Documente Academic

Documente Profesional

Documente Cultură

ULTRADUR B4300G6 (03p023)

Încărcat de

ayala castroTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ULTRADUR B4300G6 (03p023)

Încărcat de

ayala castroDrepturi de autor:

Formate disponibile

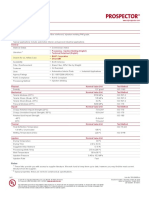

Product Information

Jan 2015

Ultradur® B 4300 G6

PBT (Polybutylene Terephthalate)

Product Description

Ultradur B 4300 G6 is an easy flowing injection molding PBT with 30% glass fiber reinforcement for

rigid, tough, and dimensionally stable parts.

Applications

Typical applications include windshield wiper arms, printed circuit boards, housings, consoles,

contact carriers, and covers.

PHYSICAL ISO Test Method Property Value

Density, g/cm 1183 1.53

Viscosity Number, cm/g 1628 102

Mold Shrinkage, parallel, % 294-4 0.34

Mold Shrinkage, normal, % 294-4 1.07

Moisture, % 62

(50% RH) 0.2

(Saturation) 0.4

RHEOLOGICAL ISO Test Method Property Value

Melt Volume Rate (250 C/2.16 Kg), cc/10min. 1133 11

MECHANICAL ISO Test Method Property Value

Tensile Modulus, MPa 527

23C 10,000

Tensile stress at break, MPa 527

-40C 204

23C 135

Tensile strain at break, % 527

23C 2.5

Flexural Strength, MPa 178

23C 200

Flexural Modulus, MPa 178

23C 8,800

Tensile Creep Modulus (1000h), MPa 899 7,500

IMPACT ISO Test Method Property Value

Charpy Notched, kJ/m2 179

23C 11

Charpy Unnotched, kJ/m2 179

23C 67

-30C 74

THERMAL ISO Test Method Property Value

Melting Point, C 3146 223

HDT A, C 75 215

HDT B, C 75 220

Coef. of Linear Thermal Expansion, Parallel, 0.25 X10-4

mm/mm C

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 1 of 3

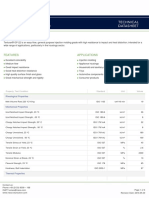

Ultradur® B 4300 G6

ELECTRICAL ISO Test Method Property Value

Comparative Tracking Index IEC 60112 375

Volume Resistivity IEC 60093 >1E13

Surface Resistivity IEC 60093 1E13

Dielectric Constant (100 Hz) IEC 60250 4

Dielectric Constant (1 MHz) IEC 60250 3.8

Dissipation Factor (100 Hz) IEC 60250 25

Dissipation Factor (1 MHz) IEC 60250 170

UL RATINGS UL Test Method Property Value

Relative Temperature Index, 0.75mm UL746B

Electrical, C 130

Flammability Rating, 1.5mm UL94 HB

Relative Temperature Index, 1.5mm UL746B

Mechanical w/ Impact, C 105

Electrical, C 130

Flammability Rating, 3.0mm UL94 HB

Relative Temperature Index, 3.0mm UL746B

Mechanical w/o Impact, C 140

Mechanical w/ Impact, C 125

Electrical, C 130

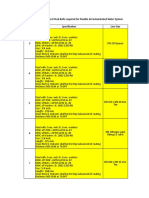

Processing Guidelines

Material Handling

Max. Water content: 0.04%

To ensure optimum part performance, this product must be dried prior to molding and maintained at

a moisture level of less than 0.04%. Dehumidifying or desiccant dryers operating at 100-120 degC

(212-248 degF) for 4 hours drying time are recommended. Further information concerning safe

handling procedures can be obtained from the Safety Data Sheet. Alternatively, please contact your

BASF representative.

Typical Profile

Melt Temperature 250-270 degC (482-518 degF)

Mold Temperature 60-100 degC (140-212 degF)

Injection and Packing Pressure 35-125 bar (500-1500 psi)

Mold Temperatures

This product can be processed over mold temperatures of 60-100 degC (140-212 degF); however,

for optimizing surface appearance, dimensional stability and part performance, mold surface

temperatures of at least 80 degC (176 degF) are preferred.

Pressures

Injection pressure controls the filling of the part and should be applied for 90% of ram travel.

Packing pressure affects the final part and can be used effectively in controlling sink marks and

shrinkage. It should be applied and maintained until the gate area is completely frozen off.

Back pressure can be utilized to provide uniform melt consistency and reduce trapped air and gas.

A maximum of 10 bar (145 psi) is recommended due to the risk of excessive shear.

Fill Rate

Fast fill rates are recommended to ensure uniform melt delivery to the cavity and prevent premature

freezing. Surface appearance is directly affected by injection rate.

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 2 of 3

Ultradur® B 4300 G6

Note

Although all statements and information in this publication are believed to be accurate and reliable,

they are presented gratis and for guidance only, and risks and liability for results obtained by use of

the products or application of the suggestions described are assumed by the user. NO

WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING

PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH. Statements or

suggestions concerning possible use of the products are made without representation or warranty

that any such use is free of patent infringement and are not recommendations to infringe any

patent. The user should not assume that toxicity data and safety measures are indicated or that

other measures may not be required.

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 3 of 3

S-ar putea să vă placă și

- Ultrason E 3010: Polyethersulfone (PESU)Document2 paginiUltrason E 3010: Polyethersulfone (PESU)AmirÎncă nu există evaluări

- Ultraform N2320 003 BK120 Q600Document2 paginiUltraform N2320 003 BK120 Q600JoelÎncă nu există evaluări

- UltrasonS6010 IsoDocument2 paginiUltrasonS6010 IsoKablayialijanÎncă nu există evaluări

- Abs - Terluran GP22Document2 paginiAbs - Terluran GP22armandoÎncă nu există evaluări

- Ultramid B3WG6 NYLON PDFDocument3 paginiUltramid B3WG6 NYLON PDFrenebbÎncă nu există evaluări

- Ultramid A3WG7 IsoDocument3 paginiUltramid A3WG7 IsoRiccardoÎncă nu există evaluări

- ABS Terluran GP35Document2 paginiABS Terluran GP35Alan MoraisÎncă nu există evaluări

- Torelina® A490MA50: Toray Resin CompanyDocument2 paginiTorelina® A490MA50: Toray Resin CompanyChunYenHuangÎncă nu există evaluări

- Petra 130 SpecsDocument2 paginiPetra 130 SpecssdecarlogaÎncă nu există evaluări

- Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Document2 paginiUltraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Phuoc Thinh TruongÎncă nu există evaluări

- Styrolution PS 476L: Technical DatasheetDocument3 paginiStyrolution PS 476L: Technical DatasheetTRUONGÎncă nu există evaluări

- Abs - Terluran GP35Document2 paginiAbs - Terluran GP35armandoÎncă nu există evaluări

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrÎncă nu există evaluări

- PocanB3235000000 GF30 1Document5 paginiPocanB3235000000 GF30 1rihabÎncă nu există evaluări

- 4lex® 10F13100Document2 pagini4lex® 10F13100srinivasaÎncă nu există evaluări

- Luran 368R: Technical DatasheetDocument3 paginiLuran 368R: Technical DatasheetVictor PuertoÎncă nu există evaluări

- TDS - Terluran GP-22 PDFDocument3 paginiTDS - Terluran GP-22 PDFebercueÎncă nu există evaluări

- Diakon® ST35G8: Lucite International Holland BVDocument3 paginiDiakon® ST35G8: Lucite International Holland BVbobÎncă nu există evaluări

- Pa 6 GF 30 (En)Document1 paginăPa 6 GF 30 (En)Alessandro WeissÎncă nu există evaluări

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 paginiCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererÎncă nu există evaluări

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 paginiStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoÎncă nu există evaluări

- CYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetDocument2 paginiCYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetBoby SaputraÎncă nu există evaluări

- Bayblend T85 XF ISO enDocument3 paginiBayblend T85 XF ISO enryanÎncă nu există evaluări

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 paginiStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoÎncă nu există evaluări

- StyrolutionTDS400700190196 PDFDocument3 paginiStyrolutionTDS400700190196 PDFMirella FaresÎncă nu există evaluări

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDocument1 paginăSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesÎncă nu există evaluări

- 4lex® 10F13500Document2 pagini4lex® 10F13500srinivasaÎncă nu există evaluări

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 paginiLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobÎncă nu există evaluări

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 paginiLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaÎncă nu există evaluări

- PC Calibre Technical DataDocument4 paginiPC Calibre Technical DataMitja GorseÎncă nu există evaluări

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pagini(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluÎncă nu există evaluări

- Styrolution TDS401600170785Document3 paginiStyrolution TDS401600170785shahin_723Încă nu există evaluări

- CYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetDocument2 paginiCYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetRodrigoMachadoÎncă nu există evaluări

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 paginiCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinÎncă nu există evaluări

- Luran HH-120: Please SelectDocument3 paginiLuran HH-120: Please SelectDavid Costi da RosaÎncă nu există evaluări

- Styrolution TDS400900481370Document3 paginiStyrolution TDS400900481370joshÎncă nu există evaluări

- Pa6 GF20 - Basf Ultramid B3eg4Document2 paginiPa6 GF20 - Basf Ultramid B3eg4armandoÎncă nu există evaluări

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDocument6 paginiDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarÎncă nu există evaluări

- LEXAN™ FR Resin 916R - EuropeDocument3 paginiLEXAN™ FR Resin 916R - EuropesrinivasaÎncă nu există evaluări

- Cycoloy Resin C1200 Americas: COMMERCIAL: PropertyDocument2 paginiCycoloy Resin C1200 Americas: COMMERCIAL: PropertymarceloÎncă nu există evaluări

- PPS Ryton R-4-230Document3 paginiPPS Ryton R-4-230thegeneral2040Încă nu există evaluări

- XENOY™ Resin 1760E - AmericasDocument4 paginiXENOY™ Resin 1760E - AmericasWellington C. de AraujoÎncă nu există evaluări

- Kapton HN Data SheetDocument5 paginiKapton HN Data Sheet谢朋亨Încă nu există evaluări

- Styrolution Basf Terluran GP-22Document3 paginiStyrolution Basf Terluran GP-22medo.k016Încă nu există evaluări

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 paginiBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoÎncă nu există evaluări

- PBT Data SheetDocument2 paginiPBT Data Sheetabhishek chaudharyÎncă nu există evaluări

- ABS Terluran GP22Document2 paginiABS Terluran GP22Alan MoraisÎncă nu există evaluări

- Astm Lupol gp3156f - EngDocument2 paginiAstm Lupol gp3156f - EngYo AÎncă nu există evaluări

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarÎncă nu există evaluări

- 2024 03 06 TDS Elastollan1185ADocument4 pagini2024 03 06 TDS Elastollan1185AChaker AbdellatifÎncă nu există evaluări

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 paginiNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezÎncă nu există evaluări

- TDS - Bayblend FR3040 EVDocument3 paginiTDS - Bayblend FR3040 EVRachit RanjanÎncă nu există evaluări

- Radipol A45 TDSDocument1 paginăRadipol A45 TDSxy2zjgÎncă nu există evaluări

- HFDK-4202 EcDocument2 paginiHFDK-4202 EcShubham BaderiyaÎncă nu există evaluări

- Novodur P2H-ATDocument3 paginiNovodur P2H-ATavinashchauhan2695Încă nu există evaluări

- Ultradur B 4300 G4: ® PBT (Polybutylene Terephthalate)Document2 paginiUltradur B 4300 G4: ® PBT (Polybutylene Terephthalate)irisÎncă nu există evaluări

- Victrex™ Peek 450G™: Product DescriptionDocument2 paginiVictrex™ Peek 450G™: Product DescriptionBerkant CangalÎncă nu există evaluări

- Luran 368 RDocument5 paginiLuran 368 RmucahitkaraballÎncă nu există evaluări

- KNG1015 Pa6-Gf15Document2 paginiKNG1015 Pa6-Gf15pava16230.meÎncă nu există evaluări

- Compliance Cycle Time (1 Junio) PDFDocument1 paginăCompliance Cycle Time (1 Junio) PDFayala castroÎncă nu există evaluări

- Parametros M33133118 (33401509) HND M30 Rev 2Document18 paginiParametros M33133118 (33401509) HND M30 Rev 2ayala castroÎncă nu există evaluări

- Screw Wear Test 2016Document1.021 paginiScrew Wear Test 2016ayala castroÎncă nu există evaluări

- Compliance Cycle Time (Julio 18) PDFDocument1 paginăCompliance Cycle Time (Julio 18) PDFayala castroÎncă nu există evaluări

- Parametros M33133118 (33401509) HND M30 Rev 2Document18 paginiParametros M33133118 (33401509) HND M30 Rev 2ayala castroÎncă nu există evaluări

- AMSOIL Synthetic Water Resistant Grease GWRDocument2 paginiAMSOIL Synthetic Water Resistant Grease GWRamsoildealerÎncă nu există evaluări

- d01 PORTAL SPLAPP PDF Useful Informations ScrutinyCases 2013 2014 Faridabad (W) R PDFDocument43 paginid01 PORTAL SPLAPP PDF Useful Informations ScrutinyCases 2013 2014 Faridabad (W) R PDFAnjali Srivastava100% (1)

- CHEM 201/L - EXPERIMENT: Elements, Compounds, and Mixture ADocument2 paginiCHEM 201/L - EXPERIMENT: Elements, Compounds, and Mixture Aroven desuÎncă nu există evaluări

- Bom of Studs & Nuts For Balance SystemDocument4 paginiBom of Studs & Nuts For Balance SystemmishtinilÎncă nu există evaluări

- CIV-MS-010-07-Rapid Chloride PermeabilityDocument7 paginiCIV-MS-010-07-Rapid Chloride PermeabilityAdil faridÎncă nu există evaluări

- Heat Calculations Practice 2 PDFDocument2 paginiHeat Calculations Practice 2 PDFRizqi HidayatÎncă nu există evaluări

- Photodiode Investigatory ProjectDocument25 paginiPhotodiode Investigatory ProjectNishant KumarÎncă nu există evaluări

- All Metal Hose, Medium Pressure, FJ Sereis (MS-02-322-E) R2Document6 paginiAll Metal Hose, Medium Pressure, FJ Sereis (MS-02-322-E) R2herysyam1980Încă nu există evaluări

- Megafil 240M enDocument1 paginăMegafil 240M endddassddÎncă nu există evaluări

- EPF3701 - Lec8 ClosuresDocument57 paginiEPF3701 - Lec8 ClosuresMuhd Khairul AmriÎncă nu există evaluări

- WO2008033224A1 Polycaprolactone PolyurethaneDocument31 paginiWO2008033224A1 Polycaprolactone PolyurethaneGİZEM DEMİRÎncă nu există evaluări

- Amp 1Document2 paginiAmp 1Revitha Kishiore KumarÎncă nu există evaluări

- Mole Concept PDFDocument43 paginiMole Concept PDFPratyushÎncă nu există evaluări

- Mixture Suspension QuizDocument9 paginiMixture Suspension QuizCatherine RenanteÎncă nu există evaluări

- Quizlet FinalSDocument26 paginiQuizlet FinalSCrisna Rivera PundanoÎncă nu există evaluări

- GCC - Plastic IndustryDocument44 paginiGCC - Plastic IndustrySeshagiri KalyanasundaramÎncă nu există evaluări

- Basf Masteremaco t288 TdsDocument2 paginiBasf Masteremaco t288 TdsharsoÎncă nu există evaluări

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 paginiForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiÎncă nu există evaluări

- Investigation of Micro-Structure and Creep Life Analysis of Centrifugally Cast Fe-Cr-Ni Alloy Reformer TubesDocument5 paginiInvestigation of Micro-Structure and Creep Life Analysis of Centrifugally Cast Fe-Cr-Ni Alloy Reformer TubesOwais MalikÎncă nu există evaluări

- Burnt Clay Building Bricks - Methods of Tests: Indian StandardDocument8 paginiBurnt Clay Building Bricks - Methods of Tests: Indian Standardmohd waseemÎncă nu există evaluări

- Surface ChemistryDocument13 paginiSurface ChemistrysunilkumarpatrosisintyÎncă nu există evaluări

- Inorganic Chemistry 2-1Document48 paginiInorganic Chemistry 2-1Oliver JumaÎncă nu există evaluări

- Fuel Types and Firing SystemsDocument80 paginiFuel Types and Firing SystemsIrshad HussainÎncă nu există evaluări

- CarbonCure Technical Note - Types of Concrete CarbonationDocument4 paginiCarbonCure Technical Note - Types of Concrete CarbonationSakineÎncă nu există evaluări

- Asme Sec Viii Closed QB (106-120)Document15 paginiAsme Sec Viii Closed QB (106-120)slxanto100% (1)

- Is549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysDocument4 paginiIs549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysSandro MendesÎncă nu există evaluări

- Program Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Document13 paginiProgram Outcomes (Pos) Addressed by The Activity: Activity No. 3: Building Envelope Systems and Assemblies 1.1Jazcel GalsimÎncă nu există evaluări

- ACI522RDocument5 paginiACI522Rraja qammarÎncă nu există evaluări

- BOQ For Plumbing Sanitary WorksDocument6 paginiBOQ For Plumbing Sanitary WorksHavoc KumarÎncă nu există evaluări

- Midland Gear Pumps Phase 1Document5 paginiMidland Gear Pumps Phase 1Рома БлошенкоÎncă nu există evaluări

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDe la EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisEvaluare: 5 din 5 stele5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDe la EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsÎncă nu există evaluări

- A Complete Guide to Safety Officer Interview Questions and AnswersDe la EverandA Complete Guide to Safety Officer Interview Questions and AnswersEvaluare: 4 din 5 stele4/5 (1)

- Workbook to Accompany Maintenance & Reliability Best PracticesDe la EverandWorkbook to Accompany Maintenance & Reliability Best PracticesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Guidelines for Auditing Process Safety Management SystemsDe la EverandGuidelines for Auditing Process Safety Management SystemsÎncă nu există evaluări

- Rules of Thumb for Maintenance and Reliability EngineersDe la EverandRules of Thumb for Maintenance and Reliability EngineersEvaluare: 4.5 din 5 stele4.5/5 (12)

- Fire Fighting Pumping Systems at Industrial FacilitiesDe la EverandFire Fighting Pumping Systems at Industrial FacilitiesEvaluare: 4.5 din 5 stele4.5/5 (3)

- Introduction to Petroleum Process SafetyDe la EverandIntroduction to Petroleum Process SafetyEvaluare: 3 din 5 stele3/5 (2)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityDe la EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityEvaluare: 5 din 5 stele5/5 (2)

- Fundamentals of Risk Management for Process Industry EngineersDe la EverandFundamentals of Risk Management for Process Industry EngineersÎncă nu există evaluări

- Epidemiology and Demography in Public HealthDe la EverandEpidemiology and Demography in Public HealthJaphet KillewoEvaluare: 5 din 5 stele5/5 (1)

- Culture, Health and Illness: An Introduction for Health ProfessionalsDe la EverandCulture, Health and Illness: An Introduction for Health ProfessionalsÎncă nu există evaluări

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersDe la EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersEvaluare: 4 din 5 stele4/5 (32)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDe la EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemÎncă nu există evaluări

- Handbook of Hazardous Chemical PropertiesDe la EverandHandbook of Hazardous Chemical PropertiesEvaluare: 5 din 5 stele5/5 (1)

- The Invisible Rainbow: A History of Electricity and LifeDe la EverandThe Invisible Rainbow: A History of Electricity and LifeEvaluare: 4.5 din 5 stele4.5/5 (21)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesDe la EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesEvaluare: 4.5 din 5 stele4.5/5 (2)

- Incidents That Define Process SafetyDe la EverandIncidents That Define Process SafetyÎncă nu există evaluări

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeDe la EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeÎncă nu există evaluări

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDe la EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesEvaluare: 5 din 5 stele5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDe la EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsEvaluare: 4 din 5 stele4/5 (11)

- Chemical Process Safety: Learning from Case HistoriesDe la EverandChemical Process Safety: Learning from Case HistoriesEvaluare: 4 din 5 stele4/5 (14)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesDe la EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesÎncă nu există evaluări