Documente Academic

Documente Profesional

Documente Cultură

QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Servicio

Încărcat de

Hamilton mirandaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Servicio

Încărcat de

Hamilton mirandaDrepturi de autor:

Formate disponibile

(/qs3/pubsys2/xml/en/manual/4310736/4310736-titlepage.

html)

Inspeccionar

Aceite lubricante

Un análisis del aceite usado puede ayudar a diagnosticar el

daño interno del motor y determinar si fue causado por uno de

los siguientes:

Mal funcionamiento del filtro de aire de admisión

Fugas de refrigerante

Aceite diluido con combustible

Partículas cerámicas o metálicas que causan desgaste.

Para obtener información adicional sobre el análisis de aceite,

consulte las recomendaciones de análisis de aceite y aceite

del motor Cummins®, Boletín 3810340.

Note : Do not disassemble an engine for repair based

only on the results of an oil analysis. The oil filter must

also be inspected. If the oil filter shows evidence of

internal engine damage, find the source of the problem

and repair the damage. Use the appropriate

procedure(s) based on the following oil filter

inspection.

Lubricating Oil Filter

WARNING

Some state and federal agencies have determined that used

engine oil can be carcinogenic and cause reproductive

toxicity. Avoid inhalation of vapors, ingestion, and prolonged

contact with used engine oil. If not reused, dispose of in

accordance with local environmental regulations.

WARNING

Carefully cut open the upper section of the combination filter.

The filter element spring is under compression and can

cause personal injury.

Use the tube cutter, Part Number 3376579, to open the upper

section of the combination filter.

Remove the filter element from the can for inspection. Check

for evidence of moisture or foreign particles.

Note : For more accurate inspection results of the filter

element, excess oil must be pressed out of the filter

media with a shop vise or similar.

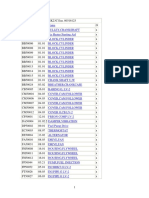

Element Probable Source

Copper Bearings and bushings

Chromium Piston rings

Iron Cylinder liners

Lead Bearings and bushings

Aluminum Pistons and bushings

Ceramic Fuel pump plungers

Steel Fuel pump roller tappet(s)

Note : If foreign particles are observed, it is always best

to positively identify them and determine their

origination.

If ceramic or steel particles are observed reference TSB140019

Fuel Pump – Plunger and Tappet Roller Inspection and Repair.

Clean and Inspect for Reuse

WARNING

Wear appropriate eye and face protection when using

compressed air. Flying debris and dirt can cause personal

injury.

For all other internal engine malfunctions which introduce

debris into the lubricating oil system, complete the following:

Replace:

Lubricating oil cooler element. Refer to Procedure 007-007 in

Section 7 (/qs3/pubsys2/xml/en/procedures/175/175-007-

007-tr.html).

Lubricating oil filter bypass valve. Refer to Procedure 007-014

in Section 7 (/qs3/pubsys2/xml/en/procedures/175/175-007-

014-tr.html).

Lubricating oil thermostat. Refer to Procedure 007-039 in

Section 7 (/qs3/pubsys2/xml/en/procedures/175/175-007-

039-tr.html).

Special care must be taken to be sure these parts are kept

extremely clean if removed.

Do not use cleaning agents, other than contact cleaner.

Clean lubricating oil cooler housing. Refer to Procedure

007-003 (/qs3/pubsys2/xml/en/procedures/175/175-007-

003-tr.html).

Clean the lubricating oil pan. Refer to Procedure 007-025

in Section 7 (/qs3/pubsys2/xml/en/procedures/175/175-

007-025-tr.html).

Remove and inspect the Lubricating oil pump for reuse.

Refer to Procedure 007-031 in Section 7

(/qs3/pubsys2/xml/en/procedures/175/175-007-031-

tr.html).

If damage is found on number 1 and number 4 rod

bearings, roll new connecting rod bearings in on all 6

journals. Refer to Procedure 001-006 in Section 1

(/qs3/pubsys2/xml/en/procedures/175/175-001-006-

tr.html). Refer to Procedure 001-007 in Section 1

(/qs3/pubsys2/xml/en/procedures/175/175-001-007-

tr.html). Refer to Procedure 001-014 in Section 1

(/qs3/pubsys2/xml/en/procedures/175/175-001-014-

tr.html). Otherwise, replace only number 1 and number 4

rod bearings.

Roll new main bearings in on all 7 main journals and new

thrust bearings on number 4 main journal.

Finishing Steps

Install lubricating oil pan and other components removed to

access main bearings. Refer to Procedure 007-025 in Section 7

(/qs3/pubsys2/xml/en/procedures/175/175-007-025-tr.html).

Install lubricating oil filter. Refer to Procedure 007-013 in

Section 7 (/qs3/pubsys2/xml/en/procedures/175/175-007-

013-tr.html).

Cebe y llene el motor con aceite lubricante nuevo. Consulte el

Procedimiento 007-037 en la Sección 7

(/qs3/pubsys2/xml/en/procedures/175/175-007-037-tr.html) .

Opere el motor a la temperatura de funcionamiento normal y

verifique que no haya fugas y que funcione correctamente.

Última modificación: 28-jul-2016

S-ar putea să vă placă și

- Detroit S60 SpecsDocument2 paginiDetroit S60 Specsgrgramm50% (2)

- Bobinas Freno de Motor Jacobs BrakeDocument2 paginiBobinas Freno de Motor Jacobs BrakePaqko EscamillaOfficialÎncă nu există evaluări

- CUMMINS N14 Specifications - ManualzzDocument3 paginiCUMMINS N14 Specifications - ManualzzChâu TínÎncă nu există evaluări

- High Pressure Fuel Lines and Transfer Tubes Removal and Installation Procedure Has Been UpdatedDocument10 paginiHigh Pressure Fuel Lines and Transfer Tubes Removal and Installation Procedure Has Been UpdatedTaufan ArifÎncă nu există evaluări

- Pin Out CelectDocument1 paginăPin Out Celect123gilligan100% (1)

- Cummins Cat Al 08-08Document4 paginiCummins Cat Al 08-08FABIAN MARTINEZ50% (2)

- PDF - Isx MotorDocument4 paginiPDF - Isx MotorJanier100% (1)

- Luces International InstalacionDocument157 paginiLuces International InstalaciondanflocaÎncă nu există evaluări

- Technical Service Bulletin: ISB4.5 CM2150 SN and ISB6.7 CM2150 SN Engine IntroductionDocument3 paginiTechnical Service Bulletin: ISB4.5 CM2150 SN and ISB6.7 CM2150 SN Engine IntroductionIan WoodsÎncă nu există evaluări

- QST30 MineriaDocument4 paginiQST30 MineriaElio Custodio Huachaca100% (1)

- Cummins n855 Engine Specs PDF FreeDocument6 paginiCummins n855 Engine Specs PDF Freema.powersourceÎncă nu există evaluări

- 4971108Document6 pagini4971108Massahiro FilhoÎncă nu există evaluări

- Air Intake System Exhaust System Exhaust GasDocument2 paginiAir Intake System Exhaust System Exhaust Gassinger50Încă nu există evaluări

- 18SP664 Cambio Actuador TurboDocument6 pagini18SP664 Cambio Actuador TurboAngel DlsgÎncă nu există evaluări

- Manual Partes Eaton Fuller RTLF-13710B PDFDocument46 paginiManual Partes Eaton Fuller RTLF-13710B PDFBayro Yobanny Aveiga VeraÎncă nu există evaluări

- Detroit Torque PDFDocument2 paginiDetroit Torque PDFMuhammad rizkiÎncă nu există evaluări

- Cummins IsxDocument3 paginiCummins IsxFaudy Jonas Gonzalez CastilloÎncă nu există evaluări

- The Delphi Advantage.: Remanufactured All Makes Diesel Fuel InjectorsDocument2 paginiThe Delphi Advantage.: Remanufactured All Makes Diesel Fuel InjectorsEphrem MichaelÎncă nu există evaluări

- Enclosed Are The February 2022 Incal Dvd-RomsDocument4 paginiEnclosed Are The February 2022 Incal Dvd-RomsEdwin Alfonso Hernandez Montes100% (1)

- Fault Code 155: Intake Manifold Air Temperature High - CriticalDocument3 paginiFault Code 155: Intake Manifold Air Temperature High - Criticalhamilton miranda100% (1)

- Aeb 02138Document33 paginiAeb 02138Bosko KalicaninÎncă nu există evaluări

- Solución de Fallas Fallas Motor IsxDocument3 paginiSolución de Fallas Fallas Motor IsxHamilton MirandaÎncă nu există evaluări

- Copia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)Document73 paginiCopia de QSK19 Engine Fuel System Familiarization (Sólo Lectura)Gallego CarlosÎncă nu există evaluări

- Ajuste de Piston Esclavo Freno MotorDocument4 paginiAjuste de Piston Esclavo Freno MotorMuriel RembertoÎncă nu există evaluări

- Aeb09202 PDFDocument16 paginiAeb09202 PDFCesar G.Încă nu există evaluări

- Vs. Caterpillar 3126E/C7: International InternationalDocument5 paginiVs. Caterpillar 3126E/C7: International InternationalClaudia Montes100% (1)

- Fault Code 261Document3 paginiFault Code 261Enrrique LaraÎncă nu există evaluări

- Firestone BagsDocument251 paginiFirestone BagsJIMJEOÎncă nu există evaluări

- TR Cummins B TSLDocument1 paginăTR Cummins B TSLX'mix ĐreamerÎncă nu există evaluări

- C-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product StructureDocument4 paginiC-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product Structurebasem elhosanyÎncă nu există evaluări

- 100-6920 ADAPTER Cat® Parts StoreDocument1 pagină100-6920 ADAPTER Cat® Parts StoreMohmed Abo Elftoh100% (1)

- Eaton Fuller RTLOF 16918B Transmission Parts ManualDocument42 paginiEaton Fuller RTLOF 16918B Transmission Parts ManualPaty CervantesÎncă nu există evaluări

- Isx15overhaulkit Content BypartnumberDocument2 paginiIsx15overhaulkit Content BypartnumberEdwin Javier Garavito Hernández100% (1)

- Ecf9 Nh3 ManualDocument20 paginiEcf9 Nh3 Manualgonza100% (1)

- Engine Fault Codes (MID, PID, SID, FMI) FREIGHTLINERDocument12 paginiEngine Fault Codes (MID, PID, SID, FMI) FREIGHTLINERhaviettuanÎncă nu există evaluări

- Injection Timing ChartDocument17 paginiInjection Timing ChartAli ArdinÎncă nu există evaluări

- "We Should Do Everything in Our Power ": CUMMINS 2021 X15 Engine PortfolioDocument6 pagini"We Should Do Everything in Our Power ": CUMMINS 2021 X15 Engine PortfolioВлаткоÎncă nu există evaluări

- RTL 14710B 1108Document38 paginiRTL 14710B 1108Adal Vera100% (1)

- C13 TorqueDocument1 paginăC13 TorqueScribdTranslationsÎncă nu există evaluări

- Kenworth T800 Brochure.Document28 paginiKenworth T800 Brochure.scribdadiddlyÎncă nu există evaluări

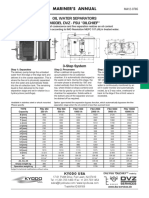

- Oil Water Separators Model DVZ - Fsu "Oilchief": 3-Step SystemDocument1 paginăOil Water Separators Model DVZ - Fsu "Oilchief": 3-Step SystemRajishkumar RadhakrishnanÎncă nu există evaluări

- Spicer Pso140 10s Pso150 Pso165 Lpso Llpso Series Parts ManualDocument46 paginiSpicer Pso140 10s Pso150 Pso165 Lpso Llpso Series Parts ManualHamilton Miranda100% (1)

- 019-440 Aftertreatment Diesel Exhaust Fluid Dosing UnitDocument9 pagini019-440 Aftertreatment Diesel Exhaust Fluid Dosing UnitIan WoodsÎncă nu există evaluări

- Caterpillar Engine Service Manual CT S Eng d343Document7 paginiCaterpillar Engine Service Manual CT S Eng d343Farshaaad HkÎncă nu există evaluări

- Diagrama CollageDocument14 paginiDiagrama CollageJuan del AngelÎncă nu există evaluări

- Every Coverage.: North American Truck Coverages For 2013 ISX15 and ISX12 EnginesDocument6 paginiEvery Coverage.: North American Truck Coverages For 2013 ISX15 and ISX12 EnginesLuis alberto100% (1)

- Drivemaster 2speed Installation InstructionsDocument17 paginiDrivemaster 2speed Installation InstructionsAngel DlsgÎncă nu există evaluări

- Cummins N14 Engine Overhaul PartsDocument9 paginiCummins N14 Engine Overhaul PartsTong Hai Wang100% (1)

- Description Description: Replacement Engine Brake Parts For JacobsDocument6 paginiDescription Description: Replacement Engine Brake Parts For JacobsAaronGomezÎncă nu există evaluări

- Eaton Fuller Heavy Duty Transmission Troubleshooting Guide Trts0910 en UsDocument42 paginiEaton Fuller Heavy Duty Transmission Troubleshooting Guide Trts0910 en Ustito del pino100% (2)

- C15 Acert: Industrial Caterpillar Engine SpecificationsDocument4 paginiC15 Acert: Industrial Caterpillar Engine Specificationsyash singhÎncă nu există evaluări

- Product identification information: Note: Must refer to the information of nameplate when look for the parts。Document781 paginiProduct identification information: Note: Must refer to the information of nameplate when look for the parts。oussama benzeggoutaÎncă nu există evaluări

- Codigos de Falla Del BHMDocument14 paginiCodigos de Falla Del BHMJusto Paniagua ChampaÎncă nu există evaluări

- c4.4 Sistema ElectricoDocument7 paginic4.4 Sistema ElectricoAngelica VergaraÎncă nu există evaluări

- TD-ScalerS324-01 Scaler S324 Tech Drawing PDFDocument2 paginiTD-ScalerS324-01 Scaler S324 Tech Drawing PDFJaa Jawad EnnÎncă nu există evaluări

- Fuller Rtlo 18918bDocument2 paginiFuller Rtlo 18918bAnthony GarzaÎncă nu există evaluări

- Eaton Fuller On Off Highway Transmissions Brochure Trsl0116 en UsDocument2 paginiEaton Fuller On Off Highway Transmissions Brochure Trsl0116 en UsSebastian Olaya0% (1)

- 3406E+and+C15+Marine+Engines Maintenance+IntervalsDocument21 pagini3406E+and+C15+Marine+Engines Maintenance+IntervalsJason McLaughlin100% (2)

- 3406E and C15 Marine Engines-Maintenance IntervalsDocument21 pagini3406E and C15 Marine Engines-Maintenance Intervalswoulkan100% (2)

- Amt 646 Midterm 2Document14 paginiAmt 646 Midterm 2Tyron CastroÎncă nu există evaluări

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument14 paginiQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton mirandaÎncă nu există evaluări

- Service Bulletin Trucks: SB730005, Adaptive Cruise With Braking, TroubleshootingDocument21 paginiService Bulletin Trucks: SB730005, Adaptive Cruise With Braking, TroubleshootingHamilton mirandaÎncă nu există evaluări

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Servicio PDFDocument3 paginiQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de Servicio PDFHamilton mirandaÎncă nu există evaluări

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDocument14 paginiQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton mirandaÎncă nu există evaluări

- QSK45-60G 4021359 GDocument6 paginiQSK45-60G 4021359 GHamilton mirandaÎncă nu există evaluări

- D13F Viscoso Fan ChekDocument2 paginiD13F Viscoso Fan ChekHamilton mirandaÎncă nu există evaluări

- Cam Timing DDEC S50Document4 paginiCam Timing DDEC S50Hamilton mirandaÎncă nu există evaluări

- DDC War Man 0014Document12 paginiDDC War Man 0014Hamilton mirandaÎncă nu există evaluări

- Engine Brake DD15Document7 paginiEngine Brake DD15Hamilton miranda100% (1)

- RR Trmt0952Document6 paginiRR Trmt0952Hamilton mirandaÎncă nu există evaluări

- NUMBER: 8 04-10 S.M. REF.: Listed in Table ENGINE: EPA07/10 DD Platform DateDocument4 paginiNUMBER: 8 04-10 S.M. REF.: Listed in Table ENGINE: EPA07/10 DD Platform DateHamilton mirandaÎncă nu există evaluări

- 3226 Fmi 13Document6 pagini3226 Fmi 13Hamilton miranda100% (2)

- 876 MC 5 X 5 TWDocument29 pagini876 MC 5 X 5 TWHamilton mirandaÎncă nu există evaluări

- D1503 - Head GasketDocument2 paginiD1503 - Head GasketIvaylo PetkovÎncă nu există evaluări

- ABB Turbocharging TPS - . - F32 - A New Series of Small Turbochargers For Higher Pressure RatiosDocument2 paginiABB Turbocharging TPS - . - F32 - A New Series of Small Turbochargers For Higher Pressure RatiosTibor AngeloÎncă nu există evaluări

- Timing Belt - AutodataDocument6 paginiTiming Belt - AutodatacecoldclubÎncă nu există evaluări

- GSX R600k7e3 PDFDocument104 paginiGSX R600k7e3 PDFAdolfoÎncă nu există evaluări

- Balita 1.3LDocument9 paginiBalita 1.3LReinaldo ArrivillagaÎncă nu există evaluări

- 2005 Diesel Ref Manual PDFDocument68 pagini2005 Diesel Ref Manual PDFWilmer P MendozaÎncă nu există evaluări

- 5Document253 pagini5julian marinÎncă nu există evaluări

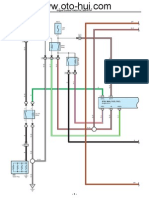

- Wiring Diagram ECU 2KD-FTVDocument13 paginiWiring Diagram ECU 2KD-FTVDam Nguyen88% (96)

- S26MC - MK - 6 - Project - Guide M20 M25 M32 M43 M281-332C M451-453 M551-552 M601CDocument241 paginiS26MC - MK - 6 - Project - Guide M20 M25 M32 M43 M281-332C M451-453 M551-552 M601CМария ЗинченкоÎncă nu există evaluări

- Cut The Cylinder Oil Bill and Reduce Emissions With The ACCDocument4 paginiCut The Cylinder Oil Bill and Reduce Emissions With The ACCKamal WanniarachchiÎncă nu există evaluări

- IC Course Guide BookDocument5 paginiIC Course Guide BookAddisu AyeleÎncă nu există evaluări

- Lifan 125cc 1P52FMI Parts List ManualDocument33 paginiLifan 125cc 1P52FMI Parts List ManualMinibikeTech92% (12)

- Aftercooler Water PlumbingDocument3 paginiAftercooler Water Plumbingtechnicaldept.mtkrÎncă nu există evaluări

- Exhaust Gas Recirculation System PDFDocument2 paginiExhaust Gas Recirculation System PDFDeniseÎncă nu există evaluări

- C85 Overhaul ManualDocument123 paginiC85 Overhaul Manualdanifer61100% (1)

- Lincoln SL1 - SLV ComparisonDocument4 paginiLincoln SL1 - SLV ComparisonJed MayÎncă nu există evaluări

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pagini2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozÎncă nu există evaluări

- Finding Top Center Position For No. 1 Piston: Shutdown SIS Previous ScreenDocument3 paginiFinding Top Center Position For No. 1 Piston: Shutdown SIS Previous ScreenbejoythomasÎncă nu există evaluări

- Marine Spec 10V12V16V2000M86 1DDocument2 paginiMarine Spec 10V12V16V2000M86 1DnaufragatoÎncă nu există evaluări

- QSK23CDocument100 paginiQSK23CNova kurniawan 3450% (2)

- Study ExpDocument41 paginiStudy ExpNishant Nagle100% (1)

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 paginiCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- CM2 Spareparts CatalogueDocument60 paginiCM2 Spareparts CataloguepapatangocomercialÎncă nu există evaluări

- 2stroke Engine Vs 4 Stroke EngineDocument7 pagini2stroke Engine Vs 4 Stroke EngineEmmanuvalBabyKizhakkelÎncă nu există evaluări

- 2006 MFS25B 30B 003-21054-1Document310 pagini2006 MFS25B 30B 003-21054-1Bob SmithscribdÎncă nu există evaluări

- Craftsman Model 143.994510 Parts ListDocument5 paginiCraftsman Model 143.994510 Parts ListRachel MeissnerÎncă nu există evaluări

- Conectores de Sensores y Actuadores de Spark 2008 1.0Document13 paginiConectores de Sensores y Actuadores de Spark 2008 1.0Victor SanchezÎncă nu există evaluări

- Discover 125ST 100T SPCDocument78 paginiDiscover 125ST 100T SPCVivek Raja92% (12)

- Sis 2.0Document3 paginiSis 2.0Jose Corcega britoÎncă nu există evaluări

- PC PC10015P Jan12 PTDocument792 paginiPC PC10015P Jan12 PTJose nildo lobato Mendes Mendes0% (1)