Documente Academic

Documente Profesional

Documente Cultură

DKDP - Manual Eng 12 - 2018

Încărcat de

Lý Chính ĐạoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

DKDP - Manual Eng 12 - 2018

Încărcat de

Lý Chính ĐạoDrepturi de autor:

Formate disponibile

CARBOAUTOMATYKA SA

Enterprise of Completion and Assembly of Automation Systems

43-100 Tychy, ul. Budowlanych 168

tel. head office: (32) 323 43 00 fax: (32) 323 43 23 Secretariat: (32) 323 42 42

e-mail: carboautomatyka@carbo.com.pl Internet: www.carbo.com.pl

Bottom Measurement Data Hub

DKDP

February 2018

SERVICE MANUAL - OPERATION AND

MAINTENANCE MANUAL

IDT 107.188 - 2

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 2/12

MAINTENANCE MANUAL

Compliance

The product complies with the basic health and safety requirements

concerning the design and manufacture of equipment and protection

systems for use in hazardous areas as defined in ATEX Directive

2014/34/EU, as well as the following harmonized standards:

PN-EN 50303:2004 (EN 50303:2000)

PN-EN 60079-0:2013 (EN 60079-0:2012)

PN-EN 60079-11:2012 (EN 60079-11:2012)

This compliance was confirmed by a Type EU Examination Certificate

OBAC 18 ATEX 0110X

issued by the Testing, Certification and Certification Center,

OBAC Sp. z o.o.,

Notified Body No. 1461

This product meets the essential requirements concerning electromagnetic

compatibility (EMC) specified in Directive 2004/35/EC and in the following

standards:

PN-EN 55011:2016-05

PN-EN 61000-4-2:2011

PN-EN 61000-4-3:2007/A2:2011

PN-EN 61000-4-4:2013-05

PN-EN 61000-4-6:2014-04

PN-EN 61000-4-20:2011

PN-EN 61000-6-2:2008

PN-EN 61000-6-3:2008/A1:2012

PN-EN 61000-6-4:2008/A1:2012

The manufacturer of the product - Enterprise of Completion and

Assembly of Automation Systems „Carboautomatyka” S.A. - issued the

EU declaration of conformity and has marked the product with "CE"

mark.

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 3/12

MAINTENANCE MANUAL

Table of contents:

1. LIST OF FIGURES................................................................................................................................................ 3

2. SAFETY INSTRUCTIONS ................................................................................................................................... 4

3. IDENTIFICATION ................................................................................................................................................ 4

4. PURPOSE ............................................................................................................................................................... 5

5. TECHNICAL DATA.............................................................................................................................................. 5

6. DESIGN AND PRINCIPLE OF OPERATION ................................................................................................... 7

7. DEVICE INSTALLATION ................................................................................................................................... 9

8. START-UP ............................................................................................................................................................ 10

9. INCORRECT OPERATION............................................................................................................................... 10

10. MAINTENANCE AND REPAIR INSTRUCTIONS......................................................................................... 10

11.1 MAINTENANCE .................................................................................................................................................. 10

11.2 STOP ANY SD CARD WRITING BEFORE DISCONNECTING THE POWER SUPPLY. ..................................................... 11

11.3 REPLACING THE DKDP_MASTER AND DKDP_ARCHIVE MODULES............................................................. 11

11.4 REPLACING DKDP_FIBER MODULES ............................................................................................................... 11

11.5 REPLACING THE DKDP_LINE / DKDP_4IN_4OUT ACTUATORS ..................................................................... 11

11.6 CONNECTING INTRINSICALLY SAFE LINES TO DKDP .......................................................................................... 11

12. PERIODIC INSPECTIONS .................................................................................................................................. 12

13. EMERGENCY PROCEDURE ........................................................................................................................... 12

14. INSTRUCTIONS FOR THE SAFE DISPOSAL OF THE DEVICE. .............................................................. 12

15. TERMS OF USE DURING THE WARRANTY PERIOD ............................................................................... 12

1. List of figures

Drawing

Name of a drawing

number

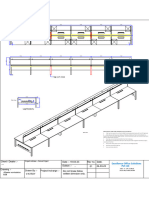

Fig. 1 General view of the DKDP Data Center Concentrator

Fig. 2 Cable routing in DKDP - exemplary configuration

Fig. 3 DKDP_FIBER module

Fig. 4 DKDP_MASTER or DKDP_ARCHIVE module

Fig. 5 DKDP_LINE module

Fig. 6 DKDP_4IN4OUT module

Fig. 7 Block diagram of the DKDP Data Center Concentrator

Fig. 8 Description of signals - connection chamber

Fig. 9 Name plate

Fig. 10 DKDP control unit - assembly dimensions

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 4/12

MAINTENANCE MANUAL

2. Safety instructions

a) The device can only be installed by specially trained personnel, in accordance with

applicable laws (among others, with regulations concerning electrical equipment

used in explosive areas). This manual is intended for trained personnel only.

b) All installation work must be carried out in accordance with the relevant local

(factory) and national standards.

c) Installation of the device should be carried out strictly in accordance with this

instruction.

d) Before starting any operations, check that the external circuits are properly connected

using appropriate plugs, while maintaining the required creepage clearances.

e) The output circuits of the device can only be combined with intrinsically safe circuits

with parameters corresponding to those specified in the technical data.

f) Intrinsically safe circuits are connected to the device should be routed in mine cables

that meet the requirements of PN-EN 50394-1:

1) in groups of one type A or B cable

or

2) individually, in cables which do not fulfill the requirements of pt. 1)

or

3) in groups, in a cable which does not fulfill the requirements of pt. 1), which

requires a system assessment

g) In systems exposed to lightning discharges, the use of external protective elements is

recommended.

3. Identification

a) Device name: Bottom Measurement Data Hub (DKDP)

Supplier/manufacturer name: Enterprise of Completion and Assembly of Automation

Systems „Carboautomatyka” S.A., tel. (32) 323-43-00; fax. (32) 323-43-23;

e-mail: carboautomatyka@carbo.com.pl; www.carbo.com.pl

b) Explanations of symbols:

DKDP / F* / L* / IO* / K* / W* / A**

where:

F* - number of DKDP_Fiber communication modules, e.g. F2

L* - number of DKDP_Line linear modules, e.g. L8

IO* - number of DKDP_4IN4OUT I / O modules, e.g. IO2

K* - type of connection chamber ( 1 : 160 x 360 x 91 mm or

2 : 250 x 400 x 161 mm)

W* - variant of the connection chamber (variants shown in

figures 107.188-M-0- ...)

A** - audiovisual alarm signals:

A00 – none,

A10 – LED,

A01 – BUZZER,

A11 – LED + BUZZER

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 5/12

MAINTENANCE MANUAL

Example labeling:

DKDP / F1 / L7 / IO3 / K2 / W1 / A11 – DKDP equipped in a single FIBER module,

7 linear modules, 3 I/O modules, a large connection

chamber in the finishing variant no. 1 and BUZZER

and a LED for alarm signaling.

c) Labeling site: housing side.

4. Purpose

The DKDP Bottom Measurement Data Hub is performs continuous acquisition,

processing, visualization and archiving of signals from measurement sensors as well as binary

inputs built directly in the control panel.

The device is intended for installation in areas characterized by a risk of methane and /

or coal dust explosion and on the surface.

Communication with field devices (gas sensors, sensors of environmental parameters,

etc.) is carried out with one pair of copper wires using FSK or RS485 transmission.

DKDP data hubs can be combined to form a local security system (max 6 DKDP

hubs). The connection between successive DKDP hubs is carried out with the use of fiber

optics (star or daisy-chain topology).

The length of the measuring line from DKDP to terminal devices may not exceed 3 km.

NOTE!

* The DKDP Bottom Measurement Data Hub, also referred to as the data hub, or the

DKDP hub

5. Technical data

Table 1: Technical data

15V DC, 1.5A (Ui = 15.6V)

DKDP power supply

from an intrinsically safe buffer PSU

Min 4h

Supply life

from an intrinsically safe buffer PSU

Display LCD 320x240 Monochromatic

Keyboard Membrane, 64 keys or 6 buttons

Surface connection Fiber-optic, 1 or 2 single-mode threads

The maximum number of DKDP hubs Up to 8 pieces

in the system connected by fiber optics or RS485

Number of working modules in a

Up to 10 pieces

DKDP

Maximum number of terminal devices

Up to 4 pcs, depending on the type of device

connected to one telemetry line

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 6/12

MAINTENANCE MANUAL

Telemetry line Baud rate Up to 6 kb/s FSK

Repetition time for a device on the Maximum of 0.25 s, with one terminal device

telemetry line on the telemetry line

Power consumption < 25 W

Length of the telemetry line < 3 km

Length of the two-state line < 3 km

Table 2 : Intrinsically safe DKDP parameters

DKDP_MASTER

BUS edge connector: 1-5 UI=15.5V

MONBUS connector 2-4, 3-4 U0=4.935V, I0=2.3mA, P0=11mW

DKDP_LINE

BUS edge connector: 1-5 UI=15.5V

U0=27.3V, I0=134mA P0=2.84W

Telemetry line L L- output

L0/R0=434mH/Ω

Analog 0-10V input

UI=14V, Ii=60mA

AVIN:1-AVIN:4

DKDP_LCDKEY

BUS edge connector: 1-5 UI=15.5V

DKDP_ARCHIVE

BUS edge connector: 1-4 UI=15.5V

DKDP_FIBER

BUS edge connector: 1-5 UI=15.5V

EXTBUS connector: 2-4,

U0=5.335V, I0=45mA, P0=0.24W, Ui=7V

EXTBUS: 2-5

DKDP_4IN4OUT

BUS edge connector: 1-5 UI=15.5V

OUT1: 1-2, OUT1: 3-4, OUT2: 1-2,

UI=60V, II=120mA, PI=330mW

OUT2: 3-4 connector

INPUTS1: 1-2,

INPUTS1: 3-4,

U0=7.875V, I0=13.5mA, P0=106mW

INPUTS2: 1-2,

INPUTS2: 3-4 connector

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 7/12

MAINTENANCE MANUAL

Table 3 : Other technical data

Ingress protection IP65

Operating temperature -20C Ta +50C

Relative humidity max 95% without condensation

Dimensions (width x depth x height) 450 x 160 x 600 mm

Weight ~ 23 kg

Marking acc. to ATEX directive I M1 Ex ia Ma I

ATEX certificate number OBAC 18 ATEX 0110X

6. Design and principle of operation

The DKDP data hub consists of (Fig. 1):

a plastic housing [1]

a display [2]

a keyboard [3]

a connection chamber [4]

built-in modules [5]

1 1

2

Archive

5

Master

In/Out

In/Out

Fiber

Line

Line

Line

Line

Line

Line

Line

Line

Line

3

Fig. 1 Bottom DKDP measurement data hub

Module description:

The DKDP_MASTER module serves as the main DKDP controller and is

equipped with a rugged, powerful 32-bit RISC processor, a total of 192 kB RAM

and 8MB FLASH memory. This module is responsible for storing the current

configuration and querying all other modules to ensure proper operation of the

whole device.

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 8/12

MAINTENANCE MANUAL

The DKDP_ARCHIVE module is used for archiving the readings from sensors.

Records are saved on two micro SD cards. The module communicates with the

MASTER and the FIBER modules.

DKDP_FIBER can be used to send information from DKDP to surfaces using a

fiber optic cable (directly or indirectly through another DKDP control unit in a

Daisy-Chain connection). The module also supports communication with other

DKDPs (for shorter distances up to 1 km) using a 3-wire RS-485 bus (EXT_BUS).

This connection is required when each DKDP has a separate optical fiber connected

to a computer, and there is a need to "exchange" alarms between them.

DKDP_FIBER is equipped with a powerful 32-bit processor, 1 MB of RAM, 8 MB

of FLASH memory, an ETHERNET controller, a fiber optic transceiver and

galvanically isolated RS485 port (EXT_BUS bus). DKDP can have 1 or 2 FIBER

modules, depending on the needs. If two modules are installed in DKDP, the

EXT_BUS bus connects them to each other.

Thanks to the FIBER module, communication between 8 DKDP hubs and a host

computer is possible. Connecting via an intrinsically safe optical fiber converter

directly to the computer as well as topologies of the star and Daisy-Chain is also

admitted.

Communication is carried out via a connectionless UDP protocol.

Communication using RS485 is carried out by means of a protocol in which one

DKDP is a master and initiates the transfer of data, and then sends their state in the

appropriate "time window". If there is no initiation of communication by the DKDP

master, the DKDP with the following number takes over its role.

At least one DKDP_FIBER module is necessary for DKDP to work.

DKD_LCDKEY - LCD display and membrane keyboard controller module. It is

used to view the current state of the DKDP hub. Due to the fact that system

dispatchers are on the surface, this module does not support any system

configuration changes. It is rather used as an aid in diagnosing faults and installing

new sensors for underground service.

It is equipped with 128 kB of RAM and 8 MB of FLASH memory as well as a

monochromatic graphic display with a resolution of 320x240 points. Depending on

the version (\ A **), it can also be used to connect a light and sound alarm siren.

The module is necessary for starting and operating the DKDP.

DKDP_LINE - line module. It is used to connect sensors to the DKDP hub.

Supported transmission methods include: FSK using a 2-wire line up to 2 km in

length or a 4-wire RS485 bus (power supply, ground, 2 RS485 wires).

The module has an insulated converter that increases the voltage on the line to

about 25 V, which ensures correct work of the sensors at the maximum length of

the tele-transmission line.

The line card can be used to connect up to 4 SC-xx series sensors, depending on the

type. In addition, the card has an RS485 transmission interface that allows the use

of sensors from other manufacturers compatible with this type of communication,

after appropriate changes in the software are made.

The card also has an analog voltage input, which is used to operate sensors with an

analogue 0.4-2V, 1-5V or 1-10V voltage output.

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 9/12

MAINTENANCE MANUAL

The type of communication is selected by configuring the type of sensor on the

dispatching computer. The card also has the ability to control the output voltage - in

addition to the ability to enable / disable it, it can also be used to change its value in

256 steps, which translates into greater efficiency of the device with shorter

transmission lines.

DKDP_4IN4OUT - Two -state input and output module, used to operate simple

contacts shorted / open, contacts with a serial diode and contacts with a resistor

divider. The module can be used to connect signals from external systems (e.g. 2

state output of the CPC-2 sensor) to the DKDP system, and to connect simple

contact devices, e.g. to control the closing of the dam 4 bi-state outputs allow

manual / automatic control of electricity at the bottom of the mine. It is then

necessary to connect the current switch with an intrinsically safe separator. Each

input / output can be stamped, i.e. its state can be controlled by a device on another

DKDP, and its state can affect another contacts within the DKDP system (up to 8

items).

Communication between the DKDP_ARCHIVE and DKDP_MASTER modules takes

place directly through the USART processors, as both printed circuit boards are installed

in the same double housing.

In addition, DKDP_ARCHIVE has an ARCHIVE_BUS bus - a bus connected to the

DKDP_FIBER module, which is used to download archive records bypassing the

DKDP_MASTER module, to reduce its load.

All modules are equipped with RGB LEDs to indicate the operating status, and executive

modules in the code counter, used to set the next number (0-9) to identify modules. In the

double housing of the DKDP_MASTER, DKDP_ARCHIVE modules, there is a code

controller, by means of which the DKDP number is set in the system.

7. Device installation

NOTE: The DKDP installation site should be chosen so as to exclude the adverse impact

of environmental factors such as dust, water, temperature and mechanical impact

(vibrations, shocks, impacts).

NOTE: The cables and wires to be connected to the DKDP must be inserted through the

glands into the connection chamber. Single wires should be terminated with

appropriate cable terminals and markers, and then screwed to the appropriate

connectors.

a) The device should be installed on slings supplied with DKDP in a position enabling the

cables to be inserted from the bottom of the device.

b) Open the front cover (door) of the DKDP junction box using the special key provided

with the DKDP to access connectors and cables.

c) Connect the power cable from the intrinsically safe power supply to the power connection

terminals located on the right side on the DIN rail.

d) Connect the intrinsically safe transmission lines to the appropriate connectors.

e) Connect the other circuits (transmission) - to external devices.

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 10/12

MAINTENANCE MANUAL

8. Start-up

The device can be started after correct installation and after verifying if all connectons are

correct. To start the device:

a) Start the intrinsically safe buffer power supply.

b) Wait (about 1 minute) until the DKDP_MASTER module finishes the start-up procedure,

during which it recognizes and configures the remaining modules.

c) Accept the commissioning report that will appear on the display - from that moment on,

dispatchers can configure the operation of the actuators.

NOTE: The control panel software description, as well as the way it is configured and

operated, contain separate instructions.

9. Incorrect operation

In the event of failure whose symptoms match those described in Table 4, follow the

instructions contained therein.

Table 4 : Faults and how to proceed to eliminate them

No. Symptom of the fault Probable cause Procedure

No power on the DKDP unit - no Power is not "reaching" the Check if the DKDP power cord is

1. lights on the UPS and the front panel DKDP unit live

of the KZ power supply panel are on

There is no report from the DKDP An incorrectly configured or Make sure that the

start-up, the diode located on the damaged DKDP_MASTER DKDP_MASTER module is

2.

DKDP_MASTER module does not module powered and properly plugged into

light up or lights up in red. the rail.

There is no report from the DKDP Incorrectly connected or Make sure that the

start-up, the diode located on the broken DKDP_LCDKEY DKDP_LCDKEY module is

3.

DKDP_LCDKEY module does not module connected to the DKDP_MASTER

light or lights up in red. module via the LCD bus.

The DKDP run report contains error Incorrectly connected or Make sure that the modules are

information about the broken module needed for properly plugged into the bus and

4. DKDP_ARCHIVE or DKDP_FIBER DKDP DKDP_ARCHIVE or that the DKDP_FIBER module is

modules DKDP_FIBER to operate connected to DKDP_MASTER and

DPDP_ARCHIVE.

The dispatcher application cannot More than one DKDP has the Make sure that DKDP has the

5. communicate with DKDP same number encoded, fiber correct number encoded,

optic damaged. Check the optical fiber.

If the above mentioned diagnostic steps do not give a positive result or a different fault occurs,

please contact the manufacturer's service department or send the damaged module to the

service center.

10. Maintenance and repair instructions

11.1 Maintenance

Suitable personnel, trained by the manufacturer of the device, can be only admitted to

carry out any operation, maintenace and replacement of the DKDP data hub modules.

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 11/12

MAINTENANCE MANUAL

Maintenance of the device consists in taking care of the proper working conditions of the

device, in accordance with the installation conditions and performing periodical checks

of the correct operation of the central unit. Suitable services should also inspect the

device from the outside and from the inside, control circuit connectors connecting the

outer compartment and the terminal modules.

NOTE! The manufacturer does not provide for repairs of modules by at the end user.

If any irregularities are found, the user should contact the service.

NOTE! The manufacturer allows the user to replace some elements, i.e.: Master modules,

Fiber, Line and 4In_4Out modules in the data hub housing;

11.2 Stop any SD card writing before disconnecting the power supply.

11.3 Replacing the DKDP_MASTER and DKDP_ARCHIVE modules

a) Open the DKDP housing.

b) Use the buttons to stop any writing on the memory cards.

c) Unplug all connected modules.

d) Pull the modules out of the rail with firm motion, pulling the lock out.

e) Encode the control panel number on the new module pair.

f) Optionally, move the SD card (to remove the card, it must be pressed gently).

g) Connect the DKDP_FIBER, DKDP_LCDKEY modules.

h) Slide the modules onto the rail with a firm motion.

i) Wait for the commissioning report and accept it.

j) The dispatcher must re-load the configuration of the actuators.

11.4 Replacing DKDP_FIBER modules

a) Open the DKDP housing.

b) Unplug all connected modules.

c) Pull the actuator out of the rail with firm motion, pulling the lock out.

d) On the new module, encode the number of the exchanged module.

e) Slide the new actuator onto the rail with a firm movement.

f) Connect the previously unplugged modules.

g) Close the control panel housing.

11.5 Replacing the DKDP_LINE / DKDP_4IN_4OUT actuators

NOTE! Actuators can be exchanged without switching off the power supply to the

control panel.

h) Open the DKDP housing.

i) Pull the actuator out of the rail with firm motion, pulling the lock out.

j) On the new module, encode the number of the exchanged module.

k) Slide the new actuator onto the rail with a firm movement.

l) Close the DKDP housing.

11.6 Connecting intrinsically safe lines to DKDP

The cables of intrinsically safe circuits should be inserted inside the DKDP connection

chamber through the glands from the bottom of the housing.

Cables should be unseated and run in such a way as to exclude the possibility of

accidental short-circuiting. The connection of the power supply and transmission lines

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

NUMBER PAGE

SERVICE MANUAL - OPERATION AND 107.188 - 2 12/12

MAINTENANCE MANUAL

to the terminals in the connection chamber should also make it impossible to

disconnect the wires. In no case should the wires of the power supply and transmission

lines intersect with the power supply cables.

12. Periodic inspections

Periodic inspection or maintenance of the DKDP bottom measurement data hub should be

carried out by representatives of the manufacturer or his authorized unit at least once a year.

During the review, the following activties are performed:

- review and cleaning of all elements included in the DKDP;

- control of technical condition and correctness of DKDP elements operation;

- control measurements of electrical parameters (power supply, output circuits, etc.);

- checking the functionality of the entire DKDP.

Each inspection should be closed with a report on the inspection carried out and the

measurements made.

13. Emergency procedure

After finding a faulty operation or failure of the DKDP data concentrator, please report the

fact to the DKDP manufacturer's 24-hour service.

The service team will consult on with the DKDP user and determine if it is necessary to come

to the site or if the fault can be removed by the user himself.

If the service team is needed on the site, it will arrive at the agreed time to the user to remedy

the failure.

Service is performed by:

The Department of Gasometric Devices

PKiMSA “Carboautomatyka” S.A. in Tychy

ul. Budowlanych 168

tel.: (32) 323 43 46 or 694 406 016

or another entity authorized by the manufacturer.

14. Instructions for the safe disposal of the device.

The crossed out bin symbol means that the product must not be disposed of in normal waste

containers. The used product should be sent to a collection point for electronic equipment.

15. Terms of use during the warranty period

Manufacturer's warranty coverage shall be maintained if the following requirements are

fulfilled:

the recommendations contained in service manuals are complied with;

markings (series number which identifies the product) are retained;

product is used as intended.

Enterprise of Completion and Assembly of Automation Systems

12.2018

CARBOAUTOMATYKA SA

S-ar putea să vă placă și

- Molecular Beam Epitaxy: Applications to Key MaterialsDe la EverandMolecular Beam Epitaxy: Applications to Key MaterialsÎncă nu există evaluări

- A Seminar Report ON "Mems Technology"Document32 paginiA Seminar Report ON "Mems Technology"nikhil jhaÎncă nu există evaluări

- Disc Brake Units Be 100, Be 125, and Be 200: Technical InformationDocument6 paginiDisc Brake Units Be 100, Be 125, and Be 200: Technical InformationJose Maria Castro PazosÎncă nu există evaluări

- Diamond Chemical Vapor Deposition: Nucleation and Early Growth StagesDe la EverandDiamond Chemical Vapor Deposition: Nucleation and Early Growth StagesÎncă nu există evaluări

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987De la EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonÎncă nu există evaluări

- Advanced Reactor Concepts (ARC): A New Nuclear Power Plant Perspective Producing EnergyDe la EverandAdvanced Reactor Concepts (ARC): A New Nuclear Power Plant Perspective Producing EnergyÎncă nu există evaluări

- ICME2017 Proceedings PDFDocument374 paginiICME2017 Proceedings PDFsrivatsanÎncă nu există evaluări

- Viet Nam: Energy Sector Assessment, Strategy, and Road MapDe la EverandViet Nam: Energy Sector Assessment, Strategy, and Road MapÎncă nu există evaluări

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965De la EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerÎncă nu există evaluări

- Additive Manufacturing A Complete Guide - 2020 EditionDe la EverandAdditive Manufacturing A Complete Guide - 2020 EditionÎncă nu există evaluări

- Nonlinear Optics: Fundamentals, Materials and DevicesDe la EverandNonlinear Optics: Fundamentals, Materials and DevicesS. MiyataÎncă nu există evaluări

- Metal matrix composites: Processing and InterfacesDe la EverandMetal matrix composites: Processing and InterfacesR EverettÎncă nu există evaluări

- Incineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987De la EverandIncineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987Robert B. DeanÎncă nu există evaluări

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationDe la EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationÎncă nu există evaluări

- Oxidation of Organic Compounds: Medium Effects in Radical ReactionsDe la EverandOxidation of Organic Compounds: Medium Effects in Radical ReactionsEvaluare: 4 din 5 stele4/5 (1)

- Siemens FactSheet ORC ModuleDocument2 paginiSiemens FactSheet ORC ModuleHimanshu1712Încă nu există evaluări

- Catálogo RULMECADocument308 paginiCatálogo RULMECArdgmaxiÎncă nu există evaluări

- Industrial Radiography A Complete Guide - 2021 EditionDe la EverandIndustrial Radiography A Complete Guide - 2021 EditionÎncă nu există evaluări

- Refractory Transition Metal Compounds: High Temperature CermetsDe la EverandRefractory Transition Metal Compounds: High Temperature CermetsÎncă nu există evaluări

- Extraccion Doble Tambor - 3000m PDFDocument4 paginiExtraccion Doble Tambor - 3000m PDFTracy GrahamÎncă nu există evaluări

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorDe la EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorÎncă nu există evaluări

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesDe la EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesÎncă nu există evaluări

- Steam Turbines A Full Range To Fit Your Needs PDFDocument20 paginiSteam Turbines A Full Range To Fit Your Needs PDFvcharles100% (1)

- Design of the Reactor Coolant System and Associated Systems for Nuclear Power Plants: Specific Safety GuideDe la EverandDesign of the Reactor Coolant System and Associated Systems for Nuclear Power Plants: Specific Safety GuideÎncă nu există evaluări

- 2010-05-31 Schunk Carbon-Brush Shaft GroundingDocument7 pagini2010-05-31 Schunk Carbon-Brush Shaft GroundingcorsairsanÎncă nu există evaluări

- The History of Gas-Insulated SubstationsDocument7 paginiThe History of Gas-Insulated SubstationsMaharajaÎncă nu există evaluări

- 2007-12 NPT Pyrolysis of EFBDocument3 pagini2007-12 NPT Pyrolysis of EFBkstan112233Încă nu există evaluări

- Danes HM A Nesh 2003Document6 paginiDanes HM A Nesh 2003Rina OktapianiÎncă nu există evaluări

- ABB CatalogueDocument6 paginiABB CatalogueNavneet SinghÎncă nu există evaluări

- Piezoelectric BrochureDocument22 paginiPiezoelectric BrochureYi LiuÎncă nu există evaluări

- 140MXC Nano Composite WireDocument5 pagini140MXC Nano Composite WireAnonymous QsXfPXxDMÎncă nu există evaluări

- Surface Engineering & Advanced Coatings SIG Final ReportDocument44 paginiSurface Engineering & Advanced Coatings SIG Final ReportMadan Pal SainiÎncă nu există evaluări

- Thermal Dynamics Ultra-Cut 200 Eng-OmDocument168 paginiThermal Dynamics Ultra-Cut 200 Eng-OmsajsigalomaÎncă nu există evaluări

- Binder Jetting of Ceramics REVIEWDocument16 paginiBinder Jetting of Ceramics REVIEWSuphaporn DaothongÎncă nu există evaluări

- MICo - Company PresentationDocument40 paginiMICo - Company PresentationJaroslav KurucÎncă nu există evaluări

- Optical LED Intensity Control 808AEDocument6 paginiOptical LED Intensity Control 808AEBanani Acharya100% (1)

- Polymer-Nano Flooding PDFDocument4 paginiPolymer-Nano Flooding PDFEslam SalamaÎncă nu există evaluări

- Applications of Induction HeatingDocument24 paginiApplications of Induction Heatingnazari_smeirÎncă nu există evaluări

- DSMTS-Metco 8450 - 8622 - 8625Document4 paginiDSMTS-Metco 8450 - 8622 - 8625Gonzalo Guerrero Cáceres0% (1)

- Ybco Superconductor Characterization Under Shear StrainDocument4 paginiYbco Superconductor Characterization Under Shear StrainRiddhesh PatelÎncă nu există evaluări

- GMFIX Code DocumentsDocument63 paginiGMFIX Code Documentsclarklipman100% (1)

- ISO 5071 1 2013 褐煤挥发份Document19 paginiISO 5071 1 2013 褐煤挥发份Winnjone YinÎncă nu există evaluări

- Teory For Acetylene VCDocument6 paginiTeory For Acetylene VCRamesh JakkanagoudarÎncă nu există evaluări

- GBT 2566-2010 - en PhotopermiabilityDocument11 paginiGBT 2566-2010 - en PhotopermiabilityYudan TonoÎncă nu există evaluări

- BMP FI-RevA-1-8.xerDocument1.590 paginiBMP FI-RevA-1-8.xerbharathyÎncă nu există evaluări

- M Tech ProjectDocument98 paginiM Tech Projectmanoj phadtareÎncă nu există evaluări

- Start-Up Experience and Results of Consteel® at The SOVEL MeltshopDocument9 paginiStart-Up Experience and Results of Consteel® at The SOVEL Meltshopعمار احسنÎncă nu există evaluări

- Insulating Fire Brick ProductsDocument3 paginiInsulating Fire Brick Productsshuyang zhang100% (1)

- PATENT - Axial Flux Motor AssemblyDocument13 paginiPATENT - Axial Flux Motor Assemblyrakeshee2007Încă nu există evaluări

- Blastcad - Noranda's Three-Dimensional Underground Blast DesignDocument7 paginiBlastcad - Noranda's Three-Dimensional Underground Blast Designsuigeneris11Încă nu există evaluări

- Tornado Diagram Macros NewDocument837 paginiTornado Diagram Macros NewChinh Lê ĐìnhÎncă nu există evaluări

- New Sun-Hoa BinhDocument39 paginiNew Sun-Hoa BinhLý Chính ĐạoÎncă nu există evaluări

- A 1 2 BMXDRA1605 3 BMXDDI1602: Item CodeDocument3 paginiA 1 2 BMXDRA1605 3 BMXDDI1602: Item CodeLý Chính ĐạoÎncă nu există evaluări

- 171-178 Bac Giang - rv1Document18 pagini171-178 Bac Giang - rv1Lý Chính ĐạoÎncă nu există evaluări

- Busbar Size Calculation (22.8.12)Document16 paginiBusbar Size Calculation (22.8.12)Jeya KannanÎncă nu există evaluări

- Power System Engineering, Computerized Tools For Analysis and Relay CoordinationDocument3 paginiPower System Engineering, Computerized Tools For Analysis and Relay CoordinationLý Chính ĐạoÎncă nu există evaluări

- Drawing - Terumo-F3 - 31.01.2020 TVE & KD Update-ModelDocument1 paginăDrawing - Terumo-F3 - 31.01.2020 TVE & KD Update-ModelLý Chính ĐạoÎncă nu există evaluări

- Renovation Washing RoomDocument12 paginiRenovation Washing RoomLý Chính ĐạoÎncă nu există evaluări

- ALCE Instrument Transformers 2012 CD R01Document20 paginiALCE Instrument Transformers 2012 CD R01Lý Chính ĐạoÎncă nu există evaluări

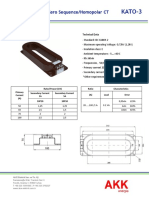

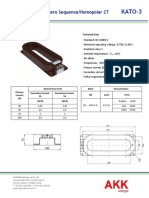

- Kato 3 en PDFDocument1 paginăKato 3 en PDFLý Chính ĐạoÎncă nu există evaluări

- Page Description Change: Elektrobudowa SaDocument2 paginiPage Description Change: Elektrobudowa SaLý Chính ĐạoÎncă nu există evaluări

- KATO-3: Zero Sequence/Homopolar CTDocument1 paginăKATO-3: Zero Sequence/Homopolar CTLý Chính ĐạoÎncă nu există evaluări

- Detailed Price For Switchgear PanelsDocument1 paginăDetailed Price For Switchgear PanelsLý Chính ĐạoÎncă nu există evaluări

- WAZ - / / Type Emergency SwitchesDocument21 paginiWAZ - / / Type Emergency SwitchesLý Chính ĐạoÎncă nu există evaluări

- SC-CH4 Manual - Eng - 25 - 09 - 2012Document29 paginiSC-CH4 Manual - Eng - 25 - 09 - 2012Lý Chính ĐạoÎncă nu există evaluări

- SC-CH4 Manual - Eng - 25 - 09 - 2012Document29 paginiSC-CH4 Manual - Eng - 25 - 09 - 2012Lý Chính ĐạoÎncă nu există evaluări

- Getting Started With DockerDocument8 paginiGetting Started With DockerdenisaÎncă nu există evaluări

- Swaroop (1) ResumeDocument4 paginiSwaroop (1) ResumeKrishna SwarupÎncă nu există evaluări

- Husqvarna 2008Document470 paginiHusqvarna 2008klukasinteria100% (2)

- TUPT AdmissionDegreeLadderizedDocument1 paginăTUPT AdmissionDegreeLadderizedromerqazwsxÎncă nu există evaluări

- Know The Escalation Matrix To ReportDocument1 paginăKnow The Escalation Matrix To ReportHemal GandhiÎncă nu există evaluări

- Walk inDocument1 paginăWalk inCHATHURÎncă nu există evaluări

- List of RDSO Coaching DrawingsDocument21 paginiList of RDSO Coaching DrawingsShubhav Manav0% (2)

- 9A01304 Fluid MechanicsDocument4 pagini9A01304 Fluid MechanicssivabharathamurthyÎncă nu există evaluări

- VW Piezometer Input Calculation Sheet V1.1Document5 paginiVW Piezometer Input Calculation Sheet V1.1Gauri 'tika' Kartika100% (1)

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 paginiIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)AmriteshbhaskarÎncă nu există evaluări

- IV-series-monitor Monitor Um 440gb GB WW 1027-3Document360 paginiIV-series-monitor Monitor Um 440gb GB WW 1027-3Quang DuyÎncă nu există evaluări

- Digital Data, Digital SignalDocument8 paginiDigital Data, Digital SignalBastomi Adi NugrohoÎncă nu există evaluări

- Claa150xp Shenzhen HBDocument22 paginiClaa150xp Shenzhen HBSatya NarayanÎncă nu există evaluări

- Philips BV Pulsera C ArmsDocument2 paginiPhilips BV Pulsera C ArmsWaheed MidoÎncă nu există evaluări

- Security Issues in Modern Automotive Systems: Patrick NischDocument6 paginiSecurity Issues in Modern Automotive Systems: Patrick NischEdson PatrícioÎncă nu există evaluări

- Module 6 DrillingDocument18 paginiModule 6 DrillingdejanflojdÎncă nu există evaluări

- HPB Install Manual ABB - Distribution BUS BarsDocument11 paginiHPB Install Manual ABB - Distribution BUS BarsArunallÎncă nu există evaluări

- Installation, and Maintenance Manual For Gas Fired, Wall-Hung BoilersDocument24 paginiInstallation, and Maintenance Manual For Gas Fired, Wall-Hung Boilersca3accoÎncă nu există evaluări

- Selected Books For Electronic Hobby Center (EHC) : A. Books (Available in The Resource Centre)Document9 paginiSelected Books For Electronic Hobby Center (EHC) : A. Books (Available in The Resource Centre)Rajalakshmi BashyamÎncă nu există evaluări

- Mike and KeyDocument25 paginiMike and KeyddscribeÎncă nu există evaluări

- GCCDocument265 paginiGCCzhenguoliÎncă nu există evaluări

- TechTrax 09 2003 ScreenReaderVersionDocument84 paginiTechTrax 09 2003 ScreenReaderVersionMCKINNONBÎncă nu există evaluări

- Solved MAT 2012 Paper With Solutions PDFDocument81 paginiSolved MAT 2012 Paper With Solutions PDFAnshuman NarangÎncă nu există evaluări

- Revista Stiinte Politice Issue 42Document264 paginiRevista Stiinte Politice Issue 42Costel111Încă nu există evaluări

- Na Edifact Desadv SpecificationsDocument17 paginiNa Edifact Desadv Specificationsrajendra2505Încă nu există evaluări

- BE Spec Flash EconomizerDocument4 paginiBE Spec Flash Economizeronkarrathee100% (1)

- Pursuit ManualDocument26 paginiPursuit Manualhunter9903Încă nu există evaluări

- Advance Java Sem 5Document18 paginiAdvance Java Sem 5Gunjan Pratim JadhavÎncă nu există evaluări

- DC and AC InterferenceDocument40 paginiDC and AC InterferenceREJI JOY ThoppilÎncă nu există evaluări

- 6seater Workstation B2BDocument1 pagină6seater Workstation B2BDid ProjectsÎncă nu există evaluări