation of

s

the theoretical torque, only the pressure acting in the

adiu

circumferential direction around the center of rotation

le r

Y

circ

must be considered. For the teeth without the meshing

Tip

point or the sealing point, the force due to the pressure rT1 :

does not need to be considered. As shown in Fig. 5, the

force due to the pressure acts on both right and left faces Fig. 5 Pressure and force acting on tooth

of the tooth evenly. In the case of the internal gear pump,

it is necessary only to consider the force caused by the Acting point of force due to

pressure on the seal side

pressure difference on the teeth with the meshing point

Acting point of force

and the sealing point. due to pressure on

→

First the force and the torque working on the driven F 1h the meshing side

→ r m1 →

gear are considered. The relationship between the F 3h F 2R

r m2 Meshing point →

pressure and the force working on the driven gear is r1 → F2

r2 F 2h u

shown in Fig. 6. Both the suction pressure p s and the O' h 0

o

delivery pressure p d act on some of the teeth of the driven Sealing

point

gear. The difference between p d and p s is denoted as 3p . (u: Pressure

→ angle of tooth)

The force due to the pressure F 1 acts on the tooth with the

→

meshing point and the force due to the pressure F 3 acts

on the sealing point in the vicinity of the tooth tip in the O': Center of driven gear

driven gear. Then, the driven gear receives the reaction

→ Fig. 6 Forces acting on driven gear

force F 2 and the circumferential component against

→ →

the sum of F 1 and F 2 are at the meshing point from the

driving gear. In the actual pump, the theoretical torque

to drive the pump depends only on the component of the

force in the circumferential direction ( h). The values

→ →

of F 1 and F 3 are known, and they can substitute for each

72 JTEKT Engineering Journal English Edition No. 1001E (2006)

−Calculation of Theoretical Torque and Displacement in an Internal Gear Pump−

In the same way, only the component of h direction The radii r m3 and r m4 from the center of the driving gear

→ → →

should be considered for the reaction force F 2 from the O to the points acting F 4 and F 6 are expressed as follows.

driving gear. Denoting that the pressure angle of the

→ r m3=(r T2+r 4)/2 ⑽

tooth face at the meshing point is u, │F 2│cosu means

→

│F 2h│. r m4=(r T2+r 6)/2 ⑾

Disregarding friction and other loss, the moment

→

equilibrium equation around the center of the driven gear The force F 5 acting on the meshing point from the

O' is expressed by the following equation from these three driven gear has the same magnitude as the aforementioned

→

forces and the radii. force F 2, though the direction is opposite. Therefore, the

→ →

→ → → h direction component F 5h of F 5 can be expressed as

│F 1h│r m1−│F 3h│r m2=│F 2h│r 1 ⑸

follows:

The equation ⑸ can be changed to the following →

→ │F 5h│=3pb(r 12−r 22) /(2r 1)} ⑿

equation to determine │F 2h│:

→ → → Disregarding the friction and other losses, the torque

│F 2h│= (│F 1h│r m1 −│F 3h│r m2)/r 1 ⑹

to rotate the driving gear against the moments due

→ →

By substituting equations ⑴ through ⑷ in equation ⑹: to F 4h and F 5h is defined as the theoretical torque T th.

→ This torque can be obtained from the moment around

│F 2h│=3pb{(r 12−r T12)(r 22−r T12)

− }/(2r 1) the center of the driving gear O, as expressed by the

=3pb(r 12−r 22)/(2r 1) ⑺ following equation.

→ → →

T th=│F 5h│r 3+│F 4h│r m3−│F 6h│r m4 ⒀

Next, the force and the torque to rotate the driving gear

are considered, as shown in Fig. 7. Just like the teeth of Substituting equations ⑻ through ⑿ in equation ⒀,

→ →

the driven gear, the forces due to the pressure F 4 and F 6

3p r

act on the teeth with the meshing point and the sealing T th(h)

= b( r 12 −r 22 )r 31 +

{ ( r 42 −r 32 )

} ⒁

2

point in the driving gear respectively loaded. Also, the

→ →

reaction force F 5 acts against the aforementioned force F 2 In the above equations, the values of r T1 and r T2 are

on the meshing point of the driven gear and the driving fixed. Because the coordinates of the meshing point and

gear. Only the components of force in the h direction the sealing point vary according to the rotational angle of

are actually producing the torque to drive the pump. The the driving gear h, r 1, r 2, r 3, r 4, r m1, r m2, r m3, r m4 as well as

→ → → → → → → →

forces generated by the hydraulic pressure F 4 and F 6 are │F 1h│, │F 2h│, │F 3h│, │F 4h│, │F 5h│, │F 6h│

the known values. Also, as in the case of the driven gear, are functions of h. However, they are not expressed as the

they can replace the equivalent concentrated forces as functions of h for simplicity of expression.

expressed below: While equation ⒁ defines the theoretical torque at

each angle, the averaged theoretical torque T th* can be

calculated by the following equation.

→ 2 p/z

F 5h * 1

→

F 4h

T th = ∫

2p/ z 0

T th(h)d h ⒂

→

→ F5

Sealing point

F 6h →

F Meshing point

Following the calculation of the theoretical torque,

r m4 r m3 5R

r3 o

the calculation of the theoretical displacement volume

0

r4 O h can be performed. Here, the theoretical displacement is

Center of

driving gear related to the theoretical torque as follows. The amount

of the work required to drive the pump for one rotation

is T th* × 2p when the averaged theoretical torque is T th*.

Consequently, because the pressure energy of 3p is given

to the oil of volume V th*, the energy given to the oil is

3pV th*. Disregarding the loss, 2pT th* and 3pV th* must be

Fig. 7 Forces acting on driving gear

equal. Then, the following equation is obtained5).

→ 2pTth

*

│F 4h│=3pb(r T2−r 4) ⑻ *

V th = ⒃

3p

→

│F 6h│=3pb(r T2−r 6) ⑼

JTEKT Engineering Journal English Edition No. 1001E (2006) 73

−Calculation of Theoretical Torque and Displacement in an Internal Gear Pump−

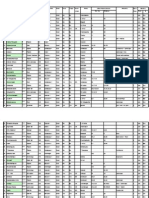

Equation ⒃ defines the relationship between Table 1 Dimensions of pump

the averaged theoretical torque and the theoretical

displacement in one revolution. The oil volume delivered Tip circle radius r T2, mm 34.9

from the pump through rotation of d h (radians) from Driving gear Root circle radius r b2, mm 27.7

the rotational angle h , V th( h ), could be obtained by No. of teeth z 10

substituting the averaged theoretical torque T th* in Tip circle radius r T1, mm 31.4

equation ⒃ for T th(h). Thus, the momentary fluctuation Root circle radius r b1, mm 38.6

of theoretical displacement would be obtained by Driven gear

Outer radius r 0, mm 43.2

equation ⒄ No. of teeth z ' 11

th h)

T( dh Gear width b , mm 11.4

th h)

V( =

3p

b r dh

= {( r 12 −r 22 )r 31 +

( r 42 −r 32 )} ⒄ 5 4 4 5 4 4

2 3 3 3

6 5 3

6 2

5 Meshing 2

With d h= 2p/360 in equation ⒄, the fluctuation of the Sealing Meshing 2 Sealing

point point 7 point point 2

7 1

delivered oil per degree can be calculated. 6 O' O 6 O' O 1

1 1 h=h1

For the internal gear pump with crescent shown in 8 7 8 7

Fig. 2, the sealing point always exists on the tip circle

h=0°

radius, and the theoretical torque is expressed as follows:

3p r

th h)

T( = b( r 12 −r T12 )r 31 +

{ ( r T22 −r 32 )} ⒅ O : Center of driving gear

2 5 O': Center of driven gear

6 5 4 4

Equation ⒅ replaces r 2 in the first term and r 4 in the 7 6 3

Sealing Meshing 3

second term of the right side of the equation ⒁ with r T1 point point 2

and r T2 respectively. Since r 2 > r T1 and r 4 < r T2 stand in 8 7 O' O 2

1

the pump, the value of the theoretical torque obtained 9 8

1

h=h2

from equation ⒅ is larger than that obtained from

equation ⒁, and hence the theoretical displacement

becomes larger too.

Fig. 8 Transfer of contact points

4. 2 Calculation Results Table 2 Pattern of number of teeth with contact point

The calculation results based on the assumption of

3p = 2 MPa will now be explained. Table 1 shows the Driving gear Meshing tooth No. Sealing tooth No.

dimensions of the test pump used for the calculation and rotation angle

Driving Driven Driving Driven

the experiment. In this internal gear pump, the driving h

gear rotates for one tooth pitch, while the teeth involved 0∼h1 1 1 6 7

in meshing and sealing in the driving and driven gears h1∼h2 2 2 6 7

change in three patterns. These patterns are shown in h2∼2p/z (rad) 2 2 7 8

Fig. 8, where the gears rotate clockwise, and each tooth

of both the gears is numbered. Initially, No. 1 driving Depending on the transfer of the meshing and sealing

gear tooth meshes with No. 1 driven gear tooth, while teeth, both the forces acting on the teeth and the moment

No. 6 driving gear tooth and No. 7 driven gear tooth arms change significantly. Figure 9 shows changes of the

→ → →

have the sealing point. When the rotational angle of the magnitudes of the forces │F 1h│, │F 2h│ and │F 3h│

driving gear exceeds h1, the meshing teeth of both the acting on the driven gear teeth. Figure 10 shows the

→

driving and the driven gears transfer to No. 2, whereas the changes of the magnitudes of the forces │F 4h│ and

→

sealing is still formed by No. 6 driving gear tooth and No. │F 6h│ acting on the driving gear teeth. At the rotating

→ →

7 driven gear tooth. When the rotation progress further, angle h = h 1, the forces │F 1h│ and │F 2h│ as well

→ → →

the teeth with the sealing point of the driving and driven as │F 4h│ (│F 5h│ is the same as │F 2h│) change

gears change to the next teeth. Table 2 summarizes these suddenly because the meshing point moves from the

results. tooth bottom to the next tooth tip of the driving gear (or

from the tooth tip to the tooth bottom of the driven gear)

with the transfer of the meshing teeth. The increase and

→ →

decrease in the forces │F 1h│ and │F 2h│ of the driven

→

gear are opposite to the │F 4h│ of the driving gear.

74 JTEKT Engineering Journal English Edition No. 1001E (2006)

−Calculation of Theoretical Torque and Displacement in an Internal Gear Pump−

This is a typical feature of the gear pumps including the 0.05

external gear pump. On both the driving and driven gears,

→ → 0.04

the forces │F 3h│ and │F 6h│ acting on the teeth with Average

Vth (h), cm /deg

the sealing point, are relatively small but they cannot be 0.03

3

negligible. 0.02

160 0.01

120 0

0 4 8 12 16 20 24 28 32 36

→

F 1h Rotational angle of driving gear, hdeg.

F, N

80 →

F 2h

→

F 3h

Fig. 12 Change of pump displacement per degree

40

As the calculated results for the test pump, the values

0 of the averaged theoretical torque T th at 3p = 2 MPa and

0 4 h1 8 12 16 20 24 28 h2 32 36

the theoretical displacement V th were 4.912 Nm and

h, deg

15.43 cm3/rev., respectively. Incidentally, the difference

Fig. 9 Change of forces acting on driven gear between the calculated result by equation ⒁ and that by

equation ⒅ amounted to about 2%.

160

120 →

F 4h

5. Experimental Measurement of Displacement

→

F 6h 5. 1 Experiment Equipment and Measuring

F, N

80

Method

With the experimental apparatus shown in Fig. 13, the

40

actual value of the displacement V th for the test pump

0

with the dimensions given in Table 1 was measured. The

0 4 h1 8 12 16 20 24 28 h2 32 36

simple experimental apparatus consists of the test pump

h, deg

① driven by a DC motor ② via pulleys and belt. The

Fig. 10 Change of forces acting on driving gear delivery pressure p d was measured with a Bourdon's tube

pressure gauge equipped at the pump outlet. The delivery

The theoretical torque T th to drive the internal gear flow from the test pump was measured with a flow meter

pump is the sum of the driving torque for the driven gear and oil temperature was measured at the pump outlet with

T 1 (the first term of right side in equation ⒅) and the a thermistor thermometer. The oil used was commercial

driving gear T 2 (the second term of right side in equation mineral oil and its density and viscosity at 80℃ were 810

⒅). The calculated results of T 1, T 2 and the theoretical kg/m3 and 0.0085 Pa·s, respectively.

torque T th (T in Fig. 11) to drive the pump are shown The test pump was operated at various pump speeds

in Fig. 11. Although T 1 and T 2 vary greatly along the N , and delivery pressures p d, and the volumetric flow rate

rotational angle h of the driving gear, they cancel out the delivered from the test pump Q was measured.

fluctuations of each other, and the total of them as T th has

little fluctuation. Also, from these results, the fluctuation

of the theoretical delivery flow rate remains very small, as ③

②

shown in Fig. 12.

6

T = T 1+ T 2 (Theoretical pump driving torque)

5 ①

④

T1 (Driving torque for driven gear)

4

T , Nm

3

Change of

2 meshing teeth T2 (Driving torque for

driving gear)

1

①Test pump ②DC motor

0 ③Torque meter ④Throttle valve

0 4 8 12 16 20 24 28 32 36

h, deg. Fig. 13 Test circuit

Fig. 11 Torques for driving each gear and pump driving

torque

JTEKT Engineering Journal English Edition No. 1001E (2006) 75

−Calculation of Theoretical Torque and Displacement in an Internal Gear Pump−

This time, the theoretical displacement V th was

calculated in the following procedure. The volumetric

6. Conclusions

flow rate was measured at various delivery pressures p d In this study, the theoretical torque and the theoretical

for three pump speeds N . From the results measured at displacement of the internal gear pump without crescent

various p d for each N , the delivery flow rate Q 0 at p d= 0 were investigated. As a result, the following results were

was then extrapolated. Dividing Q 0 by the pump speed N , obtained:

the pump displacement V th was obtained. ⑴ The calculation method for the theoretical

displacement of the pump has been constructed, based

Q 0=limQ(at N =const.) ⒆

p d→0 on calculation of the theoretical pump driving torque

from the forces acting on the gears.

V th=Q 0/N ⒇

⑵ The theoretical displacement value obtained by using

this calculation method agrees well with the value

5. 2 Experimental Results obtained by the experiment.

The measured delivery flow rates for three pump

speeds N with changing delivery pressure p d are plotted

References

in Fig. 14. In Fig. 15 the values of the pump displacement

V th are shown. They were obtained by dividing the 1) N. Emoto and A. Ito: Toyoda Koki Giho (Toyoda Koki

delivery flow rate Q 0 at p d= 0 by N for each N . Technical Review), 45, 3 (2005) 43.

The experimental result of V th agrees well with the 2) S. Takita: Toyooki Giho (Toyooki Engineering Review),

calculated one. 20 (2003) 30.

3) T. Ichikawa: Haguruma Ponpu, Nikkan Kogyo

20

Condition: Oil temperature 80℃ Shinbunsha (1962).

Q0 4) Y. Inaguma: Toyoda Koki Giho (Toyoda Koki Technical

−1

15 N =1 000min

Review), 36, 3 (1996) 25.

−1

N =800min 5) T. Ichikawa and A. Hibi: Yuatsu Kogaku, Asakura-shoten

Q, L/min

10 −1

N =600min (1979) 29.

0

0 0.5 1.0 1.5 2.0

pd, MPa

Fig. 14 Real flow of pump

16

Condition: Oil temperature 80℃

15.43

Q 0 /N (=V th ) cm /rev

15

3

14

13

0 500 1 000 1 500

−1

N , min

Fig. 15 Vth estimated from measured flow

Y. INAGUMA*

* Engineering Department, Driveline System Operations

Headquarters, PhD

76 JTEKT Engineering Journal English Edition No. 1001E (2006)

S-ar putea să vă placă și

- Printable Brinell Hardness ChartDocument4 paginiPrintable Brinell Hardness ChartSijo Kaviyil JosephÎncă nu există evaluări

- Sand and Permanent Mold Casting Errata WatermarkDocument7 paginiSand and Permanent Mold Casting Errata Watermarkprakashp111Încă nu există evaluări

- Mil HDBK 694aDocument106 paginiMil HDBK 694ahardik033Încă nu există evaluări

- Astm b86.5503 ZamakDocument7 paginiAstm b86.5503 ZamakJosé SierraÎncă nu există evaluări

- Astm-A 356Document6 paginiAstm-A 356Venkatagiri Srinivas MurthyÎncă nu există evaluări

- Astm B26 - B26M-2011 - 5343Document3 paginiAstm B26 - B26M-2011 - 5343jaskaran singh0% (1)

- Wa0025Document28 paginiWa0025Venkatagiri Srinivas MurthyÎncă nu există evaluări

- Spur Gear For I PDocument40 paginiSpur Gear For I PVenkatagiri Srinivas MurthyÎncă nu există evaluări

- Fishbone Diagram TemplateDocument2 paginiFishbone Diagram TemplateRoger McnigÎncă nu există evaluări

- Qpedia Nov10 HS Manuf Technologies1Document5 paginiQpedia Nov10 HS Manuf Technologies1etamil87Încă nu există evaluări

- GL Huyett EngineeringHandbookDocument95 paginiGL Huyett EngineeringHandbookSwetha PattelaÎncă nu există evaluări

- GL Huyett EngineeringHandbookDocument95 paginiGL Huyett EngineeringHandbookSwetha PattelaÎncă nu există evaluări

- GL Huyett EngineeringHandbookDocument95 paginiGL Huyett EngineeringHandbookSwetha PattelaÎncă nu există evaluări

- Spare ListDocument10 paginiSpare ListVenkatagiri Srinivas MurthyÎncă nu există evaluări

- Energies 10 01261 v2 PDFDocument32 paginiEnergies 10 01261 v2 PDFg1.patilÎncă nu există evaluări

- GDT Rectangle WorkshopDocument14 paginiGDT Rectangle WorkshopmagicalmarshmallowÎncă nu există evaluări

- Fishbone Diagram TemplateDocument2 paginiFishbone Diagram TemplateRoger McnigÎncă nu există evaluări

- Tourist Spots Around BangaloreDocument4 paginiTourist Spots Around BangaloreshoravkaseraÎncă nu există evaluări

- Energies 10 01113Document20 paginiEnergies 10 01113Manny CalÎncă nu există evaluări

- Open Water Diver Manual: English Translation and Revision by Till HoffmannDocument68 paginiOpen Water Diver Manual: English Translation and Revision by Till HoffmannMauricio CortesÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Automotive Transmission: Presented byDocument48 paginiAutomotive Transmission: Presented bySumit SharmaÎncă nu există evaluări

- Specifications Of: Tata LPT 1918Document1 paginăSpecifications Of: Tata LPT 1918indramaniÎncă nu există evaluări

- Blade Arrangments 1Document4 paginiBlade Arrangments 1Ravi MirzaÎncă nu există evaluări

- 3Document7 pagini3SON50% (2)

- Epi Manualcodes1Document308 paginiEpi Manualcodes1FiefjesÎncă nu există evaluări

- Allison Transmision MT4015ENDocument78 paginiAllison Transmision MT4015ENMaja Vojvodic82% (11)

- 01-02 DpiDocument52 pagini01-02 DpiRatnin PanityingÎncă nu există evaluări

- CB 160 Manual de Servicio PDFDocument336 paginiCB 160 Manual de Servicio PDFOscar Eduardo Vera Aguirre100% (2)

- Classic-Honda 125 185 200 Engine SpecDocument14 paginiClassic-Honda 125 185 200 Engine SpecCamilo Gomez100% (1)

- Massey Ferguson 6100 Series Tractor Workshop Repair Manuals PDFDocument815 paginiMassey Ferguson 6100 Series Tractor Workshop Repair Manuals PDFReinder Spriensma89% (9)

- Supreme Luxury Absolute Power: WWW - Toyotainnova.inDocument8 paginiSupreme Luxury Absolute Power: WWW - Toyotainnova.inJose TomÎncă nu există evaluări

- PAES 109 - Part 1 Pull-Type Walking-Type Agricultural TractorDocument6 paginiPAES 109 - Part 1 Pull-Type Walking-Type Agricultural TractorJerard BalalaÎncă nu există evaluări

- 414 Manual BOMBADocument114 pagini414 Manual BOMBAYonatanÎncă nu există evaluări

- Cat 826HDocument24 paginiCat 826HJesús PalomaresÎncă nu există evaluări

- Hydraulic Proportional Servo TechnologiesDocument37 paginiHydraulic Proportional Servo Technologiescristi_amaÎncă nu există evaluări

- Product Description: Extra High Performance Multipurpose Tractor LubricantDocument3 paginiProduct Description: Extra High Performance Multipurpose Tractor LubricantygramulÎncă nu există evaluări

- Toyota - Landcruiser Prado 150 - Ebrochure - Australia PDFDocument30 paginiToyota - Landcruiser Prado 150 - Ebrochure - Australia PDFErick Adrian Quintero JaramilloÎncă nu există evaluări

- ReadmeDocument3 paginiReadmeayman akrabÎncă nu există evaluări

- 20 Axial Pump and Control Service ManualDocument22 pagini20 Axial Pump and Control Service ManualJesus AguinagaÎncă nu există evaluări

- Repair Manual: ZF Getriebe GMBH SaarbrückenDocument200 paginiRepair Manual: ZF Getriebe GMBH Saarbrückenkorol965Încă nu există evaluări

- A750E ManualDocument6 paginiA750E Manualruslan158080% (10)

- Voith Diwa 6Document8 paginiVoith Diwa 6Daniel Alex Sánchez100% (1)

- Land CruiresDocument204 paginiLand CruiresFredy HernanÎncă nu există evaluări

- New Parallel Shaft Gearbox For Auger Drives in Biomass-HeatersDocument3 paginiNew Parallel Shaft Gearbox For Auger Drives in Biomass-Heaterstiele_barcelosÎncă nu există evaluări

- Laboratory Activities 20Document208 paginiLaboratory Activities 20Jaime Alejandro Berrio FernandezÎncă nu există evaluări

- Service Manual: Powershift Transmission T16000Document138 paginiService Manual: Powershift Transmission T16000Marcos Aldana VillaldaÎncă nu există evaluări

- Minimum Critical Spare ListDocument32 paginiMinimum Critical Spare ListVIBHAVÎncă nu există evaluări

- Selection of Hydraulic MotorsDocument17 paginiSelection of Hydraulic MotorsRahul100% (2)