Documente Academic

Documente Profesional

Documente Cultură

Ata 27 Dassault

Încărcat de

Jim RodriguezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ata 27 Dassault

Încărcat de

Jim RodriguezDrepturi de autor:

Formate disponibile

F2000EX EASY 02-27-00

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 1 / 2

TABLE OF CONTENTS

DGT94085 ISSUE 3

02-27 ATA 27 – FLIGHT CONTROLS

02-27-00 TABLE OF CONTENTS

02-27-05 GENERAL

Introduction

Flight control sources

Primary and secondary flight controls

02-27-10 DESCRIPTION

Introduction

Primary flight controls

Ailerons

Pitch control

Rudder

Secondary flight controls

02-27-15 CONTROL AND INDICATION

Control

Indication

02-27-20 SYSTEM PROTECTION

Introduction

Circuit breakers

Placard markings

02-27-25 NORMAL OPERATION

Introduction

ON GROUND

IN FLIGHT

02-27-30 ABNORMAL OPERATION

Introduction

SLAT abnormal operation

No 1 hydraulic system failure

No 2 hydraulic system failure

No 1 and 2 hydraulic system failure

Jamming

CAS messages

DASSAULT AVIATION Proprietary Data

02-27-00 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 2 / 2 CODDE 1

TABLE OF CONTENTS

ISSUE 3 DGT94085

INTENTIONALLY LEFT BLANK

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-05

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 1 / 4

GENERAL

DGT94085 ISSUE 3

INTRODUCTION

The primary flight controls of the Falcon 2000EX EASy airplane are hydraulically and

actuated.

The primary flight controls include two ailerons, two mechanically-linked elevators, one

horizontal stabilizer and one rudder.

Secondary flight controls include leading edge slats, trailing edge double slotted flaps and

airbrakes. All secondary flight controls are hydraulically actuated and either controlled by

control handles located in the flight deck center pedestal or automatically controlled when

specific flight conditions are met for slats or airbrakes operation.

DASSAULT AVIATION Proprietary Data

02-27-05 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 2 / 4 CODDE 1

GENERAL

ISSUE 3 DGT94085

FLT CONTROL

circuit breakers

ENG-TRM-BRK window Airbrakes

indicating auto extension

trim configuration disarm pushbutton

HSI window indicating

slats, flaps, airbrakes

SPEED LIMITATIONS

and pitch trim

placard marking

configurations

Pitch trim

on yoke

Aileron and rudder

normal trim controls, Slats / Flaps

pitch and aileron control and

emergency controls, emergency slats

and airbrakes controls switch

FIGURE 02-27-05-00 FLIGHT DECK OVERVIEW

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-05

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 3 / 4

GENERAL

DGT94085 ISSUE 3

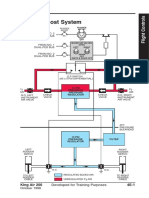

FLIGHT CONTROL SOURCES

PRIMARY FLIGHT CONTROLS

AILERON CONTROL RUDDER CONTROL ELEVATOR CONTROL

SYSTEM SYSTEM SYSTEM

- Hydraulic No 1 - Hydraulic No 1 - Hydraulic No 1

- Hydraulic No 2 - Hydraulic No 2 - Hydraulic No 2

- A1 bus for aileron trim - ESS bus for rudder trim - B1 bus for normal pitch trim

- B2 bus for emergency - Autopilot for yaw damper - ESS bus for emergency trim

aileron trim

- ESS bus for pitch Arthur

- B1 bus for aileron Arthur variable unit

variable unit

- Position of stabilizer and

- ADS2 data via ARINC bus slats control for pitch Arthur

for aileron Arthur variable variable unit

unit

SECONDARY FLIGHT CONTROLS

LEADING EDGE SLATS FLAPS AIRBRAKES

- Hydraulic No 1 for normal - Hydraulic No 2 - Hydraulic No 2

slat operation

- ESS bus for flap control - ESS bus for A/B control

- Hydraulic No 2 for

emergency slat extension

- A2 and BAT buses for

normal slat operation

- BAT bus for emergency

extension

- Angle of attack sensors for

automatic extension and

retraction

DASSAULT AVIATION Proprietary Data

02-27-05 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 4 / 4 CODDE 1

GENERAL

ISSUE 3 DGT94085

PRIMARY AND SECONDARY FLIGHT CONTROLS

Rudder

Flaps Elevator

Slat

Horizontal

stabilizer

Airbrakes

Aileron

FIGURE 02-27-05-01 PRIMARY AND SECONDARY FLIGHT CONTROLS

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 1 / 18

DESCRIPTION

DGT94085 ISSUE 3

INTRODUCTION

The primary flight control system is hydraulically and actuated. Control inputs from the flight

deck are transferred from the dual control yoke and column through a system of push-pull

rods and bellcranks, which provide manual inputs to dual hydraulic servo-actuators connected

to the appropriate primary flight control surface.

In the case of total hydraulic failure, all primary flight controls can be operated manually. In

this abnormal condition, airspeed should be limited to 260 KIAS or less.

Horizontal stabilizer, aileron and rudder trims are electrically actuated. The horizontal

stabilizer trim has a second emergency electrical motor. The ailerons have a normal and an

emergency electrical trim.

PRIMARY FLIGHT CONTROLS

Between the pilot or copilot column and yoke and a flight control surface, the control channel

is composed of:

- a series of push-pull rods acting as the mechanical link between the control column and

yoke and the servo-actuator,

- a main Artificial Feel Unit (AFU),

- a variable bellcrank, or Arthur, for roll and pitch feel control,

- a trim unit,

- a servo-actuator,

- an auxiliary artificial feel unit connected to the servo-actuator.

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 2 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

SERVO-ACTUATOR

Each primary flight control surface is actuated by its associated hydraulic servo-actuator.

The servo-actuators consist of two independent barrel and piston assemblies operating in

unison. Each of No1 and 2 hydraulic systems independently supplies a barrel and piston

assembly.

FIGURE 02-27-10-00 SERVO-ACTUATOR SCHEMATIC (ONE BARREL REPRESENTED)

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 3 / 18

DESCRIPTION

DGT94085 ISSUE 3

The servo-actuator unit is attached to the control surface and connected to the airframe by

its rods.

Movement of a control-input linkage (push-

pull rod) controls the servo-actuators by

directing hydraulic fluid to displace the dual

barrel and piston.

Movement of the servo-actuator assembly

provides force to deflect the control surface

through a connecting rod.

Should one hydraulic system fail, a bypass

valve within the corresponding barrel

interconnects the two chambers and

depressurizes the barrel of the affected

hydraulic system. This keeps possible the

movement of the inert barrel actuated by the

active one.

Should both hydraulic systems should fail,

pilot inputs can mechanically move the

entire servo-actuator assembly and deflect

the control surface by bringing the control

input lever to abutment. The by-pass valve

is restricted in order to avoid flutter.

An accumulator keeps pressure to

compensate possible hydraulic fluid leakage

and thermal retraction.

FIGURE 02-27-10-01 SERVO-ACTUATOR OPERATION

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 4 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

ARTIFICIAL FEEL UNIT

Each primary flight control incorporates a main spring-loaded Artificial Feel Unit (AFU)

upstream from its servo-actuator. The main AFU provides an aerodynamic artificial load feel

to pilot’s controls directly proportional to the input movement and to the resultant spring

compression of the AFU.

The elevator main AFU is electrically heated for high altitude flight.

FIGURE 02-27-10-02 FLIGHT CONTROL SCHEMATIC (TYPICAL)

An auxiliary spring-loaded AFU is connected to the airframe and to the auxiliary arm of each

servo-actuator. In case of control linkage disconnection, the auxiliary AFU forces the slide

valves to position the servo-actuator into the neutral position.

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 5 / 18

DESCRIPTION

DGT94085 ISSUE 3

ARTHUR VARIABLE BELLCRANK

A variable bellcrank, or Arthur, is incorporated within both the aileron and elevator control

systems to vary the artificial load feel of the flight controls. The law governing the position of

the Arthur unit is based upon specific parameters (speed or stabilizer deflection). As these

parameters change, the pivot-point of the Arthur variable bellcrank effectively increases or

decreases the AFU input arm length, thus decreasing or increasing the artificial load feel of

the control yoke. The effort applied by the pilot on the yoke to obtain the same control

surface deflection will be more important when the airplane speed is in the high range rather

than when it is in the low range.

FIGURE 02-27-10-03 ARTHUR OPERATION SCHEMATIC (TYPICAL)

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 6 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

AILERONS

Moving the pilot or copilot control yoke causes aileron deflection through a series of push-pull

rods, bellcranks and servo-actuators. The aileron flight control system also includes spring-

loaded main and auxiliary AFU, variable bellcrank and trim units.

In the event of aileron control linkage jamming, an electrically powered aileron actuator can

drive the left aileron servo-actuator. When the emergency aileron trim actuator is out of the

neutral position,

the amber AIL ZERO message appears in the CAS message window.

FIGURE 02-27-10-04 AILERON CONTROL SYSTEM

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 7 / 18

DESCRIPTION

DGT94085 ISSUE 3

AILERON ARTHUR VARIABLE BELLCRANK

This variable bellcrank is incorporated within the aileron control system to adjust the artificial

load feel of the flight controls with respect to the airplane airspeed.

The position of the Arthur unit is compared with the theoretical position computed from

ADS1 airspeed. If the difference exceeds a threshold depending on the airspeed,

The AIL FEEL CAS message appears. An Arthur unit failure may cause

higher or lower control forces than normal depending on whether the unit has failed in high

or low speed position.

AILERON TRIM UNITS

The aileron system has a normal trim and an emergency trim.

Both trim unit actuators are electrically-driven screw jacks.

Acting on the normal trim actuator moves the AFU zero reference in order to obtain a zero

reaction force. It is controlled by a dual rocker switch located on the flight deck center

pedestal. Both halves of the rocker switch must be pressed simultaneously to close the

electrical circuit and actuate the trim.

In case of aileron control linkage jamming, the emergency trim allows to control directly the

LH servo-actuator. It is controlled by two red pushbuttons located on the flight deck center

pedestal.

NOTE

Emergency aileron trim is operative even when airplane is not hydraulically powered.

Aileron trim range is displayed within the ENG-TRM-BRK windows within both pilot PDU.

When the trim is used, the ENG-TRM-BRK window pops up on the Pilot Flying side.

FIGURE 02-27-10-05 AILERON TRIM SCHEMATIC

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 8 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

PITCH CONTROL

Pilot control inputs are transmitted from the control columns through a series of push-pull

rods, bellcranks and hydraulic servo-actuator. The elevator flight control system includes

spring-loaded main and auxiliary AFU, an Arthur variable unit and a horizontal stabilizer trim.

FIGURE 02-27-10-06 PITCH CONTROL SYSTEM

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 9 / 18

DESCRIPTION

DGT94085 ISSUE 3

ELEVATOR ARTHUR VARIABLE BELLCRANK

The position of the horizontal stabilizer reflects the balance between the airplane airspeed

and its center of gravity. This parameter and the slat control govern the Arthur variable unit

position. Accordingly the Arthur unit changes the "artificial load feel" with respect to the

position of the horizontal stabilizer.

The elevator Arthur internal electronics continuously monitors the position of the Arthur

variable unit with respect to the position of the horizontal stabilizer and slat control. If the

comparison exceeds the warning threshold,

the PITCH FEEL CAS message appears and a low speed Arthur

configuration is commanded. An Arthur unit failure may cause lower control forces than

normal.

CAUTION

In-flight Arthur unit failure induces speed limitations.

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 10 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

HORIZONTAL STABILIZER TRIM UNIT

The fully movable horizontal stabilizer is used to trim the airplane on the pitch axis.

The horizontal stabilizer is actuated by one screw jack which is powered by two electric 28

VDC motors (normal or emergency mode). A dual rocker switch on both control yokes

controls the normal pitch trim. Both halves of the rocker switch must be pressed

simultaneously to close the circuit and actuate the trim. The order is cancelled with opposite

order from the other pilot.

A clacker warns that the stabilizer moves.

FIGURE 02-27-10-07 ELEVATOR TRIM SYSTEM

The emergency pitch trim rocker switch is located on the flight deck center pedestal. In the

event of horizontal stabilizer normal trim unit failure, the emergency pitch trim switch can

then actuate the stabilizer. The switch is spring-loaded to the center (off) position and has

unsteady up and down positions. Moving the switch to either operating position (up/down)

automatically disengages the normal circuit breaker located near the switch. This makes the

normal operating circuit inoperative.

Pitch trim range is displayed permanently in the HSI window and within the ENG-TRM-BRK

windows in both pilot PDU. When the trim is used, the ENG-TRM-BRK window pops up on

the pilot flying side.

On ground, in take-off configuration, if the stabilizer trim is not set within the green range

there is a < NO TAKE-OFF > aural warning and the NO TAKE-OFF CAS message

appears. The tick mark in STAB synoptic turns to red.

CAUTION

The pitch trim indication must be located in the green area for take-off.

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 11 / 18

DESCRIPTION

DGT94085 ISSUE 3

Paint marks are provided on the fin for take-off range and extreme positions of the stabilizer

for on-ground visual inspection.

Trim position

FIGURE 02-27-10-08 PAINT MARKS FOR VISUAL TRIM POSITION INSPECTION

HORIZONTAL STABILIZER / MACH TRIM OPERATION

To increase natural longitudinal stability at high Mach numbers, the Mach Trim System is

active between Mach .77 and Mach .87. The Mach trim control box supplies pitch trim

command inputs to the elevator trim to adjust the stabilizer position as the Mach number

changes. A clacker warns that the stabilizer moves.

With the Mach trim system engaged, the normal trim can be used at any time to adjust

stabilizer position. Once the normal pitch trim switch is released, the Mach trim system

resumes automatic operation.

NOTE

Mach trim is overridden by normal trim and autopilot activation.

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 12 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

RUDDER

Moving the pilot or copilot rudder pedals provides rudder deflection through a series of push-

pull rods, bellcranks and servo-actuator.

The flight control system also includes main and auxiliary spring-loaded AFU, a rudder trim

unit and a yaw damper system.

FIGURE 02-27-10-09 RUDDER CONTROL SYSTEM

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 13 / 18

DESCRIPTION

DGT94085 ISSUE 3

RUDDER TRIM UNIT

The rudder trim actuator is an electrical screw jack. The trim unit is controlled by a dual

rocker switch located on the flight deck center pedestal. Both halves of the rocker switch

must be pressed simultaneously to close the circuit and activate the rudder trim.

Acting on the trim actuator moves the AFU zero reference in order to obtain a zero reaction

force. Movement of the rudder trim switch applies power (28 VDC) to the linear rudder trim

actuator located in the fuselage.

Rudder trim range is shown within the ENG-TRM-BRK windows displayed on both pilots

PDU. When the trim is used, the ENG-TRM- BRK window pops up on the Pilot Flying side.

YAW DAMPING SYSTEM

The yaw damping system reduces oscillations around the airplane yaw axis. An electrically

powered actuator installed with the rudder control linkages upstream from the main rudder

servo-actuator compensates for these oscillations by inputs to the control linkage.

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 14 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

SECONDARY FLIGHT CONTROLS

Secondary flight controls include electrically controlled and hydraulically actuated leading-

edge slats, trailing edge flaps and airbrakes.

LEADING-EDGE SLATS

Each wing incorporates leading edge slats. Slat operation is hydraulically actuated and

electrically controlled by a slats / flaps control handle located on the flight deck center

pedestal.

Three hydraulic actuators supply each slat. Two double-acting units provide both retraction

and extension during normal slat operation and are powered by No 1 hydraulic system. The

third actuator provides only emergency extension with hydraulic power supplied by No 2

system.

Slat operation is electrically sequenced. The slat extension occurs before flap extension.

During retraction, flaps are first fully retracted then slats are retracted.

FIGURE 02-27-10-10 LEADING EDGE SLAT SYSTEM

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 15 / 18

DESCRIPTION

DGT94085 ISSUE 3

The slats are operated in three modes: normal, automatic and emergency.

- The normal operation mode consists in deploying and retracting the slats and flaps

using the slats / flaps control handle.

- The automatic operation mode is active in flight and is controlled according to Angle Of

Attack (AOA) probes. Airspeed parameter is also used to inhibit automatic operation

above 265 kt. The AOA threshold for automatic slats extension depends on slats / flaps

control handle notch.

- The emergency mode is manually activated in flight to extend slats in case of No 1

hydraulic system failure.

FIGURE 02-27-10-11 ANGLE-OF-ATTACK PROBE

In conjunction with automatic slat extension or retraction, engine ignition is activated.

The < STALL > aural warning sounds above specific AOA thresholds.

Automatic slat operation is active in flight only.

The emergency slat extension is controlled by a two-position guarded switch located on the

center pedestal. It supplies the emergency actuator hydraulic manifold directly from the BAT

bus. It allows the slats to extend for approach in the event of a No1 hydraulic system failure.

This mode of operation is intended for landing configuration only and does not provide for

slat retraction.

CAUTION

When the EMERG SLATS switch has been used, it must not be returned to the off

position.

The monitoring of slat extension / retraction is performed through microswitches indicating

slat position.

On ground, in take-off configuration, if the slats are not extended,

there is a < NO TAKE-OFF > aural warning and the NO TAKE-OFF CAS message

appears. The slat symbol turns to red.

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 16 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

TRAILING EDGE FLAPS

The trailing edge flaps consist of an inboard and outboard double slotted flaps on each wing.

A control handle located on the flight deck center pedestal operates the slats and flaps. The

handle provides the flaps geared hydraulic motor with electrical activation. The flaps are

then actuated through a series of rotating rods and screw jacks. A spring-loaded brake

within the hydraulic motor holds the flaps in their selected position.

FIGURE 02-27-10-12 FLAP SYSTEM

The difference between right and left flap position is continuously monitored to detect a

possible asymmetry. In case of asymmetry detection, a FLAPS ASYM CAS message

appears and the flap control circuit breaker trips, stopping the flap movement.

CAUTION

Selection of SF2 or SF3 notch from CLEAN notch is forbidden.

On ground, in take-off configuration, if the flaps are not deployed or are set to SF3, there is a

< NO TAKE-OFF > aural warning and the NO TAKE-OFF CAS message

appears. The flap symbol turns to red.

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-10

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 17 / 18

DESCRIPTION

DGT94085 ISSUE 3

AIRBRAKES

Three airbrake panels are provided for each wing upper surface. The airbrakes are

hydraulically actuated and electrically controlled.

The airbrakes handle is located on the flight deck center pedestal. The normal operation

mode allows selection of three notches of the handle. Setting airbrakes handle to notch 0

induces all airbrakes retraction. Setting the handle to notch 1 causes the extension of the

center airbrake panels. Selecting notch 2 causes the extension of all six airbrake panels.

FIGURE 02-27-10-13 AIRBRAKE PANEL LOCATION

Each panel is either fully deployed or fully retracted. Depending on the panel location

(inboard, center or outboard), the deflection angle of the panel when fully extended varies.

Switches allow the system to monitor airbrakes panel position.

An automatic mode allows automatic airbrake extension at landing and during Rejected

Take-Off (RTO). This mode of operation of the airbrakes depends on throttle angles and

BSCU data.

They are automatically retracted when speed decreases below 20 kt.

This automatic function enhances global braking action during landing or rejected take-off

and reduces bounces after touchdown.

The AUTO EXT. pushbutton (amber DISARM status light) located on the overhead panel

allows the crew to disarm this function.

A stall protection feature commands automatic retraction of the airbrakes when high Angle

Of Attack (AOA) is detected by the two AOA probes. The AOA threshold for automatic

retraction depends on the slats / flaps control handle notch.

The airbrakes can not be extended again until the handle is returned to notch 0, recycling

the system.

On ground, in take-off configuration, if at least one airbrake panel is not retracted there is a

< NO TAKE-OFF > aural warning and the NO TAKE-OFF CAS message

appears. The airbrake symbol on HSI window and AB1 or AB2 on speed scale turn to red.

DASSAULT AVIATION Proprietary Data

02-27-10 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 18 / 18 CODDE 1

DESCRIPTION

ISSUE 3 DGT94085

INTENTIONALLY LEFT BLANK

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-15

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 1 / 12

CONTROL AND INDICATION

DGT94085 ISSUE 3

CONTROL

FIGURE 02-27-15-00 SLATS AND FLAPS CONTROLS

FIGURE 02-27-15-01 AIRBRAKES, NORMAL AND EMERGENCY TRIM CONTROLS

DASSAULT AVIATION Proprietary Data

02-27-15 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 2 / 12 CODDE 1

CONTROL AND INDICATION

ISSUE 3 DGT94085

SYNTHETIC TABLES

Slats and flaps

TO ACTIVATE

CONTROL FUNCTION SYNOPTIC

TO DEACTIVATE

Sets slats / flaps to (Above 18,000 ft:

CLEAN notch: for 15 sec only,

(slats + flaps retracted) nil after)

See NORMAL

OPERATION

Sets slats / flaps to first

notch:

SF1 (slats + slaps 10°)

Sets slats / flaps to the

second notch:

SF2 (slats + flaps 20°)

(flaps 22° after retraction

from SF3)

Sets slats / flaps to the

third notch:

SF3 (slats + flaps 40°)

Extends the slats in

emergency mode.

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-15

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 3 / 12

CONTROL AND INDICATION

DGT94085 ISSUE 3

Airbrakes

TO ACTIVATE

CONTROL FUNCTION SYNOPTIC

TO DEACTIVATE

Sets airbrakes to CLEAN (Above 18,000 ft:

notch for 15 sec only,

(airbrake panels retracted) nil after)

See NORMAL

OPERATION

Sets airbrakes to first notch:

(center airbrake panels

deployed)

Sets airbrakes to second

notch:

(all airbrake panels

deployed)

Arms / disarms automatic AUTO EXT. mode

airbrake extension

Pushbutton

Push to DISARM

DASSAULT AVIATION Proprietary Data

02-27-15 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 4 / 12 CODDE 1

CONTROL AND INDICATION

ISSUE 3 DGT94085

Normal and emergency trims

ENG-TRM- BRK

CONTROL FUNCTION ACTIVATION

WINDOW

Activates aileron left or

right trim (trims roll axis).

Activates emergency

aileron left or right trim No synoptic

(trims roll axis).

Activates rudder left or

right trim (trims yaw

axis).

Activates horizontal

stabilizer to move up or

down (trims pitch axis).

Activates emergency

horizontal stabilizer up

or down (trims pitch

axis) and deactivates

primary trim.

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-15

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 5 / 12

CONTROL AND INDICATION

DGT94085 ISSUE 3

INDICATION

Aileron, rudder and horizontal stabilizer trim positions are displayed in the ENG-TRM- BRK

windows on pilots request and as soon as one trim control surface movement is detected

(including untimely or non-commanded movement). A green mark-up moves along a

graduated scale to indicate trim surface position. A white range (width +/- 10% of full control

surface travel) indicates the zero setting position.

NOTE

ERRONEOUS INDICATION

The first certification load is not in accordance with the white definition. The white range width is

around +/- 5%.

A green range also defines the authorized settings for take-off on the horizontal stabilizer

graduated scale.

FIGURE 02-27-15-02 ENG-TRM-BRK WINDOW, TRIM POSITIONS

NOTE

In cruise, after trimming the airplane, it is usual to have aileron and rudder trim indicators not

centered (due to differential dilatation of aileron linkage rods).

DASSAULT AVIATION Proprietary Data

02-27-15 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 6 / 12 CODDE 1

CONTROL AND INDICATION

ISSUE 3 DGT94085

Horizontal stabilizer position is also permanently displayed in the top left hand corner of the

HSI windows. Any movement of the horizontal stabilizer generates a clacker sound in the

aural warning system.

FIGURE 02-27-15-03 HSI WINDOW DISPLAY

Slat, flap and airbrake positions are displayed in the top left hand corner of the HSI. Symbols

and labels can be displayed in this dedicated area according to the following rules:

- slats / flaps / airbrakes symbols are displayed as long as:

o there is one slat, one flap or one airbrake panel extended (including untimely or non-

commanded surface movement), or

o there is a flight control CAS message displayed, or

o a flight control label is triggered (AUTO, EMERG, AUTO RET, DISARM),

- the slats / flaps / airbrakes symbols are replaced by a white CLEAN label if:

o the airplane is in the CLEAN configuration and,

o no flight control CAS message is displayed, and

o no flight control label is triggered,

- the CLEAN white label is erased (nothing is displayed) if:

o the airplane altitude is above 18,000 ft, and

o the CLEAN label has been displayed for 15 sec.

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-15

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 7 / 12

CONTROL AND INDICATION

DGT94085 ISSUE 3

Flap handle and airbrake handle positions are shown in the indicator as a magenta tick mark

(1, 2 or 3 for flap indication, 1 or 2 for airbrake indication).

The airbrake indication label (AB1 or AB2) is also displayed in airspeed tape as a reminder.

FIGURE 02-27-15-04 AIRSPEED TAPE WITH AIRBRAKE POSITION 1

SLATS, FLAPS AND AIRBRAKES SYMBOLS

Airplane is in CLEAN CLEAN label has been Slats / flaps / airbrakes

configuration. No flight control displayed for 15 sec (see indications are not valid

CAS message is displayed conditions associated to the

and no flight control label is CLEAN white label) and

triggered airplane altitude is

above 18,000ft

DASSAULT AVIATION Proprietary Data

02-27-15 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 8 / 12 CODDE 1

CONTROL AND INDICATION

ISSUE 3 DGT94085

SLAT SYMBOL

Slat extension sequence

Control handle in Control handle moved into When slats and flaps are

CLEAN notch. SF1 notch. extended, slat symbol comes

Slats are retracted and slat Selecting the SF1 position green filled and steady

symbol is not displayed. causes arrow symbol to flash

See NORMAL OPERATION (green filled to blank).

Position tick mark 1 is

displayed in magenta

Slat retraction sequence

Control handle in Control handle returned to When both slats are retracted,

SF1 notch. CLEAN notch. slat graphic is not displayed.

Slats are extended and slat Selecting the control handle Flap position, outline green, is

symbol is green filled. back to CLEAN causes arrow in 0° status.

Tick mark 1 is displayed in symbol to flash See NORMAL OPERATION

magenta. Flap position, green (green filled to blank)

outlined, is in tick mark 1 is

the 10° status displayed in white

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-15

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 9 / 12

CONTROL AND INDICATION

DGT94085 ISSUE 3

No take-off: slat graphic is Discrepancy between pilot slat

flashing red to blank. control and slat position

The slats / flaps configuration

is not allowed for take-off

Automatic slat movement Slats automatically extended

Emergency slat movement Slats extended by emergency

system

DASSAULT AVIATION Proprietary Data

02-27-15 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 10 / 12 CODDE 1

CONTROL AND INDICATION

ISSUE 3 DGT94085

FLAPS SYMBOL

Flaps extension sequence from SF1 to SF2 (from CLEAN to SF1: identical to slats

extension)

Control handle in SF1 notch: Control handle moved to SF2 When flaps reach the notch of

flaps are extended to a notch. Selecting the control 20°: flap symbol, out line

deflection angle of 10°, tick handle to the SF2 notch green, is in status 2.

marks and labels 0, 2, 3 are causes: tick mark and label 2

displayed in white, label 1 is to be displayed in magenta.

displayed in magenta and

flaps symbol, outline green, is

in status 1. Slats are

extended (green filled).

Flaps retraction sequence from SF1 to SF2 (from SF1 to CLEAN: identical to slats

retraction)

Control handle in SF2 notch: Control handle moved to SF1 When flaps reach the position

flaps are extended to a position: tick marks and labels of 10°: flaps symbol, green

deflection angle of 20°, tick 0, 2 and 3 are displayed in outlined, is in status 1

marks and labels 0, 1, 3 are white. Tick mark and label 1

displayed in white. Label 2 is are displayed in magenta.

displayed in magenta and flap Flaps symbol, green outlined,

symbol, green outlined, is in is in status 2

status 2. Slats are extended

(green filled)

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-15

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 11 / 12

CONTROL AND INDICATION

DGT94085 ISSUE 3

No take-off: flap graphic is Flap asymmetry detected

flashing red. The flap

configuration is not allowed for

take-off

AIRBRAKES SYMBOL

Airbrake extension (from 0 to AB1)

Control handle in notch 0. Control handle moved to When airbrakes are deployed,

Airbrakes are retracted and notch 1. Selecting the control airbrake symbol is displayed

airbrake symbol is not handle to notch 1 causes tick at position 1.

displayed. mark and label 1 to be

displayed in magenta.

Airbrake retraction (from AB1 to 0)

Control handle in notch 1. Control handle moved to When airbrakes are retracted,

Airbrakes are deployed, notch 0. Selecting the control airbrake symbol is

airbrake symbol is displayed handle to position 0 causes no more displayed.

at position 1. Tick mark and tick mark and label 1 to be After 2 sec displayed, turns to

label 1 are displayed in displayed in white. CLEAN display configuration

magenta. as seen before.

DASSAULT AVIATION Proprietary Data

02-27-15 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 12 / 12 CODDE 1

CONTROL AND INDICATION

ISSUE 3 DGT94085

No take-off: airbrake graphic Airbrake failure.

is flashing red. The airbrake At least one panel is in

configuration is not allowed discrepancy with control.

for take-off.

Automatic retraction Automatic extension. Airbrakes in DISARM mode:

(stall protection). no automatic extension.

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-20

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 1 / 2

SYSTEM PROTECTION

DGT94085 ISSUE 3

INTRODUCTION

The circuit protection is provided by conventional trip-free circuit breakers located above the

overhead panel and on the center pedestal.

CIRCUIT BREAKERS

FIGURE 02-27-20-00 OVERHEAD AND CENTER PEDESTAL CIRCUIT BREAKERS

DASSAULT AVIATION Proprietary Data

02-27-20 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 2 / 2 CODDE 1

SYSTEM PROTECTION

ISSUE 3 DGT94085

PLACARD MARKINGS

FIGURE 02-27-20-01 SPEED LIMITATIONS PLACARD MARKINGS

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-25

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 1 / 2

NORMAL OPERATION

DGT94085 ISSUE 3

INTRODUCTION

In the following, typical on ground and in-flight situations have been selected to help the crew

to understand the symbols provided in the various panels and displays.

ON GROUND

Flats / slats /

airbrakes

position

indication

Stabilizer in

green area

for take-off

FIGURE 02-27-25-00 PDU DISPLAY ON GROUND WITH FLAPS SET FOR TAKE-OFF

IN-FLIGHT

Flats / slats /

airbrakes

position

indication

FIGURE 02-27-25-01 PDU DISPLAY IN FLIGHT BELOW 18,000FT

DASSAULT AVIATION Proprietary Data

02-27-25 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 2 / 2 CODDE 1

NORMAL OPERATION

ISSUE 3 DGT94085

SYNOPTIC DURING AIRBRAKE RETRACTION IN SEVERAL CASES

SYNOPTIC

CONTROL OPERATION Auto airbrake

Below 18,000 ft Above 18,000 ft extension

disarmed

Airbrakes control

handle is on notch 1

Airbrakes control

handle moved to

notch 0

Airbrakes are

retracted

2 sec after airbrake

retraction

17 sec after airbrake

retraction

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-30

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 1 / 4

ABNORMAL OPERATION

DGT94085 ISSUE 3

INTRODUCTION

In the following, examples of abnormal operations have been selected to help the crew to

understand the CAS message philosophy for flight controls.

SLAT ABNORMAL OPERATION

CONTEXT RESULT

- SLATS FAIL CAS message

Slats do not extend

- Slat symbol is amber

- UNWANTED SLATS CAS message

Unwanted slat extension

- Slat symbol is amber

Failure of automatic slat system

(i.e. invalid AOA or airspeed data or Weight - AUTO SLATS CAS message

On Wheel data)

No 1 HYDRAULIC SYSTEM FAILURE

The slats are only powered by the emergency actuators. They can only be extended and not

retracted (for landing only).

The aileron, rudder and elevator control surfaces are still hydraulically powered. Flaps and

airbrakes are operating normally.

No 2 HYDRAULIC SYSTEM FAILURE

Flaps and airbrakes are inoperative.

The aileron, rudder and elevator control surfaces are still hydraulically powered. Slats are

operating normally.

No 1 AND 2 HYDRAULIC SYSTEM FAILURE

Slats, flaps and airbrakes are inoperative.

The aileron, rudder and elevator control surfaces are only mechanically actuated.

CAUTION

In case of both hydraulic systems failure, do not use emergency aileron trim to control

laterally the airplane.

DASSAULT AVIATION Proprietary Data

02-27-30 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 2 / 4 CODDE 1

ABNORMAL OPERATION

ISSUE 3 DGT94085

JAMMING

In the event of jamming of the aileron linkage, roll control is obtained through the electric

emergency actuator of the left hand aileron.

In case of jamming of the elevator linkage, the horizontal stabilizer trim allows pitch control.

¾ For further information, refer to CODDE 2 / Chapter 03 / ABNORMAL.

CAS MESSAGES

CAS MESSAGE DEFINITION

NO TAKE-OFF Airplane is not properly configured for take-off

AIL FEEL Failure of aileron Arthur unit

AIL ZERO Aileron emergency trim not in neutral position

At least one airbrake panel failed to extend when

AIRBRAKES AUTO EXTENSION

automatically commanded

At least one airbrake panel failed to extend when

AIRBRAKES DO NOT EXTEND

commanded

At least one airbrake panel failed to retract when

AIRBRAKES DO NOT RETRACT

commanded

Automatic slat system failure

AUTO SLATS (i.e. invalid AOA or airspeed data or Weight On

Wheel data)

FLAP ASYM Flaps asymetrical extension

PITCH FEEL Pitch Arthur unit failure

On parking only. Erroneous servo-actuator

accumulator position data sent to MAU 1.

SERVO ACCU LEFT TEST FAIL

A maintenance message indicates which accumulator

failed

On parking only. Erroneous servo-actuator

accumulator position data sent to MAU2.

SERVO ACCU RIGHT TEST FAIL

A maintenance message indicates which accumulator

failed

SLATS FAIL Slats failed to extend when commanded

UNWANTED SLATS Unwanted slat extension

DASSAULT AVIATION Proprietary Data

F2000EX EASY 02-27-30

ATA 27 – FLIGHT CONTROLS

CODDE 1 PAGE 3 / 4

ABNORMAL OPERATION

DGT94085 ISSUE 3

CAS MESSAGE DEFINITION

In cruise only. Erroneous servo-actuator accumulator

position data sent to MAU 1.

SERVO ACCU LEFT TEST FAIL

A maintenance message indicates which accumulator

failed

In cruise only. Erroneous servo-actuator accumulator

position data sent to MAU 2.

SERVO ACCU RIGHT TEST FAIL

A maintenance message indicates which accumulator

failed

STAB EMERGENCY Emergency pitch trim in use instead of normal one

DASSAULT AVIATION Proprietary Data

02-27-30 F2000EX EASY

ATA 27 – FLIGHT CONTROLS

PAGE 4 / 4 CODDE 1

ABNORMAL OPERATION

ISSUE 3 DGT94085

INTENTIONALLY LEFT BLANK

DASSAULT AVIATION Proprietary Data

S-ar putea să vă placă și

- Falcon 200DX FLT CTLS IDocument10 paginiFalcon 200DX FLT CTLS Itayo_bÎncă nu există evaluări

- Flight ControlsDocument44 paginiFlight ControlsMITCHELLDAZAÎncă nu există evaluări

- Falcon 200DX FLT CTLS OPSDocument8 paginiFalcon 200DX FLT CTLS OPStayo_bÎncă nu există evaluări

- Falcon 200DX FLT CTLS RUDFLPSDocument10 paginiFalcon 200DX FLT CTLS RUDFLPStayo_bÎncă nu există evaluări

- Falcon 200DX FLT CTLS STABDocument7 paginiFalcon 200DX FLT CTLS STABtayo_bÎncă nu există evaluări

- Dassault Falcon 000dx Ex LimitationsDocument62 paginiDassault Falcon 000dx Ex LimitationsDVSÎncă nu există evaluări

- Falcon 200DX FLT CTLS INDDocument8 paginiFalcon 200DX FLT CTLS INDtayo_bÎncă nu există evaluări

- DASSAULT FALCON 000DX-EX-Auto FlightDocument40 paginiDASSAULT FALCON 000DX-EX-Auto FlightkeeferÎncă nu există evaluări

- CambioDocument36 paginiCambioMaicol AlarconÎncă nu există evaluări

- Falcon 200DX FLTDECK HSIADICASDocument10 paginiFalcon 200DX FLTDECK HSIADICAStayo_bÎncă nu există evaluări

- A320 Family Flight Controls System OverviewDocument42 paginiA320 Family Flight Controls System OverviewvvÎncă nu există evaluări

- Falcon 200DX FLTDECK FMSCASDocument20 paginiFalcon 200DX FLTDECK FMSCAStayo_bÎncă nu există evaluări

- Falcon 200DX FLTDECK GENDocument8 paginiFalcon 200DX FLTDECK GENtayo_bÎncă nu există evaluări

- DASSAULT FALCON 000DX-EX-Indicating and Recording SystemDocument18 paginiDASSAULT FALCON 000DX-EX-Indicating and Recording SystemКонстантин ПучковÎncă nu există evaluări

- AOM 2-01 Airplane DescriptionDocument22 paginiAOM 2-01 Airplane DescriptionbdetalÎncă nu există evaluări

- 18-Flight Control and AutoflightDocument126 pagini18-Flight Control and AutoflightRubens CostaÎncă nu există evaluări

- DASSAULT FALCON 000DX-EX-Hydraulic System PDFDocument36 paginiDASSAULT FALCON 000DX-EX-Hydraulic System PDFjjaavvmmÎncă nu există evaluări

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 27 Flight ControlsDocument424 paginiA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 27 Flight ControlsMPIKA EUCHERÎncă nu există evaluări

- F900EX-Flight ControlsDocument40 paginiF900EX-Flight ControlsRicardo RubioÎncă nu există evaluări

- Improve Safety and Availability with the F2000EX EASy Flight DeckDocument126 paginiImprove Safety and Availability with the F2000EX EASy Flight DeckJose LaraÎncă nu există evaluări

- B Ata 27Document437 paginiB Ata 27YunJae Vincit OmniaÎncă nu există evaluări

- DASSAULT FALCON 000DX-EX-Auxiliary Power UnitDocument28 paginiDASSAULT FALCON 000DX-EX-Auxiliary Power UnitDVSÎncă nu există evaluări

- Quick Turn Fault Assistance for Airbus A318/320Document134 paginiQuick Turn Fault Assistance for Airbus A318/320Carlos Andrés Escamilla González100% (1)

- 27-94-00-040-002-A - Deactivation of The Spoiler Elevator Computer (SEC)Document7 pagini27-94-00-040-002-A - Deactivation of The Spoiler Elevator Computer (SEC)Rendi 911Încă nu există evaluări

- PneumaticDocument24 paginiPneumaticAghil ThayyilÎncă nu există evaluări

- Summary E190Document91 paginiSummary E190Mo A. El KarnighiÎncă nu există evaluări

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document5 paginiAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarÎncă nu există evaluări

- Ecam WarningDocument10 paginiEcam WarningJonson RochaÎncă nu există evaluări

- A330/340 Fuel System Controls and Indications GuideDocument5 paginiA330/340 Fuel System Controls and Indications GuideRicardo RubioÎncă nu există evaluări

- QRH Atr 76 - RN 01 - Feb 12Document186 paginiQRH Atr 76 - RN 01 - Feb 12Igor BirdÎncă nu există evaluări

- BOOKLET ATR-600 Rev 01-1 (1) (001-025)Document25 paginiBOOKLET ATR-600 Rev 01-1 (1) (001-025)Juychardson ReisÎncă nu există evaluări

- BOOKLET ATR-600 Rev 01 PDFDocument161 paginiBOOKLET ATR-600 Rev 01 PDFcesar neira100% (3)

- Airworthiness Directive Schedule: Aeroplanes Beechcraft 200 Series (Super King Air) 28 August 2014Document10 paginiAirworthiness Directive Schedule: Aeroplanes Beechcraft 200 Series (Super King Air) 28 August 2014Fayçal Mahieddine100% (1)

- Erj 170-190 Mmel Faa Rev 9Document139 paginiErj 170-190 Mmel Faa Rev 9mh.hiliryÎncă nu există evaluări

- Complete DC-8 MM R36 Vol 2Document726 paginiComplete DC-8 MM R36 Vol 2Belisario Llacchas rodas100% (1)

- Guia CB Computer Reset AirbusDocument20 paginiGuia CB Computer Reset AirbusFabian Andres Soto Lineros (LATAM)Încă nu există evaluări

- Section 2 - Operating Limitations: Z 242 L Flight ManualDocument24 paginiSection 2 - Operating Limitations: Z 242 L Flight ManualJuan Carlos Sanchez MaldonadoÎncă nu există evaluări

- 13 Flight ControlsDocument64 pagini13 Flight ControlsKola IludiranÎncă nu există evaluări

- Afm 1912 018 Faa App01Document24 paginiAfm 1912 018 Faa App01aeroÎncă nu există evaluări

- A330 ECAM Warning Reset GuideDocument45 paginiA330 ECAM Warning Reset Guideelhamdi71100% (8)

- DASSAULT FALCON 000DX-EX-EnginesDocument36 paginiDASSAULT FALCON 000DX-EX-EnginesDVSÎncă nu există evaluări

- F2000EX Safety Equipment ManualDocument18 paginiF2000EX Safety Equipment ManualDVSÎncă nu există evaluări

- CRJ Mmel Rev.19 13 May 10Document264 paginiCRJ Mmel Rev.19 13 May 10Enrique Gómez EscrihuelaÎncă nu există evaluări

- Flight ControlsDocument65 paginiFlight ControlsIludiran KolaÎncă nu există evaluări

- BD-700 MMEL Ver9Document165 paginiBD-700 MMEL Ver9ShinYamaÎncă nu există evaluări

- System DESCRIPTIONDocument129 paginiSystem DESCRIPTIONjontis jasoliyaÎncă nu există evaluări

- Mmel Bd700 Rev12 PT 91Document189 paginiMmel Bd700 Rev12 PT 91Edward ConnerÎncă nu există evaluări

- Hydraulic SystemDocument30 paginiHydraulic SystemHuy Huynh Nguyen TheÎncă nu există evaluări

- Afm Airbus A 320 PDF FreeDocument706 paginiAfm Airbus A 320 PDF FreeewiontkoÎncă nu există evaluări

- Flight InstrumentsDocument58 paginiFlight InstrumentsAnish Shakya100% (2)

- DASSAULT FALCON 000DX-EX-Airplane Diagnostic and Maintenance SystemDocument30 paginiDASSAULT FALCON 000DX-EX-Airplane Diagnostic and Maintenance SystemDVSÎncă nu există evaluări

- Mitsubishi MSCA12YV ManualDocument32 paginiMitsubishi MSCA12YV Manualsansegundo79Încă nu există evaluări

- Dated November 12, 1984, Into A Hard Copy Service Bulletin. TheDocument15 paginiDated November 12, 1984, Into A Hard Copy Service Bulletin. Themarcfrancis.mercadoÎncă nu există evaluări

- A318/A319/A320/A321: Service BulletinDocument78 paginiA318/A319/A320/A321: Service BulletinPradeep K sÎncă nu există evaluări

- 502500032_204_01Document74 pagini502500032_204_01davy.cozziÎncă nu există evaluări

- Amm34 17 00 001Document4 paginiAmm34 17 00 001Patricio MontemayorÎncă nu există evaluări

- 3 LimitationsDocument48 pagini3 LimitationsandpiauÎncă nu există evaluări

- In-Service Activities: Customer Canadair Regional Jet ServicesDocument23 paginiIn-Service Activities: Customer Canadair Regional Jet ServicesromixrayzenÎncă nu există evaluări

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersDe la EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersEvaluare: 5 din 5 stele5/5 (2)

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreDe la EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreEvaluare: 3 din 5 stele3/5 (2)

- Brief - AeroDocument8 paginiBrief - AeroJim RodriguezÎncă nu există evaluări

- Continental C75 C85 C90 O 200 Overhaul Manual Aug 2011 PDFDocument126 paginiContinental C75 C85 C90 O 200 Overhaul Manual Aug 2011 PDFshahinÎncă nu există evaluări

- Aero 2010 Q4 PDFDocument32 paginiAero 2010 Q4 PDFJim RodriguezÎncă nu există evaluări

- Air Carrier Maintenance ProgramsDocument50 paginiAir Carrier Maintenance ProgramsIr. Vinod DamodaranÎncă nu există evaluări

- Air Carrier Maintenance ProgramsDocument50 paginiAir Carrier Maintenance ProgramsIr. Vinod DamodaranÎncă nu există evaluări

- Afdc1 PDFDocument1 paginăAfdc1 PDFAshutosh KumarÎncă nu există evaluări

- Airbus A320 Flight Controls LawsDocument74 paginiAirbus A320 Flight Controls Lawspontoo97% (78)

- Primary Flight Display (PFD) Primary Flight Display (PFD)Document3 paginiPrimary Flight Display (PFD) Primary Flight Display (PFD)Anonymous QRVqOsa5Încă nu există evaluări

- Spacecraft and Aircraft Dynamics: Matthew M. PeetDocument32 paginiSpacecraft and Aircraft Dynamics: Matthew M. Peetaadhya guptaÎncă nu există evaluări

- Cockpit ControlsDocument2 paginiCockpit ControlsLoc Das NeyfusÎncă nu există evaluări

- Ata 27Document274 paginiAta 27Anh TuanÎncă nu există evaluări

- Rudder Boost System: From No. 2 Dual-Fed BusDocument8 paginiRudder Boost System: From No. 2 Dual-Fed BusAlex GuáncÎncă nu există evaluări

- EFISDocument9 paginiEFISsangeetamanishkumarÎncă nu există evaluări

- 737 Flight ControlsDocument36 pagini737 Flight ControlsCyprian Cyganek100% (1)

- Dimensions and Areas-Description and Operation 1. General: Airplane (Overall) Airplanes - 0001 Thru 0538Document7 paginiDimensions and Areas-Description and Operation 1. General: Airplane (Overall) Airplanes - 0001 Thru 0538Parfumeria KelvinCoÎncă nu există evaluări

- Module 11A.1.1 L2 2016-08-12Document136 paginiModule 11A.1.1 L2 2016-08-12Abdul Aziz Khan100% (1)

- TO 1C-130H-2-27GS-00-1: General SystemDocument96 paginiTO 1C-130H-2-27GS-00-1: General SystemLuis Francisco Montenegro Garcia100% (1)

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 27 Flight ControlsDocument424 paginiA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 27 Flight ControlsMPIKA EUCHERÎncă nu există evaluări

- Rudder Control SystemDocument7 paginiRudder Control SystemMay MaydayÎncă nu există evaluări

- 787 Hyd Spoiler LockoutDocument24 pagini787 Hyd Spoiler LockoutVIJAY CHAWLA100% (2)

- A320 Dual Hydraulic Failure G and YDocument4 paginiA320 Dual Hydraulic Failure G and YSherįl Alexx100% (1)

- Flight ControlDocument4 paginiFlight ControlazadairÎncă nu există evaluări

- NAMC Mig-35 MPF TiledDocument32 paginiNAMC Mig-35 MPF TiledAle TrigoeÎncă nu există evaluări

- Bae 146 Technical Training Manual Mechanical & Avionics Course - B1+B2 (LVL 2&3) Flight Controls General Ata 27Document17 paginiBae 146 Technical Training Manual Mechanical & Avionics Course - B1+B2 (LVL 2&3) Flight Controls General Ata 27stiveÎncă nu există evaluări

- A320 Systems Oral GuideDocument77 paginiA320 Systems Oral GuideAhmed Badi100% (4)

- 11.01.1. Aeroplane Aerodynamics and Flight ControlsDocument9 pagini11.01.1. Aeroplane Aerodynamics and Flight Controlsvalerio freyÎncă nu există evaluări

- Aircraftsystemstech Flight Control Surfaces DirectionalDocument9 paginiAircraftsystemstech Flight Control Surfaces DirectionalKiril NedkovÎncă nu există evaluări

- MAE4242 - Ch04 - Longitudinal Control PDFDocument30 paginiMAE4242 - Ch04 - Longitudinal Control PDFMatthew AustinÎncă nu există evaluări

- 0-Flight Controls - Ders TanıtımDocument3 pagini0-Flight Controls - Ders Tanıtımcanan armağanÎncă nu există evaluări

- B737 Flight Control SystemsDocument45 paginiB737 Flight Control SystemsAntonio Gonzalez Romero86% (7)

- 6 EmpennageDocument36 pagini6 EmpennageAdonis MontalbanÎncă nu există evaluări

- Airbus A319-A321 (DLH) Training Manual, ATA 27 Flight Controls Level 3Document179 paginiAirbus A319-A321 (DLH) Training Manual, ATA 27 Flight Controls Level 3Luis Eduardo Quintana Pineda100% (9)

- B737 CL - Flight Controls QuestionsDocument9 paginiB737 CL - Flight Controls QuestionsHamidreza AhanzadehÎncă nu există evaluări

- M11 Aerodynamcis, Structures and Instruments 1 of 2Document913 paginiM11 Aerodynamcis, Structures and Instruments 1 of 2kls070376100% (2)

- Flight ControlsDocument11 paginiFlight ControlsHamidreza AhanzadehÎncă nu există evaluări