Documente Academic

Documente Profesional

Documente Cultură

Sandwich Panel TDS

Încărcat de

Anson FranklinDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sandwich Panel TDS

Încărcat de

Anson FranklinDrepturi de autor:

Formate disponibile

DATA ALUfl,flNltJM

sHsET AP 45 I15O $ANBWICH PANffi;t

900 (NoMTNAL)

'*[r

--+-45

.i

AP5-LINERSHETT

$ANbv'ffcl'i PANET$ (GOTIPOSiTE FANEL,$) EAftI FE PAQDU9ED W,fft'I E]f.fFRNl$..AS*6 II*T*S{AI SFIEET

N VAnIOUSTHICKNE$S' mATINGS AswleoLOl*Es(sEE SSFABATE DATA $HEGT FOR SINGtES:F+EEE.

rFlE lNsutATloN soFE ls MAEE oF FAcToffy TNJEGTEB EtclD FoqyuREFluUe FoiAtli trv.F.rH

etdsEB egLL$ A$JD F|IRE tr?AHDAf'lT AUALITY IJFQN H,EQ$EST {$€E $FFABATE DArA SHEFT FoR

IttsuLATtoR BPEC|FdCAT|OH $).

THE.INSIJ,LAT{CIN CORE GA'{ ts-E TRODE}CEP IN VARIOUS THIQKNESSES WITH THERIIIAL Ii{$UtA.rcEiI

VALUE$A$ BE}.OW:

POLVUHEFbTANE coBE-THIC,KNESB (trvtM} T=40 Te5S

T=30 T:;&0 Te*00

w/M2"c 0.63 s.4s s,36 A,2A 0:10

OVERATL HEAT

TNANSFER K6AL/6i2h"C 0.52 O.rl0 0,&4 o'22 0.10

SGEFF.{CIENT

B,TU / Ftr !r 'F 0.11 0.063 0.069 g,CIil6 0.av

#,@,\

/siil Iso \?\

AtsD}TIOT{iAL VALUIE OF INSUTATIPN

IN SO.RRUGATED AREA

woh

THE ABOVE VALUES ARE BASED UPON A THERMAL GONDUCTIVITY

TltE HEGOHIIENBED DENSITY FOR POLYURETHANE FOAM 1S

W"

35 KG / M

I

3

36.4/a

) =0.019

min.

&.6% 18%

WM. DEG. CELSIS'$.

\ff/

OTT{EH BENSITIES AAE AVAILABLE ON REOUEST

Js:&e nsu 06. AUg ?soi

"

PANEL DP 25/4 (Fire Rated) Provisional Product Information

Description

Panel DP 25/4 (Fire Rated) is a formulated system for the production of R 141b blown Rigid Polyurethane

Foam. Panel DP 25/4 (Fire Rated) is suitable for the production of sandwich panels through discontinuous

process. The foam is flame retarded and classified B2 as per DIN 4102.

R 141b blowing agent is already mixed with Polyol.

Properties Polyrex® DP 25/4 Isorex® R 310/2

Formulated Polyol MDI Isocyanate

Viscosity at 20 ºC mPa.s 350 - 450 180 – 270

Specific Gravity at 20 ºC 1.20 1.23

Storage Temperature ºC 10 - 25 10 - 25

Stability months 6 6

Recommended Formulation

Polyrex DP 25/4 100 p.b.w

Isorex R 310/2 125 p.b.w

Processing Conditions

Material Temperature 20 - 22 ºC

Mixing Ratio Polyol / Iso 100/125 p.b.w

Mold Temperature 40 - 45 ºC

Molded Density 42 -44 Kg/m3

Lab Reactivity Profile at 20 ºC

Cream Time 30-40 sec

Gel Time 150-160 sec

Demolding Time 10-25 Min (As per thickness)

Free Rise Density 27-29 Kg/m3

Packaging

220 Kg net Polyrex 250 Kg net Isorex

Disclaimer: The technical information contained in this data sheet refers to samples made in the laboratory. Baalbaki is not responsible for the

application or processing of the material since its proper use is beyond Baalbaki’s control. (Edition No. 2012 -1-1, Date: January, 2012)

Polyurethanes Rigid Systems A Partner for Life

PANEL DP 25/4 (Fire Rated) Provisional Product Information

Physical Properties

Final Density 42 Kg/m3 DIN 53420

Compression Strength @ 10 % Deformation ASTM D 1621

1-Parallel to foam rise 0.165 – 0.210 N/mm2

2-Perpendicular to foam rise 0.100 – 0.165 N/mm2

Dimensional Stability

1- @ -20 °C ≤1 % Volume DIN 53431

2- @ +70 °C ≤1 % Volume DIN 53431

Closed Cell Content ≥94 % ASTM D 2856

Thermal Conductivity 0.021 – 0.024 W/m°K DIN 52616

Fire Behavior B2 Class DIN 4102

Disclaimer: The technical information contained in this data sheet refers to samples made in the laboratory. Baalbaki is not responsible for the

application or processing of the material since its proper use is beyond Baalbaki’s control. (Edition No. 2012 -1-1, Date: January, 2012)

Polyurethanes Rigid Systems A Partner for Life

U VALUE CALCULATION

Arabian Profile Company Ltd.

P.O.Box 3195, Sharjah, U.A.E. Tel: 06-5432624, Fax: 06-5432334

Technical Department

Calculations Sheet

Project No. : Sheet No.: 1

Project Name: Cal. : C1 Rev.: 00

Customer : Prepared by: Anjana Date: 26 - 08 - 2018

Consultant : Checked by : Waleed Date: 26 - 08 - 2018

U-VALUE FOR

SANDWICH PANEL

APL-QF-03-04 Rev. 1, July 2007

Arabian Profile Company Ltd.

P.O.Box 3195, Sharjah, U.A.E. Tel: 06-5432624, Fax: 06-5432334

Technical Department

Calculations Sheet

Project No. : Sheet No.: 2

Project Name: Cal. : C1 Rev.: 00

Customer : Prepared by: Anjana Date: 26 - 08 - 2018

Consultant : Checked by : Waleed Date: 26 - 08 - 2018

Calculation of the thermal resistance (R-value) and Thermal Transmittance (U-value) for

Sandwich panel.

Thickness K-Value R-Value

S.N Elements

(mm) W/mk (m2K/w)

Outside surface thermal resistance as per

1 I.H.V.E (Institution of Heating and Ventilating RSC - - 0.04

Engineers) guide

External sheet 0.7mm Alum. Poly. RAL1014-

2 RExt 0.7 160 4.375 x 10-6

AP45/150

3 100mm thick PU @ 40 kg/m3 density RPU 100 0.037 2.7

4 0.7mm Alum. Poly. RAL9010 AP5 liner. RLiner 0.7 160 4.375 x 10-6

Inside surface thermal resistance as per

5

I.H.V.E (Institution of Heating and Ventilating RSi - - 0.13

Engineers) guide

Total R-Value 2.87

RT = RSC + RExt + RPU + RLiner + RSi

= 0.04 + 4.375 x 10-6 + 2.7 + 4.375 x 10-6 + 0.13

= 2.87 m2K/W

U-Value = 1 = 1 = 0.348 W/m2K

RT 2.87 m2K/W

APL-QF-03-04 Rev. 1, July 2007

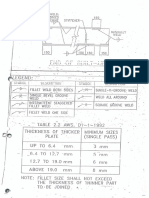

TYPICAL FIXING DETAILS OF SANDWICH PANEL

S-ar putea să vă placă și

- Etag 002 PT 2 PDFDocument13 paginiEtag 002 PT 2 PDFRui RibeiroÎncă nu există evaluări

- LPR76 TDSDocument1 paginăLPR76 TDSNelÎncă nu există evaluări

- Heat Transfer in Polymer Composite Materials: Forming ProcessesDe la EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardÎncă nu există evaluări

- Tensile Bond TestDocument14 paginiTensile Bond TestPanneer SelvamÎncă nu există evaluări

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesDe la EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerÎncă nu există evaluări

- Impact Attenuation of Playing Surface Systems and Materials: Standard Test Method ForDocument6 paginiImpact Attenuation of Playing Surface Systems and Materials: Standard Test Method ForElif SarıoğluÎncă nu există evaluări

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryDe la EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryÎncă nu există evaluări

- Thermoplastic Acrylic Resin: UT-A-357NDocument2 paginiThermoplastic Acrylic Resin: UT-A-357NSi PhamÎncă nu există evaluări

- D 2109 - 96 R00 RdixmdktotzsmdaDocument3 paginiD 2109 - 96 R00 RdixmdktotzsmdaFrancisco GuerraÎncă nu există evaluări

- ISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringDocument6 paginiISO - 8543 - EN - Method For Determination of Mass of Textile Floor CoveringibrahimÎncă nu există evaluări

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 paginiPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaÎncă nu există evaluări

- Latapoxy SP 100 TDSDocument3 paginiLatapoxy SP 100 TDSBithika DattaÎncă nu există evaluări

- Astm D1218Document7 paginiAstm D1218sawitri diah ayu komala100% (1)

- SSPC Paint 18Document5 paginiSSPC Paint 18anoopkumarÎncă nu există evaluări

- ISO 8510-2 - Adhesives Peel Test For A Flexible-Bonded-To-Rigid Test Specimen Assembly 180° Peel 12-1-2006Document12 paginiISO 8510-2 - Adhesives Peel Test For A Flexible-Bonded-To-Rigid Test Specimen Assembly 180° Peel 12-1-2006axeldanyÎncă nu există evaluări

- DC 781 Acetoxy SealantDocument3 paginiDC 781 Acetoxy SealantL.S.Încă nu există evaluări

- 3 6077 RTVDocument2 pagini3 6077 RTVgkretroÎncă nu există evaluări

- Astm D4445 10Document5 paginiAstm D4445 10Cristian Castillo0% (1)

- Selectively Removable Intermediate Coating For Aerospace PurposesDocument14 paginiSelectively Removable Intermediate Coating For Aerospace PurposesAndre CasteloÎncă nu există evaluări

- Astm E96-96m 2014Document13 paginiAstm E96-96m 2014tsalemnoushÎncă nu există evaluări

- POLYPOXY-NF Technical Data SheetDocument2 paginiPOLYPOXY-NF Technical Data SheetCommando crawlerÎncă nu există evaluări

- Uvasorb® HA-88FDDocument2 paginiUvasorb® HA-88FDXuân Giang NguyễnÎncă nu există evaluări

- Glass Flakes RCF 015Document12 paginiGlass Flakes RCF 015Fadi MagdyÎncă nu există evaluări

- Isobond: SBR Bonding AdmixtureDocument3 paginiIsobond: SBR Bonding AdmixtureHussain MarzooqÎncă nu există evaluări

- D 2574 - 97 Rdi1nzqtukveDocument4 paginiD 2574 - 97 Rdi1nzqtukveGuritno GustiantoÎncă nu există evaluări

- D1828-01 (2013) Standard Practice For Atmospheric Exposure of Adhesive-Bonded Joints and StructuresDocument3 paginiD1828-01 (2013) Standard Practice For Atmospheric Exposure of Adhesive-Bonded Joints and Structuresjose floresÎncă nu există evaluări

- B63 1100 (Rev. C 2006.07) EN - SOLID RUBBERS CATEGORY 1 COMPOUNDSDocument4 paginiB63 1100 (Rev. C 2006.07) EN - SOLID RUBBERS CATEGORY 1 COMPOUNDSDiego CamargoÎncă nu există evaluări

- ASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamDocument29 paginiASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamheobukonÎncă nu există evaluări

- Pure Epoxy Fx-E400: Technical Data SheetDocument7 paginiPure Epoxy Fx-E400: Technical Data SheetRana Ahmad Aamir100% (1)

- ASTMD937-97 PetrolatumDocument2 paginiASTMD937-97 Petrolatuminfinity1200100% (1)

- Procedures of Test For Cellular and Related Materials Determination of Resistance To Heat AgingDocument3 paginiProcedures of Test For Cellular and Related Materials Determination of Resistance To Heat AginglrobertothÎncă nu există evaluări

- ISO-8295-1995 Friction CoeficientDocument9 paginiISO-8295-1995 Friction CoeficientDaniela CamachoÎncă nu există evaluări

- Astm D 1148Document4 paginiAstm D 1148arthymanicÎncă nu există evaluări

- Astm and Iso Vocs in Coatings - Method Comparison MatrixDocument2 paginiAstm and Iso Vocs in Coatings - Method Comparison MatrixShaik ShahÎncă nu există evaluări

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 paginiDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraÎncă nu există evaluări

- Sika Waterbars: Flexible PVC WaterstopsDocument5 paginiSika Waterbars: Flexible PVC WaterstopsShamaÎncă nu există evaluări

- 10 - TDS - Emaco S22 NBDocument3 pagini10 - TDS - Emaco S22 NBaahtagoÎncă nu există evaluări

- Product Data Sheet: Butyl AcetateDocument1 paginăProduct Data Sheet: Butyl AcetateHemant RathvaÎncă nu există evaluări

- Nitoprime 31Document2 paginiNitoprime 31Balasubramanian AnanthÎncă nu există evaluări

- ASTM D3359 Standard Test Methods For Measuring Adhesion by Tape TestDocument2 paginiASTM D3359 Standard Test Methods For Measuring Adhesion by Tape TestEdgarDavidDiazCamposÎncă nu există evaluări

- ASTM D2281-10 Standard Test Method For Evaluation of Wetting Agents by Skein TestDocument3 paginiASTM D2281-10 Standard Test Method For Evaluation of Wetting Agents by Skein TestDerek Vaughn100% (1)

- Water Vapor Transmission of Materials: Standard Test Methods ForDocument12 paginiWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573Încă nu există evaluări

- Epoxy Bonding AgentDocument2 paginiEpoxy Bonding AgentbarunÎncă nu există evaluări

- ASTM C474-15 Joint Treatment Materials For Gypsum Board ConstructionDocument15 paginiASTM C474-15 Joint Treatment Materials For Gypsum Board ConstructionktloroÎncă nu există evaluări

- AS 3894-5 Method 5 Surface-ProfileDocument6 paginiAS 3894-5 Method 5 Surface-Profilejonathan nachiroÎncă nu există evaluări

- Arkaz Product BroucherDocument5 paginiArkaz Product Brouchersk mukhtarÎncă nu există evaluări

- PVC GG 1091Document1 paginăPVC GG 1091Gabs GabrielaÎncă nu există evaluări

- 4.elastoseal P100Document2 pagini4.elastoseal P100adchem123Încă nu există evaluări

- Astm D1148 - 13Document4 paginiAstm D1148 - 13faroukÎncă nu există evaluări

- Profile Requirements: 30 75 in Case of Full or Partial Blast CleaningDocument3 paginiProfile Requirements: 30 75 in Case of Full or Partial Blast CleaningIsabelo AbaoÎncă nu există evaluări

- Iso 13383 1 2012 en PDFDocument11 paginiIso 13383 1 2012 en PDFponorÎncă nu există evaluări

- BricksDocument15 paginiBricksKeysang WangmoÎncă nu există evaluări

- Artgo - Intrinsic Viscosity - Single PointDocument7 paginiArtgo - Intrinsic Viscosity - Single PointManuel PlataÎncă nu există evaluări

- Primal TT 615 Rheology ModifierDocument3 paginiPrimal TT 615 Rheology ModifierNelson LozanoÎncă nu există evaluări

- D 3194 - 17Document3 paginiD 3194 - 17Salma Farooq100% (1)

- Sandwich Panel TDS PDFDocument3 paginiSandwich Panel TDS PDFAnson Franklin100% (1)

- Ea 934naDocument4 paginiEa 934nalacsmm982Încă nu există evaluări

- 3 2536 14 3 2016 Ijcs PDFDocument7 pagini3 2536 14 3 2016 Ijcs PDFrsr ecÎncă nu există evaluări

- Aluminum LockDocument1 paginăAluminum LockAnson FranklinÎncă nu există evaluări

- RobbiathaneDocument2 paginiRobbiathaneAnson FranklinÎncă nu există evaluări

- Work Flow ChartDocument1 paginăWork Flow ChartAnson FranklinÎncă nu există evaluări

- Plate 15 & 20 MMDocument8 paginiPlate 15 & 20 MMAnson FranklinÎncă nu există evaluări

- MONTHLY Delivery Report - 2019Document16 paginiMONTHLY Delivery Report - 2019Anson FranklinÎncă nu există evaluări

- Work Flow ChartDocument1 paginăWork Flow ChartAnson FranklinÎncă nu există evaluări

- Zinc Bright Spray Astm A 780Document1 paginăZinc Bright Spray Astm A 780Anson FranklinÎncă nu există evaluări

- Monthly Capacity Forecast: Project Name Jun-19 Jul-19 Aug-19 Sep-19 Oct-19 Nov-19 Dec-19 Jan-20 Feb-20 Mar-20Document4 paginiMonthly Capacity Forecast: Project Name Jun-19 Jul-19 Aug-19 Sep-19 Oct-19 Nov-19 Dec-19 Jan-20 Feb-20 Mar-20Anson FranklinÎncă nu există evaluări

- Quality Manual Template ExampleDocument10 paginiQuality Manual Template ExampleChrill Dsilva100% (1)

- BiltupDocument9 paginiBiltupAnson FranklinÎncă nu există evaluări

- Quality Policy GeneralDocument1 paginăQuality Policy GeneralAnson FranklinÎncă nu există evaluări

- AMDS - PRS-EN Finale 020810 PDFDocument6 paginiAMDS - PRS-EN Finale 020810 PDFAnson FranklinÎncă nu există evaluări

- AISC's Code of Standard Practice For Steel Buildings and BridgesDocument44 paginiAISC's Code of Standard Practice For Steel Buildings and BridgesnkvonÎncă nu există evaluări

- Steelwise PDFDocument4 paginiSteelwise PDFBilal RasheedÎncă nu există evaluări

- Sandwich Panel TDS PDFDocument3 paginiSandwich Panel TDS PDFAnson Franklin100% (1)

- Bs en Iso 1461Document2 paginiBs en Iso 1461Anson Franklin0% (2)

- Application of Infrared Thermography Technique in Uilding Finish EvaluationDocument9 paginiApplication of Infrared Thermography Technique in Uilding Finish EvaluationNicolas De NadaiÎncă nu există evaluări

- Advances and Challenges in Alkaline Anion Exchange Membrane Fuel CellsDocument35 paginiAdvances and Challenges in Alkaline Anion Exchange Membrane Fuel CellsJosePPMolinaÎncă nu există evaluări

- CL ALOX enDocument2 paginiCL ALOX enmikael8118Încă nu există evaluări

- FLSolutions Operation ManualDocument250 paginiFLSolutions Operation ManualCooordinación Metrologia Nutermía sasÎncă nu există evaluări

- Gorki 3Document26 paginiGorki 3Shushay GebreyesusÎncă nu există evaluări

- Fluid Power CircuitsDocument176 paginiFluid Power CircuitsMike Fredskilde97% (29)

- Vessel Manways, Handholes Pose Special Sealing Challenges: Flanged PlatesDocument6 paginiVessel Manways, Handholes Pose Special Sealing Challenges: Flanged PlatesalokbdasÎncă nu există evaluări

- Essay On Corrosion - Baimourne BournebeDocument4 paginiEssay On Corrosion - Baimourne BournebeBAIMOURNE BOURNEBEÎncă nu există evaluări

- Landau Ginzburg TheoryDocument16 paginiLandau Ginzburg TheoryMalik SaifÎncă nu există evaluări

- Angeles Mark P. Assignment No. 2Document2 paginiAngeles Mark P. Assignment No. 2MARK ANGELESÎncă nu există evaluări

- Level OrbitalDocument2 paginiLevel OrbitalRizwan HaniffÎncă nu există evaluări

- F. Winterberg - Fusion-Fission-Fusion Fast Ignition Plasma FocusDocument11 paginiF. Winterberg - Fusion-Fission-Fusion Fast Ignition Plasma FocusMutrexczÎncă nu există evaluări

- Factors That Allow Life To Exist On Earth 2015Document4 paginiFactors That Allow Life To Exist On Earth 2015api-288682437Încă nu există evaluări

- Transparent WoodDocument7 paginiTransparent WoodArnab BhattacharyaÎncă nu există evaluări

- Study of Pumps in Multiple ConnectionsDocument6 paginiStudy of Pumps in Multiple Connectionsasifhameed1Încă nu există evaluări

- Scale Up ArticleDocument8 paginiScale Up ArticleAndrek QueckÎncă nu există evaluări

- Methanol Formation in The Water Gas Shift Reaction Over Copper Containing CatalystsDocument2 paginiMethanol Formation in The Water Gas Shift Reaction Over Copper Containing CatalystsDAYAMOY APLÎncă nu există evaluări

- Inmateh I - 2009Document154 paginiInmateh I - 2009Ionut Velescu100% (1)

- SMC SilencersDocument6 paginiSMC SilencersZachary NgÎncă nu există evaluări

- A744 A744m 07Document6 paginiA744 A744m 07arunrathikaÎncă nu există evaluări

- 1.1. Fossils: Picture 3.1 Cast and Mold FossilDocument6 pagini1.1. Fossils: Picture 3.1 Cast and Mold Fossilsushan19Încă nu există evaluări

- I - 6 Batch 2022 Project ReportDocument72 paginiI - 6 Batch 2022 Project Reportvilla srisuryaÎncă nu există evaluări

- Juba Form Two ExamDocument8 paginiJuba Form Two ExamHossam Abdalla SalehÎncă nu există evaluări

- XJ (X350) Cooling System Drain Fill Bleed R&IDocument4 paginiXJ (X350) Cooling System Drain Fill Bleed R&IMattÎncă nu există evaluări

- Chapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuDocument15 paginiChapter 5: Analytic Techniques: by Julia C. Drees, Matthew S. Petrie, Alan H.B. WuTanveerÎncă nu există evaluări

- Elce221 Lab 1Document6 paginiElce221 Lab 1Little VoiceÎncă nu există evaluări

- Helicopter StructureDocument10 paginiHelicopter StructuredivyaÎncă nu există evaluări

- Glass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForDocument25 paginiGlass Capillary Kinematic Viscometers: Standard Specifications and Operating Instructions ForarturoÎncă nu există evaluări

- Chemical DosingDocument3 paginiChemical DosingMasoodyÎncă nu există evaluări

- Shell Refrigeration Oils Portfolio BrochureDocument2 paginiShell Refrigeration Oils Portfolio Brochureluismanuel.g10Încă nu există evaluări

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeDe la EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeEvaluare: 5 din 5 stele5/5 (4)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsDe la EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsEvaluare: 4 din 5 stele4/5 (146)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableDe la EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableEvaluare: 3.5 din 5 stele3.5/5 (22)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeDe la EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeEvaluare: 4 din 5 stele4/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeDe la EverandChemistry for Breakfast: The Amazing Science of Everyday LifeEvaluare: 4.5 din 5 stele4.5/5 (90)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincDe la EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincEvaluare: 3.5 din 5 stele3.5/5 (137)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactDe la EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactEvaluare: 5 din 5 stele5/5 (5)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolDe la EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolÎncă nu există evaluări

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideDe la EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideÎncă nu există evaluări

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDe la EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsEvaluare: 5 din 5 stele5/5 (3)

- Introduction to Strategies for Organic SynthesisDe la EverandIntroduction to Strategies for Organic SynthesisÎncă nu există evaluări

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireDe la EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireEvaluare: 4 din 5 stele4/5 (129)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookDe la EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookÎncă nu există evaluări

- Bioplastics: A Home Inventors HandbookDe la EverandBioplastics: A Home Inventors HandbookEvaluare: 4 din 5 stele4/5 (2)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsDe la EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsÎncă nu există evaluări

- Water-Based Paint Formulations, Vol. 3De la EverandWater-Based Paint Formulations, Vol. 3Evaluare: 4.5 din 5 stele4.5/5 (6)

- Chemistry: a QuickStudy Laminated Reference GuideDe la EverandChemistry: a QuickStudy Laminated Reference GuideEvaluare: 5 din 5 stele5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookDe la EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookÎncă nu există evaluări

- Transformer: The Deep Chemistry of Life and DeathDe la EverandTransformer: The Deep Chemistry of Life and DeathEvaluare: 4.5 din 5 stele4.5/5 (13)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilDe la EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilEvaluare: 5 din 5 stele5/5 (1)

- Chemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)De la EverandChemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)Încă nu există evaluări