Documente Academic

Documente Profesional

Documente Cultură

Document Control Sheet: Mahagenco

Încărcat de

nileshwarkeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Document Control Sheet: Mahagenco

Încărcat de

nileshwarkeDrepturi de autor:

Formate disponibile

CONTROL PHILOSOPHY FOR 2 X 500 MW BHUSAWAL TPS

MAHAGENCO EFFLUENT TREATMENT PLANT

DOCUMENT CONTROL SHEET

PROJECT 2 X 500 MW BHUSAWAL THERMAL POWER STATION

CLIENT MAHARASTRA STATE POWER GENERATION CO. LTD..

CONSULTANT: TCE, BANGALORE.

DOCUMENT TITLE: CONTROL PHILOSOPHY FOR

EFFLUENT TREATMENT PLANT SECTION

IEIL DOCUMENT NO. : A4-A20154-12-304 D

REV.NO : P0

ENDORSEMENTS

P1

P0 20/05/2010 First Submission MBS RY NPD

REV. PREP. BY REVW. BY APPRVD BY SIGN.

DATE DESCRIPTION

NO. SIGN .(INITIAL) SIGN. (INITIAL) (INITIAL)

CONTROL PHILOSOPHY

DOCUMENT NO.: Page 1 of 6

A4-A20154-12-304 D Rev: P0

CONTROL PHILOSOPHY FOR 2 X 500 MW BHUSAWAL TPS

MAHAGENCO EFFLUENT TREATMENT PLANT

FOR

EFFLUENT TREATMENT PLANT

The Control Philosophy for the Effluent treatment has following sections listed

below

Reference Drawings.

General Description for Effluent treatment Plant

General Description for Sludge Handling System.

Control & Monitoring philosophy for ETP from DM-PLC

Electrical Motor Drive Control Philosophy – 415 V

REFERANCE DRAWINGS:

P & I diagrams & Layouts for the reference are listed below.

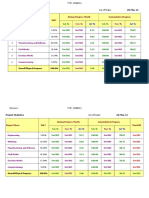

Sr.No Revision

Drawing Title P & ID Number

No

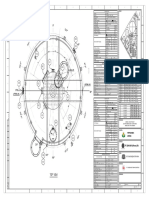

01 P & ID for Effluent Treatment plant A1-A20154-01-12 Rev – R0

06 Equipment Layout for Effluent Treatment A1-A20154-02-04 Rev - 4b

plant

07 Legend Sheet A1-A20154-01-13 Rev - 0

General Description for Pretreatment Plant – Non DM service:

Equipment List :-

SR QUANTITY

Tag Nos. DESCRIPTION

NO in Nos.

1 EQT Waste water collection & equalization tank. 1 no

2 P18 A/B Waste equalization pumps 2 nos

3 P19 A/B HRSCC feed pumps 2 nos

4 HRSCC High rate solid contact clarifier 1 no

5 CWST Clear water storage tank 1 no

6 CFT Centrifuge feed tank 1 no

7 P20 A/B Centrifuge feed pumps 2 nos

8 CENT-4 Centrifuge 1 no

9 TFT TPI feed tank 1 no.

10 P21A/B TPI Feed pump 2 nos

11 TPI Tilted plate interceptor 1 no.

DOCUMENT NO.: Page 2 of 6

A4-A20154-12-304 D Rev: P0

CONTROL PHILOSOPHY FOR 2 X 500 MW BHUSAWAL TPS

MAHAGENCO EFFLUENT TREATMENT PLANT

12 DT4-C Alum Solution preparation Tank 1 no

DT-3D Polyelectrolyte Solution preparation Tank 1 no

13

14 DT-3E Polyelectrolyte Solution preparation Tank 1 no

15 DP5-A/B Alum Solution Dosing Pumps 2 nos

16 DP6 – A/B Polyelectrolyte Dosing Pumps 2 nos

17 DP7-A/B Polyelectrolyte Dosing Pumps 2 nos

Effluent treatment system is designed to treat maximum influent flow of 427.2 m3/hr of

effluent water from Coal decanter, CT blow down, Boiler blow down, DM /SF/CPU waste,

Brine filter backwash floor washing and miscellaneous services and it is suitable for

manual operation.

ETP plant consist one waste collection cum equalization tank (EQT) ,High rate solid

contact clarifier (HRSCC), Clear water storage tank (CSW), Centrifuge feed tank (CFT) ,

Dewatering centrifuge (CENT), TPI Feed Tank (TFT) Tilted plate Interceptor (TPI)

Chemical dosing system is also provided for dosing of Alum and Polyelectrolyte in HRSCC

The Effluents from various streams (Coal decanter, CT blow down, Boiler blow down,

DM/SF/CPU waste, Brine filter backwash floor washing and miscellaneous services ) is

collected in Compartment –I of EQT, after collection, Effluent is transferred to

Compartment –II of EQT by means of waste equalization pump (P18-A/B).to get uniform

quality of collected effluent, than it get transferred to HRSCC with the help of HRSCC feed

pump ( P19 A/B ). Level switches LS 1204, LS 1205 are for High alarm and low tripping

of respective pumps (P18 A/B, P19 A/B) , Two separate level indicators (LIFB-1201/1202)

are also provided for local monitoring of level in Comp-I & II respectively. Air agitation is

also carried out in both compartments with the help of air blower (B-6 A/B/C)

Effluent from Comp-II of EQT is pumped to HRSCC by means of HRSCC feed pump

(P19A/B). One local flow indicator is provided (FI 1201) at inlet pipe of HRSCC to measure

the flow. The HRSCC is designed for operation with normal rated input of 861.7 m3/hr,

Coagulation and flocculation are the basic process that occurs in HRSCC. Suspended

impurities will get removed from water during the process. Consists of speed reduction

gear drive operated central propeller & agitator to ensure effective coagulation, flocculation

& clarification.

Alum & Polyelectrolyte solution are dosed in the draft tube of HRSCC by means of dosing

pumps DP-5 A/B, DP-6-A/B respectively, in order to have proper coagulation &

flocculation. Dosing of alum & Polyelectrolyte to the system is manually controlled by

adjusting the dosing rate of the respective pumps . Alum and Polyelectrolyte dosing tanks

(DT-4C & DT-3 E) are provided with agitators to facilitate preparation and mixing of

solution. Level switch (LS 1201/1202 ) are provided on DT-4C & DT-3E for high alarm and

low level tripping of dosing pumps DP5-A/B & DP-6 A/B respectively.

DOCUMENT NO.: Page 3 of 6

A4-A20154-12-304 D Rev: P0

CONTROL PHILOSOPHY FOR 2 X 500 MW BHUSAWAL TPS

MAHAGENCO EFFLUENT TREATMENT PLANT

The clarified water from HRSCC is allowed to flow through the channel to the Clear water

storage tank (CWST). Level switch (LS 1206) is provided in CWST for Low as well as High

alarm at PLC. One float & board type level indicator (LIFB-1203) is also provided for local

monitoring of level.

The clarified water is reused for make of service and ventilation system. Separate service

makeup and ventilation makeup pumps are provided to transfer clarified water to service

and ventilation system respectively. Some part of the clarified water is recycled to use for

dilution of chemicals like Alum and polyelectrolyte in chemical house of ETP.

Instruments like Flow totalizer (FQAH 1201), Conductivity meter (Cond-1201), Turbidity

meter (Turb-1201) & PH meter (PH-1201) are provided at discharge header of service

make up pump to monitor quality of clarified water in PLC

One separate Tilted plate interceptor system is provided for separation of oil from oily

effluent. In this system oily effluent from fuel oiling /transformer area is collected in Tilted

plate interceptor feed tank (TPI feed tank), The oily effluent is than feed to Tilted plate

interceptor (TPI) Unit with the help of TPI feed pump (P21 A/B). Level switch (LS 1208) is

provided at TPI feed tank for High alarm & low tripping of the pump `P21`. Oil separation is

carried out in TPI, the separated oil comes out from oil skimmer continuously, and the

same separated oil will be collected & disposed. Oil free water is transferred to EQT by

gravity for further processing. During separation of oil, some sludge may get separated

from effluent, the same sludge is collected & transferred to centrifuge feed tank for further

dewatering process.

General Description Sludge handling system:

Sludge disposal operation of HRSCC is operated manually. Sludge from HRSCC will be

collected in Centrifuge feed tank (CFT) by gravity through Telescopic Sludge sump (TSS-

HRSCC). CFT is provided with Level switch (LS-1207) for high & low alarm and low level

tripping of centrifuge feed pump (P20-A/B) .Collected sludge is .fed to centrifuge (CENT-4)

for dewatering by help of “centrifuge feed pump” (P20 A/B).

Polyelectrolyte solution is dosed at the inlet of centrifuge by means of dosing pumps (DP-

7-A/B), Dosing of Polyelectrolyte to the system is manually controlled by adjusting the

dosing rate of the pump. Polyelectrolyte dosing tank (DT-3D) is provided with agitator to

facilitate preparation and mixing of solution. Level switch (LS 1203) is provided on DT3-D

for high alarm and low level tripping of dosing pumps DP7-A/B.

The sludge from the centrifuge will be collected & disposed. Clarified water is recycle to

EQT for processing.

Control & Monitoring philosophy for ETP plant

The ETP plant system shall be monitor & controlled by local control panel located in ETP

plant area. As per the operation philosophy mentioned in the tender specifications, the

DOCUMENT NO.: Page 4 of 6

A4-A20154-12-304 D Rev: P0

CONTROL PHILOSOPHY FOR 2 X 500 MW BHUSAWAL TPS

MAHAGENCO EFFLUENT TREATMENT PLANT

operation of all valves in ETP system shall be operated in manual mode only.

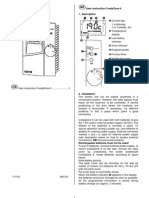

The PLC based system considered in the philosophy mentioned above identifies control of

some drives as an interlock feature (indicated in the P & ID) and rest will be manual-

based. On/off, trip Indications for drive and instrument high, low alarm will be available on

the Local control panel.

The complete operation logic of monitoring and interlock system is incorporated in the ETP

plant PLC system. The ETP plant equipments shall be operated through the PLC based

Local control panel.

The ETP - PLC for above-mentioned system have following features.

a) The PLC system has redundant CPU, Power supply,

communication modules ,cables & non redundant I/O’s

b) The processor shall contain program memory with read/write

capability & shall be solid state RAM with battery back up.

c) The PLC has supervisory functions like MMI which shows the

reading of all analyzer /transmitter, alarm & any abnormalities

etc. All engineering activity for ETP plant shall be carried out

through PLC & operation activity from PLC based Local control

panel in ETP Plant control room.

d) ETP plant status indication will be communicated to the DM-SF

PLC through FO (fiber optic) link. & same will be available in DCS

through DM-SF PLC.

Electrical Motor Drive Control Philosophy For 415 V Drive –

The 415 V drives, except for manually operated drives, will be operable from

remote (PLC at control room) as well as from local push button station,

located near drive. Remote manual operation (Start/Stop) of 415 V drives will

be performed in two modes. Normal mode of operation will be carried out from

PLC. Permissive & trip condition will display on MMI. Control command

Start/stop under normal mode will be generated in PLC & issued through

interposing relays mounted in respective MCC Electrical protections from the

drives will be realized form the MCC, where as process interlocks &

protections will be realized in PLC. Operation of the drive from PLC will only

be possible upon fulfillment of all process & protection interlock.

Local / Remote selection will be carried from the MCC .Local operation will be

carried out from LPBS near drive and remote operation from PLC. Emergency

stopping of drive will envisage from the local push button station. The stop

push button will be stay put type & provided with press to local & turn to

release. Key less type mechanism & will be directly wired to the MCC. Stop

operation from respective starter module in MCC has not been envisaged.

Following signal exchange will take place between MCC & PLC.

DOCUMENT NO.: Page 5 of 6

A4-A20154-12-304 D Rev: P0

CONTROL PHILOSOPHY FOR 2 X 500 MW BHUSAWAL TPS

MAHAGENCO EFFLUENT TREATMENT PLANT

1. Drive start command for 415 V drive

2. Drive Stop command for 415 V drive

3. For Status feedback for 415 V drive

On feed back

Off feedback

Trip Feedback

Selector switch Remote

CT input for Current Transducer (above 30 kW)

Control Philosophy for Electrical Incoming System –

The status input of relevant electrical equipment & electrical parameter

mentioned below is considered as input to the PLC for displaying the electrical

status of the system.

Following signal exchange will take place between Electrical systems – LT

Panels & PLC

a) Status Feedback of Breaker ON

b) Status Feedback of Breaker OFF

c) Status Feedback for Breaker Trip

d) Status Feedback of Spring charged.

e) Status Feedback of Breaker in test mode.

f) Status Feedback of Breaker in service mode.

g) Status Feedback of Breaker trip circuit healthy.

h) ON Command - Incomers/Bus-couplers.

i) OFF command - Incomers/Bus-couplers.

j) For Metering of the LT panels. --

Current.

Voltage.

Power.

The control & operation philosophy as described above is in line with the

tender specifications.

DOCUMENT NO.: Page 6 of 6

A4-A20154-12-304 D Rev: P0

S-ar putea să vă placă și

- Brother Filtration Catalog 2018Document40 paginiBrother Filtration Catalog 2018khalifapkÎncă nu există evaluări

- Technical Paper SiC Ceramic MembranesDocument5 paginiTechnical Paper SiC Ceramic MembranesEman El DsoukyÎncă nu există evaluări

- 4 740078 G0 I 795 09 GE Water & Process TechnologiesDocument2 pagini4 740078 G0 I 795 09 GE Water & Process TechnologiesniginpÎncă nu există evaluări

- SBG1 01 0H 3 MST 0028 C Chemical Dosing System OP Instruc - JCM - OMDocument46 paginiSBG1 01 0H 3 MST 0028 C Chemical Dosing System OP Instruc - JCM - OMzainudin simonÎncă nu există evaluări

- SMP PH AnalyserDocument4 paginiSMP PH AnalyserSreekanthMylavarapuÎncă nu există evaluări

- r0 Proposal of Gree Tophill Lars - Ehi Rev1Document45 paginir0 Proposal of Gree Tophill Lars - Ehi Rev1Anonymous fS6Znc9Încă nu există evaluări

- Tender 2Document43 paginiTender 2pbhat83Încă nu există evaluări

- WTP PackageDocument67 paginiWTP PackageDevam KengeÎncă nu există evaluări

- Vessel Process Data Sheet1Document3 paginiVessel Process Data Sheet1AJAY1381Încă nu există evaluări

- Volume IIA Technical SpecificationDocument83 paginiVolume IIA Technical SpecificationSanjeev Kumar DasÎncă nu există evaluări

- AL MARAI HADCO ETP - Process Description and SeqDocument43 paginiAL MARAI HADCO ETP - Process Description and SeqHumaid ShaikhÎncă nu există evaluări

- WTP Boq-FinalDocument3 paginiWTP Boq-FinalT M Murshed Mukul100% (1)

- CERAFILTEC Product BrochureDocument27 paginiCERAFILTEC Product Brochurexxxx222xxxxÎncă nu există evaluări

- Degasifier 18-02-2017 Sheet 1Document1 paginăDegasifier 18-02-2017 Sheet 1Abu SuraisyÎncă nu există evaluări

- Dosing Pump - LimeDocument2 paginiDosing Pump - LimemeisamÎncă nu există evaluări

- Tender Documents Other Than SCC 0fd1e7Document183 paginiTender Documents Other Than SCC 0fd1e7Ankit PatelÎncă nu există evaluări

- Operation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreDocument17 paginiOperation & Maintenance Manual: Vishwasri-Oak Park CoimbatoreSathishkumar DhamodaranÎncă nu există evaluări

- LP ValveDocument72 paginiLP ValvetataircÎncă nu există evaluări

- DOW Ultrafiltration SFD 2660Document2 paginiDOW Ultrafiltration SFD 2660juliancardonaÎncă nu există evaluări

- 0D107Line ListDocument1 pagină0D107Line Listgeverett2765Încă nu există evaluări

- Aeration Solutions Comparison Chart - VlightDocument2 paginiAeration Solutions Comparison Chart - VlightprannoyÎncă nu există evaluări

- Shut Down Jobs of HRSG 1 & 2 DATEDocument2 paginiShut Down Jobs of HRSG 1 & 2 DATEmy shift DÎncă nu există evaluări

- MarthaCluster ApplicationProgramDocument115 paginiMarthaCluster ApplicationProgramGiovanni De CesareÎncă nu există evaluări

- Marketing Management of Ro SystemDocument16 paginiMarketing Management of Ro SystemPramit Kumar PattanaikÎncă nu există evaluări

- Envicare - Product - Water Softner ADocument2 paginiEnvicare - Product - Water Softner AshaileshvcÎncă nu există evaluări

- UZGTL ITB Index20121120Document69 paginiUZGTL ITB Index20121120Hyun Jin Yoo0% (1)

- Batching of Dosing Chemicals For BoilersDocument4 paginiBatching of Dosing Chemicals For BoilersDavid Muñoz CastroÎncă nu există evaluări

- HWTT Seawater DesalinationDocument33 paginiHWTT Seawater DesalinationGoedarz KarimiÎncă nu există evaluări

- NEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work InstructionsDocument7 paginiNEOPRSP001WI017 - Rev. 01 - Pages 07 - Cleaning in Place of RO System Work Instructionsalialharbi021Încă nu există evaluări

- 1000LPH RO System HinadaDocument5 pagini1000LPH RO System HinadaBrenda HaroÎncă nu există evaluări

- All Brochures ETIDocument33 paginiAll Brochures ETIPuji RahmawatiÎncă nu există evaluări

- 70-GD-MFB-001 (Rev B) TS - System Description and Operation Philosophy For MSF PlantDocument71 pagini70-GD-MFB-001 (Rev B) TS - System Description and Operation Philosophy For MSF Planta_mohid17Încă nu există evaluări

- Diligent Etp 1000m3Document18 paginiDiligent Etp 1000m3Prabhakar DhamaleÎncă nu există evaluări

- 0331-CAL-ING-014-010-0001 - R0 - HVAC System - Hydraulic - Calculation - Report PDFDocument302 pagini0331-CAL-ING-014-010-0001 - R0 - HVAC System - Hydraulic - Calculation - Report PDFOleg ShkolnikÎncă nu există evaluări

- Annexure II (Operation & Control Philosophy For SUF - REV 0)Document13 paginiAnnexure II (Operation & Control Philosophy For SUF - REV 0)Pankaj kumar SwainÎncă nu există evaluări

- WTP PresentationDocument23 paginiWTP Presentationdeepak2628Încă nu există evaluări

- Duhigg. Group Study From New York TimesMagazine. February 28 2016.Document10 paginiDuhigg. Group Study From New York TimesMagazine. February 28 2016.Jacqueline KBÎncă nu există evaluări

- RO-MAN Reverse Osmosis Manual For 200 and 300 GPD SystemsDocument15 paginiRO-MAN Reverse Osmosis Manual For 200 and 300 GPD SystemsasankandessÎncă nu există evaluări

- Safet Valve Data SheetDocument3 paginiSafet Valve Data SheetMathivanan AnbazhaganÎncă nu există evaluări

- PP10CC 00 3mav MR Abc 001Document9 paginiPP10CC 00 3mav MR Abc 001anbesivam87Încă nu există evaluări

- STG Instrument ListDocument12 paginiSTG Instrument Listhari reddyÎncă nu există evaluări

- 0591-8530-BQ-0001 - F1-Bill of Quantities PDFDocument13 pagini0591-8530-BQ-0001 - F1-Bill of Quantities PDFSoumiyaÎncă nu există evaluări

- LT-DC-LE130733-1-CI-503, RevFDocument28 paginiLT-DC-LE130733-1-CI-503, RevFSUSOVAN BISWASÎncă nu există evaluări

- 1000LPH RO System Quotation - HinadaDocument5 pagini1000LPH RO System Quotation - HinadaramzibtrÎncă nu există evaluări

- 100 PF01Document87 pagini100 PF01Việt Hoàng Bùi100% (2)

- 20-01-BRGA-MEC-RFQ-0002 - RevA RFQ For API PumpsDocument20 pagini20-01-BRGA-MEC-RFQ-0002 - RevA RFQ For API PumpsBagus SigitÎncă nu există evaluări

- 9504A-9504B Pump Skid As Build Drawing PDFDocument2 pagini9504A-9504B Pump Skid As Build Drawing PDFnull nullÎncă nu există evaluări

- Va Tech Wabag Va Tech Wabag Va Tech Wabag Va Tech Wabag Reliance Industries LimitedDocument1 paginăVa Tech Wabag Va Tech Wabag Va Tech Wabag Va Tech Wabag Reliance Industries LimitedRamKS80100% (1)

- Line List: Bandar Abbas Gas Condensate Refinery ProjectDocument31 paginiLine List: Bandar Abbas Gas Condensate Refinery Projectmb_sirousÎncă nu există evaluări

- Equipment at HPSDocument60 paginiEquipment at HPSSam100% (1)

- RODM PresentationDocument67 paginiRODM PresentationSekharÎncă nu există evaluări

- S Curves - DM PlantDocument6 paginiS Curves - DM PlantnikunjÎncă nu există evaluări

- 3000 GPDDocument6 pagini3000 GPDM.A. MonimÎncă nu există evaluări

- Desalination WriteUpDocument17 paginiDesalination WriteUpguptaaniruddhÎncă nu există evaluări

- Sea Water Intake System System DescriptionDocument39 paginiSea Water Intake System System Descriptionکالرو تحریک اتحادÎncă nu există evaluări

- Seapak Series: Integrated Ultrafiltration and Seawater Reverse Osmosis Platform For 1,000 - 10,000 M /dayDocument2 paginiSeapak Series: Integrated Ultrafiltration and Seawater Reverse Osmosis Platform For 1,000 - 10,000 M /dayadalcayde2514100% (1)

- Cooling Tower RO SystemDocument7 paginiCooling Tower RO SystemAbdul SamadÎncă nu există evaluări

- Control Philosophy - DM PlantDocument11 paginiControl Philosophy - DM Plantnileshwarke100% (1)

- Chemical DosingDocument24 paginiChemical DosingIskerÎncă nu există evaluări

- Control Philosophy - DM PlantDocument11 paginiControl Philosophy - DM Plantnileshwarke100% (1)

- Control Philosophy - DM PlantDocument11 paginiControl Philosophy - DM Plantnileshwarke100% (1)

- BFV For CW System1Document1 paginăBFV For CW System1nileshwarkeÎncă nu există evaluări

- MDBFP Mech. Seal ReplacementDocument3 paginiMDBFP Mech. Seal ReplacementnileshwarkeÎncă nu există evaluări

- ICICI Pru Iprotect Smart PDFDocument16 paginiICICI Pru Iprotect Smart PDFapsastryÎncă nu există evaluări

- My Family and Friends Worksheet 1Document2 paginiMy Family and Friends Worksheet 1Rabi Kumar PatraÎncă nu există evaluări

- 4 o PDFDocument1 pagină4 o PDFMihai DanielaÎncă nu există evaluări

- 5 U PDFDocument1 pagină5 U PDFnileshwarkeÎncă nu există evaluări

- 3 I PDFDocument1 pagină3 I PDFnileshwarkeÎncă nu există evaluări

- 1 ADocument1 pagină1 ALaura Figueira BarrosÎncă nu există evaluări

- 2 e PDFDocument1 pagină2 e PDFnileshwarkeÎncă nu există evaluări

- Exhibitor 35804 PDFDocument36 paginiExhibitor 35804 PDFulton1237624Încă nu există evaluări

- BSC (Hons) in Civil EngineeringDocument33 paginiBSC (Hons) in Civil EngineeringFaisal NazeerÎncă nu există evaluări

- Computer Science With Java by Sumita Arora Pdf. TutorialDocument3 paginiComputer Science With Java by Sumita Arora Pdf. TutorialSouryadeep MazumderÎncă nu există evaluări

- Supersonic AerodynamicsDocument54 paginiSupersonic AerodynamicsLuis Daniel Guzman GuillenÎncă nu există evaluări

- Scheduled Power Interruption For April 23-24, 2019Document1 paginăScheduled Power Interruption For April 23-24, 2019glaiÎncă nu există evaluări

- Medellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFDocument16 paginiMedellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFajay d1212Încă nu există evaluări

- Loadsand Load PathsDocument34 paginiLoadsand Load PathsAnonymous pD2ymRUgu0% (1)

- Quantum Multiport PackerDocument1 paginăQuantum Multiport Packersmithyry2014Încă nu există evaluări

- Class 10 Science (Physics) MCQs Chapter 11 QuestionsDocument28 paginiClass 10 Science (Physics) MCQs Chapter 11 QuestionsKSA TEXTILEÎncă nu există evaluări

- 64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BDocument18 pagini64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BChu Thi ThuanÎncă nu există evaluări

- 7749289-TheClandestineChemist 'Snotebook PDFDocument28 pagini7749289-TheClandestineChemist 'Snotebook PDFTonÎncă nu există evaluări

- OBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895Document7 paginiOBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895SwapnasaritÎncă nu există evaluări

- Chapter 11Document38 paginiChapter 11Ismail HussainÎncă nu există evaluări

- Problem Sheet 12-13 QuestionsDocument1 paginăProblem Sheet 12-13 QuestionsWill Morgan-EvansÎncă nu există evaluări

- Usage of D6T-44L - 8L - 1A Thermal SensorDocument23 paginiUsage of D6T-44L - 8L - 1A Thermal SensorEduardo ggÎncă nu există evaluări

- Foundation Engineering Shot NotesDocument21 paginiFoundation Engineering Shot NotesSejal VermaÎncă nu există evaluări

- Advanced Database - Chap 5Document84 paginiAdvanced Database - Chap 5Anhtho LeeÎncă nu există evaluări

- Report Torsion TestDocument27 paginiReport Torsion TestCherif ChokeirÎncă nu există evaluări

- LIDO Introduction PDFDocument127 paginiLIDO Introduction PDFStiliyana Bakalova100% (2)

- Engineering Major: Brandon University Courses by YearDocument2 paginiEngineering Major: Brandon University Courses by YearnavidÎncă nu există evaluări

- New Build Snagging List TemplateDocument13 paginiNew Build Snagging List TemplatekekerodeÎncă nu există evaluări

- Gasoline Direct InjectionDocument21 paginiGasoline Direct InjectionhoangÎncă nu există evaluări

- 132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Document134 pagini132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Sunil S I ShippingÎncă nu există evaluări

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 paginiData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Brochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Document20 paginiBrochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Fernando Cesar PérezÎncă nu există evaluări

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 paginiSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Volvo (Dem) and Haldex: History, Function, Diagnosis and RepairsDocument6 paginiVolvo (Dem) and Haldex: History, Function, Diagnosis and RepairsNecsaszNorbertÎncă nu există evaluări

- Design of Ms Pipe:: - (40 MM NB, Class'b'Document4 paginiDesign of Ms Pipe:: - (40 MM NB, Class'b'Kancharla Naga Ratna KumarÎncă nu există evaluări

- Credazone 6 GiudeDocument3 paginiCredazone 6 Giudeguddu84Încă nu există evaluări

- FonaDocument36 paginiFonaiyadÎncă nu există evaluări