Documente Academic

Documente Profesional

Documente Cultură

01 Qulaity Control Plan - Asf QC QCP 001

Încărcat de

Ahmad Nabil ElsharkawyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

01 Qulaity Control Plan - Asf QC QCP 001

Încărcat de

Ahmad Nabil ElsharkawyDrepturi de autor:

Formate disponibile

QUALITY CONTROL DEPARTMENT REV.

1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 1 of 8

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL DEPARTMENT REV. 1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 2 of 8

LIST OR REVISIONs

Approved By Reviewed By Prepared By Comment Date .Rev

Ahmed Safwat Ahmed Safwat For Implementation 01-01-2019 0

Ahmed Safwat Ahmed Safwat Change in procedure number 01-03-2019 1

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL DEPARTMENT REV. 1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 3 of 8

INDEX

No. DESCRIPTION PAGE.

1 INTRODUCTION 4

2 SCOPE 4

3 REFERENCE 4

4 DEFINITIONS 4

5 RESPONSIBILITIES 4

6 QUALITY PLAN METHOD 5

7 PROJECT QUALITY ASSURANCE 5

8 PROJECT QUALITY CONTROL 6

9 PROJECTS AUDITS AND QUALITY REVIEW 6

10 MANAGEMENT ESCALATION PLAN 7

11 QUALITY TEAM ROLES AND RESPONSIBILITIES 7

12 QUALITY PLAN AUDIT LOG 7

13 QUALITY PLAN APPROVAL 7

14 APPENDICES 7

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL DEPARTMENT REV. 1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 4 of 8

1. INTRODUCTION

The purpose of this document is to describe the necessary information required to effectively manage project quality,

from project planning to delivery, comprising quality objectives in the project, roles and responsibilities, and the Quality

Management approach to ensure that the quality objectives are achieved.

The intended audience is the project team and any senior leaders whose support is needed to carry out the plan.

2. SCOPE

2.1. The scope is to assure the quality of the project deliverables and the quality of the processes and procedures used

to manage and develop the deliverables in order to comply with the ASF quality control procedures and client

specification and the international governing standard.

2.2. This Quality Plan is to be continually reviewed, and any changes to the plan will be handled by the project's

procedure for Change Management.

3. REFERENCE

3.1. ISO 9001:2015

3.2. AWS D1.1 – Steel Structural Welding Code

3.3. EN 1090 - Technical Requirements of the execution of the steel structure

3.4. ASME – ASME Boilers and Pressure Vessel Codes

3.5. API – American Petroleum Institute

3.6. Project Specification

3.7. ASF Quality Control Procedure

4. DEFINITIONS

4.1. QCM: Quality Control Manager

4.2. QCPE: Quality Control Project Engineer

4.3. QCSH: Quality Control Section Head

4.4. MDB Manufacture Data Book

4.5. Customer Satisfaction: The customer satisfaction criteria describe when each deliverable is complete and

acceptable as defined by the customer. Deliverables are evaluated against these

criteria.

4.6. Project Audit: A Project Audit aims to verify if the project is being managed properly according to

the organization’s standards and guidelines, and that the project plan is being

followed. The main purpose of the Project Audit is to identify any project

management errors that may have occurred during the execution of the project.

4.7. Project Review: A Project Review is a health check of the project. The main purpose of the Project

Review is to make sure that the project is on time, on schedule, on scope, and on

budget, as well as highlighting key issues the project is facing.

4.8. Stakeholder Expectation: Stakeholder expectations describe when a project process is effective as defined by

the project stakeholders. An example is the review and approval of all high impact

changes to the project.

5. RESPONSIBILITIES

5.1. QCM is responsible ensure that the deliverables of the project are fit for purpose, is consistent and meets both

external and internal requirements. This includes regulatory compliance and customer satisfaction and

expectations. The Quality Manager conducts quality assurance activities like audits and reviews to ensure that

processes and procedures in the project are sufficient for their purpose and are applied and followed.

The role includes responsibility for:

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL DEPARTMENT REV. 1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 5 of 8

5.1.1. Revise and establish the project's quality procedures, standards and specifications.

5.1.2. Review project requirements and makes sure they are met.

5.1.3. Establish and maintain control and documentation procedures.

5.1.4. Monitor performance by gathering relevant data and produce quality reports.

5.1.5. Make suggestions for changes and improvements and how to implement them.

5.1.6. Manage reported deviations from the Quality Plan, either by ensuring that the Quality Plan is followed, or

through a Change Request adapting the Quality Plan to better reflect the reality of the project.

5.2. QCM is responsible to establish who will be the QCPE for the project and if this will be a full-time or part-time role.

Outline the QCPE responsibilities in that role is to discuss how the QCPE will interact with the project manager and

other team members in accomplishing these responsibilities. Other quality management roles and responsibilities

for the project are outlined later in this document.

5.3. QCSH is responsible to apply the Quality Control procedures and assure that is complying with project expectation

and assure that the customer satisfaction will be achieved and will be the focal target.

6. QUALITY PLAN METHOD

The Quality plan is developed and approved during the project planning phase to confirm major deliverable/milestone

acceptance criteria and managed approved processes

6.1. QULAITY PLAN PROCESS include

6.1.1. Quality assurance activities focus on the processes being used to manage and deliver the solution to evaluate

overall project performance on a regular basis. Quality assurance is a method to ensure the project will satisfy

the quality standards and will define and record quality reviews, test performance, and customer acceptance.

6.1.2. Quality control activities are performed continually to verify that project management and project deliverables

are of high quality and meet quality standards. Quality assurance also helps uncover causes of unsatisfactory

results and establish lessons learned to avoid similar issues in this and other projects.

6.1.3. Project team members and key stakeholders agree at the project planning stage on formal project processes

and major deliverable acceptance criteria that will be used to evaluate final deliverable results before the

results are formally approved.

6.2. QUALITY OVERVIEW

Describe the background and context for the project to provide its justification. Identify the business value of the

proposed deliverables. This section can be copied from the project charter or a similar document. The project

goals/objectives or scope statement is usually sufficient. The overview can include a high-level view of the project

schedule, assumptions, dependencies, risks, and cost.

6.3. QUALITY STANDARD

List all quality standards previously defined by the company or organization that this project will follow for its

deliverables. Include a description of how the project will satisfy the quality standards.

6.4. QUALITY TOOLS

List all quality-related tools that the project will employ, how the tools will be used, and who will be responsible

for managing and reporting from these tools reference to Equipment calibration list DOC no. ASF-QC-CAL-002

7. PROJECT QUALITY ASSURANCE

Quality assurance helps to establish if a deliverable is acceptable based on the processes used to create it. Quality

assurance processes are used to evaluate overall project performance frequently and to determine that quality reviews

were held, deliverables tested, and customer acceptance acquired.

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL DEPARTMENT REV. 1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 6 of 8

7.1. PROJECT MONITORING PROCESSES

Define the monitoring and control processes planned for the project and how they will satisfy project quality

standards and ensure project quality. Specify how the QCM will obtain project-related information and how that

information will be used to control the process.

7.2. PROJECT IN-PROCESS QUALITY MONITORING

Describe the quality metrics and measurements to be used as a part of each work process in the project. Identify

in-process measurement points, and identify who on the project team will be responsible for managing the quality

metric checkpoints.

8. PROJECT QUALITY CONTROL

8.1. PROJECT DELIVERABLES

Write a high-level description of all key, measurable deliverables of the project that will be tested for satisfactory

quality level.

MILESTONE DELIVERABLE

8.2. Project Quality Control Procedures

List of the major quality control activities and processes that this project will include as per below:

A. Material Receiving Inspection Procedure DOC. no. ASF-QC-MRI-001

B. Handling and Storage of Filler Materials Procedure DOC. no. ASF-QC-WCH-001

C. Welding Control Procedure DOC. no. ASF-QC-WCP-001

D. Welding Repair Procedure DOC. no. ASF-QC-RP-021

E. Fabrication Control Procedure DOC. no. ASF-QC-FAB-001

F. Visual Testing Procedure DOC. no. ASF-QC-VT-001

G. Liquid Penetrant Testing Procedure DOC. no. ASF-QC-PT-001

H. Magnetic Particle Testing Procedure DOC no. ASF-QC-MT-001

I. Ultrasonic Testing Procedure DOC. no. ASF-QC-RT-001

But not limited to ASF quality control procedure reference to DOC. no. ASF-QC-QR-002

8.3. QUALITY CONTROL FORMS

List of qualify control forms will be used in the project in order to verify the project execution in each step as a

method of controlling the deliverables quality reference to DOC no. ASF-QC-QR-003

8.4. PROJECT DELIVERABLES TEST & ACCEPTANCE PROCESS

Define the planned test and acceptance processes that will be used to validate project deliverable quality, and

describe how these processes will verify deliverable quality.

8.5. PROJECT DELIVERABLES ACCEPTANCE CRITERIA

Define the deliverable quality acceptance criteria based on quality standards for project deliverables as the criteria

will be used in acceptance testing. Establish how the criteria will be used to assess project quality.

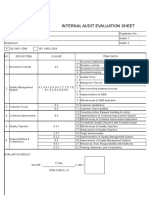

9. PROJECT AUDITS AND QUALITY REVIEW

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL DEPARTMENT REV. 1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 7 of 8

Identify the project quality audits and reviews that will be performed. Discuss the planned schedule. Describe how the

results of these audits and reviews will be factored into project planning and implementation. Discuss the process of

lessons-learned reviews and how those lessons can benefit the project team as the project continues.

PROJECT QUALITY AUDIT REVIEW PLANNED DATE QUALITY REVIEW AUDITOR COMMENTS

10. MANAGEMENT ESCALATION PLAN

Define the plan for escalating unresolved quality noncompliance issues up the management chain. The standard initial

level of escalation is from the project manager to their immediate manager.

ESCALATION LEVEL MANAGEMENT TITLE NAME

11. QUALITY TEAM ROLES AND RESPONSIBILITIES

Identify quality-related responsibilities of the project team and list specific task-related quality responsibilities, including

responsibility for specific acceptance tests and project audits.

PROJECT TEAM ROLE QA RESPONSIBILITIES QC RESPONSIBILITIES

12. QUALITY PLAN AUDIT LOG

List all quality-related issues and resolutions resulting from quality plan audits and reviews.

QUALITY REVIEW DATE ACTIVITY REVIEWED ISSUE RESOLUTION REMARKS

13. QUALITY PLAN APPROVALS

PREPARED BY: QCSH

REVIEWED BY QCM

APPROVED BY CLIENT REPRESENTATIVE

CONSULTED BY THIRD PART (IF ANY)

14. APPENDICES

If you determine that additional information is needed to effectively communicate the project quality management

information, add additional sections as needed.

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

QUALITY CONTROL DEPARTMENT REV. 1

QUALITY CONTROL PLAN PROCEDURE Date: 01-03-2019

ASF-QC-QCP-001 Page: 8 of 8

QUALITY CONTROL PLAN PROCEDURE

ASF-QC-QCP-001

S-ar putea să vă placă și

- Establishing A CGMP Laboratory Audit System: A Practical GuideDe la EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideÎncă nu există evaluări

- Quality ManualDocument24 paginiQuality ManualArun PadmanabhanÎncă nu există evaluări

- Quality Assurance ProcedureDocument6 paginiQuality Assurance ProcedureTrivesh Sharma100% (1)

- SLPG Q 0000 24001 019 001 4 0Document15 paginiSLPG Q 0000 24001 019 001 4 0sivagnanamÎncă nu există evaluări

- 07 Ebi 4e3 Project Quality-SoeDocument25 pagini07 Ebi 4e3 Project Quality-SoestefhaniekaniaÎncă nu există evaluări

- PQMS, MS, ITP, CHECKLIST, NCR, MOCKUP SAMPLES - Session 1,2 & 3 PDFDocument155 paginiPQMS, MS, ITP, CHECKLIST, NCR, MOCKUP SAMPLES - Session 1,2 & 3 PDFUma Mahesh Raju100% (1)

- Project Quality PlanDocument29 paginiProject Quality PlanRami KhedroÎncă nu există evaluări

- 7 QMP Construction WorksDocument15 pagini7 QMP Construction WorksssteliomadeiraÎncă nu există evaluări

- Project Quality PlanDocument72 paginiProject Quality PlanMuhammad zeshan javed100% (2)

- QMS Vol. 1 PDFDocument436 paginiQMS Vol. 1 PDFCamilo Jorquera100% (2)

- Mominnovation Sdn. BHD.: Table of ContentsDocument41 paginiMominnovation Sdn. BHD.: Table of ContentsRoif SamsulÎncă nu există evaluări

- Quality-Plan in Manufacturing Og Pre-Eng'Ng StructuresDocument23 paginiQuality-Plan in Manufacturing Og Pre-Eng'Ng StructuresPageduesca Rouel100% (1)

- QP-04 Internal AuditDocument5 paginiQP-04 Internal AuditScha Affin100% (1)

- Clendale Quality ManualDocument15 paginiClendale Quality Manualgroup fesiÎncă nu există evaluări

- Quality in Construction Works: An Introduction To QA/QC Concept and Quality Management System Based On ISO 9001:2008Document38 paginiQuality in Construction Works: An Introduction To QA/QC Concept and Quality Management System Based On ISO 9001:2008sid_calayag100% (2)

- Quality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakDocument47 paginiQuality Hold Points System Handbook: Produced by Jabatan Kerja Raya SarawakConnielya AdamÎncă nu există evaluări

- Project Quality PlanDocument76 paginiProject Quality PlanDanOtah100% (4)

- Quality Assurance POLICY & Quality ManualDocument150 paginiQuality Assurance POLICY & Quality Manualayman100% (1)

- Q3a Project Quality PlanDocument25 paginiQ3a Project Quality PlanMohammad Ummer100% (5)

- Saep 1161Document51 paginiSaep 1161Anonymous 4IpmN7OnÎncă nu există evaluări

- Quality PlanDocument44 paginiQuality PlanAbhishek SharmaÎncă nu există evaluări

- Unit 3d TQM ConstructionDocument15 paginiUnit 3d TQM ConstructionTulika GuptaÎncă nu există evaluări

- 04 - Product Traceability Procedure - Asf-Qc-Ptp-001Document5 pagini04 - Product Traceability Procedure - Asf-Qc-Ptp-001Sherif Yehia0% (1)

- Type 1 - Se Qaqc Gen PlanDocument24 paginiType 1 - Se Qaqc Gen PlansacdawoodÎncă nu există evaluări

- Preliminary Quality Assurance and Quality ComplianceDocument17 paginiPreliminary Quality Assurance and Quality CompliancePioneer Power SystemsÎncă nu există evaluări

- Overall Project Quality Management PlanDocument62 paginiOverall Project Quality Management Planlee100% (9)

- Quality ManualDocument20 paginiQuality ManualBin khammash and sons Co.Încă nu există evaluări

- Mts-Iac-21-0035 (Peqp)Document12 paginiMts-Iac-21-0035 (Peqp)jonel.javierÎncă nu există evaluări

- B94 PQP Seksyen 28Document42 paginiB94 PQP Seksyen 28Roif Samsul100% (1)

- Mts-Iac-21-0034 (Proc)Document13 paginiMts-Iac-21-0034 (Proc)jonel.javierÎncă nu există evaluări

- Mts-Iac-21-0036 (Expt)Document13 paginiMts-Iac-21-0036 (Expt)jonel.javierÎncă nu există evaluări

- Control PlanDocument3 paginiControl PlanFerdie OSÎncă nu există evaluări

- QP-GEN-03 Prosedur Internal AuditDocument9 paginiQP-GEN-03 Prosedur Internal AuditFendiÎncă nu există evaluări

- Quality Assurance Plan ChecklistDocument8 paginiQuality Assurance Plan ChecklistJanell Parkhurst, PMP100% (8)

- Online Education Portal Project: Uality Anagement LANDocument10 paginiOnline Education Portal Project: Uality Anagement LANHehe HoÎncă nu există evaluări

- 217-05 - Internal Quality AuditsDocument8 pagini217-05 - Internal Quality Auditsyusuf.yuzuakÎncă nu există evaluări

- 00 Saip 13Document12 pagini00 Saip 13immuÎncă nu există evaluări

- 1 ApqpDocument30 pagini1 ApqpVIPIN YADAVÎncă nu există evaluări

- KCT Quality ManualDocument30 paginiKCT Quality ManualBALAJIÎncă nu există evaluări

- Security Operations: BS EN ISO 9001: 2008Document23 paginiSecurity Operations: BS EN ISO 9001: 2008nipun sharmaÎncă nu există evaluări

- 03 Welding Control Procedure - Asf QC WCP 001Document7 pagini03 Welding Control Procedure - Asf QC WCP 001el_sharkawy2011100% (1)

- Quality Plan - DraftDocument31 paginiQuality Plan - DrafterikdelosantosÎncă nu există evaluări

- Project Quality Plan (JFJS-788)Document18 paginiProject Quality Plan (JFJS-788)mominÎncă nu există evaluări

- Cas 050624 Qa QC ManualDocument33 paginiCas 050624 Qa QC ManualEdo FaiZal CandraWinataÎncă nu există evaluări

- Quality Plan TemplateDocument22 paginiQuality Plan TemplateDia Putranto HarmayÎncă nu există evaluări

- 6.1 Quality ManualDocument47 pagini6.1 Quality ManualmÎncă nu există evaluări

- Qa & QC Manual - DraftDocument15 paginiQa & QC Manual - DraftNayla Shafea Azzahra100% (1)

- Supplier Quality Manual: SQA 2104 - Rev. 10.1Document35 paginiSupplier Quality Manual: SQA 2104 - Rev. 10.1Anonymous CoGUaJ100% (1)

- QAP Chennai MetroDocument23 paginiQAP Chennai Metrosreesailam100% (1)

- SAEP-1154 - Guideline For Contractor's Quality PlanDocument51 paginiSAEP-1154 - Guideline For Contractor's Quality PlanMohammed Harris100% (1)

- Metodología PropuestaDocument16 paginiMetodología PropuestaDaniel ThomsonÎncă nu există evaluări

- Quality MGMT in ConstructionDocument76 paginiQuality MGMT in ConstructionAri Setiawan100% (1)

- Internal Audit Evaluation SheetDocument16 paginiInternal Audit Evaluation SheetHarnani Nanik100% (1)

- Outline Project Quality Plan (Outline PQP) : 其士建築 (香港) 有限公司 Chevalier Construction (Hong Kong) LimitedDocument28 paginiOutline Project Quality Plan (Outline PQP) : 其士建築 (香港) 有限公司 Chevalier Construction (Hong Kong) LimitedWong ChanÎncă nu există evaluări

- Project Quality Plan.Document27 paginiProject Quality Plan.Adeel RazzaqÎncă nu există evaluări

- The Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsDe la EverandThe Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsÎncă nu există evaluări

- NDT - BookDocument142 paginiNDT - BookAhmad Nabil ElsharkawyÎncă nu există evaluări

- The Environment in Which BA Is ConductedDocument17 paginiThe Environment in Which BA Is ConductedAhmad Nabil ElsharkawyÎncă nu există evaluări

- All Period PDFDocument1 paginăAll Period PDFAhmad Nabil ElsharkawyÎncă nu există evaluări

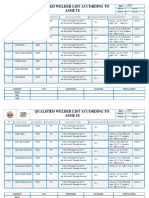

- Welder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Document1 paginăWelder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Ahmad Nabil ElsharkawyÎncă nu există evaluări

- 2019 Price List: Inspector (CAWI, CWI, SCWI) Certified Welding Educator (CWE)Document1 pagină2019 Price List: Inspector (CAWI, CWI, SCWI) Certified Welding Educator (CWE)Ahmad Nabil ElsharkawyÎncă nu există evaluări

- Plant Layout & Piping Design: PL L1 Basic MeduleDocument11 paginiPlant Layout & Piping Design: PL L1 Basic MeduleAhmad Nabil ElsharkawyÎncă nu există evaluări

- Head TANKDocument1 paginăHead TANKAhmad Nabil ElsharkawyÎncă nu există evaluări

- Qualified Welder List According To Asme IxDocument5 paginiQualified Welder List According To Asme IxAhmad Nabil ElsharkawyÎncă nu există evaluări

- 16 Calibration LogDocument1 pagină16 Calibration LogAhmad Nabil ElsharkawyÎncă nu există evaluări

- ANSI Pipe SchedulesDocument2 paginiANSI Pipe SchedulesAhmad Nabil ElsharkawyÎncă nu există evaluări

- LicenseDocument1 paginăLicenseProdromos MpasmatzisÎncă nu există evaluări

- Pages From Calibiration CertificateDocument1 paginăPages From Calibiration CertificateAhmad Nabil ElsharkawyÎncă nu există evaluări

- Handbook - Filler Metal ASTM Steels PDFDocument1 paginăHandbook - Filler Metal ASTM Steels PDFAhmad Nabil ElsharkawyÎncă nu există evaluări

- Head TANK PDFDocument1 paginăHead TANK PDFAhmad Nabil ElsharkawyÎncă nu există evaluări

- Burner TANKDocument1 paginăBurner TANKAhmad Nabil ElsharkawyÎncă nu există evaluări

- Auxelary TANKDocument1 paginăAuxelary TANKAhmad Nabil ElsharkawyÎncă nu există evaluări

- Ahmed Saeed Abd El-Mawgod AshoushDocument2 paginiAhmed Saeed Abd El-Mawgod AshoushAhmad Nabil ElsharkawyÎncă nu există evaluări

- Weld TechDocument18 paginiWeld TechAhmad Nabil ElsharkawyÎncă nu există evaluări

- Chemical TANKDocument1 paginăChemical TANKAhmad Nabil ElsharkawyÎncă nu există evaluări

- Pressure Test Record HylDocument4 paginiPressure Test Record HylAhmad Nabil ElsharkawyÎncă nu există evaluări

- PT Report Elmahd FormDocument1 paginăPT Report Elmahd FormAhmad Nabil ElsharkawyÎncă nu există evaluări

- Moustafa C VDocument4 paginiMoustafa C VAhmad Nabil ElsharkawyÎncă nu există evaluări

- Reboiler TankDocument1 paginăReboiler TankAhmad Nabil ElsharkawyÎncă nu există evaluări

- Itp PipingDocument4 paginiItp PipingAhmad Nabil ElsharkawyÎncă nu există evaluări

- Hindustan Petroleum Corporation Limited Tender: Piping Works Gresham HouseDocument6 paginiHindustan Petroleum Corporation Limited Tender: Piping Works Gresham HouseAhmad Nabil ElsharkawyÎncă nu există evaluări

- ASME Application Form Sept 2015 - June 2016Document2 paginiASME Application Form Sept 2015 - June 2016Ahmad Nabil ElsharkawyÎncă nu există evaluări

- Item # 11.1Document1 paginăItem # 11.1Ahmad Nabil ElsharkawyÎncă nu există evaluări

- February TIME SHEETDocument4 paginiFebruary TIME SHEETAhmad Nabil ElsharkawyÎncă nu există evaluări

- Selecting ERP Consulting PartnerDocument7 paginiSelecting ERP Consulting PartnerAyushmn SikkaÎncă nu există evaluări

- CH 07Document41 paginiCH 07Mrk KhanÎncă nu există evaluări

- A Guide About Bank AccountsDocument6 paginiA Guide About Bank AccountsHelloprojectÎncă nu există evaluări

- ExerciseQuestions SolutionDocument11 paginiExerciseQuestions SolutionMaria Zakir100% (2)

- Capstone Project Final Report - PatanjaliDocument60 paginiCapstone Project Final Report - PatanjaliSharvarish Nandanwar0% (1)

- Performance Analysis of Chinas Fast Fashion ClothDocument10 paginiPerformance Analysis of Chinas Fast Fashion ClothQuỳnh LêÎncă nu există evaluări

- New ISO 29990 2010 As Value Added To Non-Formal Education Organization in The FutureDocument13 paginiNew ISO 29990 2010 As Value Added To Non-Formal Education Organization in The Futuremohamed lashinÎncă nu există evaluări

- PAC DocumentDocument554 paginiPAC DocumentOlakachuna AdonijaÎncă nu există evaluări

- Chapter 2 Management Accounting Hansen Mowen PDFDocument28 paginiChapter 2 Management Accounting Hansen Mowen PDFidka100% (1)

- Sales SUALOGDocument21 paginiSales SUALOGEynab Perez100% (1)

- Din 11864 / Din 11853: Armaturenwerk Hötensleben GMBHDocument70 paginiDin 11864 / Din 11853: Armaturenwerk Hötensleben GMBHkrisÎncă nu există evaluări

- Et Ref MessagesDocument2.848 paginiEt Ref MessagesNitish KumarÎncă nu există evaluări

- One Point LessonsDocument27 paginiOne Point LessonsgcldesignÎncă nu există evaluări

- Pledge, REM, Antichresis DigestsDocument43 paginiPledge, REM, Antichresis DigestsAnonymous fnlSh4KHIgÎncă nu există evaluări

- A Reaction PaperDocument6 paginiA Reaction PaperRedelyn Guingab Balisong100% (2)

- USP Cat Jan-FEB 2013 SandipDocument294 paginiUSP Cat Jan-FEB 2013 SandipNarendra SaiÎncă nu există evaluări

- Coping With Institutional Order Flow Zicklin School of Business Financial Markets SeriesDocument208 paginiCoping With Institutional Order Flow Zicklin School of Business Financial Markets SeriesRavi Varakala100% (5)

- Supply Chain Supply Chain: Hype RealityDocument8 paginiSupply Chain Supply Chain: Hype Realitycons theÎncă nu există evaluări

- The Power of Early Contractor Involvement Volume 12 Issue 2Document4 paginiThe Power of Early Contractor Involvement Volume 12 Issue 2Odilon KongoloÎncă nu există evaluări

- Investor PDFDocument3 paginiInvestor PDFHAFEZ ALIÎncă nu există evaluări

- SCADocument14 paginiSCANITIN rajputÎncă nu există evaluări

- "Now 6000 Real-Time Screen Shots With Ten Country Payrolls With Real-Time SAP Blueprint" For Demo Click HereDocument98 pagini"Now 6000 Real-Time Screen Shots With Ten Country Payrolls With Real-Time SAP Blueprint" For Demo Click Herevj_aeroÎncă nu există evaluări

- Set 5Document21 paginiSet 5Ako Si Paula MonghitÎncă nu există evaluări

- Chapter 4 The Market Forces of Supply and DemandDocument76 paginiChapter 4 The Market Forces of Supply and DemandGiang NguyễnÎncă nu există evaluări

- FOD Awareness: Basic Training in Foreign Object Damage PreventionDocument35 paginiFOD Awareness: Basic Training in Foreign Object Damage PreventionHumberto AnguloÎncă nu există evaluări

- 01 Activity 1 - ARG: Facility Management Concepcion, Stephanie Kyle S. BM303Document2 pagini01 Activity 1 - ARG: Facility Management Concepcion, Stephanie Kyle S. BM303Stephanie Kyle Concepcion100% (3)

- What Is Strategy? The Importance of Strategy?Document5 paginiWhat Is Strategy? The Importance of Strategy?Jade Del MundoÎncă nu există evaluări

- Tax Invoice: U64204GJ2008PTC054111 24AADCG1959N1ZA 9984 GJDocument1 paginăTax Invoice: U64204GJ2008PTC054111 24AADCG1959N1ZA 9984 GJMrugesh Joshi50% (2)

- Economics and Finance Personal StatementDocument1 paginăEconomics and Finance Personal StatementNicolescu AdrianÎncă nu există evaluări

- JollibeeDocument3 paginiJollibeeArgel Linard Francisco Mabaga100% (1)