Documente Academic

Documente Profesional

Documente Cultură

Lifting Equation For Manual Lifting

Încărcat de

Shafiqul IslamTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lifting Equation For Manual Lifting

Încărcat de

Shafiqul IslamDrepturi de autor:

Formate disponibile

l of Ergono

na

Journal of Ergonomics

r

m

Jou

ics

Shahu, J Ergonomics 2016, 6:2

DOI: 10.4172/2165-7556.1000159

ISSN: 2165-7556

Review Article Open Access

The NIOSH Lifting Equation for Manual Lifting and Its Applications

Rashmi Shahu*

Department of Industrial Engineering, Shri Ramdeobaba College of Engineering and Management, Nagpur, India

*Corresponding author: Rashmi Shahu, Department of Industrial Engineering, Shri Ramdeobaba College of Engineering and Management, Nagpur, India, Tel:

9923587842; E-mail: rashmishahu17@gmail.com

Received date: October 31, 2015; Accepted date: March 21, 2016; Published date: March 27, 2016

Copyright: © 2016 Shahu R. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use,

distribution, and reproduction in any medium, provided the original author and source are credited

Abstract

The literature on the problems caused by frequent lifting and lowering tasks has grown rapidly in the past few

decades. This paper focuses on presenting literature on the NIOSH Lifting Equation, which is used for calculating

injure-free lifting capabilities for workers who perform two-handed manual lifting tasks and using the study as a basis

for applying it to a manufacturing company Technocrats India, Nagpur. The papers acquired for the study focus on

the importance of the equation to reduce the effect of Low Back Pain (LBP) associated with various lifting

operations. The result of the study is a systematic research and compilation of various aspects of the equation and

its applications at construction sites and industrial organizations and its use at a manufacturing company where the

manufacturing process comprises the machining of the Cylinder Body part and Valve body part. The equation will be

used for these to know the effect of the work on workers. The final assessment of the study is that for successful

outcomes for reduction in Work related Musculoskeletal Disorders (WMSDs) and LBP, the equation should be

thoroughly considered for manual lifting practices.

Keywords: NIOSH lifting equation; Work related musculoskeletal well-known and used tools for assessing physical hazards at workplace

disorders; Manual lifting; Low back pain include:

Introduction Well known and used tools for assessing physical hazards at

workplace

The National Institute of Occupational Safety and Health (NIOSH)

felt the need for the development of a technique to mitigate the effects • Arbetplatsprovaren: A Swedish language, internet-based survey of

of Low Back Pain (LBP) and Work related Musculoskeletal Disorders physical and psychosocial aspects of the workplace.

(WMSDs) associated with lifting and lowering tasks [1-5]. It published • Arbetsmiljön i skolan: A Swedish language checklist tool for

the Work Practices Guide for Manual Lifting. The WPG included a improving school work environments.

summary of literature regarding lifting operations before 1981 [6]. The • Cumulative Trauma Disorder–Risk Assessment (CTD-RAM):

NIOSH lifting equation was first developed in 1981 and was called the Upper limb assessment tool for predicting injury incidence rates.

standard NIOSH lifting equation, the equation was then reformed in This assessment model predicts injury incidence rates and assesses

1991 and was called the revised NIOSH lifting equation [1]. The job risk. It further quantifies risk factors by strength, fatigue, and

revised NIOSH lifting equation included aspects such as asymmetry, posture. The CTD-RAM specifies acceptable limits on work design

coupling, frequency, etc. for manual lifting [7]. These parameters for a given individual.

proved to be of greater importance and more training is required for • ErgoIntelligence and Ergomaster: Software tools implementing a

their use [8]. The equation was designed to provide a limit beyond number of different checklist tools.

which there would be a need to take ergonomic measures to curtail the

• ErgoEquations (Online Ergonomic Tools-Office Solutions):

risks [5]. A study indicated that approximately 650,000 workers every

Contains an ergonomic analysis for musculoskeletal complaints,

year suffer injuries and illnesses caused by overexertion, repetition etc.

including the Discomfort survey, which assesses discomfort levels

which have caused the US businesses to incur compensations between

before and after implementing ergonomic solutions to document

$15 to $20 billion dollars a year [1] Back injuries prevail as most

effectiveness; employee training; and ergonomic program

common and costly in agriculture too, i.e., California agriculture has

documentation and planning.

an average of 3,350 back injuries each year which accounts for more

than $30 million [9]. The lifting equation is applicable to two-handed • Ergonomiska Checklista Datorarbete: A simple checklist for

lifting tasks. One- and two-handed repetitive lifting tasks form a part evaluation of computer workplaces.

of many occupations. Thus the metabolic demands of one- and two- • Ergonomitermometer: A Swedish language tool using a

handed tasks should be clearly understood to know if they would ‘thermometer’ metaphor to help assess risk levels. This site contains

provide similar outcomes because a job design which would take this a number of other ‘work environment’ checklists adapted to

into consideration would prevent injuries related to lifting tasks. various sectors.

• ISO/TS 20646-1: A procedure for reducing work-related

Various other Manual Material Handling (MMH) methods exist of

musculoskeletal disorders including a risk assessment checklist.

which NIOSH forms a part. A few of these methods include Snook

The checklist considers lifting, carrying, and work requiring high

Tables, ACGIH TLV, WA L&I, 3DSSPP, etc. of which Snook Tables,

physical force.

NIOSH and ACGIH TLV are compared below. Also, some of the other

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 2 of 10

• Job Hazard Pro (Production Technology Engineering and 3 rows wide/5 3 rows wide/5

Management Services): Evaluates potentially harmful situations in Pallet stacking cases high/2 rows cases high/3 rows

the plant or office. deep deep

• Keyserling Checklist: A classic, simple, risk factor checklist easily

adapted to users’ needs. Table 1: Characteristics of containers.

• Manual Handling Assessment Chart (MAC): Like the NIOSH

equation this allows easy assessment of MMH tasks. Horizontal Distance in cm Vertical Height in cm

• Manual Handling Guidance: Checklists for task, equipment, (as defined by the tool) (floor to handle height)

environment and individual risk factors. The Manual Handling

23 25

Guidance checklists can be used to identify risk factors for manual

handling. 23 53

• Manual Tasks Risk Assessment Tool (ManTRA): A checklist from

the University of Queensland. 30 81

• NIOSH Survey: A musculoskeletal checklist by the US NIOSH. 30 109

• OCRA: A short checklist-based index for assessing risk due to

30 137

repetitive movements.

• Ovako Working Posture Analysis System (OWAS): For rapid 30 165

assessment of postural loads at work.

30 193

• PLIBEL: A 1-page checklist, mostly of physical risk factors,

available in several different languages. This is a method for the

identification of musculoskeletal stress factors and risks. Table 2: Hand grasps task measurements of horizontal distance for a

• Quick Exposure Checklist (QEC): For assessing risk factors for given vertical height.

work-related musculoskeletal disorders.

The EI values were calculated to get the outcome. An EI greater than

• Rapid Entire Body Assessment Tool (REBA): Similar to RULA but

1.0 reveals the extent to which the load exceeds a recommended

with a whole body focus.

weight. The outcome of the study is given in the Table 3.

• Rapid Upper Limb Assessment Tool (RULA): Provides a ‘score’ for

upper limb demands by McAtamney and Corlett. Vertical NIOSH ACGIH TLV Snook

• Risk Filter: From the UK Health and Safety Executive, this two Height

15 l 23 l 15 l 23 l 15 l 23 l

stage tool focuses on upper limb MSD risk. Lift Origin

(cm)

• Strain Index: Combines time, repetition, load, and posture into a

single index focused on hand/wrist load. 25 1.17 1.79 1.23 1.88 1.58 2.15

• Work Environment Survey Tool (WEST): Provides both traditional

53 1.14 1.74 0.96 1.46 1.58 2.15

ergonomic and occupational hygiene analysis possibilities.

81 1.15 1.75 1.23 1.88 1.58 2.15

Comparison of Snook Tables, NIOSH equation and

109 1.18 1.80 1.08 1.64 1.58 2.15

ACGIH TLV

137 1.24 1.89 1.08 1.64 1.58 2.15

An example including 2 different milk cases was considered to

compare the three MMH methods. The details of the two milk cases 165 1.34 2.05 2.46 3.75 2.11 2.76

are given in Table 1 and the values of the horizontal distance and

193 1.52 2.32 2.46 3.75 2.11 2.76

vertical height are given in Table 2.

Characteristics of Containers Table 3: EI Values of each tool, at each vertical height origin, for both

the 15 l and 23 l cases.

Characteristic 23 L case 15 L case

Weight 26 kg 17 kg All analytical tools predicted a greater musculoskeletal risk with the

heavier load (23 L) versus the lighter load (15 L). ACGIH TLV and

Wide 33 cm 33 cm Snook are easier to apply, but NIOSH risk predictions are more

sensitive to incremental changes in lift input values.

Long 48 cm 33 cm

Tall 28 cm 28 cm Comparison of Standard and Revised Equation

Handle distance from bottom of

25 cm 25 cm

Comparison between 1981 standard NIOSH lifting equation and

case the revised NIOSH lifting equation has been given in Table 4 [7].

Cases to a pallet 30 45

Standard NIOSH Lifting Equation Revised NIOSH Lifting Equation

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 3 of 10

Standard Lifting Location 30 inches above the floor and 6 inches horizontally 30 inches above the floor and the horizontal

forward of the mid-point between the ankles dimension has been

increased to 10 inches

Load Constant 90 pounds (40 kg) 51 pounds (23 kg)

Calculated Limits Action Limit (AL), Maximum Permissible Limit Recommended Weight Limit (RWL), Lifting Index

(MPL=v3AL) (LI<=1.0)

Multiplicative Weighting Factors horizontal, vertical, distance, and frequency two new ones - asymmetry and coupling

Analysis Procedure Single-task analysis procedure Multi-task analysis procedure

Table 4: Comparison of standard and revised NIOSH equation.

Use of NIOSH Equation for multi-task analysis object relative

to the floor

Multi-task analysis uses the single task RWL equation and

additional indices to determine the overall cumulative physical Distance the

Distance

demands of the lifting station. Multitask analysis is used in lifting D

object is

Multiplier

DM = (0.82 + DM = (0.82 +

moved (4.5 / D)) (1.8 / D))

operations where weights and heights vary [1]. vertically

(DM)

Calculation of VLI for the NIOSH Equation Asymmetry

Asymmetric

A Multiplier AM = (1 - (0.0032A))

angle

The Variable Lifting Index (VLI) can be calculated by first knowing (AM)

the Frequency Independent Lifting Index (FILI) for each of the tasks

Frequency

that are selected for analysis, then depending upon the task variability and duration

Frequency

F Multiplier

each of the lifts is fitted into FILI categories (one to nine). These values of lifting

(FM)

and the corresponding frequency of lifts in each category are then activity

input into the Composite Lifting Index (CLI) [4]. Coupling or

quality of the

Coupling

About the Equation C

workers grip

on the

Multiplier

(CM)

object(good,

Calculations to be carried out to find outcomes of equation fair, poor)

The revised NIOSH lifting equation (1991) is used to evaluate the

Table 5: Details of variables used in the equation.

manual lifting tasks, [1-3]. The primary outcome of the lifting equation

is the RWL which gives the limit of the maximum weight that all Interpretation of outcomes of the equation:

healthy workers can lift. Once the RWL is determined the Lifting index

(LI) is calculated from it. The value of the LI suggests the level of stress If the LI is less than 1.0, there are nominal or no chances of LBP or

that will be associated with the specified lifting task being evaluated, WMSDs to the working healthy employees. However, if the LI is

[10]. The equation is as follows, [2,10]: greater than 1.0, there is an increased risk of such injuries, [11,12]. As

explained by Waters et al. [3], the Load Constant is taken to be 51 lbs.

RWL = LC (51 lbs) × HM × VM × DM × AM x FM × CM This is considered to be the maximum recommended weight of the

LI = Weight / RWL load that can be lifted by employees under ideal conditions. The

frequency multipliers required for the equation can be determined

Details of variables, multipliers used in the equation from its respective table [3].

Waters et al. [3] explained the multipliers and the derivations of the Use of NIOSH Equation for one- and two - handed lifting

equations which would use the respective variables to determine the

tasks

multipliers [11], explained the variables with which the multipliers can

be calculated. All of these have been specified in Table 5. Sevene et al. compared the psychophysical and physiological work

stress for identical lifting tasks which could be performed with either

Variables Description Multiplier

Value in Value in one or two hands. The result of the study is in Table 6 which shows no

Centimetres Inches

significant difference in terms of physiological and psychophysical

Horizontal stress, when good coupling exists. RPE is a scale that assesses work-

Horizontal

H

location of the

Multiplier HM = (25/H) HM = (10/H)

related stress which is caused by a particular activity. It takes into

object relative account a combination of factors such as; perceived fitness, fatigue

(HM)

to the body

levels, environmental conditions, effort, etc.

Vertical VM = (1 –

Vertical VM = (1 – 0.003 | Metabolic Lifting conditions

V Multiplier 0.0075 | V - 30

location of the V - 75 |) Parameters

(VM) |)

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 4 of 10

Dominant Hand Non-Dominant Hand Both Hands • Biomechanical

• Psychophysical

O2 Consumption 14.3 14.4 15.7

(ml/kg/min)

• Physiological

Liters of O2/min 1.0 1.0 1.1 Reasons for selection of the three criteria

kCal/min 5.1 5.1 5.6 These were selected because these factors affected the lifting

operations majorly. Based on these criteria the various equations for

Heart Rate 103.4 105.4 107.1

knowing the multipliers were derived. Using these multipliers the

RPE (Rating of 9.4 10.0 9.4 Recommended Weight Limit (RWL) could be determined. Thus, the

Perceived Exertion) major use of these criteria was to know the RWL. RWL defines a limit

for the weight that all healthy workers can lift while performing a

Table 6: Metabolic parameters with respect to lifting conditions. lifting operation [3,13]. A study indicated that the revised NIOSH

lifting equation describes the specific values used to establish a

Criteria for Defining the Equation Recommended Weight Limit (RWL) and these were based on the three

criteria [3].

Three criteria were used for defining the equations (both standard

The three disciplines with their cut-off values and design criteria are

and revised equations, [3,13] namely:

presented in a tabular form in Table 7.

Discipline Design criterion Cut-off value

Biomechanical Maximum disc compression force 3.4 kN (770 lbs)

Physiological Maximum energy expenditure 2.2-4.7 kcal/min

Psychophysical Maximum acceptable weight Acceptable to 75% female workers and about 99%

male workers

Table 7: Criteria used to develop the lifting equation [3].

Reason for using a combination of the three criteria

The biomechanical criteria should maintain L5/S1 compression

below 3400 N. The base of the spine is made up of the intricate L5/S1

vertebral segment [3,7]. The idea of using a combination of the three

disciplines was to minimize the risks that tasks related to lifting can

cause as either one of the three considered one at a time or even a

combination of two would not mitigate the effects to an extent that

would be protective of workers [3,13] Also these three criteria

contradict one another to an extent, for example: metabolic data

suggest is more efficient to lift heavier weights less frequently than to

lift lighter weights more frequently; however, biomechanical studies

suggest the load should be minimized by lifting lighter weights more

frequently to reduce muscle and vertebral stresses. Also, when lifting Figure 1: Example showing the integration of the biomechanical,

from the floor, results from psychophysical studies suggest that psychophysical and physiological criteria to determine CAL values

workers can lift loads that are heavier than those estimated from for each frequency for one condition (K-S range, D ¼ 51 cm, box

biomechanical or physiological studies [3]. Thus, a combination of the width ¼ 75 cm). The composite acceptable load (CAL) was assumed

three criteria is to be used [6,12] gave a graphical representation of the to be the most conservative of the three criteria [12].

combination of the three criteria and how the RWL and Composite

Acceptable Load (CAL) are determined based on it is shown below in

Figure 1 [12].

Assumptions

Phinder et al. [13] stated the following assumptions under which the

NIOSH Lifting Equation is to be considered (these would not hold if

the lifting factors were interdependent):

1. Lifting factors are independent of each other

2. Effects of multipliers are co-operative

3. Each factor contributes about the same amount of risk to the

overall risk of low-back injury due to a given lifting task [13].

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 5 of 10

General Applications The maximum value of the Lifting Index is shown to be 7.3 for Dry

Wall Installer so the risk factor for it is the most because the LI shows

At construction sites to know maximum LI of all that it is too heavy. To improve the condition, the improvements that

Choi et al. suggested were to

construction materials and make recommendations

1. Use more than 2 workers

Choi et al. [2] stated that; for construction workers to reduce their

2. Use mechanical handling aids

exposure to risks, they need to know the weights of common

construction materials. Negligence of this would lead to pain or 3. Use 25% lighter weight drywall

injuries among workers.

At construction sites to compare LI for materials before and

The results of the study are as given in Figure 2. It shows the Lifting

after making optimizations

Index (LI) with respect to various occupations carried out at the

construction site. Godwin et al. [11] gave the assessment of Work related

Musculoskeletal Disorders (WMSDs) caused by lifting activities during

building construction. The result before and after optimization are

shown below in Table 8.

Figure 2: Lifting Index with respect to occupation [2].

Object Weight (kg) LI = (Weight/RWL)

Normal Conditions Optimized Conditions (RWL = 23 kg)

(RWL = 6.83 kg)

Bag of Cement 50.0 kg 7.32 2.17

9-inch Hollow Block 20.80 kg 3.05 0.90

6-inch Hollow Block 16.70 kg 2.45 0.73

5-inch Solid Block 22.50 kg 3.29 0.93

6-inch Solid Block 26.67 kg 3.91 1.16

Full head pan of sand 37.80 kg 5.53 1.64

Full head pan of stone 30.30 kg 4.44 1.32

Table 8: Lifting Index for various objects before and after optimization [11].

At construction sites to calculate LI to know pain caused due

to lifting tasks

Adeyemi et al. [14] catered to lifting tasks and pain caused due it

among workers at construction sites in the South-western Nigeria. The

results indicated the following:

More than 70% of the workers are at an increased risk of problems

caused by lifting tasks. This is depicted in Figure 3.

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 6 of 10

At auto parts manufacturing firm to know LBP level before

and after redesign

Meepradit et al. [16] considered 17 samples working in auto parts

manufacturing. The job was to lift boxes of varying sizes, ranging from

15.7 to 28.7 pounds with duration of 1 h-4 h a day. The following were

the outcomes of the study [16,17].

Questionnaires for workers for the analysis of musculoskeletal

symptoms on a scale ranging from 0 (no pain) to 10 (worst pain)

before and after redesign. The ergonomics redesigns included

Figure 3: Pain in body regions in 12 months [14]. 1. Load being brought closer to the worker (by training);

2. Height of objects being placed to be raised (to reduce the vertical

distance between the origin and destination of the lift);

Level of ergonomics training to workers for working methods was

found to be low. This is depicted in Figure 4. 3. Origin and destination of lift to be brought closer (to reduce the

angle of twist).

The new procedures were trained to the workers. The result was a

safer LI (<1.0) as shown on Table 10.

Worker (n=17)

Low Back Pain

Before redesign After redesign

Level

0 0 0

1 0 0

2 1 3

Figure 4: Response of workers to ergonomics training [14]. 3 1 0

4 1 3

Redesigning of work methods was found to be necessary to reach

5 3 4

the acceptable LI value.

6 2 5

At casting firms to calculate LI to assess risks due to various

7 3 1

lifting tasks

8 0 1

Singh [15] studied the low back injury risk and work factors in few

small scale casting firms of Northern India for a total of 40 workers. 9 3 0

The result of the study was the risk level based on the Lifting Index

calculated using the equation. Also, the percent of workers for whom 10 3 0

actions need to be taken were calculated and the result is tabulated in

the Table 9 [15]. Table 10: Low Back Pain level among workers [16].

Lifting Number of Percentage of

Index

Risk level Actions

workers workers (%)

To compare MAWL and Heart rate values of Construction

workers and Household Workers

None

0-1 Safe 6 15 Maiti and Ray [18] conducted a study to know the Maximum

necessary

Acceptable Weight Limit (MAWL) for ten Indian adult female

2-Jan Low Necessary 13 32.5 Construction Workers (CW) and eight Indian adult Female household

Necessary workers (HW). The results of the study are as shown in Figure 5. These

3-Feb Medium 11 27.5

soon women were regularly over-exerted at work. Their MAWL was found

to be 15 kg which is half of the safe load limit (30 kg) for adult female

3 and

High Necessary now 10 25 workers.

above

Table 9: Lifting index values based on various tasks at the casting firms

and their analysis [15].

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 7 of 10

Figure 6: Average heart rate values for CW and HW [18].

Figure 5: Average MAWL for three vertical distances for CW and At hospitals to know weight of patients that will be safe for nurses to

HW [18]. lift.

Waters [6] took into consideration a study regarding the weight of

The effect of work duration on heart rate is given in Figure 6. Heart patients that would be safe for nurses to lift. The results obtained under

Rate was calculated to help estimate the MAWL level for variable work the following three conditions using the NIOSH Lifting Equation as

duration [18]. shown in Table 11 are:

A nurse raising a patient’s leg off the bed for surgery.

Patient’s weight Weight of leg Weight patient can Maximum limit Weight to be Excess weight to Suggestions

lift on his own lifted by each be lifted by

nurse nurse(s)

A nurse raising a patient’s leg off the bed for surgery Use a leg lift or limb

positioned

150 lbs 24 lbs - 35 lbs - -

200 lbs 31 lbs - 35 lbs - -

250 lbs 39 lbs - 35 lbs - 4 lbs

300 lbs 47 lbs - 35 lbs - 12 lbs

Two nurses helping a patient to stand from a chair Use a lifting device or a

sit-to-stand device

180 lbs - 90 lbs 35 lbs 45 lbs 10 lbs

Four nurses moving a fully dependent patient

200 lbs - - 35 lbs 50 lbs 15 lbs Use a lifting- assist

device

Table 11: Weight beyond the maximum weight that the nurse has to lift.

Lifting of three boxes under specified conditions to calculate PWC Three rectangular box size: X (35 × 24 × 28 cm), Y (44 × 34 × 17

of workers: cm) and Z (58 × 38 × 24 cm)

Singh et al. [18] considered a situation with the following These were considered for the evaluation of Physical Work Capacity

considerations: (PWC) of Indian male workers during manual lifting [18].

Frequency of lifts: 2, 5 and 8 lifts/min, The results of the study are shown in Table 12 [18].

Weight of load: 7, 14 and 21 kg More significant Less significant factors

factors

Vertical height: waist, shoulder and maximum reach

Horizontal distance: 25, 40 and 55 cm Oxygen Intake Lifting frequency (% Box size (% contribution

contribution 43.28), 1.23), Horizontal

Laboratory condition: 21°C, 27°C and 33°C Lifting load (11.34) distance (0.30)

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 8 of 10

Heart Rate Lifting frequency (49.85), Horizontal distance standard-tub trial (70% of workers reporting symptoms). Thus, the

Vertical height (18.28), (0.87) standard tubs were replaced by smaller picking tubs, the outcome was

Environmental condition that the LI reduced from 3.4 to 2.4 [9].

(11.12)

Application at Technocrats India

Table 12: Effect of lifting variables on heart rate and oxygen intake.

Based on the above study of the NIOSH Equation, it is being applied

Singh et al. [18] also gave suggestions on ways to improve at Technocrats India, Nagpur which is a partnership firm established in

physiological cost of workers. A few of them are: 1986 at Mumbai. It manufactures various types of components for

automotive sector, Agriculture sector, Earth moving sector, Defense

1. Beyond 5 lifts/min, reduce frequency of lift as per

Industries, etc. The company has started a new fully equipped plant in

anthropometric detail of worker

Nagpur, Maharashtra in April 2008.

2. For weight more than 23 kg, use two or more workers

3. Heavier objects to not be lifted above shoulder height Of the various components, the components presently being

4. Proper handles to boxes and training to use them to be provided, manufactured are the Hydraulic Cylinder Head and the Valve body

etc. parts for one of its esteemed client, Mahindra and Mahindra Ltd. Due

to excessive lifting and lowering tasks that had been observed over a

period of time, the equation was put to use in the company.

At wine yard to know risk involved during lifting and make

improvements Initially the plant layout was designed for the company to

specifically know the flow of materials and their handling by various

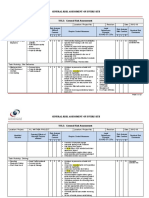

Meyers et al. [9] suggested that manual wine-grape harvesting is operators for both, the cylinder head and the valve body parts (Figure

highly strenuous and physically demanding work, involving risks of 7).

chronic back injury. The findings showed the physical impact of work

had a large increase in WMSD symptoms on workers during the

Figure 7: Flow of material: Valve body part and Cylinder body part respectively.

For frequency of lifts the following calculations were carried out as

given in Table 13.

Process Cycle

Operation Man Allocation TMU Online Offine Spraying Op Time (Min) Time Output/Shift Output/Day

CNC 1 1200 0.52 0.03 0.17 3.38 4.07 165 329

VMC01 1 1417 0.65 0.03 0.17 3.35 4.22 159 320

VMC02 1 1450 0.67 0.03 0.17 3.35 4.19 160 320

VMC03 1 1233 0.54 0.03 0.17 3.45 4.16 161 322

Conventional Drilling M/C 1 1756 1.02 0.03 0 0.72 1.74 384 769

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 9 of 10

18.37 159 320

Table 13: Task allocation: Cylinder body part.

A total of 38 operators form a part of the machining, of which 8 are Origin is for the operator lifting the part from the bin/table and

for the cylinder body part machining. Measurements for the variables placing it into the CNC. Destination is for the operator removing the

for Cylinder body part have been given in Table 13, 14a and 14b. Based part from the CNC and placing it on the table where it is inspected and

on these the RWL and LI were calculated. Measurements and then stacked.

calculations for valve body part will be carried out in the further

phases of the work.

ID V VM H HM D DM A AM C CM L Dur F FM RWL LI

1 39.37 0.93 3.97 1 4.17 1 83 0.71 Poor 0.9 17.63 8 0.3 0.81 11.07 1.59

2 11.85 0.85 7.91 1 3.97 1 87 0.71 Poor 0.9 17.63 8 0.32 0.81 10.11 1.74

3 39.37 0.93 4.17 1 4.13 1 79 0.76 Poor 0.9 17.63 8 0.33 0.81 11.85 1.49

4 16.37 0.89 7.99 1 8.11 1 84 0.71 Poor 0.9 17.63 8 0.27 0.81 10.59 1.66

5 12.16 0.85 15.35 0.67 4.13 1 88 0.71 Poor 0.9 17.63 8 0.3 0.81 6.77 2.6

6 39.37 0.93 8.07 1 4.09 1 86 0.71 Poor 0.9 17.63 8 0.33 0.81 11.07 1.59

7 16.06 0.89 12.2 0.83 4.17 1 87 0.71 Poor 0.9 17.63 8 0.3 0.81 8.79 2.01

8 16.18 0.89 4.56 1 4.96 1 84 0.71 Poor 0.9 17.63 8 0.3 0.81 10.59 1.66

Table 14a: LI calculations for cylinder body part (Origin).

ID V VM H HM D DM A AM C CM L Dur F FM RWL LI

10.11

1 8.18 0.85 4.09 1 4.33 1 88 0.71 Poor 0.9 17.63 8 0.3 0.81 1.74

8

10.11

2 9.05 0.85 7.99 1 7.95 1 83 0.71 Poor 0.9 17.63 8 0.28 0.81 1.74

8

10.83

3 8.18 0.85 4.09 1 4.33 1 82 0.76 Poor 0.9 17.63 8 0.27 0.81 1.63

1

10.11

4 11.92 0.85 8.18 1 7.95 1 89 0.71 Poor 0.9 17.63 8 0.3 0.81 1.74

8

10.83

5 8.03 0.85 8.03 1 3.97 1 76 0.76 Poor 0.9 17.63 8 0.3 0.81 1.63

1

10.83

6 8.42 0.85 3.97 1 4.33 1 78 0.76 Poor 0.9 17.63 8 0.27 0.81 1.63

1

10.83

7 8.97 0.85 4.05 1 7.91 1 82 0.76 Poor 0.9 17.63 8 0.3 0.81 1.63

1

10.11

8 12.16 0.85 7.91 1 7.67 1 85 0.71 Poor 0.9 17.63 12 0.28 0.81 1.74

8

Table 14b: LI calculations for cylinder body part (Destination).

The result after using the equation shows that for the Cylinder body The increased LI was majorly seen because of the poor coupling, the

part for all 8 operators, the LI came out to be greater than 1.0. This angle of asymmetry and the vertical location of the object. The

indicates there is a risk of LBP and other injuries to the workers horizontal location, the distance of lift and the frequency of lifts were

associated with the lifting tasks (both at the origin and the found to be within proper limits.

destination).

In order to mitigate the effects so as to reduce the LI, it has been

suggested to use roller conveyers to move the part easily. Also, it was

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

Citation: Shahu R (2016) The NIOSH Lifting Equation for Manual Lifting and Its Applications. J Ergonomics 6: 15. doi:

10.4172/2165-7556.1000159

Page 10 of 10

suggested to provide tables with appropriate height for placing the 8. Dempsey PG (2002) Usability of the revised NIOSH lifting equation

object both at the origin and the destination and it was advised to Ergonomics 45: 817-828.

provide proper rest periods at regular intervals [19-21]. 9. Meyers JM, Miles JA, Faucett J, Fathallah F, Janowitz I, et al. (2006)

Smaller loads reduce risk of back injuries during wine grape harvest”,

California Agriculture 60: 25-31.

Conclusion 10. Waters TR, Putz-Anderson V, Garg A (1994) Applications Manual for the

The NIOSH Lifting Equation has its application in a variety of fields Revised NIOSH Lifting Equation. The National Institute for Occupational

Safety and Health, CDC, USA.

to reduce the Low Back Pain caused by manual lifting tasks at

workplaces. The study based on these applications is being used to 11. Godwin HC, Chuckwuemeka H, Okpala CC (2013) Ergonomic

assessment of musculoskeletal disorders from load-lifting activities in

know effectiveness of lifting tasks in order to ensure safe working building construction. International Journal of Advanced Engineering

practices of workers at Technocrats. The result shows increased LI for Technology 4: 01-06.

all the 8 operators working on the Cylinder Body part machining. 12. Potvin JR (2014) Comparing the revised NIOSH lifting equation to the

Suggestions regarding using proper heighted tables and roller psychophysical, biomechanical and physiological criteria used in its

conveyers were made so that the working will be more protective of development. International Journal of Industrial Ergonomics 44: 246-252.

workers. 13. Phinder ADJ, Frost GA (2011) Prospective evaluation of the 1991 NIOS

Lifting Equation. Published by the Health and Safety Executive.

Future Work 14. Adeyemi O, Adejuyigbe S, Akanbl O, Ismaila S, Adekoya AF (2013)

Manual lifting task methods and low back pain among construction

On carrying out a detailed study on Cylinder Body part, the results workers in the Southwestern Nigeria. Global Journal of Researches in

were found to be not very safe for workers so a detailed study will also Engineering 13: 27-34.

be carried out for the Valve body part to know the effects of it on the 15. Singh LP (2013) Prevalence of low back injury (lbi) risk due to manual

operators. lifting tasks among small scale casting industry workers. Wyno Academic

Journal of Engineering and Technology Research 1: 30-36.

16. Meepradit P, Sunee N, Chantrasa R (2015) The Application of NIOSH

References Lifting Equation to Prevent Musculoskeletal Disorder Risks. Journal of

1. Temple R, Adams T (2000) Ergonomic Analysis of a Multi-Task Industrial Biosciences and Medicines 3: 39-44.

Lifting Station Using the NIOSH Method. Journal of Industrial 17. Maiti R, Ray GG (2004) Determination of maximum acceptable weight of

Technology 16: 2-6. lift by adult Indian female workers. International Journal of Industrial

2. Choi SD, Borchardt JG, Proksch TL (2012) Translating academic research Ergonomics 34: 483-495.

on manual lifting task observations into construction workplace “Good 18. Singh N, Belokar RM, Walia RS (2012) Physiological evaluation of

Practices”. Journal of Safety, Health and Environmental Research8: 3-10. manual lifting tasks on Indian male workers. International Journal of

3. Waters TR, Putz-Anderson V, Garg A, Fine LJ (1993) Revised NIOSH Engineering and Advanced 2: 8-16.

equation for design and evaluation for manual lifting tasks. Ergonomics 19. http://www.ryerson.ca/content/dam/hfe/documents/hf-tools-beta200.pdf

36: 749-776. 20. https://ergoweb.com/study-compares-lifting-analysis-methods-niosh-

4. Waters TR, Baron SL, Piacitelli LA, Anderson VP, Skov T, et al. (1999) equation-vs-snook-tables-vs-michigan-3dsspp-vs-washington-calculator-

Evaluation of the revised NIOSH lifting equation Across-sectional vs-acgih-tlvs/

Epidemiologic study. Spine 24: 386-395. 21. Waters T, Occhipinti E, Colombini D, Alvarez- Casado E, Hernandez-

5. Elfeituri FE, Taboun SM (2002) An Evaluation of the NIOSH Lifting Soto A (2009) The variable lifting index (VLI): a new method for

Equation: A Psychophysical and Biomechanical Investigation. evaluating variable lifting tasks using the revised NIOSH lifting equation

International Int J Occup Saf Ergon 8: 243-258. Proceedings of the 17th Triennial Congress of the International

6. Waters TR (2007) When is it safe to manually lift a patient? The American Ergonomics Association, Beijing, China. Taiwan, ROC: International

Am J Nurs 107: 53-58. Ergonomics Association, pp. 1-3.

7. Weames GG, Stothart P, Robertson DGE (1994) Comparison of the 1991

NIOSH lifting equation and M. erector spinae EMG. Proc CSB, Calgary 8:

152-153.

J Ergonomics Volume 6 • Issue 2 • 1000159

ISSN:2165-7556 JER, an open access journal

S-ar putea să vă placă și

- Unit VI L&D Case StudyDocument6 paginiUnit VI L&D Case StudyBrooke Misty Ann BaileyÎncă nu există evaluări

- BDS Catlogue PDFDocument298 paginiBDS Catlogue PDFShafiqul IslamÎncă nu există evaluări

- Mindfulness and Acceptance For Addictive Behaviors Applying Contextual CBT To Substance Abuse and Behavioral AddictionsDocument354 paginiMindfulness and Acceptance For Addictive Behaviors Applying Contextual CBT To Substance Abuse and Behavioral AddictionsAlejandra Vergara83% (6)

- Behavior Based SafetyDocument27 paginiBehavior Based SafetySuresh KumarÎncă nu există evaluări

- DM PH&SD P4 TG21Document2 paginiDM PH&SD P4 TG21jillianixÎncă nu există evaluări

- Inspection Trade UnionsDocument35 paginiInspection Trade UnionsVenky Chowdary VankayalapatiÎncă nu există evaluări

- Aetiology, Pathology and Management of Enterocutaneous FistulaDocument34 paginiAetiology, Pathology and Management of Enterocutaneous Fistularoselinekhadija100% (1)

- Ergonomics Principles and GuidelinesDocument18 paginiErgonomics Principles and GuidelinesArpan Gautam100% (1)

- 3M Dbi-Sala Fall Protection: Full Line CatalogDocument132 pagini3M Dbi-Sala Fall Protection: Full Line CatalogBenjamin HidalgoÎncă nu există evaluări

- Viking S30 Liferafts: Liferafts With Extended Service IntervalsDocument4 paginiViking S30 Liferafts: Liferafts With Extended Service IntervalsCrystal FishÎncă nu există evaluări

- NEBOSH Diploma in Environmental Management Unit ED1 (2010 Specification)Document5 paginiNEBOSH Diploma in Environmental Management Unit ED1 (2010 Specification)Raz BiophyÎncă nu există evaluări

- Sba Guidance v1 Apr 23Document17 paginiSba Guidance v1 Apr 23Rajneesh SainiÎncă nu există evaluări

- Fall Protection PlanDocument11 paginiFall Protection PlangrantÎncă nu există evaluări

- Theory of AccidentDocument36 paginiTheory of AccidentLeonardo Aji Nugraha100% (1)

- Safe Work PracticesDocument5 paginiSafe Work PracticesLigsanan John PatrickÎncă nu există evaluări

- Oshas 18000Document10 paginiOshas 18000JanaÎncă nu există evaluări

- Integrated Management System 2016Document16 paginiIntegrated Management System 2016Mohamed HamedÎncă nu există evaluări

- Example Question Paper and Examiners' Feedback On Expected Answers (FC1)Document11 paginiExample Question Paper and Examiners' Feedback On Expected Answers (FC1)Safiullah KamawalÎncă nu există evaluări

- 2020 ProQual NVQ L6 Candidate Eligibility QuestionaireDocument2 pagini2020 ProQual NVQ L6 Candidate Eligibility QuestionaireMohamed BasbasÎncă nu există evaluări

- 4 August 2021 ExamDocument5 pagini4 August 2021 ExamRafa'eel BickooÎncă nu există evaluări

- Iso45001 2018 Iosh Branch Presentation 16-01-2020Document76 paginiIso45001 2018 Iosh Branch Presentation 16-01-2020sohaibÎncă nu există evaluări

- Crane Hoist and Sling Safety ProgramDocument25 paginiCrane Hoist and Sling Safety ProgramalongÎncă nu există evaluări

- Forklift Safety - Preventing Injuries & Deaths: OSHA Training RequirementsDocument3 paginiForklift Safety - Preventing Injuries & Deaths: OSHA Training RequirementsJohn Vem BansagÎncă nu există evaluări

- Making Workplace Safer: Work Health and SafetyDocument6 paginiMaking Workplace Safer: Work Health and SafetySteve McleanÎncă nu există evaluări

- Risk Management or Environmental Health and Safety or Safety ManDocument3 paginiRisk Management or Environmental Health and Safety or Safety Manapi-121419389Încă nu există evaluări

- Safety Process, Management System & Organization - Lecture 2Document21 paginiSafety Process, Management System & Organization - Lecture 2eyes100% (1)

- Implementation of Behaviour Based SafetyDocument11 paginiImplementation of Behaviour Based SafetyAnoop NairÎncă nu există evaluări

- SOP-Storage of ExplosivesDocument6 paginiSOP-Storage of Explosivesmanoj100% (1)

- 20 Amazing Tips To Pass NEBOSH IGC ExaminationDocument3 pagini20 Amazing Tips To Pass NEBOSH IGC ExaminationgeologistlakhanÎncă nu există evaluări

- Guidelines For Personal Protective Equipment (Ppe) : JUNE 2020Document40 paginiGuidelines For Personal Protective Equipment (Ppe) : JUNE 2020Tanri Andita Wicaksono100% (1)

- Accident Investigation and ReportingDocument19 paginiAccident Investigation and Reportingvebsdgr8Încă nu există evaluări

- PJ-RTTS-DI-ERP-009 Rev. B, EMERGENCY RESPONSE PLAN-MNS-1Document17 paginiPJ-RTTS-DI-ERP-009 Rev. B, EMERGENCY RESPONSE PLAN-MNS-1عايض ال سلطان100% (1)

- N 06300 IP1038 Human Factors Competancy Assurance Rev 0 Dec 2012 PDFDocument12 paginiN 06300 IP1038 Human Factors Competancy Assurance Rev 0 Dec 2012 PDFsubragkÎncă nu există evaluări

- Bsi Iso 45001Document2 paginiBsi Iso 45001koushkiÎncă nu există evaluări

- Example Question Paper and Examiners' Feedback On Expected Answers (NGC1)Document12 paginiExample Question Paper and Examiners' Feedback On Expected Answers (NGC1)ASHLEYÎncă nu există evaluări

- Safety ProgramDocument21 paginiSafety ProgramSits RdddÎncă nu există evaluări

- Safety CultureDocument5 paginiSafety CultureprisignsÎncă nu există evaluări

- IG 1 Element 3 New Slides Part 2 ModifiedDocument75 paginiIG 1 Element 3 New Slides Part 2 ModifiedPradeepÎncă nu există evaluări

- Safety Checklist After RainDocument3 paginiSafety Checklist After RainWasni TheresiaÎncă nu există evaluări

- NEBOSH International General CertificateDocument3 paginiNEBOSH International General CertificateAhmad Fadhli0% (2)

- (Env Safety) 1 - Global Safety Management - ENDocument49 pagini(Env Safety) 1 - Global Safety Management - ENNguyen Anh TuanÎncă nu există evaluări

- 4.2 Unit GC2: Controlling Workplace Hazards: Learning OutcomesDocument18 pagini4.2 Unit GC2: Controlling Workplace Hazards: Learning Outcomesnavin100% (2)

- WB 2731 - HotWorkProgram 2Document12 paginiWB 2731 - HotWorkProgram 2pikas100% (1)

- Hand Operated Chain Lever Hoists SI 12.3Document2 paginiHand Operated Chain Lever Hoists SI 12.3reda mesbahÎncă nu există evaluări

- Hse Manager Interview Questions and AnswersDocument3 paginiHse Manager Interview Questions and AnswerssureshÎncă nu există evaluări

- Health and Safety Standard Assignment BriefDocument13 paginiHealth and Safety Standard Assignment BriefMuhammad SadatÎncă nu există evaluări

- AL - WATHBA PROJECT General - Risk - Assessment-OHSDocument27 paginiAL - WATHBA PROJECT General - Risk - Assessment-OHSMuhammad YounasÎncă nu există evaluări

- Guide To Injury ClassificationDocument2 paginiGuide To Injury ClassificationWilliams AmadiÎncă nu există evaluări

- Risk Assessment of The Workplace Standard of Best Practice - Version 3 May 2015 - FINALDocument37 paginiRisk Assessment of The Workplace Standard of Best Practice - Version 3 May 2015 - FINALMohamed AbdullahÎncă nu există evaluări

- 6845.2.1.1-EN-Rev.5 Critical Risk Control Protocols PDFDocument72 pagini6845.2.1.1-EN-Rev.5 Critical Risk Control Protocols PDFDragoljub ĐorđevićÎncă nu există evaluări

- Employee Welfare Management - Basha PDFDocument44 paginiEmployee Welfare Management - Basha PDFL. V B ReddyÎncă nu există evaluări

- Chelston Decorators Health and Safety PolicyDocument13 paginiChelston Decorators Health and Safety PolicySam MurrayÎncă nu există evaluări

- IG1 - 0031 ENG OBE Answer Sheet V1Document3 paginiIG1 - 0031 ENG OBE Answer Sheet V1Ali AwanÎncă nu există evaluări

- Risk Assessment PDE HS PoliciesDocument21 paginiRisk Assessment PDE HS PoliciesVuong BuiÎncă nu există evaluări

- Health and Safety ManagementDocument7 paginiHealth and Safety ManagementSamuel Mawutor GamorÎncă nu există evaluări

- Nebosh Hse Certificate in Health and Safety Leadership ExcellenceDocument10 paginiNebosh Hse Certificate in Health and Safety Leadership ExcellenceNguyen Van Thanh100% (1)

- Accident Investigation and ReportingDocument13 paginiAccident Investigation and ReportingGiamaica LegaspiÎncă nu există evaluări

- Risk Assessment For Heaven. INC Short FilmDocument2 paginiRisk Assessment For Heaven. INC Short FilmHarryGeorgePrestonÎncă nu există evaluări

- Day 04 IGCDocument60 paginiDay 04 IGCAnonymous iI88LtÎncă nu există evaluări

- Top 25 Internal Audit Interview Questions With Answers: Free EbookDocument77 paginiTop 25 Internal Audit Interview Questions With Answers: Free EbookMajestyÎncă nu există evaluări

- Confined SpacesDocument38 paginiConfined SpacesKilli Ndutz SuperHolicÎncă nu există evaluări

- Notes IG1 Element 3 15.10.2020Document77 paginiNotes IG1 Element 3 15.10.2020Shagufta MallickÎncă nu există evaluări

- Behavior-based safety A Clear and Concise ReferenceDe la EverandBehavior-based safety A Clear and Concise ReferenceÎncă nu există evaluări

- BNBC Code 2014Document748 paginiBNBC Code 2014Nurus Salam100% (2)

- CSI Health and Safety - Update - Oct 2008 Final Vers 10.10.08Document18 paginiCSI Health and Safety - Update - Oct 2008 Final Vers 10.10.08Shafiqul IslamÎncă nu există evaluări

- Health Safety StatementDocument22 paginiHealth Safety StatementShafiqul IslamÎncă nu există evaluări

- ETP Assessment GuideDocument79 paginiETP Assessment GuideAl Mamun HossainÎncă nu există evaluări

- Hindi EiaDocument12 paginiHindi EiaShafiqul IslamÎncă nu există evaluări

- Weather ForecastDocument1 paginăWeather ForecastShafiqul IslamÎncă nu există evaluări

- TretmentDocument21 paginiTretmentshaikh rizwan mustafa100% (1)

- Noise Polll Rules 2004Document11 paginiNoise Polll Rules 2004Shafiqul IslamÎncă nu există evaluări

- Health and Safety Environmental ManagementakistanDocument40 paginiHealth and Safety Environmental ManagementakistanAminullah01Încă nu există evaluări

- Title: Improved Survival Time Trends in Hodgkin's Lymphoma BibliographyDocument2 paginiTitle: Improved Survival Time Trends in Hodgkin's Lymphoma BibliographyShaine NantinÎncă nu există evaluări

- UrosepsaDocument2 paginiUrosepsaHazir AziriÎncă nu există evaluări

- Management of Pneumonia in Intensive Care: Andrew Conway MorrisDocument17 paginiManagement of Pneumonia in Intensive Care: Andrew Conway MorrisWillian Palma GómezÎncă nu există evaluări

- Ro10 Bukidnon Provincial Medical Center Malaybalay CityDocument37 paginiRo10 Bukidnon Provincial Medical Center Malaybalay Citycaleb castilloÎncă nu există evaluări

- Lesson Plan - Observation 1 - MathDocument12 paginiLesson Plan - Observation 1 - Mathapi-633388485Încă nu există evaluări

- Lack of Sleep Research PaperDocument8 paginiLack of Sleep Research Papergw1sj1yb100% (1)

- Report 8b3a3101Document11 paginiReport 8b3a3101Pooja AgarwalÎncă nu există evaluări

- Library - Uns.ac - Id Digilib - Uns.ac - Id: Daftar PustakaDocument6 paginiLibrary - Uns.ac - Id Digilib - Uns.ac - Id: Daftar PustakaJulistin haiÎncă nu există evaluări

- CMS MLN Cognitive Assessment and Care Plan Services CPT Code 99483Document4 paginiCMS MLN Cognitive Assessment and Care Plan Services CPT Code 99483Salomon GreenÎncă nu există evaluări

- 8 Effect of Exercises in The Management of PDFDocument254 pagini8 Effect of Exercises in The Management of PDFAmalia RiaÎncă nu există evaluări

- Counterfeit DrugsDocument2 paginiCounterfeit DrugsfreeBlidaman0967% (3)

- DOTSLong 5.4Document2 paginiDOTSLong 5.4JAY JR. APONÎncă nu există evaluări

- Unit 2Document15 paginiUnit 2StudentÎncă nu există evaluări

- Freezing in ParkinsonDocument14 paginiFreezing in ParkinsonGermaine Sperberg DuhartÎncă nu există evaluări

- Nursing/Nursing Forms/Gordon's 11 Functional Health Patterns Aoih0718Document14 paginiNursing/Nursing Forms/Gordon's 11 Functional Health Patterns Aoih0718jelaÎncă nu există evaluări

- 01 Conference Nursing 2023 - Tentative Program - R2Document1 pagină01 Conference Nursing 2023 - Tentative Program - R2Nurul syakinah Binti mohd mohidÎncă nu există evaluări

- "Natural Amphetamine" Khat: A Cultural Tradition or A Drug of Abuse?Document21 pagini"Natural Amphetamine" Khat: A Cultural Tradition or A Drug of Abuse?Eliana TorresÎncă nu există evaluări

- 封面Document5 pagini封面xiaoxin zhang100% (1)

- Pestle Analysis of Cdo-Foodspear Inc.: Science City of Munoz, Nueva EcijaDocument6 paginiPestle Analysis of Cdo-Foodspear Inc.: Science City of Munoz, Nueva EcijaPrincess NietoÎncă nu există evaluări

- Nursing ManagementDocument24 paginiNursing ManagementSimran Josan100% (1)

- Pathfit 2: Exercise Myths and FallaciesDocument7 paginiPathfit 2: Exercise Myths and FallaciesKeen Jude CaminosÎncă nu există evaluări

- CW2500 Part A - ISS 26052015Document10 paginiCW2500 Part A - ISS 26052015mitramgopalÎncă nu există evaluări

- M.pharm SyllabusDocument47 paginiM.pharm SyllabustusharphaleÎncă nu există evaluări

- 1.2 Patient Care Coordinator DepartmentDocument16 pagini1.2 Patient Care Coordinator DepartmentIurii IuriiÎncă nu există evaluări

- How To Be A Business OwnerDocument34 paginiHow To Be A Business Ownersimbarashe mukondo100% (2)

- Design Brief PDFDocument8 paginiDesign Brief PDFNur Shahmira Ahmad ShahÎncă nu există evaluări