Documente Academic

Documente Profesional

Documente Cultură

Metallurgical Engineering

Încărcat de

APPI NAIDU0 evaluări0% au considerat acest document util (0 voturi)

118 vizualizări3 paginiThe document provides an overview of the syllabus for the Metallurgical Engineering course. It is divided into 11 units covering topics such as elementary principles of metallurgy, fuels and refractories, metallurgical thermodynamics, physical metallurgy, heat treatment technology, ferrous and non-ferrous extractive metallurgy, material testing, mechanical metallurgy, foundry technology, and welding technology. It also includes annexures specifying the number of questions to be set from each unit and providing sample questions.

Descriere originală:

Syllabus

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document provides an overview of the syllabus for the Metallurgical Engineering course. It is divided into 11 units covering topics such as elementary principles of metallurgy, fuels and refractories, metallurgical thermodynamics, physical metallurgy, heat treatment technology, ferrous and non-ferrous extractive metallurgy, material testing, mechanical metallurgy, foundry technology, and welding technology. It also includes annexures specifying the number of questions to be set from each unit and providing sample questions.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

118 vizualizări3 paginiMetallurgical Engineering

Încărcat de

APPI NAIDUThe document provides an overview of the syllabus for the Metallurgical Engineering course. It is divided into 11 units covering topics such as elementary principles of metallurgy, fuels and refractories, metallurgical thermodynamics, physical metallurgy, heat treatment technology, ferrous and non-ferrous extractive metallurgy, material testing, mechanical metallurgy, foundry technology, and welding technology. It also includes annexures specifying the number of questions to be set from each unit and providing sample questions.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

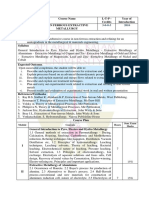

ANNEXURE I

METALLURGICAL ENGINEERING

1. ELEMENTARY PRINCIPLES OF METALLURGY: Introduction to metallurgy – ores

& ore dressing, Methods of ore sampling – Communition – Screening & Classification -

Principles and processes of Pyro, hydro and electrometallurgy –Minerals of commercially

important metals.

2. FUELS, REFRACTORIES AND PYROMETRY: Classification of solid, liquid and

gaseous fuels – Testing and properties of important fuels-Manufacture and characteristics of

Metallurgical Coke - Combustion of fuels – Properties, manufacture and selection of

Refractories, Principles and operation of important pyrometers.

3. METALLURGICAL THERMODYNAMICS: Introduction and applications of

thermodynamics –First Law of thermodynamics- Thermo chemistry - Second Law of

thermodynamics - Ellingham diagrams - Fugacity, activity and equilibrium constant -Phase

equilibria - Solutions

4. PHYSICAL METALLURGY: Structure of metals and Alloys – Solidification -

Diffusion – Binary thermal equilibrium diagrams-Iron-carbon diagram- important non-

ferrous binary alloy systems – Microscopic and macroscopic examination of metals and

alloys.

5. HEAT TREATMENT TECHNOLOGY: Heat treatment of plain carbon steels -

Annealing, Normalizing, Hardening and tempering of steels – TTT diagrams - Hardenability

- Grain size, Quenching media. Alloy steels & Effect of alloying elements on plain carbon

steels – Stainless steels, tool steels – Case hardening techniques. Special heat treatment

techniques such as Austempering , Martempering, sub-zero treatment - Heat treatment of

Non-ferrous metals and alloys – Age hardening - Heat Treatment Furnaces .

6. FERROUS EXTRACTIVE METALLURGY: Iron ores and preparation of iron ores -

Blast furnace plant and equipment – blast furnace reactions - irregularities and recent trends -

sponge iron & methods of production – Ferroalloys – types and applications. Steel making by

Bessemer, LD, Kaldo, OLP, Open hearth and Electric furnaces –New techniques in steel

making – Vacuum treatment of liquid steel - Ingot defects - Continuous casting.

7. NON-FERROUS EXTRACTIVE METALLURGY: Extraction of copper – Pyro and

hydrometallurgical methods & refining - Aluminum- Extraction, Anode effect, Refining -

Zinc and Lead - Pyro and hydrometallurgical extraction and refining. Extraction of

Magnesium by Dows and pidgeon processes. Extraction of Titanium by Kroll’s process -

Refining by Van arkell’s process-Extraction of Thorium and Zirconium.

8. MATERIAL TESTING: Tension test. Stress- strain relationships, necking

phenomenon. Hardness tests-principles and types. Impact testing-Notched bar impact tests.

Transition temperature. Fatigue, Stress cycles, S-N diagram, Factors affecting Fatigue. Creep

testing - creep curve, Stress - rupture test. Non-destructive testing- Principles, methods and

applications of liquid penetrant, Radiography, Ultrasonic Magnetic particle and Eddy current

test.

9. MECHANICAL METALLURGY: Plastic deformation of metals – lattice defects –

Slip and Twinning - CRSS –Strengthening mechanisms. Strain hardening - Hot and Cold

working - Recovery, recrystallisation and grain growth. Metal forming processes-Rolling,

Forging, Extrusion & Sheet metal forming processes and defects – Thermo mechanical

treatments – isoforming and ausforming. Powder metallurgy. Methods of powder production,

Characterization, Compaction, Sintering and applications of Powder Metallurgy.

10. FOUNDRY TECHNOLOGY: Patterns: Types, materials and pattern allowances,

Moulding Sands - properties and Testing, Moulding Processes and equipment: Sand casting,

Die casting, Shell moulding, Centrifugal casting, Investment casting and CO2 process-Cores:

Types of Cores and properties, pouring and feeding of castings. Cast irons – types,

Melting of Cast irons - Grey, S.G and Malleable iron. Aluminium, Copper and Steel Foundry

practices. Defects in Castings. Cleaning & Salvage of Castings.

11. WELDING TECHNOLOGY: Basic concepts of Welding - Principles and processes of

various welding techniques such as Oxy-acetylene, Shield Arc welding, Inert gas welding-

TIG and MIG - Special welding processes- Plasma, resistance, electro slag, electron beam,

thermit and Laser. Soldering and brazing– Weldability, factors affecting weldability – Heat

affected Zone, Microstructure – Post weld treatments –Welding defects –Inspection and

testing.

ANNEXURE II

Number of question to be set Unit wise (Total 100)

METALLURGICAL ENGINEERING

UNIT NO TOPICS MARKS

I ELEMENTARY PRINCIPLES OF

05

METALLURGY

II FUELS, REFRACTORIES AND

06

PYROMETRY

III METALLURGICAL THERMODYNAMICS 08

IV PHYSICAL METALLURGY 11

V HEAT TREATMENT TECHNOLOGY 12

VI FERROUS EXTRACTIVE METALLURGY 12

VII NON-FERROUS EXTRACTIVE

10

METALLURGY

VIII MATERIAL TESTING 08

IX MECHANICAL METALLURGY 10

X FOUNDRY TECHNOLOGY 09

XI WELDING TECHNOLOGY 09

Total 100

ANNEXURE III

MODEL QUESTIONS FOR METALLURGICAL ENGINEERING

1. Rawmaterial for production of Aluminium is -------

1)Bauxite

2) Cryolite

3) Alumina

4) Gibbsite

2. No of slip systems in FCC structure

1) 12

2) 48

3) 16

4) 03

3. ASTM grain size is measured by ------formula

1) N=2 n-1

2)n=2N-1

3) N=2n-1

4)n=2N-1

4. In proximate analysis of coal___________ is determined.

1) Hydrogen, Nitrogen, Oxygen & Carbon

2) Moisture, ash, Volatile matter & carbon

3) Hydrogen, ash, Oxygen & Carbon

4) Sulphure, Moisture & Carbon.

5. In Iso-thermal process

1) dp=0

2) dt=0

3) dq=0

4) dv=0

6. In LD Process Oxygen is released through the lance at a pressure of __________ .

1) 150-175 psi

2) 100-150 psi

3) 200-250 psi

4) <100 psi

S-ar putea să vă placă și

- Metals From Ores: 2. Scope of Extractive MetallurgyDocument48 paginiMetals From Ores: 2. Scope of Extractive MetallurgyAdetiyo Burhanudin HakimÎncă nu există evaluări

- Engineering Ist Year VIVA Workshop QuestionsDocument4 paginiEngineering Ist Year VIVA Workshop Questionsbekar101275% (24)

- 7 MetallurgyDocument2 pagini7 MetallurgyNarasimha Murthy InampudiÎncă nu există evaluări

- Special ElectivesDocument31 paginiSpecial ElectivesSagarias AlbusÎncă nu există evaluări

- ME3392 SyllabusDocument2 paginiME3392 Syllabusmanoj1316kumar_63152Încă nu există evaluări

- Mett.7th SemDocument9 paginiMett.7th SemLokesh DahiyaÎncă nu există evaluări

- E3 Mme Sem1Document13 paginiE3 Mme Sem16659sukaÎncă nu există evaluări

- E2 S2 MME SyllabusDocument15 paginiE2 S2 MME SyllabusPradeepÎncă nu există evaluări

- 12M304Document2 pagini12M304vinaysammÎncă nu există evaluări

- Schmidt + Clemens: Weld Repair Practices in High Temperature MaterialsDocument46 paginiSchmidt + Clemens: Weld Repair Practices in High Temperature MaterialsmanojballaÎncă nu există evaluări

- Nptel: Steel Making - Web CourseDocument2 paginiNptel: Steel Making - Web CourseSahil JhambÎncă nu există evaluări

- Thermodynamic of Cyanidation of Gold: TermodinamikaDocument14 paginiThermodynamic of Cyanidation of Gold: TermodinamikaJonas Lodewyk HutapeaÎncă nu există evaluări

- Metallurgy SyllabusDocument1 paginăMetallurgy SyllabusSathrudhan ChoudharyÎncă nu există evaluări

- Panorama Final 11-07-2012 PDFDocument292 paginiPanorama Final 11-07-2012 PDFSomdeep DuttaÎncă nu există evaluări

- Sixth Semester: Teaching Scheme Credits 4 ObjectivesDocument15 paginiSixth Semester: Teaching Scheme Credits 4 ObjectivesNitin RautÎncă nu există evaluări

- Me8351 Manufacturing Technology-I SyllabusDocument1 paginăMe8351 Manufacturing Technology-I SyllabusAnonymous ZB6qyhD6Încă nu există evaluări

- Karhu 2020Document11 paginiKarhu 2020James RCÎncă nu există evaluări

- Automoius Sem III & IV SYLLABUSDocument21 paginiAutomoius Sem III & IV SYLLABUS10rajÎncă nu există evaluări

- Study Materials: Physical Metallurgy of Non - Ferrous Metals & AlloysDocument25 paginiStudy Materials: Physical Metallurgy of Non - Ferrous Metals & AlloysSuvodip ChatterjeeÎncă nu există evaluări

- Material Tech Master File Cp01 - I SemDocument50 paginiMaterial Tech Master File Cp01 - I SemvinayakÎncă nu există evaluări

- MT305 Nonferrous Extractive MetallurgyDocument2 paginiMT305 Nonferrous Extractive MetallurgyMerrin John VarkeyÎncă nu există evaluări

- Mt-I Syllabus PDFDocument1 paginăMt-I Syllabus PDFThenarasumohanveluÎncă nu există evaluări

- Production of Sponge Iron Powder by Reduction of Rolling Mill Scale PDFDocument9 paginiProduction of Sponge Iron Powder by Reduction of Rolling Mill Scale PDFLevent öncelÎncă nu există evaluări

- ME104 Manufacturing Process: Suggested ReadingsDocument1 paginăME104 Manufacturing Process: Suggested ReadingsAditya KumarÎncă nu există evaluări

- Tratamientos TermicosDocument52 paginiTratamientos TermicosGuillermo Esqueda SilvaÎncă nu există evaluări

- 3 CamelliDocument4 pagini3 CamelliSilvia CamelliÎncă nu există evaluări

- Base Metal AlloysDocument85 paginiBase Metal AlloysmeghaÎncă nu există evaluări

- Engineering Chemistry IIDocument4 paginiEngineering Chemistry IISatyam SahuÎncă nu există evaluări

- EmmDocument1 paginăEmmBalaji KingÎncă nu există evaluări

- Mf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreDocument2 paginiMf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanÎncă nu există evaluări

- Computer Integrated Manufacturing 05 63xxDocument97 paginiComputer Integrated Manufacturing 05 63xxAnonymous mcFvPwzXÎncă nu există evaluări

- ME8351 Manufacturing Technology I Syllabus Regulation 2017Document2 paginiME8351 Manufacturing Technology I Syllabus Regulation 2017Dr.S.Ravi CITÎncă nu există evaluări

- Metallurgy and Chemistry of Metals: Chem 18Document19 paginiMetallurgy and Chemistry of Metals: Chem 18Milvy Faith C. SyjongtianÎncă nu există evaluări

- ME6403 Emm SyllabusDocument1 paginăME6403 Emm SyllabusdsathiyaÎncă nu există evaluări

- Thermodinamics of Leaching BauxiteDocument13 paginiThermodinamics of Leaching BauxiteAldo JasricoÎncă nu există evaluări

- Wear Resistance of High Chromium White Cast Iron For Coal Grinding RollsDocument9 paginiWear Resistance of High Chromium White Cast Iron For Coal Grinding RollsJoseph CureÎncă nu există evaluări

- Fulltext01 PDFDocument88 paginiFulltext01 PDFvajidqcÎncă nu există evaluări

- Mechanical EngineeringDocument2 paginiMechanical EngineeringSuravaram Krishna PrasadÎncă nu există evaluări

- Mms Manual LabDocument47 paginiMms Manual Labgosaye desalegnÎncă nu există evaluări

- Syllabus MM2303Document2 paginiSyllabus MM2303Hridisaran PandeÎncă nu există evaluări

- Chapter VI. Non-Ferrous MaterialsDocument42 paginiChapter VI. Non-Ferrous MaterialsAjab Ajab AjabÎncă nu există evaluări

- Chemistry Notes VtuDocument160 paginiChemistry Notes VtuNarayan S. Burbure67% (3)

- Refining Processes in The Copper Casting Technology: S. Rzadkosz, M. Kranc, A. Garbacz-Klempka, J. Kozana, M. PiękośDocument4 paginiRefining Processes in The Copper Casting Technology: S. Rzadkosz, M. Kranc, A. Garbacz-Klempka, J. Kozana, M. PiękośエリタノアンソネーÎncă nu există evaluări

- Intro KeramerDocument26 paginiIntro Keramertv009334Încă nu există evaluări

- Engineering Materials and Metallurgy SyllabusDocument2 paginiEngineering Materials and Metallurgy SyllabusSuganthiVasanÎncă nu există evaluări

- MSE Lab ManualDocument35 paginiMSE Lab Manualprashant patilÎncă nu există evaluări

- Engineering MetallurgyDocument2 paginiEngineering MetallurgyROOSSVELT PRABHU K A VÎncă nu există evaluări

- Kuliah Ekstraksi 16 September 2016Document96 paginiKuliah Ekstraksi 16 September 2016HediekaÎncă nu există evaluări

- E2 Mme Sem1Document15 paginiE2 Mme Sem1pshelkeÎncă nu există evaluări

- Govpub C13 PDFDocument46 paginiGovpub C13 PDFSanchit GoelÎncă nu există evaluări

- Experimental Analysis of Aluminium Alloy Reinforced With Rare Earth MetalsDocument12 paginiExperimental Analysis of Aluminium Alloy Reinforced With Rare Earth MetalsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- B Tech 4th SemDocument21 paginiB Tech 4th SemKamurti Ajay KumarÎncă nu există evaluări

- Corrosion Characterization of Aluminium 6061/ Tib2 Metal Matrix Composites in Sodium Hydroxide MediumDocument5 paginiCorrosion Characterization of Aluminium 6061/ Tib2 Metal Matrix Composites in Sodium Hydroxide MediumEditor IJTSRDÎncă nu există evaluări

- Annexure I Mechanical EngineeringDocument2 paginiAnnexure I Mechanical EngineeringNaga Sai MuthyalaÎncă nu există evaluări

- TP 499Document36 paginiTP 499Daiara Budi AlvesÎncă nu există evaluări

- Assignment 1Document35 paginiAssignment 1NitinSrivastavaÎncă nu există evaluări

- Thermodynamics of Secondary Steel MakingDocument14 paginiThermodynamics of Secondary Steel MakingPinÎncă nu există evaluări

- SKB L1 Final Introduction To MSMDocument23 paginiSKB L1 Final Introduction To MSMEmpty DivineÎncă nu există evaluări

- Chemistry Notes 18CHE12 (All. Websites)Document94 paginiChemistry Notes 18CHE12 (All. Websites)arpitaÎncă nu există evaluări

- 20ME403 Engineering Materials and Metallurgy Unit - 1 Digital MaterialDocument55 pagini20ME403 Engineering Materials and Metallurgy Unit - 1 Digital MaterialDark ranger YtÎncă nu există evaluări

- Extractive Metallurgy 3: Processing Operations and RoutesDe la EverandExtractive Metallurgy 3: Processing Operations and RoutesÎncă nu există evaluări

- Metalock ProcessDocument3 paginiMetalock ProcessabrarÎncă nu există evaluări

- Simb Catalogue 2014-15Document132 paginiSimb Catalogue 2014-15Pcfs100% (2)

- South Bend Lathe TrainingDocument68 paginiSouth Bend Lathe TrainingSMWilson100% (2)

- Section 3Document42 paginiSection 3renebbÎncă nu există evaluări

- Electrode CalculationDocument2 paginiElectrode Calculationkoyahassan100% (10)

- 2008 - 8 - DIN Threaded FittingsDocument10 pagini2008 - 8 - DIN Threaded FittingsandytuorÎncă nu există evaluări

- J.A.Ghani, K. Othman, M.N.A. Rahman, B.M. Deros and C.H.C.HaronDocument5 paginiJ.A.Ghani, K. Othman, M.N.A. Rahman, B.M. Deros and C.H.C.HaronJesús Adrián Santana LuzÎncă nu există evaluări

- Involute IGW PRESENTATION JUNE 2017Document31 paginiInvolute IGW PRESENTATION JUNE 2017prakash 3Încă nu există evaluări

- DR 600001Document4 paginiDR 600001UditChampaneriaÎncă nu există evaluări

- G33 ThreadingDocument8 paginiG33 ThreadingAvinash KumarÎncă nu există evaluări

- CATIA Apt CodeDocument24 paginiCATIA Apt CodeparipasuÎncă nu există evaluări

- CNC Applications: Introduction To Turning CentersDocument10 paginiCNC Applications: Introduction To Turning Centershazreen othmanÎncă nu există evaluări

- 01 A Tower Material 220kv Line ZebraDocument15 pagini01 A Tower Material 220kv Line ZebraVaibhav JainÎncă nu există evaluări

- I. Reading Development A. Before You ReadDocument11 paginiI. Reading Development A. Before You Readhilda wirandaÎncă nu există evaluări

- Keedex Price Book - 2015Document12 paginiKeedex Price Book - 2015Security Lock DistributorsÎncă nu există evaluări

- Machines and Systems For Metal Sheet WorkingDocument8 paginiMachines and Systems For Metal Sheet WorkingStefa - Folding, Slitting and Forming MachinesÎncă nu există evaluări

- Common G and M Codes For CNC MachinesDocument2 paginiCommon G and M Codes For CNC MachinesSiddhrajsinh ZalaÎncă nu există evaluări

- Demo in TleDocument47 paginiDemo in TleRose Amor Mercene-LacayÎncă nu există evaluări

- Steel ShotDocument6 paginiSteel ShotExcel Hydro Pneumatics (INDIA) EHPIÎncă nu există evaluări

- Costing Format - Press ToolDocument6 paginiCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- Electro Spark Metal Engraving PensDocument1 paginăElectro Spark Metal Engraving Pensdjordjes123100% (1)

- Din 6388 Boquilla Elastica PDFDocument14 paginiDin 6388 Boquilla Elastica PDFCristianÎncă nu există evaluări

- First Year Theory ITIDocument2 paginiFirst Year Theory ITImangla prasadÎncă nu există evaluări

- Nontraditional Manufacturing ProcessesDocument157 paginiNontraditional Manufacturing ProcessesKiran AsknaniÎncă nu există evaluări

- Airel F-35770Document46 paginiAirel F-35770papashoÎncă nu există evaluări

- Brandix ReportDocument55 paginiBrandix ReportCharitha RanwalaÎncă nu există evaluări

- Lecture 04Document27 paginiLecture 04t75zswxgwfÎncă nu există evaluări

- Manual Lathes: The World Turns On Colchester LathesDocument8 paginiManual Lathes: The World Turns On Colchester Lathesfarid said errahmaniÎncă nu există evaluări