Documente Academic

Documente Profesional

Documente Cultură

Plumbing Inspection Checklist: Pass Fail Partial Pass

Încărcat de

Abhijeet SharmaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plumbing Inspection Checklist: Pass Fail Partial Pass

Încărcat de

Abhijeet SharmaDrepturi de autor:

Formate disponibile

Plumbing Inspection Checklist RESULT OF INSPECTION

Pass

Fail

Partial Pass

Project : 300 Rooms Hotel (Leela) - GARUD

Date:

INSPECTION ITEMS A D N/A INSPECTION ITEMS A D N/A

1. Make sure that all piping is properly supported 1. Check the listing of manufacture’s approvals –

and strapped – 308.1 303.1

2. Check the materials and workmanship – 1102.6 20. Check for approval agency - 303.4.1

21. Require all concealed work to be left exposed

3. Check heights of vents above fixture rims – 905.4 until after the inspection – 405.8

4. Follow vents to the roof, checking for size and

22. Access to concealed equipment - 405.8, 422.5

length limits – 905.1

5. Building traps shall be provided with a clean out 23. Water heaters shall be located and connected so

and a relief vent or fresh air intake on the inlet as to provide access for observation,

side of the trap -1002.6 maintenance, servicing and replacement – 501.4

6. Relief vent or fresh air intake shall be carried 24. An inspection opening shall be provided over

above grade & terminated in a screened outlet either the inlet or outlet baffle of every treatment

located outside the building – 1002.6 tank – 802.5

7. Drainage and vent water test, filling stack with

25. Check water pressure with a gauge 312.5

water – 312.2

8. Drainage and vent air test – 312.3 26. Verify that piping is properly supported – 308.1

27. Plumbing systems shall not be located in an

9. Gravity sewer test 312.6 elevator shaft or in an elevator equipment room –

301.6

10. Check waste pipe for required size and type – 28. In inspecting layout and size of water piping –

301.5 603.1

11. Add up units to determine size of main drain – 29. Separation of water service and building

1103.1 sewer/drain – 603.2

12. Check that drain pipe is supported – 306.1 30. Location of full-open valves – 606.1

13. Check horizontal pipes for proper grade – 905.2 31. Check for cross-connections – 608.1

14. Verify that all piping in the ground is suitably 32. Determine number of fixture units for each branch

protected - 306.2 line – 710.1

33. Septic tank shall be not less than 50-0 gallons and

15. Make sure that backfill is code complaint - 306.3 the secondary tank shall be not less than 250

gallons – 802.2

16. Check trap sizes and location 504.7.1 34. Drain well shall be a minimum of 50’ deep

35. Septic tank shall have not less than two tanks –

17. Check cleanouts – 708.2-4, 708.4

802.3

18. Inspect system for leaks and workmanship – 36. Tank shall have sanitary tees or baffles to distribute

1102.6 flow – 802.3

19. Where pipe is to be installed by tunneling it is 37. Septic tank manhole cover shall have (2) 24” x 24”

protected – 306.4 access/manhole covers at grade – 802.4

20. Inspect backflow prevention – 312.9 38. Alternate materials and required testing - 105.2-3

Note: This form is intended as a general checklist and is not intended to address all possible conditions of approval.

A = Approved, D = Disapproved, N/A = Not applicable

Notes:

MEPF Contractor OWNER / PMC

S-ar putea să vă placă și

- Checklist (Underground Pipe Laying Report) : Mr. Aden LiuDocument36 paginiChecklist (Underground Pipe Laying Report) : Mr. Aden LiuADEN LIU100% (1)

- Sanitary Check ListDocument36 paginiSanitary Check ListankurÎncă nu există evaluări

- Sanitary Check ListDocument52 paginiSanitary Check ListankurÎncă nu există evaluări

- Plumbing Inspection ChecklistDocument1 paginăPlumbing Inspection ChecklistSiti Rohani IsdrisÎncă nu există evaluări

- Check ListDocument1 paginăCheck ListPradeep MalhotraÎncă nu există evaluări

- FPM 222 Checklist PlumbingDocument4 paginiFPM 222 Checklist PlumbingAarnav SinghÎncă nu există evaluări

- M - HW - Pipework INSPECTION CHECKLISTDocument1 paginăM - HW - Pipework INSPECTION CHECKLISTmandelaria01Încă nu există evaluări

- 115A - Water Proofing Checklist For ToiletDocument1 pagină115A - Water Proofing Checklist For Toiletbeshnu garanaikÎncă nu există evaluări

- M - Sanitary & Plumbing INSPECTION CHECKLISTDocument1 paginăM - Sanitary & Plumbing INSPECTION CHECKLISTmandelaria0163% (8)

- Checklist - Fire FightingDocument1 paginăChecklist - Fire FightingAarnav SinghÎncă nu există evaluări

- Installation Check Sheet For Ahu FahuDocument2 paginiInstallation Check Sheet For Ahu FahuSamer AliÎncă nu există evaluări

- 15.checklist For Interior PlasteringDocument4 pagini15.checklist For Interior PlasteringPradeep MalhotraÎncă nu există evaluări

- Fire Pro ChecklistDocument81 paginiFire Pro ChecklistADEN LIUÎncă nu există evaluări

- 1A-Check List - CI Pipes - InstallationDocument1 pagină1A-Check List - CI Pipes - InstallationRajput AmitÎncă nu există evaluări

- PlumbingDocument1 paginăPlumbingGabriel GabeÎncă nu există evaluări

- M - NG - Pipework INSPECTION CHECKLISTDocument1 paginăM - NG - Pipework INSPECTION CHECKLISTmandelaria01Încă nu există evaluări

- Project: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistDocument2 paginiProject: Contract Ref: Project No: Location: Drawing Ref: Rfi No: Descrption: VRF System Installation Inspection ChecklistWasim AhmedÎncă nu există evaluări

- Installation of Domestic Water Piping SystemDocument1 paginăInstallation of Domestic Water Piping SystemosamamaeÎncă nu există evaluări

- Check List For Fire Alarm & Voice Evacuation SystemDocument1 paginăCheck List For Fire Alarm & Voice Evacuation SystemmohammadÎncă nu există evaluări

- Fire Fighting PipesDocument1 paginăFire Fighting PipesMIDHUN RAJÎncă nu există evaluări

- Checklist For VDFDocument1 paginăChecklist For VDFGabriel GabeÎncă nu există evaluări

- Quality Control - Works Inspection: Glazed DoorsDocument1 paginăQuality Control - Works Inspection: Glazed DoorsParasÎncă nu există evaluări

- T&C Chilled Water BalancingDocument1 paginăT&C Chilled Water BalancingAzwan SunlineÎncă nu există evaluări

- M - AC Pipework INSPECTION CHECKLISTDocument1 paginăM - AC Pipework INSPECTION CHECKLISTmandelaria01Încă nu există evaluări

- A-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksDocument25 paginiA-2.2!10!20-01 - Checklist For Plumbing and Fire-Fighting WorksUnna Malai50% (2)

- Quality Control - Works Inspection: Granite Door FrameDocument1 paginăQuality Control - Works Inspection: Granite Door FrameParas100% (1)

- QA/Qc - Checklist Sewer LineDocument2 paginiQA/Qc - Checklist Sewer Lineyash shah100% (2)

- Checklist For Sanitary Wares Installation (Ibis)Document4 paginiChecklist For Sanitary Wares Installation (Ibis)Rommel Leyva100% (1)

- CHECKLIST For Installation & Testing of Chilled Water Pipe WorkDocument1 paginăCHECKLIST For Installation & Testing of Chilled Water Pipe WorkTHEOPHILUS ATO FLETCHER100% (1)

- Sanitary and Plumbing checklist-Rev-R7Document1 paginăSanitary and Plumbing checklist-Rev-R7Guna SekaranÎncă nu există evaluări

- Work Method Statement For False Flooring.Document4 paginiWork Method Statement For False Flooring.Punk GowthamanÎncă nu există evaluări

- Checklist For Above Ground Water Piping InstallationDocument1 paginăChecklist For Above Ground Water Piping InstallationBelal Alrwadieh50% (2)

- Plastering Checklist PDFDocument1 paginăPlastering Checklist PDFabdelmjidÎncă nu există evaluări

- Plumbing - Check List - FlatDocument3 paginiPlumbing - Check List - FlatMd AbdulÎncă nu există evaluări

- Subcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoDocument1 paginăSubcontractor: Equipment / Ref.: Manufacturer: Model: Serial NoAzwan SunlineÎncă nu există evaluări

- CHECKLIST For Installation of Above Ground Drainage Pipe WorkDocument1 paginăCHECKLIST For Installation of Above Ground Drainage Pipe WorkTHEOPHILUS ATO FLETCHERÎncă nu există evaluări

- Sunken Filling ChecklistDocument1 paginăSunken Filling ChecklistASHOKKUMARÎncă nu există evaluări

- Quality Control - Works Inspection: Aluminium SkirtingDocument1 paginăQuality Control - Works Inspection: Aluminium SkirtingParasÎncă nu există evaluări

- Plumbing ChecklistDocument6 paginiPlumbing ChecklistsreenathÎncă nu există evaluări

- Final Checklist-SLABDocument2 paginiFinal Checklist-SLABAh Rashed100% (1)

- Barkat Infraprojects: Checklist Fabrication / Fixing of Structural SteelDocument1 paginăBarkat Infraprojects: Checklist Fabrication / Fixing of Structural SteelZahid SayyedÎncă nu există evaluări

- Checklist For Installation of Pressurization UnitDocument1 paginăChecklist For Installation of Pressurization Unitvictor100% (3)

- C4M Aluminium Sliding WorksDocument1 paginăC4M Aluminium Sliding WorksKishoreÎncă nu există evaluări

- CHECKLIST For Installation of of Hot & Cold Water Supply Pipe WorkDocument1 paginăCHECKLIST For Installation of of Hot & Cold Water Supply Pipe WorkTHEOPHILUS ATO FLETCHERÎncă nu există evaluări

- Checklist For Tiles FlooringDocument2 paginiChecklist For Tiles FlooringKishoreÎncă nu există evaluări

- Pour CardDocument1 paginăPour CardJohn DoeÎncă nu există evaluări

- Date: Plaster Commencement Permission Name of The Work: Floor Drawing No. Location Sr. No. Check PointsDocument2 paginiDate: Plaster Commencement Permission Name of The Work: Floor Drawing No. Location Sr. No. Check PointsAnonymous Of0C4dÎncă nu există evaluări

- Checklist Underground FF Piping InstallationDocument1 paginăChecklist Underground FF Piping Installationbeho2000Încă nu există evaluări

- Portals - 0 - Checklist For Internal Plumbing WorkDocument2 paginiPortals - 0 - Checklist For Internal Plumbing Workrahul kumarÎncă nu există evaluări

- Electrical Inspections ChecklistDocument6 paginiElectrical Inspections Checklistasyraf azaharyÎncă nu există evaluări

- Checklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationDocument4 paginiChecklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationBeni N SoloÎncă nu există evaluări

- Quality Checklist For Site Works: Water ProofingDocument1 paginăQuality Checklist For Site Works: Water ProofingLordgie AgtucaÎncă nu există evaluări

- CHECKLIST For Installation & Testing of Fire Fighting Pipe WorkDocument1 paginăCHECKLIST For Installation & Testing of Fire Fighting Pipe WorkTHEOPHILUS ATO FLETCHER50% (2)

- Check List For Block Brick WorkDocument4 paginiCheck List For Block Brick Workvenugopal mvvÎncă nu există evaluări

- Inspection & Test Plan For Cold-Hot Water (PPR) Pipe Work: 1 MaterialDocument1 paginăInspection & Test Plan For Cold-Hot Water (PPR) Pipe Work: 1 Materialrkss100% (1)

- Kempegowda International Airport - NSPR: Before Concreting Description Checked & Found Ok Remarks YES NO N/ADocument2 paginiKempegowda International Airport - NSPR: Before Concreting Description Checked & Found Ok Remarks YES NO N/Adhanush gtÎncă nu există evaluări

- Checklist For Wall Tiling or Dado WorkDocument1 paginăChecklist For Wall Tiling or Dado WorkDinesh Kumar PatelÎncă nu există evaluări

- Testing and CommissioningDocument15 paginiTesting and CommissioningAnil Radheshwar100% (2)

- Plumbing ChecklistDocument1 paginăPlumbing Checklistnussufull100% (3)

- 06 Sec. 4 Sewer TestingDocument22 pagini06 Sec. 4 Sewer TestinglingamkumarÎncă nu există evaluări

- ESG20200224 - Service Guide For Galaxy Z Flip - Bloom1 PDFDocument50 paginiESG20200224 - Service Guide For Galaxy Z Flip - Bloom1 PDFAbhijeet SharmaÎncă nu există evaluări

- ESG20200227 Upload Customer Invoice During Instt PDFDocument2 paginiESG20200227 Upload Customer Invoice During Instt PDFAbhijeet SharmaÎncă nu există evaluări

- ESG20200227 Upload Customer Invoice During Instt PDFDocument2 paginiESG20200227 Upload Customer Invoice During Instt PDFAbhijeet SharmaÎncă nu există evaluări

- Statutory Compliance Certificate PDFDocument1 paginăStatutory Compliance Certificate PDFAbhijeet SharmaÎncă nu există evaluări

- Distribution Board - Inspection Form Identification: Inspected By: Technician Signature: Date: Inspection Items Item Non-Compliance Pass Fail N/ADocument1 paginăDistribution Board - Inspection Form Identification: Inspected By: Technician Signature: Date: Inspection Items Item Non-Compliance Pass Fail N/ASyed AmjadÎncă nu există evaluări

- Form A 3Document1 paginăForm A 3Budy SinagaÎncă nu există evaluări

- Adsorbents and Adsorption Processes For Pollution ControlDocument30 paginiAdsorbents and Adsorption Processes For Pollution ControlJoao MinhoÎncă nu există evaluări

- Pantera 900Document3 paginiPantera 900Tuan Pham AnhÎncă nu există evaluări

- Neopuff PDFDocument4 paginiNeopuff PDFoechimÎncă nu există evaluări

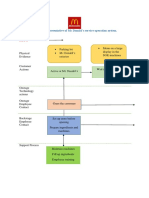

- Blueprint Huynh My Ky Duyen 2022 McDonald'sDocument2 paginiBlueprint Huynh My Ky Duyen 2022 McDonald'sHuỳnh Mỹ Kỳ DuyênÎncă nu există evaluări

- Royal British College IncDocument5 paginiRoyal British College IncLester MojadoÎncă nu există evaluări

- BV Lesson Plan 4Document3 paginiBV Lesson Plan 4api-252119803Încă nu există evaluări

- 6 Kuliah Liver CirrhosisDocument55 pagini6 Kuliah Liver CirrhosisAnonymous vUEDx8100% (1)

- Narrative Report On Weekly Accomplishments: Department of EducationDocument2 paginiNarrative Report On Weekly Accomplishments: Department of Educationisha mariano100% (1)

- Basic Electrical Engineering NotesDocument25 paginiBasic Electrical Engineering NotesAnas AnsariÎncă nu există evaluări

- Electromagnetic Spectrum 1 QP PDFDocument13 paginiElectromagnetic Spectrum 1 QP PDFWai HponeÎncă nu există evaluări

- WWW Spectrosci Com Product Infracal Model CVH PrinterFriendlDocument3 paginiWWW Spectrosci Com Product Infracal Model CVH PrinterFriendlather1985Încă nu există evaluări

- Service Manual: Multifunction Electrical Tester CalibratorDocument106 paginiService Manual: Multifunction Electrical Tester CalibratorJuan Carlos Ferrer OrtizÎncă nu există evaluări

- Acute Renal Failure in The Intensive Care Unit: Steven D. Weisbord, M.D., M.Sc. and Paul M. Palevsky, M.DDocument12 paginiAcute Renal Failure in The Intensive Care Unit: Steven D. Weisbord, M.D., M.Sc. and Paul M. Palevsky, M.Dkerm6991Încă nu există evaluări

- Chemical Engineering Projects List For Final YearDocument2 paginiChemical Engineering Projects List For Final YearRajnikant Tiwari67% (6)

- General Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsDocument12 paginiGeneral Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsHazel EncarnacionÎncă nu există evaluări

- EP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsDocument28 paginiEP500 Standard Electropneumatic Positioner: Installation and Maintenance InstructionsAlan ValdezÎncă nu există evaluări

- Money Tree International Finance Corp. Checklist of Standard Loan RequirementsDocument2 paginiMoney Tree International Finance Corp. Checklist of Standard Loan RequirementsAgape LabuntogÎncă nu există evaluări

- Border Collie Training GuidelinesDocument12 paginiBorder Collie Training GuidelinespsmanasseÎncă nu există evaluări

- University of Puerto Rico at PonceDocument16 paginiUniversity of Puerto Rico at Ponceapi-583167359Încă nu există evaluări

- NG Teng Fong Discharge DocumentsDocument14 paginiNG Teng Fong Discharge DocumentsAnonymous yGwMIPJRawÎncă nu există evaluări

- Null 6 PDFDocument1 paginăNull 6 PDFSimbarashe ChikariÎncă nu există evaluări

- MSDS - Granular Silica GelDocument3 paginiMSDS - Granular Silica GelLailal HaqimÎncă nu există evaluări

- Goals in LifeDocument4 paginiGoals in LifeNessa Layos MorilloÎncă nu există evaluări

- SPA - MichaelDocument1 paginăSPA - Michaelgilberthufana446877Încă nu există evaluări

- DT 2107Document1 paginăDT 2107Richard PeriyanayagamÎncă nu există evaluări

- Finite Element Analysis Project ReportDocument22 paginiFinite Element Analysis Project ReportsaurabhÎncă nu există evaluări

- Care of Clients With Problems in OxygenationDocument5 paginiCare of Clients With Problems in OxygenationSkyla FiestaÎncă nu există evaluări

- Drug-Nutrient Interaction in Prescriptions ForDocument7 paginiDrug-Nutrient Interaction in Prescriptions ForRafika DitaÎncă nu există evaluări

- A Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceDocument16 paginiA Comprehensive Review of Cementitious Grouts - Composition, Properties, Requirements and Advanced PerformanceiporrasÎncă nu există evaluări

- Guideline On Smacna Through Penetration Fire StoppingDocument48 paginiGuideline On Smacna Through Penetration Fire Stoppingwguindy70Încă nu există evaluări