Documente Academic

Documente Profesional

Documente Cultură

TDFSummaryrev 2

Încărcat de

danielTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TDFSummaryrev 2

Încărcat de

danielDrepturi de autor:

Formate disponibile

Tire Derived Fuel

Summary

! Rubber Type: Shredded, 1-inch to 2-

inches

! Tires Used: 155 million tires used

annually for TDF

o Cement industry: 58 million

o Pulp and paper mills: 39 million

o Electric utilities: 27 million

o Industrial/institutional boilers: 21

million

o Dedicated tire-to-energy facilities: 10

million

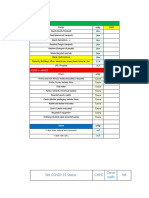

Cement

Industrial Kilns

Boilers 37% (58

14% (21 Million)

Million)

Tire-to-

Energy

Facilities Pulp &

7% (10 Electric Paper

Million) Utilities 25% (39

17% (27 Million)

Million)

! Energy Comparison

o Generates up to 33% more energy

than coal and up to 220% more

energy than wood

o TDF: up to 15,500 BTU per pound

o Coal: 12,750 BTU per pound

o Wood: 4,375 BTU per pound

! Disadvantages

o Lack of public awareness (general

16000

public and public officials)

14000 o NIMBY syndrome (not-in-my-

12000 backyard)

BTU per pound

10000 o Public perception (black smoke looks

8000 bad)

6000

4000 ! Sources:

2000 o A Laboratory and Field Evaluation of

0 the Use of Waste Materials in

TDF Coal Wood Highway Construction (S.N.

Amirkhanian, 1999)

o U.S. Scrap Tire Markets in the United

! Advantages

States: 2005 Edition (Rubber

o More energy potential per pound than

Manufacturers Association, 2006)

coal or wood

o Conservation of other resources (coal

and wood)

o TDF produces lower emissions of

Sulfur Oxides, Nitrogen Oxides, and

total Hydrocarbons than coal.

Asphalt Rubber Technology Service • Clemson University

2002 Hugo Drive • Clemson, SC 29634

Phone: (864) 656-6799 • Fax: (864) 656-6186 • Email: arts@ces.clemson.edu

Website: www.ces.clemson.edu/arts

S-ar putea să vă placă și

- Course Name: Environmental Engineering Sessional II Course Code: CEE 4634Document8 paginiCourse Name: Environmental Engineering Sessional II Course Code: CEE 4634Md Al FarabeÎncă nu există evaluări

- Energy Efficiency in BuildingsDocument72 paginiEnergy Efficiency in Buildingsahtin618100% (1)

- S2.1 - Waste To Energy in Vietnam - Mr. Le Trong Linh 2Document16 paginiS2.1 - Waste To Energy in Vietnam - Mr. Le Trong Linh 2Ho SangÎncă nu există evaluări

- ENVIRONMENTAL STATEMENTREPORT Form V SAIDocument9 paginiENVIRONMENTAL STATEMENTREPORT Form V SAIMohit TiwariÎncă nu există evaluări

- DR Pal Chana - UKIERI Congress Mar 2011Document32 paginiDR Pal Chana - UKIERI Congress Mar 2011Ashok Kumar TiwariÎncă nu există evaluări

- Cummins PEM ElectrolyzersDocument12 paginiCummins PEM ElectrolyzersSid KalraÎncă nu există evaluări

- 2018 6 Natural Resource Usage and SustainabilityDocument51 pagini2018 6 Natural Resource Usage and SustainabilityNirob MahmudÎncă nu există evaluări

- LNGDocument136 paginiLNGwahyu hidayatÎncă nu există evaluări

- Calculation Sheet Generation 5 - Tissue Paper - Version 5.9Document17 paginiCalculation Sheet Generation 5 - Tissue Paper - Version 5.9HariÎncă nu există evaluări

- Ramme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFDocument68 paginiRamme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFerosÎncă nu există evaluări

- The Way Concrete Recycling Should Be: Fuminori Tomosawa, Takafumi Noguchi and Masaki TamuraDocument14 paginiThe Way Concrete Recycling Should Be: Fuminori Tomosawa, Takafumi Noguchi and Masaki TamuraToni ArangelovskiÎncă nu există evaluări

- The Elephant in The Room: 2010 The Status of Carbon ManagementDocument33 paginiThe Elephant in The Room: 2010 The Status of Carbon ManagementKevin VespermanÎncă nu există evaluări

- Blow Moulding Trends U K Saroop 12062007 PDFDocument47 paginiBlow Moulding Trends U K Saroop 12062007 PDFkathiravanpr_6744097Încă nu există evaluări

- Financiamiento Gesti N y Tecnolog As PDFDocument61 paginiFinanciamiento Gesti N y Tecnolog As PDFBenjamín Fernández CruzÎncă nu există evaluări

- 21 Cti Sem2 005Document16 pagini21 Cti Sem2 005testÎncă nu există evaluări

- Energy Efficiency Buildings: Prof Deng Shiming Department of Building Services EngineeringDocument28 paginiEnergy Efficiency Buildings: Prof Deng Shiming Department of Building Services Engineeringaecom ZHSÎncă nu există evaluări

- Concrete Recycling-1 PDFDocument56 paginiConcrete Recycling-1 PDFPRASHANTHÎncă nu există evaluări

- RT3 06 SingaporeDocument22 paginiRT3 06 SingaporeAbhinav AshishÎncă nu există evaluări

- Cold Milling Machine (Owning&Operating) CostsDocument16 paginiCold Milling Machine (Owning&Operating) CostsMohammad Younes100% (1)

- 10 Lao PDR Energy Statistics 2018 Chapter 3Document32 pagini10 Lao PDR Energy Statistics 2018 Chapter 3AllanÎncă nu există evaluări

- Goenvi Presentation 2022Document19 paginiGoenvi Presentation 2022Keshav GargÎncă nu există evaluări

- 2018 - Technology Roadmap - Exe SummaryDocument4 pagini2018 - Technology Roadmap - Exe Summarydr_akanÎncă nu există evaluări

- UltraTech AFR Presentation PDFDocument11 paginiUltraTech AFR Presentation PDFAnonymous Cxriyx9HIXÎncă nu există evaluări

- UltraTech AFR Presentation PDFDocument11 paginiUltraTech AFR Presentation PDFRandeep YadavÎncă nu există evaluări

- UltraTech AFR Presentation PDFDocument11 paginiUltraTech AFR Presentation PDFPraveen Awasthi100% (1)

- Welspun Ec PCB PDFDocument40 paginiWelspun Ec PCB PDFraghuarjunÎncă nu există evaluări

- ZCL ENV STATEMENT Plant - Doc-1Document40 paginiZCL ENV STATEMENT Plant - Doc-1BangaloreanÎncă nu există evaluări

- Pragati GTCC EIADocument23 paginiPragati GTCC EIAProbodh1Încă nu există evaluări

- The Role of Waste To Energy (WTE) in A Circular Economy SocietyDocument35 paginiThe Role of Waste To Energy (WTE) in A Circular Economy SocietyJorge MartinezÎncă nu există evaluări

- The Use of Alternative Fuels and Their Contribution To A Sustainable Cement IndustryDocument18 paginiThe Use of Alternative Fuels and Their Contribution To A Sustainable Cement IndustryminingnovaÎncă nu există evaluări

- Local Opportunities To Influence Carbon Footprints: Andrea Sarzynski March 19, 2009 Montgomery County Speaker SeriesDocument28 paginiLocal Opportunities To Influence Carbon Footprints: Andrea Sarzynski March 19, 2009 Montgomery County Speaker SeriesM-NCPPCÎncă nu există evaluări

- Challange BalanceDocument42 paginiChallange BalancemaveryqÎncă nu există evaluări

- 71 LC3 The Cuban ExperienceDocument38 pagini71 LC3 The Cuban ExperienceMirza BasitÎncă nu există evaluări

- Sustainable Development Study CenterDocument10 paginiSustainable Development Study CenterMalik WazÎncă nu există evaluări

- GCF Redd+ Frel PerformanceDocument20 paginiGCF Redd+ Frel Performancekadek oki febrianÎncă nu există evaluări

- Fact Sheet Brick Sector IndiaDocument8 paginiFact Sheet Brick Sector IndiapvkarthickÎncă nu există evaluări

- 02 Infograph POY FDY enDocument1 pagină02 Infograph POY FDY enanil kapadiaÎncă nu există evaluări

- U38 - Aspen (7-7-03)Document57 paginiU38 - Aspen (7-7-03)kreutzÎncă nu există evaluări

- NRMCA - RecyclingCalculator - Vs 2010 1-1Document71 paginiNRMCA - RecyclingCalculator - Vs 2010 1-1Georges BaderÎncă nu există evaluări

- Biomass To Heat and PowerDocument20 paginiBiomass To Heat and Powerrays_nitaÎncă nu există evaluări

- Iata Steele eDocument31 paginiIata Steele ePabloÎncă nu există evaluări

- Presentation - Slides Woodworks LCA Puettmann SubmittedDocument26 paginiPresentation - Slides Woodworks LCA Puettmann SubmittedNichÎncă nu există evaluări

- Concrete From Plastic: NHMF Eastern Asset Management ForumDocument21 paginiConcrete From Plastic: NHMF Eastern Asset Management Forumved prasad SapkotaÎncă nu există evaluări

- Pultrusion WW 06 2012 Rev3 Us FinalDocument8 paginiPultrusion WW 06 2012 Rev3 Us FinalPradeep MahalikÎncă nu există evaluări

- Future Shocks 2Document6 paginiFuture Shocks 2Bob FisherÎncă nu există evaluări

- Proposed Treatment and Reuse of Dairy WastewaterDocument29 paginiProposed Treatment and Reuse of Dairy WastewaterTrần Hồng NgọcÎncă nu există evaluări

- PYROLITIC OIL POWER SYSTEM 12MWeDocument39 paginiPYROLITIC OIL POWER SYSTEM 12MWeMurat CengizÎncă nu există evaluări

- Energy, Environment & SustainabilityDocument37 paginiEnergy, Environment & SustainabilityStrings AIÎncă nu există evaluări

- ECOPATH Holdings & AR Presentation 2018Document34 paginiECOPATH Holdings & AR Presentation 2018uchenna chieduÎncă nu există evaluări

- Pakistan - Alternative Fuels and The Cement IndustryDocument9 paginiPakistan - Alternative Fuels and The Cement IndustryecorporatesÎncă nu există evaluări

- Incineration Proposal (Technical & Commercial)Document4 paginiIncineration Proposal (Technical & Commercial)Ibrahim AlbrefkaniÎncă nu există evaluări

- Environment: Site COVID-19 Status: Chec Other Staffs NBDocument2 paginiEnvironment: Site COVID-19 Status: Chec Other Staffs NBrajÎncă nu există evaluări

- FOR The Study ON The Development of Pulp and Paper Industry IN The Republic of LithuaniaDocument144 paginiFOR The Study ON The Development of Pulp and Paper Industry IN The Republic of LithuanianitinÎncă nu există evaluări

- Biomass As An Alternative For Coal in Ontario Biomass As An Alternative For Coal in OntarioDocument17 paginiBiomass As An Alternative For Coal in Ontario Biomass As An Alternative For Coal in Ontariodaffodils2Încă nu există evaluări

- Testing Tire Tread Wear LaboratoryDocument8 paginiTesting Tire Tread Wear LaboratorysiritapeÎncă nu există evaluări

- Wood Pellet WorkshopDocument15 paginiWood Pellet Workshopsita deliyana FirmialyÎncă nu există evaluări

- TheNaturalGasIndustry 102605 1 PDFDocument63 paginiTheNaturalGasIndustry 102605 1 PDFIbtihaj AtiqÎncă nu există evaluări

- Management of Thermal Power Plants in India: Paper Presented at BAQ 2006 at Yogykarta, IndonesiaDocument19 paginiManagement of Thermal Power Plants in India: Paper Presented at BAQ 2006 at Yogykarta, Indonesiaapi-26797747Încă nu există evaluări

- Leachate Recirculation Using Tire Scraps - An Economical Solution For Solid Waste ManagementDocument5 paginiLeachate Recirculation Using Tire Scraps - An Economical Solution For Solid Waste ManagementAnnals of Earth, Environment, and Infrastructure EngineeringÎncă nu există evaluări

- Sand Stories: Surprising Truths about the Global Sand Crisis and the Quest for Sustainable SolutionsDe la EverandSand Stories: Surprising Truths about the Global Sand Crisis and the Quest for Sustainable SolutionsÎncă nu există evaluări

- Tally TestDocument2 paginiTally TestHK DuggalÎncă nu există evaluări

- ABPS3103 Topic 7Document20 paginiABPS3103 Topic 7Damon CopelandÎncă nu există evaluări

- Project Reference List - ReferenceDocument7 paginiProject Reference List - ReferenceGohdsÎncă nu există evaluări

- What Is Public Choice Theory PDFDocument8 paginiWhat Is Public Choice Theory PDFSita SivalingamÎncă nu există evaluări

- Coas b1 AcksDocument1 paginăCoas b1 AcksSanah KhanÎncă nu există evaluări

- Foreign Trade: Ricardian ModelDocument11 paginiForeign Trade: Ricardian Modelellenam23Încă nu există evaluări

- Drivers of International BusinessDocument38 paginiDrivers of International BusinessAKHIL reddyÎncă nu există evaluări

- 0413 Germany Yapp PDFDocument9 pagini0413 Germany Yapp PDFBharatÎncă nu există evaluări

- Chapter 2.0Document22 paginiChapter 2.0MOHAMAD ASHRAF BIN MOHAMAD TAJARI MoeÎncă nu există evaluări

- Value ChainDocument31 paginiValue ChainNodiey YanaÎncă nu există evaluări

- 10 TPH Cil Equipment-20171022Document10 pagini10 TPH Cil Equipment-20171022KareemAmen100% (1)

- Full Download Strategic Management Concepts and Cases Competitiveness and Globalization 11th Edition Hitt Solutions ManualDocument36 paginiFull Download Strategic Management Concepts and Cases Competitiveness and Globalization 11th Edition Hitt Solutions Manualowen4ljoh100% (25)

- Hni 72Document1 paginăHni 72Arsh AhmadÎncă nu există evaluări

- T1 General PDFDocument4 paginiT1 General PDFbatmanbittuÎncă nu există evaluări

- L12022 Laser Cutter Flyer SinglesDocument4 paginiL12022 Laser Cutter Flyer SinglesPablo Marcelo Garnica TejerinaÎncă nu există evaluări

- Forklift Driving Training MalaysiaDocument2 paginiForklift Driving Training MalaysiaIsogroupÎncă nu există evaluări

- Global Strategic Planning: ObjectivesDocument4 paginiGlobal Strategic Planning: ObjectivesHitesh GevariyaÎncă nu există evaluări

- Law University SynopsisDocument3 paginiLaw University Synopsistinabhuvan50% (2)

- Europe VATContactsDocument2 paginiEurope VATContactsEriwaÎncă nu există evaluări

- ID Pembentukan Portofolio Optimal Dengan MoDocument9 paginiID Pembentukan Portofolio Optimal Dengan MoIlham AlfianÎncă nu există evaluări

- Account Statement From 3 Nov 2020 To 3 May 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument8 paginiAccount Statement From 3 Nov 2020 To 3 May 2021: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceRajwinder SandhuÎncă nu există evaluări

- Bilo GraphyDocument9 paginiBilo Graphyvimalvijayan89Încă nu există evaluări

- 25-JUNE-2021: The Hindu News Analysis - 25 June 2021 - Shankar IAS AcademyDocument22 pagini25-JUNE-2021: The Hindu News Analysis - 25 June 2021 - Shankar IAS AcademyHema and syedÎncă nu există evaluări

- History of Tata SteelDocument13 paginiHistory of Tata Steelmanoj rakesh100% (4)

- Luis Rodrigo Ubeda: Mission, Values and Culture of POTCDocument6 paginiLuis Rodrigo Ubeda: Mission, Values and Culture of POTCLuis Rodrigo ÚbedaÎncă nu există evaluări

- Woodward Life Cycle CostingDocument10 paginiWoodward Life Cycle CostingmelatorÎncă nu există evaluări

- Solutions For InequalitiesDocument2 paginiSolutions For InequalitiesCrynos DanÎncă nu există evaluări

- mt4 IndicatorDocument4 paginimt4 IndicatorNikhil Pillay100% (1)

- Skills For Smart Industrial Specialization and Digital TransformationDocument342 paginiSkills For Smart Industrial Specialization and Digital TransformationAndrei ItemÎncă nu există evaluări

- Air Asia CompleteDocument18 paginiAir Asia CompleteAmy CharmaineÎncă nu există evaluări