Documente Academic

Documente Profesional

Documente Cultură

Tyre Tests Interpretation of Experimental Data: by Albert G. Fonda, M.S.

Încărcat de

Shaswata BoseTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tyre Tests Interpretation of Experimental Data: by Albert G. Fonda, M.S.

Încărcat de

Shaswata BoseDrepturi de autor:

Formate disponibile

348

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL

DATA

By Albert G. Fonda, B.M.E., M.S.*

The test techniques and associated equipment developed for use of the Air Force-Cornell

Tire Tester have permitted road tests yielding unique data on the cornering charaaer-

istics of pneumatic tyres. Account is given of tests performed for the Dunlop Tire and

Rubber Corporation, involving variations of inflation pressure (18 to 45 lb. per sq. in.),

camber (&30 deg.), and steer (f30 deg.) ;these angular ranges are unprecedented. The

tyres were nominally 5~00,6.00, and 7.00by 16 section, of normal construction but smooth

and round to eliminate effects deriving from tread pattern.

The ensuing data analysis was based upon familiarity with aircraft derivative notation,

the advantages of which are described, and upon simple tyre theory, which is outlined in

an appendix. The outstanding conclusions, from a practical standpoint, are (1) that

camber thrust strongly affects the static stability of the typical automobile; (2) that the

motor cycle operates with negligible slip angle below 35-deg. tilt, whereas above 35-deg.

tilt appreciable slip angle must be developed; (3) that a plot of pneumatic trail against

side force has great value because of its linearity and ready significance; and (4) that tyre

theory should be utilized to permit rational, concise interpretations of empirical data.

INTRODUCTION X , Y,Z Stability axes (or, with subscripts, other axes).

THEAir Forcecornell Tire Tester has been in use since x,y,z Distance components (or, as subscripts, directions).

May 1955 as a tool of research in the cornering character- a S-P, slip angle of test tyre.

istics of pneumatic tyres. The research has found its P Trail angle of fifth wheel relative to truck.

impetus in the relative exhaustion of less powerll methods S Steer angle of test wheel relative to truck.

of improving the design of not only tyres, but also the U Relaxation length (stiffness parameter).

vehicles on which they are used, including aeroplanes when $ Camber angle of test tyre.

moving on the ground as well as automobiles. This paper I I Absolute value; amplitude.

relates the experience of the Cornell Aeronautical Labor- For a further description of the stability axes and of the

atory (C.A.L.) in utilizing this flat-road tyre tester, describes notation, reference may be made to Appendix VI of Paper

certain of the experimental data so obtained, and pursues 111.

an analysis of these data to show their utility.

TYRE PARAMETERS

Notation Every invention passes through three stages: the first,

C aFy/ac(;C1 at front of vehicle, C, at rear. wherein requirements are approximately satisfied by in-

F Force component (with subscript) from ground on vention; the second, in which endurance is developed to

tyre. make the invention practical; and the third, wherein

K Lateral stiffness per unit cross-section. research and analysis fully develop the possibilities of the

L Length of free circumference of tyre. invention. The first and second stages have been essentially

I Half-contact-length of tyre. completed for the pneumatic tyre, but the third is still very

M Moment component (with subscript) from ground much under way. The activity of C.A.L. lies in this stage

on tyre. of research and analysis, the stage wherein the parameters

P Tyre inflation pressure. of tyre behaviour are defined, evaluated, and intelligently

S Circumferential distance around tyre equator. modified.

The MS.of this paper was received at the Institution on 30th August

1956. Cornering Properties

* Project Engineer, Military Tire Research, Vehicle Dynamics The basic fundons of tyres fall into three classifications:

Department, Cbrnell Aeronautical Laboratory, Inc., Buffalo,

New York,United States of America. ride, propulsion and braking, and cornering.

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 349

Tyre-cornering properties express those mechanical ‘Six ForceMoment’ Components

characteristics of tyres giving guidance of the vehicle upon Any solid or elastic body may be restrained by a set of three

its path. Principal of these is the relation of side force Fy forces at, and three moments about, some one point of the

to slip angle a, the lateral angle of attack of the tyre on the body. The Air Force-Cornell Tire Tester is a complete

road. However, to be more general, there are a number of and versatile facility by virtue of the fact that it measures all

dependent variables (drag, side force, overturning moment, six of these components under realistic conditions of

aligning torque, static deflexion, circumferential creep, etc.) operation. However, the action exerted upon the tyre by the

that are functions of a large number of independent ground (or on any body by any external medium) involves,

variables (load, braking moment, slip angle, camber angle, in general, not six but nine quantities. This occurs because,

idation pressure, rim size, cord angle, etc.). for three forces lying in mutually perpendicular planes,

This complex of functional relationships can be expressed there are six variables of position (that is, lever arms), two

as follows : for each force. Thus, in general,

F,, Fyy M,, M,, etc. = f (Fx, My,a, 4, P, rim, etc.1 (59) . rill, = YZFx-ZyFy . . . (62a)

where a real advantage of this presentation is the possibility, My= --x,F,+z$, . . . (62b)

obtained from concise notation, of expanding the relation M, = X~F~-Y,F,. . . . (62~)

into a detailed description of the relationships upon which It is evident by inspection that each moment vector has

data are needed. This process of expansion may use partial- two additive components, only the sum of which can be

derivative notation to isolate the various relationships. measured in terms of the restraining moments applied to

When applied to equation (59) without regard to the actual the body.

phenomena, derivative notation gives : If the axis system is carefully chosen, however, the lever

aF, aFy aFy arms may be made distinguishable, for under certain

a, a+ ap

Fy = /~+q5--kg-+Fz--+etc. aF, . (60) conditions one may be known, or if unknown, may be

assumed either minor or constant. Thus, for the ‘stability

where each partial derivative is the rate of change of the axes’ of the tyre, the six lever arms above become :

dependent variable Fy with one independent variable, y z Lateral offset of load (function of Fy and 4).

regardless of its variations with other variables. In many zy Rolling height of tyre.

instances, of course, a variable is determined as ‘dependent’ x, Longitudinal offset of load (function of rolling

or ‘independent’ merely according to the observer’s point resistance).

of view or the particular conditions of an experiment. z, Rolling height of tyre.

Anassumption implied bythe formof equation (60) is that xy Pneumatic trail.

each partial derivative is a constant, regardless of the value yx Lateral offset of drag (function of Fy and 4).

of any independent variable. Since, for instance, aFylacx = 0

at and only at F, = 0, this assumption is obviously in- The recognition of these six moment arms associated with

appropriate. A rearrangement, based on understanding of the three force components may result in rational inter-

the particular phenomena, may be made of equation (60). pretations from studies of otherwise uninterpretable

We may assume a set of standard conditions a = 0, q5 = 0, moment data. The original six measured variables might be

p = po#O, F, = F,o#O, etc., and then evaluate the rates supplemented by measuring, for instance, zy ss z, (rolling

of change of Fy (etc.) for variations from these conditions. height) from which may be gained a knowledge of y, and

Then, equation (60) assumes the more appropriate form x, (load offsets). Any such moment-arm analysis could not

be attempted without prior recourse to stability axes with

their inherent applicability to tyre behaviour.

The existence of six moment arms is a logical consequence

of the finite size of the contact area in which distributed

forces occur. This concept suggests another measurement

problem: what are the force distributions (apart from the

magnitude and location of the total force) in the contact

This equation shows a series of tyre-behaviour para- plane and at other boundaries? Even a six-component

meters (CoyaC/ap, azFYja+apetc.), each of which is a facility would need additional equipment to investigate

suitable subject for empirical research. By elaboration upon these problems. Fortunately, this type of problem is the

equation (61) (that is, by specifying the etc. in terms such exception; the general rule (gained from aeronautical

as construction effects or friction effects), a multitude experience) is that the six restraining components should be

of such derivatives are imaginable. From this long list of measured if a multi-purpose facility is intended.

unknowns must be chosen those of which the evaluation is

economically justifiable, and of these, a portion must be

scheduled into a programme which does not continue Optional Algebraic Signs

indefinitely. One such programme, and its results, is Even after an axis system has been defined, with its own

discussed in this paper. positive directions, a question of sign still exists at the point

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

350 ALBERT G. FONDA

of applying the chosen sign conventions to the measured teams would be needed, using the test apparatus in turn.

quantities. In the case of vectors, the question is whether However, the testing techniques, much less the demand for

an action is measured, or its equal but opposite reaction. the data, have not yet reached this stage of development,

For instance, the vectors F,, F,,, F, are defined in Paper I11 since, at present, each test programme requires some new

as those from the ground upon the tyre, rather than the item of equipment (with associated shakedown) to permit

opposite vectors from the tyre upon the ground (f,., fy, f, the desired technique.

according to Paper 111). Fortunately, most investigators The technique of greatest merit for steering is to hold

seem to adopt the assumption that the forces from the each desired angle for about three seconds and then to

ground upon the tyre are measured. Similar agreement does steer rapidly to a new angle. This procedure is continued

not exist for angles, notably slip angle a. The question in progressively to a positive peak, back to zero (with or with-

this case is one of observer location :is the ‘observer’ on the out pauses), then to a negative peak, and then to zero. The

wheel looking at the motion axes, or on the motion axes recorder is run continuously, but only the periods of steady-

looking at the wheel? The same lack of agreement exists state operation are subsequently analysed. The record-

between assumptions for aerofoil angle of attack, in flight reading apparatus permits a visual averaging which

and in the wind tunnel, and for basically the same eliminates the higher-frequency variations intentionally

reasons. passed by the signal filters.

The observer in flight is located at the wing, watching the A previous technique involved steering at an approx-

airstream; the observer outside the wind tunnel is aligned imately steady rate through the same sequence of angles.

with the airstream, observing the wing attitude. This Visual averaging of the resulting slanted traces was in-

situation corresponds to observers in the car as against those herently less accurate and produced more data scatter. This

on the tyre-test truck. The former leads to a = 8-S condition required, therefore, the reduction of many more

(where 6 is thought of as a modifier to a 8) as used in data to permit averaging after plotting. The newer tech-

Papers I1 and V, while the latter leads to a = 8-p (where nique consequently gives a major cost saving.

/Iis thought of as a modifier to a g S), as used in Paper I11 In developing steering techniques, an appreciable amount

and the present paper. The difference is irresolvable on any of effort was required for equipment development. As an

logical basis, and has never been resolved merely for the initial experiment, a hand pump was used to pressurize the

sake of uniformity in the aircraft industry. The convenience steering actuator, but this method proved too slow and

of a definition which pleases the respective types of ob- fatiguing. An electrical pump and accumulator were there-

server probably justifies the slight confusion in the auto- fore provided; the steer rates now available permit any

motive, as well as the aircraft, industry. desired type of steady-state test, and will also permit (if

controllable) many types of transient input when the

TYRE-TEST P R O C E D U R E S demand arises. The rapid fluid flow also flushes away air

The Air Force-Cornell Tire Tester has been in operation which could previously be removed only by bleeding at

since October 1954, on a series of programmes preceded fittings.

by a period of shakedown and technique development. At one time a technique was used in which the wheel was

The developed techniques fall into three classes, and are steered while up, stopped suddenly at a desired angle, and

performed in this order for any test programme : calibrating then dropped at known load. The sudden stop would

and zeroing, recording, and data processing. Appendix X produce system pressurization to minimize the compliance

describes the calibrating and zeroing procedures for the of the steering to the side force as it developed. However,

benefit of those who contemplate the construction and use the transient of truck yaw produced by the sudden side

of similar equipment. force required a long pause at steady steer angle, in order

to yield usable data. Thus, contrary to expectations, n a

reduction of tyre wear was achieved by this technique. In

Recording of Test Data actual fact, tyre wear under any technique, including the

The greater amount of the data obtained with the Air technique finally adopted, has been much less than ex-

Force-Cornell Tire Tester are obtained during outdoor pected. A tread life of 100 to 5,000 miles of test could be

runs, although some indoor data are obtained, including expected, of which only 10 miles is typically used.

tyre compliances and contact prints. In the outdoor tests,

records are taken while the chosen tyre is steered under Data Processing

chosen conditions of speed, load, pressure, camber, and

road condition. For the next run, at least one test condition Because the use of recording oscillographs is standard

is altered. Such runs are continued until the scheduled practice at the Laboratory, specialized equipment is on hand

series of tests on that tyre is completed. A typical number of for processing this form of data. This processing centres

runs per tyre is ten, and these can be completed in one to about IBM* digital computers that use punched cards. The

two hours. A number of mounted tyres can be carried on first set of data cards is produced from the oscillograph

the truck, so that a great mass of data can be gathered in a record by means of a combined optical enlarger and card

day of continuous testing. If this potential were to be

punch. Averaging is performed by the operator when he

continually utilized (as it is for a wind tunnel), several large * International Business Machine.

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 35 1

aligns a movable hairline with the chosen trace. The digital and Mz(aligning), vary with a,whereas drag F, and load F,

computer will then process the cards into printed tabula- remain essentially constant. These plots constitute the

tions involving all force and angle summations, as well as the basic presentation of all cornering-behaviour data ob-

calibration and zero factors. If resolution for camber is made, tainedon any programme. This form of the data is no longer

an intermediate set of cards is punched, sorted in terms of characteristicof the tester, but instead is characteristic solely

camber angle, and processed. Finally, the printed tabula- of tyre behaviour relative to stability axes. From this

tions are hand-plotted, although facilities have recently point, further analysis is a matter of the interpretation of

become available for automatic plotting. At various stages pure tyre data and will be discussed subsequently, in terms

after development of the record, the data are inspected to of a particular test programme.

detect errors such as faulty or mis-set instrumentation or

faulty calculation.

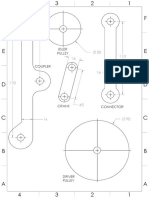

The resulting plots, shown in Fig. 58, are point by point DUNLOP-CORNELL TYRE T E S T S

presentations of three forces and two moments (braking By Spring of 1955, the Air Force-Cornell Tire Tester had

force being zero to date) against slip angle. Of these, the achieved the operational level specified by the Air Force, as

side force, F,, and its dependent moments, M, (overturning) proven by the short sample programme of actual tests

D U N L O P C O R N E L L TYKE TESTS

6.00 -It SRT TYRE 5 ' CAMBER 30 LB. PER SQ. IN. CODE:6 ABC 3

K KIM 0 SHEET I

u

z

Fig. 58. Typical Plot oj Dunlop-Cornell Data

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

b

Fig. 58. Typical Plot of Dunlop-Cornell Data

which followed the period of technique development, The variables chosen were steer angle (f30 deg.),

equipment development, and general shakedown. The Air camber angle (f30 deg.), and inflation pressure (18 to 45

Force had no immediate plans for testing, but did recognize lb. per sq. in.). The ranges were intentionally wide (f30

the benefits which would accrue from permitting use of the deg. being unprecedented) to guarantee recognition of weak

apparatus on programmes for the tyre manufacturers and trends and explore the boundaries of operation. Tyre size

the automobile manufacturers. Research upon automotive varied from a nominal 5.00to a nominal 7.00 on a 16-inch

tyres would not only specifically improve the apparatus, rim. Conventional carcass construction was used, but all

but would react favourably upon tyre design in general. tread was omitted. This gave a smooth, round, treadless

The first such sponsor, the Dunlop Tire and Rubber tyre (SRTT, Fig. 59) intended as a simplifiedmechanism for

Corporation of America, proposed an imaginative series of basic investigation. Load variations were omitted because

tests of interest to them and to their parent company in (1) only a vehicle applying the rated load of 925 lb. to each

England. The objective was to determine, over wide ranges, tyre was to be considered; (2) the cancellation of load-

the effects of predominant vehicle-operating variables and increase effects by load-decrease effects, both due to load

of tyre-size variables, in such a manner that the basic role transfer, was recognized; and (3) the omission helped to

of the tyre would be emphasized, to indicate criteria in the hold the programme to a tractable size.

choice of a tyre for a given vehicle. This problem of reasonable programme size occurs every

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 353

to be large; the programme is a 'family tree' with each

generation a type of variable ;the potentialnumber of tests is

extreme. The solution is to prune the tree vigorously until

it has a practical size and meaningful shape. The traditional

method of testing, resulting from extreme pruning, is to

change only one variable at a time from some standard

condition, on the theory that such effects can then be

superimposed. This method does drastically reduce the

programme, but in many instances cannot be justified.

C.A.L. has developed some special techniques for 'rationally

random' pruning, when needed.

The compromise reached in the DunlopCornell pro-

gramme (Fig. 60) resulted in a total of thirty-eight

different configurations, as actually run. These consisted of

thirty-four configurations obtained by means of the three

main variables, plus one for wet road (additional pressures

were planned), plus one repeat run per tyre (after comple-

tion of all other runs) to detect any wear effects. Fewer

pressures and cambers were used for the 5.00 and 7-00sizes

Fig. 59. Dunlop Smooth, Round, Treadless Tyres than for the 6.00 size. Four alternative seauences of steer

angle were used and three consecutive samples of each tyre

time a tyre-test programme is planned, the present one not size, in each instance to minimize effects of tyre wear.

excepted. The problem occurs because the number of Experience now indicates that tyre wear is less critical than

possible configurations is roughly the number of values of expected, so that better continuity of testing can be

each independent variable (other than a) raised to the power provided. These tests were performed in May and June

of the number of variables. Each of these numbers tends of 1955.

HOT PRESSURE, CAMBER, SLIP ANGLE,

LB. PER SQ. IN. DEG. DEG.

18

SECTION ROAD

7.00 DRY

18

D'(REPEAT)

30 0

>

CONSTRUCTION TREAD RIM LOAD C

STANDARD NONE 5K-16 925 LB.

/(4)SETTINGS

A &4' WET 38 0

.

33

A

25

B

C 2 IS', 20°, 30'

SAMPLE 2 LIFT-STEER-DROP

TECHNIQUE

: SETTINGS

C

D &3", 8', 15' 5-00 DRY 28 0, 0 REPEAT

SAMPLE 3 D

13 * 0

Fig. 60. Dunlop-Come11 Tyre Test Programme

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

354 ALBERT G. FONDA

CONVENTIONAL ANALYSIS OF T H E D A T A indicate that the small tyre could be operated ‘under-

The Dunlop-Cornell tyre tests resulted in thirty-eight pairs inflated’to improve its ride and still obtain the samecornering

of basic data plots, one pair of which has been shown (Fig. stiffness as a larger size. The data above 30 lb. per sq. in.

58). This form of thedata is farfrom being readilyinterpret- for the 6.00 tyre show a cross-plot slope graduallydecreasing

able, since the effect of any variable, except slip angle, can to about 1 lb./deg. per lb./sq. in. at 45 lb. per sq. in. Thus,

be detected only by comparison between similar curves of in terms of cornering stiffness, the effectiveness of increased

which the differences are not obvious. Analysis should be pressure decreases as the pressure increases.

performed which will reduce the basic data plots to under-

standable commentary on tyre behaviour. This commentary

should have utility for both tyre design and vehicle design.

For both these purposes, the form of the data will steadily

gain utility as it approaches the form needed for equations

I60 h

of vehicle motion.

Midway in this process is a significant transition form:

graphiccross-plotsof the slopes, peaks, intercepts, etc. of the

basic data plots, against some independent variable. Each

such crossplot thus reveals the effects of one such variable.

Cross-plots as such are a conventional tool, but their full

potentialities are often not utilized. The fairing of lines to

fit data on a cross-plot can give a true improvement of testing

accuracy, as extraneous effects tend to be thus faired out.

These lines, if straight or nearly straight, may then be

mathematically expressed as slopes and intercepts. For

Dunlop, a full cross-plot analysis was made of the thirty-

eight plots of side force (F,) against slip angle (a),beginning

with the fitting of smooth curves to the data, followed by

evaluation and tabulation of the slopes, intercepts, positive

peaks and negative peaks of these curves. From this tabula-

tion, all the cross-plots (Figs. 61 through 65) were made.

OO l 20

PRESSURE-LB.

40

PER SQ. IN.

60

Fig. 62. Cornering Stiffness against Pressure

0 5.00-16 6.00-16 + 7.00-16

Similar plots of cornering stiffness against camber were

made, but, contrary to curves appearing in the literature

(BulP), no definite trends appeared. On the other hand,

camber does definitely affect the Fy versus 01 intercept. This

‘camber thrust’ plottedagainst camber angle (Fig. 63) shows

a surprisingly constant slope to 30 deg. for all tyre sizes.

The result may be compared with the traditional ap-

proximation Fy= W tan 4 which, only by coincidence, also

expresses the condition of tilt equilibrium for the motor

cycle. A tangent 4 function is not straight, but curves

5.W TYRES

PRESSURE-LB. PER SQ. IN.

6130 TYRES 7.00 TYRES

upward until, at 30 deg., its slope has increased by 34 per

cent and its height by 10 per cent. The observed slopes (Fig.

Fig; 61. Cornering Stiffness against Pressure (fmeach tyre 63) were 20,16, and 17.5 lb. per deg. at the nominal 925-1b.

size) load, as compared with an initial slope of 16-1 lb. per deg.

for a function of 925 tah 4. Therefore, as an approximation,

The slope aFy/aa, or cornering stil€ness, is plotted against the tangent 4 function varies from excellent to poor, de-

pressure for each tyre size (Fig. 61) and superimposed for all pending on the tyre and the camber angle. A later dis-

three sizes (Fig. 62). Evidently, tyre size has little effect on cussion will show the significance of this distinction with

this result, since all three sizes show a stiffness of 115 lb. per regard to the motor cycle.

deg. at 25 lb. per sq. in. and substantially equal variations Average peak side force plotted against pressure (Fig. 64)

with pressure (3-3lb./deg. per lb./sq. in.). The ‘standard’ indicates that values on the order of the tyre load are easily

pressures had been chosen for equal tyre deflections, being attained, and in fact, exceed it. This fact indicates that

28 lb. per sq. in. for the 5.00,25 lb. per sq. in. for the 6.00, despite the seemingly adverse conditions, friction coeffi-

and 23 lb. per sq. in. for the 7.00 sizes. These data thus cients are attained on the road equal to those attained in the

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

T Y R E TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 355

+-DEGREES

5M) TYRES 6.00 TYRES 7.00 TYRES

o 30 ib. per sq. in.

0 25 lb. per sq. in.

+ 20 lb. per sq. in.

Fig. 63. Camber Thrust against Camber Angle

PRESSURE-LB. PER SQ. IN. PRESSURE-LB. PER SQ. IN. PRESSURE-LB. PER SQ. IN.

5.00 TYRES 6.00 TYRES 7.00 TYRES

I, 200

1,000

925

800

a

2

I

600

P

Y

9

;

;

400

200

0

10 20 30 40 50

INFLATION PRESSURE-LB. PER SQ. IN.

b

Fig, 64. Peak Side Force against Pressure

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

356 ALBERT G . FONDA

lMOTOR CYCLE I.F.S. IMOTOR CYCLE I.F.S. IMOTOR CYCLE

*I.F.S. I 7 I

"'

-20 -10 0 10 20 -20 -10 0 10 20 -20 -10 0 10 20

F,r/J

--

'l" DEG. -- DEG. -- DEG.

I51 I5I IF, I

5.00 TYRES 6.00 TYRES 7.00 TYRES

Fig. 65. Peak Side Force against Camber

laboratory (1121.0). The effect of pressure is to increase tyre design could be optimized for a particular car or type of

peak side force at the rate of about 10 lb. per lb./sq. in. in car. These comments are made in recognition of the fact

the range of standard inflation 5 5 lb. per sq. in. Increases that presentation of data is an inescapable problem when

of tyre size in this pressure range (Fig. 64b) cause increases tyre tests are made, and that a standard means of presenta-

of peak side force. As the pressure rises beyond 30 lb. per tion is as desirable as a standard notation.

sq. in. for the 6.00 tyre, the peak force drops and then In the case of aligning-torque data, there are to date

rises again. The isolated test on a wet road shows p = 0.63 even fewer standardized presentations than for side-force

at 38 lb. per sq. in. for the 6.00 tyre. Lack of time and lack data. The practice of plotting side force against aligning

of suitable weather precluded further wet-road tests. torque was introduced by Gough115 and thoroughly

The effectof camber on peak side force is shown (Fig. 65) discussed by him ; its many advantages do not need to be

by plotting the peaks against a special parameter Fy4/lFy1. repeated at this time. C.A.L. has plotted a portion of the

This parameter has the magnitude of 4, but the sign of Dunlop-Cornell tyre data on similar co-ordinates (Fig. 66).

Fy+,and is positive for a motor cycle rounding either a This plot shows, for comparison, two similar tyres drum

right- or a left-hand curve. The typical independent front tested by Dunlop of England (Goughl15. 118). The data

suspension, on the other hand, has negative 4 due to the fall mainly in the fourth (and second) quadrants, because

body roll for positive Fy and vice versa, so that Fy+ is

always negative. The positive cross-plot slopes (2.0,2.7, and Table 6. Tyre Derivatives for Three Tyre Sections

2.5 lb. per deg.) indicate that camber of the motor cycle type

will increase the peak side force available from a tyre. I 1 1 7-00 1

Parallelogram suspension will, on the other hand, decrease

available peak side force. This effect is strongest, the data

shows, for the smallest tyre. The implications of these

camber effects for both the motor cycle and the automobile

aa

Tyreseaion

a = Of3 deg.

p = 251b.per

Fz= 925 lb.

1 1 I I 5.00

115

6.00

'15

115

Units

lb. per deg.

will be presented in a later section.

a = Of3 deg. 3.3 29 3-1 lb./deg. per

A summary of the various cross-plot slopes may be p = Std. f51b. lb./sq. in.

concisely presented, Table 6, by the use of derivative

notation. Values of derivatives could be similarly quoted in -- ,

handbooks if such notation were used, just as rated load,

dimensions, and rolling radius are now quoted. Load effects

could be expressed by additional derivatives, such as

a2Fy/aFzaawhich is, numerically, the slope of the popular

Fy versus Fz curve for a = 1 deg. The aeronautical designer

uses such listingsof derivativevalues,from wind-tunnel tests,

p = Std. f 5 !b.

+=0

per sq. m.1

10

I 1 -1

10 12.5 Ib./deg. per

lb./sq. in.

to choose among aerofoil sections. The automotive designer

could do likewise if such tyre data were available. Further-

more, judgements could be formed of desirable values, and

these could be specified as tyre design objectives. These

I-

TY)PCak

a+

p = Std.

4 = Of30deg.

2 for

7for

2.7 2 5 lb. per deg.

criteria might well vary from make to make of car, so that a (Largest values underlined ; note lack of consistency.)

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 357

M , is mainly negative for positive F . By placing side force UNCONVENTIONAL ANALYSIS OF THE DATA

Y

on the abscissa, the major convexity is up and down, rather After the M, versus Fy plot for the 0 to 30 deg. slip-angle

than lateral, and the plot becomes a 90-deg. rotation of range was inspected, it seemed that, despite the interesting

Gough's choice. shape of the curve, it was too confusing a curve; to be

more precise, it was too curved. It is the nature of any

phenomenon that once functions of the data are found that

give a straight-line data plot, these fmctions, be they simple

or complex, very probably have true relevance to the nature

of the phenomenon and are, in any case, of great utility.

Therefore, it is valid to plot and replot data until a straight

line is formed, so that an empirical relation (form mx+b on

those co-ordinates) can be fitted. This gave justification for

continued analysis involving unconventional co-ordinates .

However, such trial plots are preferably not made at

random, but with some intuition and understanding of the

problem. There were many clues available in the case of

these tyre data. Aligning torque can be regarded as an input

applied by the driver (via the steering wheel) to the tyres,

whereby the tyres produce the side force on the vehicle a d

on the driver. Thus, in the sense of servo mechanics, the

input M , and the output F,, are coupled by the transfer

function Fy/Mz (output against input). In the kinematic

sense, MJF, is a force-ratio mechanical advantage of the

0 200 400 600 800 driver over the lateral acceleration force. In equation (62c),

SIDE FORCE FY-LB. we noted M , = xyFy-y,F,; since y , and F, should both be

small, M , / F y ~ x ywhich

, is also significant. Finally, Gough

Fig. 66. Comparative M , against Fy Plots

had already shown lines of constant M,/Fy, pneumatic

7.60-15 trail (Fig. 67), on his Fy against M , plots. These reasons

1,000 Ib. load led to the trial of a plot of pneumatic trail ( t ) against side

24 lb. per sq. in. inflation

From Gough-Fig. 10 (Ref. 118). force (Fy), which is an innovation, so far as is known.

6.40-15 on 44 J Rim

8 cwt. (896 lb.) load I I I I

24 lb. per sq. in. inflation 200

From Gough-Fig. 6 (Ref. 115)

7.00-16 Treadless on 5 K rim

925 lb. load

23-25 lb. per sq. in. inflation (hot) 0

From Dunlop-Come11 Tests, June 1955.

Such data have, it is believed, never been presented ai

J

1. -200

for slip angles beyond about 10 deg. As shown, a minor z

lateral convexity occurs, because of (1) the reduction of I

side force after its peak, combined with (2) the correspond- 2

I

ing positive increase of aligning torque. Neither quantity -400

varies rapidly with slip angle in this region, so that, on the

M, versus F,, co-ordinates, these slip angles are quite

closely spaced. This plot of Dunlop-Cornell data shows - 600

stronger aligning torque and less slip angle for a given side

force than the English data, in the region from 0 to 8 deg. of

slip angle. This must be the result of (1) drum-to-highway

difference, (2) tread-to-treadless difference, or (3) con-

struction-and-diameter difference, in order of decreasing

likelihood. More data are needed to distinguish further

among these possibilities. Only a limited amount of data

were analysed in this manner, with the objective of showing

the shape of the curve for extreme slip angles. However, The result (Fig. 68) is shown, in this case, on an outline

such comparisons constitute definite progress toward a final of the actual contact area of the tyre tested. This display is

understanding of the relationship between the drum test appropriate, because t versus Fy shows the position in the

and the more valid, but more difficult, highway test. contact area of the side force, against its own magnitude.

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

358 ALBERT G. FONDA

OUTLINE OF ACTUAL PRINT

KINGPIN OF TYRE AS TESTED

MECHANICAL L°CAT’oN

Fig. 68. Pneumatic Trail Against Side Force

--DEGREES

Thus, the plot has very real physical significance in terms CI

lof conditions in the contact area. The kingpin location can Fig. 69. Side Force and Aligning Torque Against Slip Angle

be spotted on this plot to show mechanical and total trail. ( a ) t = -2~56+0.0031F’

Another graphic advantage is the great compaction of data (b) t = -2.38+0.0025Fy

in the skid region, from 10 deg. to 30 deg., into the near ( c ) Curved t versus Fy

vicinity of the friction limit and zero trail. This compaction

is quite appropriate because slip angle is of little importance be expressed as (aM,/aF,), a2M,/aFY2, and aFy/aa; a

to tyre behaviour in the skid region. The equispacing of fully ‘force-moment derivative’ form of notation thus ap-

trail values desirably avoids the expansion of small values, pears. These moment derivatives could be added to the

which was observed (Fig. 67) at these large side forces. list which was proposed for inclusion in reference hand-

On the other hand, perhaps too much attention is called to books.

t at s m a l l values of Fy. Since it is difficult to measure t from Pressure, load, and tyre construction would, of course,

M , and Fy when both are small, it may, by the same token, affect the values of these derivatives. Some pressure effects

be unimportant to the driver ; this possibility requires were revealed (Fig. 70) when actual data values o f t against

further investigation. Fy were plotted for four of the thirty-eight configurations

But the most significantfact, by far, is the close approxi- tested. Before these plots were made, Mz against F, was

mation to linearity exhibited by this t versus Fy plot. It plotted for the a = f 5 deg. range and a straight line was

appears that we have found-much more easily than would fitted; its slope gave an approximation of to, shown by

have been expected-a set of co-ordinates upon which broken lines, whereas its negligible intercept indicated little

aligning-torque data become linear. This linearity allows error, at Fy = 0, in the average M,. The increased values of

fitting of a straight line of the form t = ti+lFyI(at/aFy) trail with decreasing inflation pressure evidently occur

where ti is the intercept and at/aFy is the slope. The advan- because of the greater contact length at lower pressure. The

tage is that only two parameters need now be specified as a cross-plot would certainly reveal a derivative such as i3to/ap.

replacement for the whole complex M , versus Fy curve. Two However, there comes a point at which purely empirical

such functions were tried as approximations to the original investigations reach a point of diminishing returns, because

data curve,namely (a) t = -256+O.OO3l1Fyl, which was a of excessive complexity. A proper application of tyre-

fit to the steeper slope appearing from 1 deg. to 4 deg., and behaviour theory should greatly simpllfy such a situation by

(b) t = -2-38+040251Fyl, which was a fit to the data from revealing broader significances hidden in limited empirical

5 deg. to 11 deg. For all three curves M , versus F, was data.

tabulated, then plotted (Fig. 69) against a; the latter The present problem can be approached by the method of

required use of a corresponding F. versus CL curve. non-dimensionalization, namely of the t versus Fy curve,

Evidently (a) is a poor appromation beyond 4 deg., since we know that a reduction in the total number of

whereas (b) is good below 5 deg. (in fact excellent below variables affecting the curve can thereby be obtained. Side

3 deg.), and is thus a valid means of calculating M , from Fy force, F,, can obviously be non-dimensionalized by the

in the region a = f 11 deg. Since the approximation Fy = divisor F, (normal load), and gives a ‘cornering coefficient’

aaF,/aa can be applied up to 6 or 8 deg., the whole normal Fy/Fz (Goughl15)on the abscissa, with the value Fy[F, = p

operating range for both M, and Fy is covered by only three corresponding to peak side force. The divisor for t should

tyre parameters: ti, at/aF,, and aFy/aa. These can also have length units; for instance, as Gough suggests, the root

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 359

I

z

-.-I

I

-2

-3

z _I

I

-2

-3

-1.000 -800 -600 -400 -200 0 200 400 600 81x) 1,000

Fj -LB. F -LB.

U b

High pressure : Standard pressure : Low pressure: Standard pressure :

(30 lb. per sq. in.) 7A3 Do (25 lb. per sq. in.) 7A7 DQ (18 lb. per sq. in) 7A14 Da (25 lb. per sq. in.) 7A7'

(30 lb. per sq. in.) 7B3 0 (25 lb. per sq. in.) 7B7 (18 lb. per sq. in.) 7B14 0 (25 lb. per sq. in.) 7B7'

(28 lb. per sq. in.) 7C3 +

(23 Ib. per sq. in.) 7C, 0 7 w (18 Ib. per sq. in) 7C14 +

(23 lb. per sq. in.) 7C7'

Fig. 70. Pneumatic TraiI Against Side Force for Various Pressures

of the product of tyre diameter and tyre deflexion. There is in which 1 is the half-contact length and u is the relaxation

more basis in theory, however, for the divisor t,, the value length, a stiffness parameter of the tyre. This expression

of pneumatic trail calculated from a theory such as that may be plotted as values oft, against 1 for various values of

theory given in Appendix XI. This value is obtained by u (Fig. 71).

dividing the expression for M,, equation (73), by that for The stiffness parameter u may be evaluated in a number

Fy,equation (74), giving : of ways (Appendix XI) ;for present purposes, the easiest

method was to evaluate the standing lateral stiffness

aFy/ay and to divide this into the cornering stiffness, giving

the sum l+u. Tyre contact prints were made to give

measurement of 1; the resulting values oft, shown in Fig. 71

1 - IN. were in fair agreement with corresponding values of to.

0 I 2 3 4 5 6

(The largest uncertainty was because of hysteresis in Fy

against y.) I n the resulting plot of t/t, against Fy/Fz(Fig.

72), the value of t/t, at Fy = 0 would be 1.0, if the theory +

Fig. 71. Calculated Pneumatic Trail Against Half-contact 0 0.2 0.4 0.6 0.8 1.0 1.2

Length

IFylIFz

Fig. 72. Ratio t / t , Against Ratio Fy/Fz

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

360 ALBERT G. FONDA

were complete in all respects. The theory used predicts a computing process in which the theoretical equations are

constant trail, regardless of Fy; the observed reduction of utilized. This simulator must be provided with data

trail with Fy is a function of tyre-to-road slippage, not regarding the vehicle constants, the tyre behaviour, and the

considered in this theory. This decrease is therefore an disturbing inputs (including those of the driver). The

empirical function of the tyre-road friction coefficient p. resulting calculated behaviour must be judged good or bad,

Therefore, the non-dimensional plot (t/t,) against according to the same subjective criteria the driver-critic

(Fy/F,) consists of a family of curves for various values of p would utilize. Ultimately, such a simulator can become not

and p only, at least for normal ranges of pressure, load, and merely an automobile simulator but a tyre, car, and driver

even tyre construction. This plot promises, therefore, to simulator. To attain this level, the automobile simulator

give a ‘master curve’ which is valid for a great variety of should be expanded at one end to include tyre theory, so

operating conditions for various tyres. Then by making that laboratory data (for example, 1, u, and I-)may be used

simple, cheap, non-rolling tests upon tyres, that is, lab- instead of road behaviour data; and expanded at the other

oratory tests, values of I and u for various conditions end to include driver behaviour, both as an element in the

could be determined. These would become the handbook control loop and as an ‘excellence meter’ incorporating

values from which, by use of the master curve, M , versus subjective-opinion criteria.

Fy could be found for given p and F,. Further laboratory Tyre-behaviour data are obviously indispensable to the

measurements of the second basic stiffness parameter, K accomplishment of this goal. Like any link in any chain, the

(Appendix XI), would allow prediction of the Fy versus question is not whether it is needed, but of how difficult it

a behaviour, at least in the linear region. It would seem is to forge this link to the required minimum strength. It

profitable, therefore, to place h t u r e emphasis on the use of seems apparent that tyre-behaviour data are at present one

tyre theory to interpret tyre data, rather than to rely of the weakest links in the vehicle-dynamics chain. It seems

entirely upon the empirical approach, since it is possible furthermore that the most profitable approach will be found

thereby to reveal the hidden significances of empirical data. in the verification and use of tyre-behaviour theory allowing

complex predictions from simple observations.

UTILITARIAN SIGNIFICANCE

Specific Applications

General Philosophy Utilization of the data on tyre behaviour obtained on the

The ultimate goal of human research is human benefit; the Dunlop programme may be demonstrated in two examples,

research is conducted on the assumption that, by ‘studying both showing the effect of camber, for the automobile in one

and understanding’ a phenomenon, ways can be found to case and the motor cycle in the other. The latter will be a

make better use of that phenomenon. ‘To study’ implies the unique study permitted by the unique data. The former

collection of empirical data, whereas ‘to understand’ will demonstrate the utility of derivative notation.

specifies that theory be devised whereby such data may be It is known to many that the adoption of independent front

thereafter predicted. Such predictions of complex phe- suspension (I.F.S.) in lieu of a solid axle not only avoids the

nomena necessarily proceed, ultimately, from observations problem of shimmy, but also increases the static margin of

of simple phenomena. The merit of the entire process lies the car by moving the neutral steer point aft a good 6 inches.

in the probability that the ultimate goal can be more This increase occurs because, with I.F.S., the wheels are

economically achieved by simple observation plus theory, maintained approximately parallel with the body and thus

than by complex observation. In many instances, it is only produce camber thrust which reduces the side force at a

after considerable research that specific, rather than general, given slip angle. This effective reduction of front cornering

objectives can be stated; this accomplishment is another stiffness can be calculated from two tyre derivatives and the

advantage of the method. vehicle derivative d+ldFy, the rate of (front) wheel camber

To apply this philosophy to vehicle dynamics, we may with side-force-per-wheel. For a typical American sedan,

note that the complex phenomenon of vehicle behaviour is d41dFy is -0.009 deg. per Ib. which signifies -1 deg. of

observed every day by the millions of people who drive and camber per 111 Ib. of side force. The pertinent equations,

ride in our various forms of transportation. This mass of assuming constant pressure and constant average load, are :

observation, however, produces little analytical criticism of aFy aFy

vehicle behaviour. Even a trained, professional driver-critic aa a+ for the tyre, and

Fy = a-++C-

is hampered by the confusion of data in any single driving

test, and by the great difficulty of altering the conditions of d4

test. The trial-and-error construction of prototypes for this

4=F

dFy

for the automobile.

-

purpose is expensive in the case of the automobile, pro- Substitution of the second into the first, differentiation,

hibitively so in the case of the aeroplane. The alternative to and rearrangement gives :

this procedure is to replace the vehicle, for example the

automobile, by the more economical simulator. This may

be an analogue computer constructed on the basis of a

theory of automobile behaviour, or even a mathematical

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 36 1

C 2 / C l + C 2 . This increase equals a 9-in. rearward re-

location of the neutral steer point. Thus, I.F.S. camber

thrust (a type of roll steer) is revealed as the predominant

contributor to the understeer of modern automobiles.

Designers may well consider variations of the tyre para-

meter aF,/a+ as opposed to variations of the vehicle

parameter d+/dFy.The effectof independent rear suspension

upon neutral steer point (Bastow59) should also be recog-

nized.

Whereas, for the automobile, slip angle is primary and

camber angle is secondary, the roles are (as recognized by

Wilson-Jones'87) reversed for the motor cycle. This fact

may be demonstrated by a plot of side force against slip

angle for various camber angles (Fig. 73), based on Dunlop-

2 4 6 8 10 I2 14 15

SLIP ANGLE, a -DEGREES Cornell data, but somewhat idealized. The dotted line for

I.F.S. demonstrates the above-calculated reduction of slope,

Fig. 73. Side Force Against Slip Angle fm Various Camber and extends the trend to peak side force. The nearly vertical

Angles line for motor cycle behaviour demonstrates the minor im-

portance of slip angle in the normal operating region, that

Substituting previously quoted values for the tyre is up to 35 deg. tilt (ay = 0.70g). Beyond this point,

derivatives gives : appreciable slip angle is required, rising to about 4 deg. at

48 deg. tilt, the motor cycle's potential limit. The same

dF,=-- 115

17 - 99.5 lb. per deg.

conclusions can be drawn more accurately from a plot of side

du .

force against camber angle for various slip angles (Fig. 74).

l+m The motor cycle, when in equilibrium in tilt, must operate

This value is the effective front cornering stiffness with +.

along the line F,, = W tan Although the tyre data are only

I.F.S. The loss of 15-5lb. per deg. compared with a solid approximate above Fy = 700 lb. or 4 = 30 deg., it is evident

front axle is a 14 per cent reduction of the effective that the potential limit is approximately 4 = 48 deg. with

CI= (dFY/dw),,and a 7 per cent increase of the effective a = 4 deg. This rather amazing potential (a,, = 1-15g) is

LIMIT OF DATA

I .ooo

800

m

A

, 600

ir.

L

Y

Y

9

UJ 400

G?

*

200

C

-I 0 0 10 20 30 40 50

CAMBER ANGLE, 4 - DEG.

Fig. 74. Side Force Against Camber Angle for Various Slip Angles

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

362 ALBERT G . FONDA4

not realizable for the American touring motor cycle because method may be used exclusively. By ‘noise’ is meant, first,

its crash bar will rub on the ground at about 35 deg. or 40 audible noise (including squeal) and, second, tyre-behaviour

deg. of tilt. The resulting transfer of load to a metal surface noise. Appreciable attention has been given to audible noise

reduces the side force and causes a skid-out, and also recorded on magnetic tape and studied, in some cases, by

reduces the righting moment due to side force. This reduc- spectral analysis. The ease and precision of controlling the

tion will probably exceed the increase due to load transfer ; test variables is a functional advantage, opposed by the

the net excess overturning moment introduces a ‘spill’ as undesirably high ambient noise level of the truck. Study of

well as a skid. the transient variations of inflation pressure may be of value,

A competition motor cycle uses no crash bar and has a and methods for doing so are at hand. The second type of

raised foot-rest and a raised silencer or none at all. The noise, tyre-behaviour noise, has been only cursorily eval-

steady tilt angle of the motor cycle, when operated by a uated to date. By use of the two-axis recorder, continuous

master rider over a smooth, lugh-fiiction surface, can indeed (intinite-number-of-point) plots have been obtained of

approach 50 deg., with cornering speeds well in excess (5 to side force against slip angle and aligning torque against

10 per cent) of those for automobiles on the same course. side force (Fig. 75). The force and moment signals were

Under less ideal conditions, one vehicle or the other may lightly filtered, sufficient only largely to eliminate recorder

hold the advantage; the differences are complexly de- overshoot. These records reveal that the side force is slightly

pendent upon course layout and surface condition versus noisy, and low-speed tests have indicated that this results

accelerating and handling abilities. A critical factor for the mainly from irregularity of pressure distribution and carcass

motor cycle is road roughness, since it causes reduction of stiffness in the contact area, rather than from inertia-

load and, hence, of side force and righting moment. The induced load variations. The much greater noisiness of the

excess overturning moment will then induce a falling torque would be, understandably, explained by the same

motion which is combated by the natural free-control phenomena. This high noise level explains the difficulty

stability (Wilson-Jonesl87)of the cycle and by the driver’s experienced in obtaining consistent torque data. In either

reactions. There will be, for instance, increased steer angle, case, any apparent average behaviour differences (attributed

hence, increased slip angle and perhaps increased side force. to other variables) may be questioned when they approx-

However, at a tilt angle of say 40 to 45 deg., the recovery imate or are smaller than this behaviour noise. Indeed, the

tendency will not be sufficient, and consequently, a sudden apparent close repeatability of the cornering stiffness (137

spill will occur. It is interesting to debate the effect of, for and 138 Ib. per deg. in Fig. 75) cannot be maintained on the

instance, centre-of-gravity height, which in the steady average, although no rigorous tests for repeatability have

state is irrelevant. Investigations at C.A.L. are in progress been made.

to obtain tyre data from normal motor cycle tyres, with their With regard to the future, the possibilities in testing may

differences of construction, to compare with data on the be expressed in terms of possible modifications of the

Dunlop SRTT. equipment, some probable and some improbable. The most

improbable is the extension of tyre-behaviour data in dry

CONCLUSION sand (Kerrllg), because the present device does not have

the ideal functions for this type of test, nor could it main-

Recent, Current, and Future Tyre Tests tain those it does have under sandy conditions. A possibility

The Air Force-Cornell Tire Tester has been utilized since is the testing of motor cycle tyres at 30 deg. to 50 deg. of

the Dunlop tests for various programmes of ‘cornering- camber; most likely this test would involve no changes to

behaviour’ tyre tests. That is, various independent variables the tester, but would rather involve provision of a ditch to

such as pressure, load, camber, and construction have been accommodate the lowered load cell, while testing at low

investigated to discover their effects upon the tyre force-and- speed.

moment versus slip-angle behaviour. In these cases, the A series of major modifications actually under way are

results are still under study and have not yet been reported. those for the Tire Dynamics Investigations being sponsored

Such tests do, however, constitute the major field of suit- by the Air Force (MRB, ARL, Wright AFB), which will

ability of this research device, and the number of con- furnish data on both transient and steady-state tyre be-

ceivable research problems (even among the above-quoted haviour. These data are needed for continued analysis of the

variables) is virtually unlimited. It is becoming evident serious military problem of aircraft nosegear shimmy. For

that this vast programme must be guided according to this programme, instrumentation modifications will include

the suggestion of Hadeke1105 (Appendix XI) and others, new strain-gauge circuits by which each bridge gives a total

namely, that the empirical data should be analysed on a force or moment, rather than a component axle-tip force ;

basis of tyre theory. Thus, the whole programme is en- and will include accelerometers by which any hub-and

compassed by and implicit in the problem of developing wheel inertia effects are removed from the side force and

and verifying tyre theory. The major use of the Air Force- load signals. Equipment modifications include a steering

Cornell tester, both current and future, therefore lies in the servo-mechanism for pulse or sinusoidal inputs, a brake

gradual solution of this problem. installation, and a dual-wheel installation. The complexity

In research involving tyre noise, the analytical method of this programme is a natural consequence of the desire to

immelately becomes highly complex and the empirical predict prototype behaviour, rather than to chance a

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AND INTERPRETATION OF EXPERIMENTAL DATA 363

(a) Side force against slip angle.

(b) Aligning torque against side force.

Fig. 75. Data of Two-axis Recoroh

prototype disaster. The resulting enlargement of the range of tyre behaviour m a y also be correlated, by means of

capabilities of the tester will be of importance also to non- tyre theory, with friction studies on the contacting materials.

military interests. Effects of road roughness might be investigated, prefer-

The brake installation, for instance, will be important ably at low speeds to eliminate suspension effects. On the

for tests of tyre braking behaviour without slip angle and, other hand, an oscillating test load might be applied to

even more significantly, cornering behaviour with braking. duplicate, on smooth roads, rough-road and suspension

The effect of propulsive torque on cornering behaviour effects. Additional sensing elements might be added to

should also, eventually, be investigated; it is just possible detect the steady and/or transient force distributions, as

that the Air Force’s dual-wheel installation will permlt one well as the force-moment totals. A related investigation

wheel to supply the other with power. With the brake would be the construction of an i n s m e n t e d wheel or

installation, the peak braking force as well as the peak side suspension to allow force-moment measurements of tyres

force (and transitions thereto) may be investigated with on the car; slip-angle measurements would be required in

respect to road materials and surface treatments. The 111 addition.

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

364 ALBERT G . FONDA

Speed effects might be investigated either in the zero-to- protractors or inclinometers. Horizontal forces are applied with a

cable, pulley, and chain hoist from a lift truck and are measured

critical range where they are minor, or in the critical range, by a hanging beam balance. Vertical forces are applied by the

where the internal masses and dampings of the tyre are tester-loading system against a platform beam balance through an

excited with sufFicient rapidity to be influential. (Another hydraulic jack. Recently some continuous calibrations have been

type of speed effect involves the 6lm break-through time on made, in which each tester strain-gauge-beam signal was con-

wet roads). If necessary, the top speed of the truck could be tinuously and immediately plotted against a strain-gauge-proving-

ring signal by means of a 2-axis recorder. Prohibitive time would

raised (for instance, by Jato units, with a tail fm for stability) have been required to obtain, read, and plot the same information

or the truck could be replaced by a high-speed bus, if an oscillograph had been used to record a long succession of

wingless aeroplane, or rocket sled. The attractive alternative calibration conditions. The mud-shield effect described in Paper

of the moving road also provides the usual advantages of an I11 was recognized only by use of t h i s continuous plotting equip-

ment. There has been, however, no indication that this shield had

indoor installation. The expense of such approaches produced any serious effect upon prior test data.

suggests substitution, if possible, of prediction theory Zeroing is performed at the start of each day of testing and, in

verified from data obtained at lover speeds, or on drums, part, at the start of each set of runs on a given tyre. First, by using

and then converted. The present test device was designed a jack to support the wheel in mid-air, zero load, drag, and moments

for the possibility of drum testing, with or without the are applied and a record is taken. If a subsequent wheel change

appreciably affects unsprung (by the gauge beams) weight, this

presence of the truck. zero is repeated. Second, while the test wheel, as well as the fifth

It is evident that the possibilities for empirical research wheel, is freely trailed, records are made for zero side force and

upon the pneumatic tyre are many and varied, and that slip angle. This procedure inherently produces a zero intercept of

much future research effort upon these problems is justified the F, versus a data and is repeated for each tyre to remove any

effects of tyre construction dissymmetry. The balance potentio-

for the sake of improvements in vehicular transportation. meters (Figs. 43 and 44, Paper 111) are adjusted to give approx-

imately zero bridge unbalance for typical zero inputs, but these

ACKNOWLEDGEMENTS settings are not critical.

Certain zero trace positions are slightly shifted when the wheel

The sponsors of the research described are the Mechanical is put into rotation, since a horizontal link load is induced by

Branch, Aircraft Laboratory, Wright Air Development bearing-and-seal friction and appears as a drag force and an

Center, U.S.A.F., which made possible the creation of the aligning torque. The link load is evaluated every few months by

apparatus ; the Mechanics Research Branch, Aeronautical replacing the l i i with a spring scale, and calculated corrections

are thereafter made. This zero shift is absent when the brake-

Research Laboratory, Wright Air Development Center, torque linkage is fitted. An additional set of trace zero shifts does

U.S.A.F., which is sponsoring tyre dynamics investi- occur when the wheel is cambered, due to the wheel-and-hub

gations; the Dunlop Tire and Rubber Company of weight, but this effect disappears when the data are resolved back

America, whose programme of testing and analysis to uncambered (stability) axes.

supplied most of the presented data; and Cornell Aero- Another standard procedure is to set the height of the hinge box

on the bed-plate, in order to adjust to zero the pitch attitude of the

nautical Laboratory, which made possible additional tests load cells as influenced by variations of tyre size, load, inflation,

and analysis, as well as most of the time for the writing and camber. This procedure avoids the necessity for correcting

and presentation of this paper. X and Z vectors for pitch attitude, or equivalently, avoids ‘mech-

anical trail’ as measured at the intersection of the Z measurement

axis with the ground plane. These bed-plate settings are calculated

beforehand from knowledge of tyre height and variations in height

with pressure, load, and camber, some of which the tyre manu-

APPENDIX X facturer can supply, and from knowledge of the truck height

variation with reacted load due to its suspension compliance. The

CALIBRATING AND ZEROING

predicted settings are then checked on the road. A setting accuracy

This description of pre-test procedures is given to convey certain of & & deg. (&Ainch mechanical trail) is maintained, and does

semi-routine, but practical, information of value to those who permit minor variations of load, pressure, and camber without

contemplate the construction and use of similar equipment, and resetting.

is omitted from the main text only for its lack of general engineering

interest.

The oscillograph is a recorder which photographically plots

continuous histories (traces) of a number of points of light, of APPENDIX XI

which each maintains a position varying with an instrumented

force, moment, or position. Calibration consists of determining THEORY O F LATERAL TYRE DEFORMATION

each such rate of variation, or the slope of the output against input This appendix is a recapitulation of the basic tyre theory introduced

plot, while zeroing consists of determining each trace position for by TemplelOs*(40) and von Schlippelol and utilized by a number

zero input, or the intercept of that plot. The two operations are of subsequent theorists. There is much to indicate, however, that

performed separately because a number of factors can affect the the majority of the researchers and designers in the tyre industry

zero, which is easily checked, whereas the calibration is inherently have little appreciation of the theory. This is an unfortunate

stable and not easily checked. circumstance, for the theory is quite simple and quite effective. For

Calibration is performed before every major programme of t h i s reason, a version of the derivation is now presented, based

testing, for instance once a month in periods of active test, although on the more complete presentation by Hadeke1105 in his monumental

efforts are now being made to verify and utilize the inherent ‘digest of present knowledge’, but with an emphasis upon the

calibration stability over even longer periods. T h e technique of physical concepts involved.

calibration is to apply known inputs, record the outputs, and plot

one against the other after developing, reading, and tabulating the * The number following the asten’sk denotes a reference giveti by

trace-position records. Positions are applied by reference to HadekelloJ and is specified in Appendix X I I of this paper.

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

TYRE TESTS AKD INTERPRETATION OF EXPERIMENTAL DATA 3 65

Both Temple and von Schlippe express the lateral distortion It may be noted that the force on the free forward portion is

pattern of a tyre in terms of the shape of its deflected equatorial

line. In the contact area, this line (assuming no slippage) is immobile Kylo, on the contacted forward portion is K

relative to the ground, and therefore has the shape of the path of

the wheel, for example, straight for steady slip angle or when the contacted aft portion is K 2, and on the aft free

non-rolling. Outside the contact area, the deflexion (Fig. 76) portion is K y p . These add up to the F,, in equation (70), and with

decreases toward zero in the manner of a stretched string (repre- their respective moment arms to the Mz in equation (71).

senting the circumferential cords tensioned by inflation) restrained

by lateral springs (representing the lateral component of stiffness).

*CONTACT LENGTH+

EQUATORIAL LINE

F .

WHEEL CENTRE-LINE

+

-.

/ -’ s--?

.+.

Fig. 77. Standing Lateral Deflexion

WHEEL CENTRE-LINE

I t now remains only to define yl andyz for various conditions of

interest, for either rolling or non-rolling tyres. For a non-rolling

Fig. 76. Deflected Equatorial Line tyre with uniform lateral deflexion (Fig. 77), y1 =y2, so that

Fy = 2Ky(u+l), giving a standing lateral stiffness of

This shape is approximated by the exponential relations

-+I) 3

dY

= 2K(u+I) . . . . (72)

y = y l e T * * * * * * (65)

Conversely, for pure yaw (Fig. 78), -y1 =yz = la, so that

for s> I (forward of the contact area), and

Y =yze

-(L+/-s)

0

. . . . .

(66) 1

Mz = - 2 K l a r ~ + u ( u + l ) giving a standing torsional stiffness of

for s<L+l (aft of the contact area) where y and s are the lateral da

. . (73) .

and circumferential co-ordinates, I is the half-contact length, L is

the length of the free circumference, and (Iis a stiffness parameter. u Now if a standing tyre is deflected both laterally and angularly,

corresponds to the time constant of a capacitor, the charge of which as in Fig. 76, and then rolled forward, parallel to its undeflected

decays exponentially in time, as lateral tyre deflexion decays in heading, the contact line maintains its angle a (now slip angle)

distance. Any tangent to the exponential line (Fig. 76) subtends but the deflexion approaches a new value. This value will be such

a distance u, in which length (termed ‘relaxation length’) the that theequatorial line iscontinuous at the forward contact edge,that

1 is, the contact line is tangent to the forward exponential (Fig. 79).

deflexion decreases to - of its prior value. The same exponential Then an element coming down around the tyre is laterally

deflected at an increasing (exponential) rate, until the instant of

relation applies to many experhents which may be performed with

contact, whereupon the deflexion rate holds constant. Any condi-

-1 decreases of a variety of

a tyre, whereby values of u appear for tion other than tangency at the forward edge cannot exist except

just after a step input of deflexion; hence, the condition of tangency

parameters plotted against distance (either s or x). holds for any continuously varying input (Segell23), as well as

These expressions for the lateral tyre distortion permit derivation for steady slip angle. The result is thatyl andy2 are both dependent

of the force and moment corresponding to any set of operating

conditions, from the orientation and shape of the equator in the

contact region. Temple does this by integrating force from the

ground on the tyre over the contact length only, but including an

infinitesimal length of free equator a t each end. For present

purposes, we will follow the reasoning of von Schlippe, who

integrates the force from the tyre on the rim over the entire

circumference. The element of force dFy on each cross-sectional

element of length ds, laterally deflected a distancey, is

? I WHEELCENTRE:LINE

dFy = Kyds . . . . . .

(67)

which defines K as the lateral stiffness per unit length. Thus, u and

AXLE CENTRE-LINE -I

Fig. 78. Standing Angular Dejlexion

K are the relevant stiffness parameters.

The total force on the tyre will be

F - Kyds

y - s

. . . . . (68) - FORWARD

<

and the moment about the origin will be approximately

M

4

- sKyds. . . . . . (69)

I I I -

Assuming hereafter that the contact line is straight, and per-

forming the integrations forward (equation 65), in, and aft (equation

/

WHEEL CENTRE-LINE

66) of the contact area, we obtain

Fy =KCyi+yz)(o$l) .. . . . . (70) AXLE CENTRE-LINE

12

M z = K ( ~ ~ - Y z ) [ ~ + u ( ~ + u.) ] . . * (71) Fig. 79. Rolling Defexiun

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

366 ALBERT G. FONDA

on a in such a manner that y1 = oa and y2 = (o+2Z)a (Fig. 79). static elasticity, etc.), firstly, because the two basic parameters K

Then substitution into equations (70) and (71) and differentiation and (I completely specify the behaviour of the tyre under both

with respect to a gives static and rolling conditions, and secondly, because these para-

meters are more likely to exhibit clear laws of variation (with tyre

(74) size, load, and inflation pressure) than other quantities’.

while dM,/da remains unchanged from equation (73), since the

rolling deformation consists merely of superimposed angular and

lateral deformations due to M z and Fy, respectively. These APPENDIX XI1

deformations are nand y = (u+l)a, where by substituting the latter

into equation (72) we obtain equation (74), as would be expected. REFERENCES

Modifications to these equations are given by Hadeke1105 (quoting All references which are identified by superscript numbers without

Templelos* (40), von Schlippe and Dietrichlol, MaierlO5* (361, parentheses will be found in the master reference list given in

Fromm99, Julienlos* (231, and Forsterlos* (27)) in which various Appendix I11 of Paper I.

effecrs are considered, such as beam stiffness of the carcass, T h e remaining references, which appear with parentheses, are

variation of K with cross-section shape changed by loading from the more exhaustive reference list of Hadekel (105) and are

(Thorsenlo7 and Andrewsll,), slippage in the contact area, longitu- listed below:

dinal slip, path curvature (Fig. 52, Paper 111), and so on. These

theories deserve study, development, and application by any 105* (23) Julien, M. A. 1937 J1. SociCtC des Ingenieurs

advanced student of tyre behaviour. de l’Automobile, April, ‘L’envirage et la Tenue de

These are only second-degree effects, however. T h e primary Route’.

facets of tyre behaviour evolve from the theory and equations 105* (27) Forster, B. (Undated) DKF, ZB 22, ‘Versuche zur

given above. The three constants 1, u, and K, being basic, appear Feststellung des Haftvermogens von Personen-

repeatedly in various behaviour equations. Thus, a number of wagen-Bereifungen’ .

expressions may be written for K and u in terms of empirical 105* (36) Maier, E. 1943 LGL Report 169, ‘Zur Frage der

measurements, such as 1, dFy/dy, dy/ds, and many others. These Seitenbeanspruchungen von Flugzeugfahrwerken’,

overlapping solutions permit the establishment of firm values for (M.O.S. T I B Library Translation 277, ‘Lateral

K and U. T o quote Hadekel, this ‘should be a much more rewarding Stresses on Aircraft Undercarriages’.

task than the oft-repeated (but always inconclusive) mere measure- 105* (40) Unpublished work kindly communicated (to Hadekel)

ment of particular elasticity characteristics (cornering power, by Professor G. Temple, F.R.S.

Downloaded from pad.sagepub.com at PENNSYLVANIA STATE UNIV on May 10, 2016

S-ar putea să vă placă și

- Race - Car Front WingsDocument11 paginiRace - Car Front WingsMarcos Soar100% (1)

- Numerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageDocument13 paginiNumerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageZizo StarkÎncă nu există evaluări

- Piper CubDocument84 paginiPiper CubDavid Scott100% (1)

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDocument361 paginiUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- Calculus II by Paul DawkinsDocument379 paginiCalculus II by Paul Dawkinsdandalf02100% (1)

- Aerodynamics Analysis of F-16 AircraftDocument6 paginiAerodynamics Analysis of F-16 AircraftDavid VươngÎncă nu există evaluări

- NASA Report - Theory For Computing Span Loads and Stability Derivatives Due To Side Slip, Yawing, and Rolling For Wings in Subsonic Compressible FlowDocument79 paginiNASA Report - Theory For Computing Span Loads and Stability Derivatives Due To Side Slip, Yawing, and Rolling For Wings in Subsonic Compressible Flowmssj87Încă nu există evaluări

- CPM Algebra1Document212 paginiCPM Algebra1JiHyun Lim100% (1)

- Book - Mathematical Methods For EngineersDocument860 paginiBook - Mathematical Methods For EngineersFazle HaiderÎncă nu există evaluări

- Curs Analiza MatematicaDocument407 paginiCurs Analiza MatematicaIra LoghinÎncă nu există evaluări

- Automobilechassisandbody 160622030425Document95 paginiAutomobilechassisandbody 160622030425Thomas TamangÎncă nu există evaluări