Documente Academic

Documente Profesional

Documente Cultură

A Simple Yet Intelligent Control Centre, Capable of Operating Up To 240 Actuators in A Single Loop, With A Touch Screen Interface For Ease of Use

Încărcat de

Steven AlbertoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Simple Yet Intelligent Control Centre, Capable of Operating Up To 240 Actuators in A Single Loop, With A Touch Screen Interface For Ease of Use

Încărcat de

Steven AlbertoDrepturi de autor:

Formate disponibile

As DC Pl

se S/ an

tM SC tC

an AD on

ag A tro

em ll e Off-site Connection

Laptop en r

Work Station

t

HOST

ETHERNET

NETWORK

A simple yet intelligent control centre,

capable of operating up to 240 actuators

in a single loop, with a touch screen

interface for ease of use.

The Rotork Master Station and its field networks

have been designed for use in all industries and

applications where robust and reliable plant control

and monitoring is required.

Supervisory Plant Control

Rotork Master Station with intuitive

touch screen user interface

Up to three separate field networks

on one Rotork Master Station

CLASSIC

Multiple host (Ethernet and serial) 2-Wire Current Loop

connectivity

20 km distance

240 nodes

Asset management and data logging

Built-in redundancy support

Existing Pakscan systems upgradeable General Purpose

Field Control Unit

to Rotork Master Station

S PT

All Pakscan field networks 55

open to third party devices Mixer Compressor Solenoid Pressure

Valve Transmitter

Efficient low cost install E/H

with minimum cost of ownership

Electro-hydraulic

Valve

Over 170,000 existing installed

Pakscan field devices

Backed by Rotork global support Including 3 rd Party

Field Devices

Motor Operated Control

Valve Valve

Supervisory Plant Control

The Rotork Master Station and Pakscan Classic Asset management and data logging

current loop network system is the world leader The Rotork Master Station has many features to enable the

in actuation control automation, providing management of the assets connected to it.

comprehensive solutions for modern plant control • On-screen analysis of field device alarms and status

and monitoring. • Communication to DCS/PLC or asset management system

With its high level of innovation, intelligent design and • Advanced features and logs for field device maintenance

ongoing Rotork global support ensures your operation will • Valve torque profiles

always run smoothly, efficiently and effectively. The system

allows for backward compatibility with existing Pakscan Multiple host connectivity

systems and support for an Open Modbus RTU field network The Rotork Master Station is fully pre-configured, providing easy

enables easy integration of other third party devices. integration with proven communications to all major DCS and PLC

suppliers via Modbus TCP, and optionally Modbus RTU, protocols.

Intuitive touch screen user interface

• Multiple host communications

Large touch screen interface and web pages share the same

intuitive menu structure focused on providing quick device set up, • Multiple databases for maximum data transfer efficiency

interrogation and issue resolution. • Touch screen display allows local stand alone operation

• NAMUR NE107 diagnostic icons for easy recognition of status

Easily upgrade existing Pakscan systems

• Full configuration via touch screen or web interface

Rotork Master Station has backwards compatibility with Pakscan

• Multilingual interface options IIE and P3 systems for field and host connectivity.

• Dedicated service ethernet port maintains separation between • Easy upgrade of existing Pakscan networks

configuration and monitoring systems and systems for

• Rotork Master Station can replace existing IIE and P3 Master

controlling the process

Stations without further network or device changes

Up to three field networks on one Rotork Master Station

All Pakscan field networks open for third party devices

The modular product design means a single Rotork Master Station

can operate multiple field networks. • All Rotork and third party actuation products are supported

• Pakscan Classic and Modbus networks • Rotork actuator can act as a hub for connection of digital I/O

into the various networks

• Multiple combinations of network Add In Modules (AIMs) in a

single Rotork Master Station Efficient low cost install with minimum cost of ownership

• 240 field devices across the field network modules Direct cost reductions are made by using a single twisted

• Control and monitor third party devices such as mixers, pair cable.

pumps and transmitters • Long wired loop lengths without external repeaters

Built-in redundancy support • Fast installation and commissioning = reduced downtime

Along with single and dual configurations, the Rotork Master Station • A choice of mounting options

can be supplied in hot standby configuration with built-in redundancy • Wiring accessible from the front panels

support. All network communications are secure with fault tolerance, • No expensive specialist software required

allowing continued operation of the plant when a fault occurs.

• Hot standby configuration duplicates all interfaces; Backed by Rotork global support

no single point of failure • Worldwide service and commissioning support

• Standby system seemlessly takes control if failure occurs • Documentation and on-site / in-house training

• In-built diagnostic features • Service engineers are fully trained in the Rotork Master Station

• Automatic fault location and indication on screen and associated field networks

A full listing of the Rotork sales Corporate Headquarters

Rotork plc

and service network is available tel

fax

+44 (0)1225 733200

+44 (0)1225 333467

Electric Actuators and Control Systems

on our website. email mail@rotork.com Fluid Power Actuators and Control Systems

Gearboxes and Gear Operators

Precision Control and Indication

Projects, Services and Retrofit

www.rotork.com

PUB059-047-00 As part of a process of on-going product development, Rotork reserves the right to amend Rotork is a corporate

and change specifications without prior notice. Published data may be subject to change. member of the Institute of

Issue 06/19 For the very latest version release, visit our website at www.rotork.com Asset Management

The name Rotork is a registered trademark. Rotork recognises all registered trademarks.

Published and produced in the UK by Rotork. POWJB0619

S-ar putea să vă placă și

- Indicator Controller Cum TransmitterDocument1 paginăIndicator Controller Cum TransmitterTrumen Technologies PVT LtdÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Taktis Flyer 2017Document6 paginiTaktis Flyer 2017Technical OfficeÎncă nu există evaluări

- High-Performance D/A-Converters: Application to Digital TransceiversDe la EverandHigh-Performance D/A-Converters: Application to Digital TransceiversÎncă nu există evaluări

- Sisteme Informatice În Energetică: Ș.L.DR - Ing. Nicoleta Arghira Prof - Dr.ing. Sergiu Stelian IliescuDocument31 paginiSisteme Informatice În Energetică: Ș.L.DR - Ing. Nicoleta Arghira Prof - Dr.ing. Sergiu Stelian Iliescudoctornegrila100% (1)

- TSCL 9.6Mwp ArchitectureDocument1 paginăTSCL 9.6Mwp ArchitectureRaj GaneshÎncă nu există evaluări

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsDe la EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsÎncă nu există evaluări

- Tónová Korekce S TDA1524 - RumunskoDocument3 paginiTónová Korekce S TDA1524 - Rumunskoquad electronicsÎncă nu există evaluări

- Training CourseDocument376 paginiTraining CourseHuynh DuongÎncă nu există evaluări

- Nuts & Volts 25-10 - Oct 2004Document108 paginiNuts & Volts 25-10 - Oct 2004blahblahname100% (2)

- Delta Monitoring Solution: Quick, Simple, Reliable. Always Care About Your Needs !Document3 paginiDelta Monitoring Solution: Quick, Simple, Reliable. Always Care About Your Needs !vanhuong87Încă nu există evaluări

- 527 Ref OPOLE SENDocument8 pagini527 Ref OPOLE SENMichal KowalczykÎncă nu există evaluări

- IgnitionArchitecture HubandSpoke RedundancyDocument1 paginăIgnitionArchitecture HubandSpoke Redundancyshamendu royÎncă nu există evaluări

- Cement FOR CONSTRUCTIONDocument7 paginiCement FOR CONSTRUCTIONIsaiah JohnÎncă nu există evaluări

- Solution-Brief Locamation EN v2Document4 paginiSolution-Brief Locamation EN v2JYOTHEESWARA NAIDUÎncă nu există evaluări

- MC33390Document16 paginiMC33390bettinemed2023Încă nu există evaluări

- Nuts & Volts 25-09 - Sep 2004Document108 paginiNuts & Volts 25-09 - Sep 2004blahblahname100% (2)

- SSt-Eclipse Model E6xx/7xx DSP-Based Digital Servo DrivesDocument3 paginiSSt-Eclipse Model E6xx/7xx DSP-Based Digital Servo DrivesRchrdStrkÎncă nu există evaluări

- Solar Inverter UNO-DM-1.2/2.0/3.0 Tl-Plus-Q: From 1.2 To 3.0 KWDocument4 paginiSolar Inverter UNO-DM-1.2/2.0/3.0 Tl-Plus-Q: From 1.2 To 3.0 KWArjunÎncă nu există evaluări

- SERIES E1400: Edition 24 Subject To AlterationsDocument19 paginiSERIES E1400: Edition 24 Subject To Alterationsoctavinavarro8236Încă nu există evaluări

- Controller For EspDocument2 paginiController For EspJohn WatsonÎncă nu există evaluări

- Microcontroller and Triacs ON THE 110/240V MAINS: Application NoteDocument12 paginiMicrocontroller and Triacs ON THE 110/240V MAINS: Application NoteMaha SoeÎncă nu există evaluări

- IEEE Paper On The Wind Access TrubineDocument7 paginiIEEE Paper On The Wind Access TrubineTejeshwiniÎncă nu există evaluări

- Model 950A Antenna Control System: Full Featured Inverter Drive ControlDocument2 paginiModel 950A Antenna Control System: Full Featured Inverter Drive ControlAsif SharifÎncă nu există evaluări

- RMC 150 DatasheetDocument20 paginiRMC 150 DatasheetIthanLeonardoÎncă nu există evaluări

- 34 - 3al 42941 Acaa TnaaaDocument12 pagini34 - 3al 42941 Acaa TnaaaJonatan SoaresÎncă nu există evaluări

- A Numerical Protection Relay Solution: Application ReportDocument7 paginiA Numerical Protection Relay Solution: Application Reportjp2udhayaÎncă nu există evaluări

- Low Voltage Switchgear Key Switchgear FeaturesDocument4 paginiLow Voltage Switchgear Key Switchgear FeaturesHector De La Cruz HernandezÎncă nu există evaluări

- QuickTrip ELECTRO-HYDRAULIC TRIP BLOCK ASSEMBLY FOR INDUSTRIAL STEAM TURBINESDocument1 paginăQuickTrip ELECTRO-HYDRAULIC TRIP BLOCK ASSEMBLY FOR INDUSTRIAL STEAM TURBINESsunny vermaÎncă nu există evaluări

- 1SXU000023C0202 - RevA - 02 Motor Overload ProtectionDocument60 pagini1SXU000023C0202 - RevA - 02 Motor Overload ProtectionMelly SyafriliaÎncă nu există evaluări

- Easergy P3 External Presentation - FinalDocument49 paginiEasergy P3 External Presentation - Finalsahar_javdani144Încă nu există evaluări

- Tm1703acp eDocument6 paginiTm1703acp eenjiniring sbklÎncă nu există evaluări

- Advanced BLDC Motor DriveDocument71 paginiAdvanced BLDC Motor DriveKurt ZhiÎncă nu există evaluări

- Energymanagement Overview Eng 092014Document8 paginiEnergymanagement Overview Eng 092014Prasanto SoerjonoÎncă nu există evaluări

- Nuts & Volts 25-08 - Aug 2004Document108 paginiNuts & Volts 25-08 - Aug 2004blahblahname100% (1)

- Standards For The Smart Grid: Richard DeblasioDocument10 paginiStandards For The Smart Grid: Richard DeblasioAlbai HakiÎncă nu există evaluări

- 1969 Rockefeller - Fault Protection With A Digital Computer PDFDocument27 pagini1969 Rockefeller - Fault Protection With A Digital Computer PDFOmar Chayña VelásquezÎncă nu există evaluări

- Allgon Coverage Systems - Repeater Catalogue - ALGPC0201Document23 paginiAllgon Coverage Systems - Repeater Catalogue - ALGPC0201Virgil Peiulescu0% (1)

- TGA-B Brochure 00Document4 paginiTGA-B Brochure 00Jorge GoyÎncă nu există evaluări

- Engen GarageDocument6 paginiEngen GarageThabangÎncă nu există evaluări

- Varicon eDocument6 paginiVaricon eHugo Samuel López VasquezÎncă nu există evaluări

- Lovato - Automatic Transfer Switch Controllers (ATS)Document18 paginiLovato - Automatic Transfer Switch Controllers (ATS)Mostafa ShannaÎncă nu există evaluări

- Rex 3930 Ed1 EngDocument2 paginiRex 3930 Ed1 EngA-selam IbraÎncă nu există evaluări

- TPS54620 4.5-V To 17-V Input, 6-A, Synchronous, Step-Down SWIFT™ ConverterDocument47 paginiTPS54620 4.5-V To 17-V Input, 6-A, Synchronous, Step-Down SWIFT™ ConverterShakti SinghÎncă nu există evaluări

- Omogoye .O.S, Ogundare .A.B, Ojo .F.Epage 1Document7 paginiOmogoye .O.S, Ogundare .A.B, Ojo .F.Epage 1kalu chimdiÎncă nu există evaluări

- NG Uk RTR 0220 r15 PDFDocument9 paginiNG Uk RTR 0220 r15 PDFDuong Thai BinhÎncă nu există evaluări

- Smart Energy Solution GuideDocument20 paginiSmart Energy Solution GuideedordonezÎncă nu există evaluări

- Hoja de Especificacion de Liebert SiteLink 12Document5 paginiHoja de Especificacion de Liebert SiteLink 12slifer250987Încă nu există evaluări

- GSK983Ta-HV Connection ManualDocument34 paginiGSK983Ta-HV Connection ManualLucasÎncă nu există evaluări

- ASCO SERIES 185 Automatic Transfer Switches 100-400 Ampere Sizes Operator's ManualDocument16 paginiASCO SERIES 185 Automatic Transfer Switches 100-400 Ampere Sizes Operator's ManualSantiago JuradoÎncă nu există evaluări

- Moxa Application Flyer - IEC61850 Substation Automation ComputerDocument5 paginiMoxa Application Flyer - IEC61850 Substation Automation ComputerMichael Parohinog GregasÎncă nu există evaluări

- Gs50a01a11-01en 002Document9 paginiGs50a01a11-01en 002Dhirender DagarÎncă nu există evaluări

- Datum Electronics: Pto 420 Series Shaft Torque & Power Monitoring System Handbook and Installation GuideDocument6 paginiDatum Electronics: Pto 420 Series Shaft Torque & Power Monitoring System Handbook and Installation Guidehechano2Încă nu există evaluări

- 9500 MPR Release 1.0/1.1 Technical Description: Version 2.0 - May 2008Document17 pagini9500 MPR Release 1.0/1.1 Technical Description: Version 2.0 - May 2008Juanzbar Huaman SialerÎncă nu există evaluări

- Optocoupler Selection GuideDocument28 paginiOptocoupler Selection GuideAnonymous 0CnvpxSÎncă nu există evaluări

- Snag List KPIs at 21 March - Electrical Remains - 86 (3125383)Document4 paginiSnag List KPIs at 21 March - Electrical Remains - 86 (3125383)adnanÎncă nu există evaluări

- Its-03 Includes Cts in The Reverse Direction To The Osm Resulting in Opposite Power Flow WhenDocument2 paginiIts-03 Includes Cts in The Reverse Direction To The Osm Resulting in Opposite Power Flow WhenAnonymous 4KVQOT5jeHÎncă nu există evaluări

- Busbar Scheme (Siemens)Document78 paginiBusbar Scheme (Siemens)Hanis Halim100% (1)

- Scotle Technology Group Ltd. Scotle IR6000 V3. BGA Rework Station. User Manual.Document17 paginiScotle Technology Group Ltd. Scotle IR6000 V3. BGA Rework Station. User Manual.zigmund zigmundÎncă nu există evaluări

- Screenshot 2022-10-03 at 3.45.41 PMDocument15 paginiScreenshot 2022-10-03 at 3.45.41 PMNMP Kumar UÎncă nu există evaluări

- Bs 7835 11Kv LSZH Single Core Screened CableDocument2 paginiBs 7835 11Kv LSZH Single Core Screened CablefoaadahmadÎncă nu există evaluări

- CRN NsycrnDocument2 paginiCRN NsycrnJc RoblesÎncă nu există evaluări

- Cblephsu 03Document6 paginiCblephsu 03Saheb PriyadarshiÎncă nu există evaluări

- Leroy Somer LSA 54.2Document16 paginiLeroy Somer LSA 54.2Seno PT. AAEÎncă nu există evaluări

- Ultrasonic System For Solar Panel CleaningDocument5 paginiUltrasonic System For Solar Panel CleaningGugui68Încă nu există evaluări

- Amx Leclerc Main Battle Tank For The Year 2000Document6 paginiAmx Leclerc Main Battle Tank For The Year 2000Timia TalashekÎncă nu există evaluări

- Chapter 16Document54 paginiChapter 16BSIT3_IT116Încă nu există evaluări

- Examination of VRLA Battery Cells Sampled From The Metlakatla Battery Energy Storage SystemDocument8 paginiExamination of VRLA Battery Cells Sampled From The Metlakatla Battery Energy Storage System87GÎncă nu există evaluări

- Service Manual: Chassis No. GA-7SDocument29 paginiService Manual: Chassis No. GA-7SErry Kusuma WardanaÎncă nu există evaluări

- Manual Amptron Ai205Document3 paginiManual Amptron Ai205OdirNtanÎncă nu există evaluări

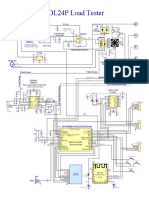

- DL24P Schematic DiagramDocument1 paginăDL24P Schematic DiagramLAN JR HOUSE0% (1)

- Block Diagram: X555LD Repair GuideDocument7 paginiBlock Diagram: X555LD Repair Guideharsha371Încă nu există evaluări

- 15A04802 Low Power VLSI Circuits & SystemsDocument1 pagină15A04802 Low Power VLSI Circuits & SystemsMALLAVARAPU NARASAREDDYÎncă nu există evaluări

- Merus A2 Module User Manual 3.1 PDFDocument110 paginiMerus A2 Module User Manual 3.1 PDFFawad NoorÎncă nu există evaluări

- Activity 3 Robotics 2Document2 paginiActivity 3 Robotics 2Jessa TirambuloÎncă nu există evaluări

- Avr Gavr-8a DatasheetDocument3 paginiAvr Gavr-8a Datasheetkhhoa0% (1)

- Question Bank CAD CAMDocument7 paginiQuestion Bank CAD CAMAjay Kumar AgarwalÎncă nu există evaluări

- Toshiba 32SW9UADocument50 paginiToshiba 32SW9UAXavier AxiakÎncă nu există evaluări

- 3 Blue Copper ProteinsDocument15 pagini3 Blue Copper ProteinsSergio BetancurÎncă nu există evaluări

- Ch. 11: Liquids and Intermolecular Forces: - GasesDocument22 paginiCh. 11: Liquids and Intermolecular Forces: - GasesJozel Bryan Mestiola TerrìbleÎncă nu există evaluări

- 1953 3 AudioDocument76 pagini1953 3 Audiokimbalsummers801100% (1)

- Arf1500 PDFDocument4 paginiArf1500 PDFbookreader1968Încă nu există evaluări

- WL 299CDocument19 paginiWL 299CSorin GhitaÎncă nu există evaluări

- DC 25 Ub 25Document4 paginiDC 25 Ub 25nameÎncă nu există evaluări

- Data Link ProtocolsDocument19 paginiData Link ProtocolsSeravana KumarÎncă nu există evaluări

- Cable Sizing CalculationDocument15 paginiCable Sizing CalculationShubhankar KunduÎncă nu există evaluări

- Eit (Internship) Iium Report - Mechatronics (2022)Document17 paginiEit (Internship) Iium Report - Mechatronics (2022)FareezÎncă nu există evaluări