Documente Academic

Documente Profesional

Documente Cultură

Abistir 7120

Încărcat de

Phung LucDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Abistir 7120

Încărcat de

Phung LucDrepturi de autor:

Formate disponibile

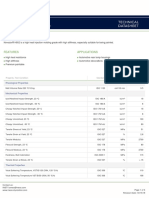

TECHNICAL DATA SHEET

ABISTIR 7120/V0-UV BIANCO 0154

AD340038S

Acrylonitrile-Butadiene-Styrene Compound (ABS)

Description Flame retardant ABS grade, good fluidity, UV stabilized

Color White

Norm compliance Compliant with Regulation (EC) No 1907/2006 (REACh)

Processing technology Injection moulding

Physical properties Typical value (SI) Typical value (EN) Test method

Density 1.25 g/cm³ 1.25 g/cm³ ASTM D792

Mold Shrinkage 0.4 % 0.4 % INTERNAL

Melt Flow Index 220°C/10kg 50 g/10min 50 g/10min ASTM D1238

Water absorption (24 h/23°C) 0.15 % 0.15 % ASTM D570

Mechanical properties Typical value (SI) Typical value (EN) Test method

Tensile strength at yield 37 MPa 5365 psi ASTM D638

Tensile elongation at break 7% 7% ASTM D638

Flexural Modulus 2100 MPa 304500 psi ASTM D790

IZOD impact strength, notched (23 °C) 110 J/m 2.057 ft·lb/inch ASTM D256

Thermal properties Typical value (SI) Typical value (EN) Test method

Vicat B (50°C/h at 50 N) 80 °C 176 F° ASTM D1525

HDT Heat Deflection Temperature A (1,82 MPa) 72 °C 161.6 F° ASTM D648

Flammability Typical value (SI) Typical value (EN) Test method

Flame Rating (1,6 mm) V0 Class V0 Class UL94

Flame Rating (3,2 mm) V0 Class V0 Class UL94

GWIT (Glow Wire Ignition Temperature) 960 °C/mm 960 °C/mm IEC 60695-2-13

Processing conditions Typical value (SI) Typical value (EN)

Drying 2h/80 °C 2h/176 °F

Injection moulding Typical value (SI) Typical value (EN)

Recommended processing temperatures:

1st Zone 180 °C 356 °F

2nd Zone 200 °C 392 °F

3rd Zone 210 °C 410 °F

Mould 40-60 °C 104-140 °F

Last update: 09/12/2014 SO.F.TER. GROUP Page: 1 of 2

TECHNICAL DATA SHEET

Storage

This product should be stored in a covered facility and kept away from moisture and heat.

Disclaimer

The figures reported in this Technical Data Sheet are based on tests and analyses carried out in SO.F.TER. laboratories on

injection-moulded specimens. These figures indicate the typical material properties and are not to be considered a

specification.The user shall always carry out his own tests and analyses in order to verify the suitability of the material for the

specific application.Test carried out at 23°C unless otherwise stated.

For technical or commercial information:

EUROPE

SO.F.TER. SPA, Via Mastro Giorgio 1, 47122 Forlì, Italy, tel +39 0543 790411

info.it@softergroup.com

USA

SO.F.TER. USA, 400 Innovative Way, Lebanon, TN 37090, US, tel +1 844 657 6383 (THINKSOFTER)

info.us@softergroup.com

BRAZIL

SO.F.TER. BRASIL, Av. Edgar Hoffmeister, 275, CEP 93700-000, Campo Bom, RS, Brazil , tel +55 51 2123 2610

info.br@softergroup.com

MEXICO

SO.F.TER MEXICO, Circuito Mexiamora Norte 345, Puerto Interior, Silao, G.to , Mexico 36275, tel +52 472 722 6923

info.mx@softergroup.com

www.softergroup.com

Last update: 09/12/2014 SO.F.TER. GROUP Page: 2 of 2

S-ar putea să vă placă și

- Wpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetDocument2 paginiWpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetankitÎncă nu există evaluări

- PBT Data SheetDocument2 paginiPBT Data Sheetabhishek chaudharyÎncă nu există evaluări

- Pulse A 35-105 BlackDocument3 paginiPulse A 35-105 BlackTaoufik KheddarÎncă nu există evaluări

- POLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESDocument3 paginiPOLYLAC® PA-765: Page 1 of 3 "POLYLAC®" PA-765 Data Provided by IDESPhuoc Thinh TruongÎncă nu există evaluări

- TDS - Acrylic V045 - From TrinseoDocument3 paginiTDS - Acrylic V045 - From TrinseoVio AmarieiÎncă nu există evaluări

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 paginiUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoÎncă nu există evaluări

- Novodur P2H-ATDocument3 paginiNovodur P2H-ATavinashchauhan2695Încă nu există evaluări

- Pao 100Document2 paginiPao 100Антон СтепураÎncă nu există evaluări

- Technical Data SheetDocument2 paginiTechnical Data SheetIVANCHUÎncă nu există evaluări

- Celanese Corporation Celanex® 1400A Polybutylene TerephthalateDocument2 paginiCelanese Corporation Celanex® 1400A Polybutylene TerephthalateTomGaliciaÎncă nu există evaluări

- Spectrasyn™ 10: Polyalphaolefin (Pao) FluidDocument2 paginiSpectrasyn™ 10: Polyalphaolefin (Pao) FluidMaram YasserÎncă nu există evaluări

- Styron ATECH 1175 DatasheetDocument3 paginiStyron ATECH 1175 DatasheetbobÎncă nu există evaluări

- ABS HI 121 MaterialDocument2 paginiABS HI 121 Materiallenderahul1705Încă nu există evaluări

- Rhetech Polypropylene Gc10P100-00Document3 paginiRhetech Polypropylene Gc10P100-00James FaunceÎncă nu există evaluări

- Abs Irpc Polimaxx SP100Document2 paginiAbs Irpc Polimaxx SP100countzeroaslÎncă nu există evaluări

- Elix ABS M220: Technical InformationDocument3 paginiElix ABS M220: Technical InformationDiegoTierradentroÎncă nu există evaluări

- Elix ABS E401: Technical InformationDocument3 paginiElix ABS E401: Technical InformationDiegoTierradentroÎncă nu există evaluări

- Cf-Pla TDSDocument1 paginăCf-Pla TDSilkerÎncă nu există evaluări

- SABIC Cycolac MG47FDocument3 paginiSABIC Cycolac MG47FChu ChuÎncă nu există evaluări

- Spectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidDocument2 paginiSpectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidMaram YasserÎncă nu există evaluări

- San 330IDocument2 paginiSan 330INguyễn Hồng NamÎncă nu există evaluări

- Elix Pc-Abs 5130Document4 paginiElix Pc-Abs 5130DiegoTierradentroÎncă nu există evaluări

- POM KEPITAL F30-03 enDocument2 paginiPOM KEPITAL F30-03 enAthonioMourinhoÎncă nu există evaluări

- Hoja Tecnica Tairirex GP5000Document2 paginiHoja Tecnica Tairirex GP5000Jaimito Ramirez RodasÎncă nu există evaluări

- Shear Flat SlabDocument1 paginăShear Flat Slabadnan-651358Încă nu există evaluări

- Eccoh 5836 TDS01 2018-10Document2 paginiEccoh 5836 TDS01 2018-10bobÎncă nu există evaluări

- Z70B I2 R4 EnglishDocument1 paginăZ70B I2 R4 English阿康Încă nu există evaluări

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDocument3 paginiNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeÎncă nu există evaluări

- Ultramid A205fDocument3 paginiUltramid A205fSATHISH KUMAR SÎncă nu există evaluări

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 paginiStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoÎncă nu există evaluări

- Elix Ultra hh4115Document3 paginiElix Ultra hh4115DiegoTierradentroÎncă nu există evaluări

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobÎncă nu există evaluări

- San 335TDocument2 paginiSan 335TNguyễn Hồng NamÎncă nu există evaluări

- 400 00285217en Hdpe 6200 TdsDocument2 pagini400 00285217en Hdpe 6200 TdsOriana Gudiño GaliñoÎncă nu există evaluări

- DOWLEX™ 2047G: Polyethylene ResinDocument3 paginiDOWLEX™ 2047G: Polyethylene Resinujang sukartaÎncă nu există evaluări

- SABIC PP 5703P Polypropylene Homopolymer For Injection MoldingDocument2 paginiSABIC PP 5703P Polypropylene Homopolymer For Injection MoldingMédi ChegmaÎncă nu există evaluări

- San 310CTRDocument2 paginiSan 310CTRNguyễn Hồng NamÎncă nu există evaluări

- Technical Data SheetDocument2 paginiTechnical Data SheetIVANCHUÎncă nu există evaluări

- Elix ABS P2M-AT: Technical InformationDocument3 paginiElix ABS P2M-AT: Technical InformationDiegoTierradentroÎncă nu există evaluări

- PC - Trinseo Emerge 8701HH GF10Document3 paginiPC - Trinseo Emerge 8701HH GF10armandoÎncă nu există evaluări

- Data Sheet: FFKM: Material: PerfluoroelastomerDocument1 paginăData Sheet: FFKM: Material: PerfluoroelastomerParth ShahÎncă nu există evaluări

- Kepital F20 - 03Document2 paginiKepital F20 - 03Kumaar RanjanÎncă nu există evaluări

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezÎncă nu există evaluări

- CYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetDocument2 paginiCYCOLAC™ Resin - DL100 - Asia - Technical - Data - SheetKishore Gowda A SÎncă nu există evaluări

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 paginiLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanÎncă nu există evaluări

- PP Gf30 - Suplen v30 LCDocument2 paginiPP Gf30 - Suplen v30 LCarmandoÎncă nu există evaluări

- 300.056 Magnum 3416 SCDocument3 pagini300.056 Magnum 3416 SCEnrique ChavezÎncă nu există evaluări

- PolyMax PLA TDS V4Document2 paginiPolyMax PLA TDS V4fÎncă nu există evaluări

- Cycoloy Resin C1200 Americas: COMMERCIAL: PropertyDocument2 paginiCycoloy Resin C1200 Americas: COMMERCIAL: PropertymarceloÎncă nu există evaluări

- Hdpe Alathon H5520 EquistarDocument2 paginiHdpe Alathon H5520 EquistarEric Mahonri PereidaÎncă nu există evaluări

- HDPE Blow Ineos-G50-100Document2 paginiHDPE Blow Ineos-G50-100luisalbertolvÎncă nu există evaluări

- CPVC Geon PM280Document1 paginăCPVC Geon PM280angelokyoÎncă nu există evaluări

- CYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetDocument2 paginiCYCOLOY™ Resin - XCY620 - Asia - Technical - Data - SheetAthiwat TriwattanapornÎncă nu există evaluări

- EnCounter 3GF20Document1 paginăEnCounter 3GF20srinivasaÎncă nu există evaluări

- Lexan™ Copolymer 943X: Region AmericasDocument3 paginiLexan™ Copolymer 943X: Region AmericasAdirSchoierÎncă nu există evaluări

- Injection Grade: GPPS (General Purpose Poly Styrene)Document2 paginiInjection Grade: GPPS (General Purpose Poly Styrene)Andy KayÎncă nu există evaluări

- Styrolution PS 476L: Technical DatasheetDocument3 paginiStyrolution PS 476L: Technical DatasheetTRUONGÎncă nu există evaluări

- An Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesDe la EverandAn Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesÎncă nu există evaluări

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesDe la EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesÎncă nu există evaluări

- Materials Data for Cyclic Loading: Low-Alloy SteelsDe la EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsEvaluare: 5 din 5 stele5/5 (2)

- Asia Lanneret 2630Document1 paginăAsia Lanneret 2630Phung LucÎncă nu există evaluări

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDocument2 paginiALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucÎncă nu există evaluări

- Asia Lanneret EPDM-2019Document2 paginiAsia Lanneret EPDM-2019Phung LucÎncă nu există evaluări

- High Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Document2 paginiHigh Density Polyethylene Grade Used in Injection Molding Melt Index: 62 Density: 0.942Phung LucÎncă nu există evaluări

- ALTECH PE-HD A 2010/550 GF10: Technical Data SheetDocument2 paginiALTECH PE-HD A 2010/550 GF10: Technical Data SheetPhung LucÎncă nu există evaluări

- PermaStat 600 UVDocument2 paginiPermaStat 600 UVPhung LucÎncă nu există evaluări

- High Density Polyethylene Conduit Grade Melt Index 0.30 Density 0.949Document1 paginăHigh Density Polyethylene Conduit Grade Melt Index 0.30 Density 0.949Phung LucÎncă nu există evaluări

- LG Abs Af365bDocument2 paginiLG Abs Af365bPhung LucÎncă nu există evaluări

- Colorfast Pba2000Document2 paginiColorfast Pba2000Phung LucÎncă nu există evaluări

- Kibilac PW-957Document1 paginăKibilac PW-957Phung LucÎncă nu există evaluări

- Wonderloy PC 540Document2 paginiWonderloy PC 540Phung LucÎncă nu există evaluări

- Tenac C 4520Document2 paginiTenac C 4520Phung LucÎncă nu există evaluări

- Pelican Skid MateDocument11 paginiPelican Skid MatePhung LucÎncă nu există evaluări

- Denyl 6 NDocument2 paginiDenyl 6 NPhung LucÎncă nu există evaluări

- Ultradur B2520Document2 paginiUltradur B2520Phung LucÎncă nu există evaluări

- Application:: Properties Test Method English SIDocument2 paginiApplication:: Properties Test Method English SIPhung LucÎncă nu există evaluări

- Petra 130Document2 paginiPetra 130Phung LucÎncă nu există evaluări

- Dupont Delrin 527UV BK701Document4 paginiDupont Delrin 527UV BK701Phung LucÎncă nu există evaluări

- Denyl 6 0037 HDocument2 paginiDenyl 6 0037 HPhung LucÎncă nu există evaluări

- DS Battery Cover Flyer enDocument2 paginiDS Battery Cover Flyer enPhung LucÎncă nu există evaluări

- Mitsubishi Iupilon S-2000 Series UL File CardDocument2 paginiMitsubishi Iupilon S-2000 Series UL File CardPhung LucÎncă nu există evaluări

- Tenac 4013ADocument3 paginiTenac 4013APhung LucÎncă nu există evaluări

- Proposition 65 Chemical List Dec 2017Document22 paginiProposition 65 Chemical List Dec 2017Phung Luc100% (1)

- Light Stabilizers CytecDocument7 paginiLight Stabilizers CytecPhung LucÎncă nu există evaluări

- Proposition 65 Safe Harbor Limits May 2017Document9 paginiProposition 65 Safe Harbor Limits May 2017Phung LucÎncă nu există evaluări

- Plastics Technology Practice PDFDocument35 paginiPlastics Technology Practice PDFabi lash100% (1)

- Additive Manufacturing and Sand Casting Foundries Practices in NigeriaDocument9 paginiAdditive Manufacturing and Sand Casting Foundries Practices in NigeriaNurudeen Adekunle RajiÎncă nu există evaluări

- ZMorph Materials LibraryDocument101 paginiZMorph Materials Libraryaskey69Încă nu există evaluări

- Material Property Charts Lecture Unit 2 Pptchaen23Document22 paginiMaterial Property Charts Lecture Unit 2 Pptchaen23pranavÎncă nu există evaluări

- Gf-Injection Molding Condition PDFDocument2 paginiGf-Injection Molding Condition PDFTrieubinhan NguyenÎncă nu există evaluări

- ISO 1133 For Melt Flow Rate PDFDocument17 paginiISO 1133 For Melt Flow Rate PDFchemist_tma67% (3)

- C Concept BrochureDocument12 paginiC Concept BrochureCharles YaoÎncă nu există evaluări

- Esh 12-710W Esh 12-710W: Esc 100-12 Esc 150-12 FR Esc 100-12Document2 paginiEsh 12-710W Esh 12-710W: Esc 100-12 Esc 150-12 FR Esc 100-12muhammadÎncă nu există evaluări

- Safe Handling and Storage of Styrene MonomerDocument45 paginiSafe Handling and Storage of Styrene MonomerchayanunÎncă nu există evaluări

- 3D Printer Filament GuideDocument1 pagină3D Printer Filament GuideBobbyÎncă nu există evaluări

- Reverse Engineering of A Spur Gear: A Minor Project ReportDocument31 paginiReverse Engineering of A Spur Gear: A Minor Project ReportRAMACHANDRA DASÎncă nu există evaluări

- ZE Twin-Screw ExtrudersDocument30 paginiZE Twin-Screw ExtrudersSimas Servutas100% (1)

- Plastic Piping HandbookDocument359 paginiPlastic Piping Handbookgnilagg100% (4)

- Chemical Tanker OperationDocument179 paginiChemical Tanker OperationDilli BabuÎncă nu există evaluări

- PC and ABSDocument8 paginiPC and ABSDaisyÎncă nu există evaluări

- FDM Materials - Overview 2015Document2 paginiFDM Materials - Overview 2015bloodterry2284Încă nu există evaluări

- Experimental Corroboration of Investment Casting Using Fused Deposition Modeling Process of RapidprototypingDocument10 paginiExperimental Corroboration of Investment Casting Using Fused Deposition Modeling Process of RapidprototypingKishor AshtankarÎncă nu există evaluări

- ABS HI 121 MaterialDocument2 paginiABS HI 121 Materiallenderahul1705Încă nu există evaluări

- EP PPT 1Document88 paginiEP PPT 1satyam parasharÎncă nu există evaluări

- Non Metallic MaterialsDocument16 paginiNon Metallic Materialsthisisjinesh100% (1)

- Tyco Plastic ConduitsDocument6 paginiTyco Plastic ConduitsOliver HermosaÎncă nu există evaluări

- PPO SlideDocument29 paginiPPO SlideRadhashyam GiriÎncă nu există evaluări

- CW January 2020Document60 paginiCW January 2020maheshgupteÎncă nu există evaluări

- Feedstock Recycling and Pyrolysis of Waste Plastics - IndexDocument30 paginiFeedstock Recycling and Pyrolysis of Waste Plastics - Indexprem101Încă nu există evaluări

- High Performance Plastics Materials Guide: Craftech Industries'Document20 paginiHigh Performance Plastics Materials Guide: Craftech Industries'akirloskarÎncă nu există evaluări

- Storage System 11Document14 paginiStorage System 11PT.CAHAYA ANUGERAH SAKTIÎncă nu există evaluări

- Abs Af312A: Description ApplicationDocument2 paginiAbs Af312A: Description ApplicationAdonis BasilioÎncă nu există evaluări

- 9.automatic TranformationDocument12 pagini9.automatic Tranformation차지훈Încă nu există evaluări

- Polymers ScanDocument31 paginiPolymers Scandivoo0984Încă nu există evaluări

- Plastics Study MaterialDocument44 paginiPlastics Study MaterialSri NavinÎncă nu există evaluări