Documente Academic

Documente Profesional

Documente Cultură

196000-175# 096000-175#

Încărcat de

Junior IungDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

196000-175# 096000-175#

Încărcat de

Junior IungDrepturi de autor:

Formate disponibile

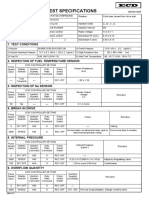

INJECTION PUMP TEST SPECIFICATIONS 196000-1754

MANUFACTURER TOYOTA

INJECTION PUMP 196000-175#

ENGINE TYPE 5L VE4/10F2200RND175

VEHICLE MODEL HIACE S.B.W ROTATION Clockwise viewed from GOVERNOR TYPE All speed

drive side

RATED VOLTAGE 12V INJECTION ORDER A-B-C-D INJECTION INTERVAL 90° ± 30'

Dimension KF (mm) 6.40 ± 0.10 Dimension MS (mm) 0.45 ± 0.10

Dimension K (mm) 3.30 ± 0.10 Dimension PS (mm)

1. TEST CONDITIONS

Nozzle 093400-0540 (DN12SD12A) Feed Pressure 19.6 kPa ( 0.2 kgf/cm2)

Nozzle Opening Pressure 14.7 ± 0.5 MPa ( 150 ± 5 kgf/cm2) High Pressure Pipe Ø2 X Ø6 X 840 mm

Test Oil SAE J967 (ISO4113) Fuel Temperature 40 - 45 °C (104 - 113°F)

NOTE : Apply 6 volts DC across the fuel cut solenoid during adjustment.

2. PRE-ADJUSTMENT Applying 0 V to T.C.V.

Lever Position Pump Speed Absolute Pressure Fuel Delivery Max. Spread

in Delivery

(deg) (rpm)

(kPa) (mmHg) (mm3/st) (cc/200st) (mm3) (cc)

Full Load 28.5 ± 5° 1200 101.3 ± 0.2 760.0 ± 1.5 63.6 ± 0.5 12.7 ± 0.1 2.0 0.4

(Full position)

High Speed 2450 101.3 ± 0.2 760.0 ± 1.5 27.0 ± 2.5 5.4 ± 0.5

3. ADJUSTMENT OF INTERNAL PRESSURE Applying 0 V to T.C.V.

Lever Position Pump Speed Absolute Pressure Internal Pressure Remarks

(rpm) (kPa) (mmHg) (kPa) (kgf/cm2)

Full 500 101.3 ± 0.2 760.0 ± 1.5 343.5 ± 29.5 3.5 ± 0.3 By the regulating valve

2100 101.3 ± 0.2 760.0 ± 1.5 647.0 ± 29.0 6.6 ± 0.3

4. OVERFLOW QUANTITY CHECK Applying 0 V to T.C.V.

Lever Position Pump Speed Absolute Pressure Overflow Quantity Remarks

(rpm) (kPa) (mmHg) (L/h) (cc/1000st)

Full 2200 101.3 ± 0.2 760.0 ± 1.5 22 - 48 167 - 364

NOTE : The overflow valve belonging to the pump should be used checking.

5. ADJUSTMENT OF TIMER Applying 0 V to T.C.V.

Lever Position Pump Speed Absolute Pressure Piston Travel Remarks

(rpm) (kPa) (mmHg) (mm)

Full 800 101.3 ± 0.2 760.0 ± 1.5 2.05 ± 0.40

1200 101.3 ± 0.2 760.0 ± 1.5 3.81 ± 0.40

1900 101.3 ± 0.2 760.0 ± 1.5 6.89 ± 0.40

2200 101.3 ± 0.2 760.0 ± 1.5 7.30 ± 0.24 Max. piston travel

NOTE : Hysteresis at each pump speed is less than 0.3 mm.

196000-1754

6. ADJUSTMENT OF DAC Applying 0 V to T.C.V.

Lever Pump Absolute Pressure Fuel Delivery Max. Spread Remarks

Speed in Delivery

Position

(rpm) (kPa) (mmHg) (mm3/st) (cc/200st) (mm3) (cc)

Full 1200 101.3 ± 0.2 760.0 ± 1.5 63.6 ± 0.5 12.7 ± 0.1 2.0 0.4

1200 85.3 ± 0.2 640.0 ± 1.5 57.0 ± 1.5 11.4 ± 0.3

7. ADJUSTMENT OF FUEL DELIVERY Applying 0 V to T.C.V.

Lever Pump Absolute Pressure Fuel Delivery Max. Spread Remarks

Speed in Delivery

Position

(rpm) (kPa) (mmHg) (mm3/st) (cc/200st) (mm3) (cc)

Full 1200 101.3 ± 0.2 760.0 ± 1.5 63.6 ± 0.5 = A 12.7 ± 0.1 = A 2.0 0.4 By full load setting screw

2450 101.3 ± 0.2 760.0 ± 1.5 27.0 ± 2.5 5.4 ± 0.5 By max. speed setting screw

2300 101.3 ± 0.2 760.0 ± 1.5 42.3 ± 4.0 8.5 ± 0.8

Less than Less than

2700 101.3 ± 0.2 760.0 ± 1.5 5.0 1.0

100 101.3 ± 0.2 760.0 ± 1.5 80.0 ± 10.0 16.0 ± 2.0 7.0 1.4 By governor sleeve plug

500 101.3 ± 0.2 760.0 ± 1.5 55.2 ± 2.0 11.0 ± 0.4 2.5 0.5

2000 101.3 ± 0.2 760.0 ± 1.5 60.8 ± 1.8 12.2 ± 0.4 2.5 0.5

8. SETTING OF LOAD SENSING TIMER Applying 0 V to T.C.V.

Lever Position Pump Speed Absolute Pressure Fuel Delivery Remarks

(rpm) (kPa) (mmHg) (mm3/st) (cc/200st)

Start of Load Sensing 1200 101.3 ± 0.2 760.0 ± 1.5 (A 5.0) ± 2.0 (A 1.0) ± 0.4 By governor shaft

End of Pressure Drop 1200 101.3 ± 0.2 760.0 ± 1.5 44.6 ± 1.0 8.9 ± 0.2 Check

Check Points 1. Piston Travel at End of Pressure Drop : 2.17 ± 0.50 mm (Pump speed 1200 rpm)

2. Dimension of Governor Shaft : L = 1.25 ± 0.75 mm

196000-1754

9. SETTING OF ADJUSTING LEVER AT LOW SPEED Applying 0 V to T.C.V.

Lever Pump Absolute Fuel Delivery Max. Spread Remarks

Position Speed in Delivery

(deg) (rpm) (kPa) (mm3/st) (cc/500st) (mm3) (cc)

16.5 ± 5° 350 101.3 ± 0.2 15.2 ± 1.5 = B 7.6 ± 0.8 = B 1.7 0.9 Lever setting

(760.0 ± 1.5 mmHg)

(Idle)

425 101.3 ± 0.2 (B 8.5) ± 2.5 (B 4.3) ± 1.3

(760.0 ± 1.5 mmHg)

10. SETTING OF ADJUSTING LEVER AT PARTIAL RANGE : Not Applicable

Pump Speed Absolute Pressure Fuel Delivery Remarks

3

(rpm) (kPa) (mmHg) (mm /st) (cc/500st)

11. CHARACTERISTIC OF A.C.S.D. Applying 0 V to T.C.V.

Lever Position Pump Speed Absolute Pressure Measuring Value Remarks

(rpm) (kPa) (mmHg)

Idle 350 101.3 ± 0.2 760.0 ± 1.5 0.69 ± 0.10 mm Piston Travel

3

350 101.3 ± 0.2 760.0 ± 1.5 0 mm /st Idle-up Quantity (0 cc/500st)

Fuel temperature : 39 - 41°C

12. ADJUSTMENT OF T.C.V.

Lever Position Pump Speed Absolute Pressure Piston Travel Remarks

(rpm) (kPa) (mmHg) (mm)

At End of 1200 101.3 ± 0.2 760.0 ± 1.5 3.81 ± 0.70 With applying 6.0 ± 0.1 (V)

Pressure Drop

13. SETTING OF DIAPHRAGM FOR HEATER & POWER STEERING Applying 0 V to T.C.V.

Absolute Pressure : 101.3 ± 0.2 kPa (760 ± 1.5 mmHg)

Pump Speed Vacuum Pressure Fuel Delivery Remarks

3

(rpm) (kPa) (mmHg) (mm /st) (cc/500st)

475 46.7 350 21.9 ± 1.0 11.0 ± 0.5 A/C Idle up, Make ACSD free

14. ADJUSTMENT OF POWER CONTROL : Not Applicable

Lever Position Pump Speed Boost Pressure Fuel Delivery Remarks

3

(rpm) (kPa) (mmHg) (mm /st) (cc/200st)

196000-1754

15. ADJUSTMENT OF THROTTLE POSITION SENSOR : Not Applicable

Lever Position Pump Speed Absolute Pressure Fuel Delivery Sensor Remarks

Output

(rpm) (kPa) (mmHg) (mm3/st) (cc/500st) Voltage (V)

16. FINAL CHECK AFTER ADJUSTMENT

1. Range of lever angle between idle and full lever position is 45 ± 3°.

2. After adgustment has been completed, delivery quantity must be 0 mm3/st (0 cc/200st)

when voltage at fuel cut solenoid is reduced to zero. (Pump Speed Np = 100 rpm)

S-ar putea să vă placă și

- Injection Pump Test Specifications 196000-517#Document4 paginiInjection Pump Test Specifications 196000-517#Edinson Ariel Chavarro QuinteroÎncă nu există evaluări

- Injection Pump Test Specifications 191000-490#Document3 paginiInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- EI5501Document4 paginiEI5501aaa bbb100% (1)

- Injection Pump Test SpecificationsDocument3 paginiInjection Pump Test SpecificationsJunior IungÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument3 paginiInjection Pump Test Specificationsadmin tigasaudaraÎncă nu există evaluări

- Injection Volume Adjustment Test Conditions: 6c-59-1.tifDocument33 paginiInjection Volume Adjustment Test Conditions: 6c-59-1.tifElvis Eliud HernándezÎncă nu există evaluări

- 096000-4860 Toyata Hilux-4 Runner PDFDocument4 pagini096000-4860 Toyata Hilux-4 Runner PDFBaytolgaÎncă nu există evaluări

- Injection Pump Test S Pecifications 196000-417#Document4 paginiInjection Pump Test S Pecifications 196000-417#Juan Gabriel Ochoa100% (1)

- 196000-6060 Injection Pump Test SpecificationsDocument4 pagini196000-6060 Injection Pump Test SpecificationsMiguel RojasÎncă nu există evaluări

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 paginiInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungÎncă nu există evaluări

- Injection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxDocument3 paginiInjection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxBaytolga100% (3)

- Injection Pump Test Specifications 093000-677#Document3 paginiInjection Pump Test Specifications 093000-677#Pedro Abellan100% (1)

- Injection Pump Test Specifications 092000-512#Document3 paginiInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- 7540Document10 pagini7540pruebaÎncă nu există evaluări

- 4720Document3 pagini4720Junior IungÎncă nu există evaluări

- 196000-4270 - Toyota Tabela Teste PDFDocument4 pagini196000-4270 - Toyota Tabela Teste PDFJaqueline S. S. Maicá100% (1)

- Injection Pump Test SpecificationsDocument3 paginiInjection Pump Test SpecificationsMartin Miguel Gomez SalviÎncă nu există evaluări

- Injection Pump Calibration DataDocument2 paginiInjection Pump Calibration DataСергей ВладимировичÎncă nu există evaluări

- Injection Pump Test Specifications: CPS21 AVM2PC-20hpDocument2 paginiInjection Pump Test Specifications: CPS21 AVM2PC-20hpDilakartikaÎncă nu există evaluări

- EB8870Document2 paginiEB8870Miguel RojasÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument3 paginiDpico: Inj. Pump Calibration DataСергей ВладимировичÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument2 paginiInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroÎncă nu există evaluări

- Test Plan: 9521A030: Pump SpecificationDocument3 paginiTest Plan: 9521A030: Pump Specificationjohnny sabinÎncă nu există evaluări

- Injection pump test specifications for Hino W04D engineDocument2 paginiInjection pump test specifications for Hino W04D engineBaytolgaÎncă nu există evaluări

- 093400-5350 Mitsubishi PDFDocument2 pagini093400-5350 Mitsubishi PDFBaytolgaÎncă nu există evaluări

- Test Plan Delphi TechnologiesDocument2 paginiTest Plan Delphi TechnologiesFRANCISCOÎncă nu există evaluări

- (Oto-Hui - Com) Edc Hino s05Document2 pagini(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500Încă nu există evaluări

- 0 400 866 208 TestPlanDocument2 pagini0 400 866 208 TestPlanคุณชายธวัชชัย เจริญสุข100% (2)

- Injection Pump Test SpecificationsDocument1 paginăInjection Pump Test SpecificationsMiguel RojasÎncă nu există evaluări

- CALIBRATION DATA FOR INJECTION PUMPDocument2 paginiCALIBRATION DATA FOR INJECTION PUMPMiguel RojasÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument3 paginiInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroÎncă nu există evaluări

- Injection Pump Test SpecificationsDocument2 paginiInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroÎncă nu există evaluări

- 104740-0976 - Ford RangerDocument6 pagini104740-0976 - Ford RangerBaytolgaÎncă nu există evaluări

- Ford HSDI pump specification and ISO test procedureDocument2 paginiFord HSDI pump specification and ISO test proceduretaniaÎncă nu există evaluări

- BOSCH EP test values for diesel fuel injection equipmentDocument3 paginiBOSCH EP test values for diesel fuel injection equipmentNemo NeoÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©Daniel Marin MoralesÎncă nu există evaluări

- Injection Pump Specification ©Document4 paginiInjection Pump Specification ©murillo_rodriguez8382100% (1)

- 3031 PDFDocument4 pagini3031 PDFMihai-Eugen Popa100% (1)

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration DataMiguel RojasÎncă nu există evaluări

- Injection Pump Calibration Data: 1. Test ConditionsDocument3 paginiInjection Pump Calibration Data: 1. Test ConditionsElson DorigonÎncă nu există evaluări

- 9412Document3 pagini9412Mihai-Eugen Popa100% (1)

- DATODocument1 paginăDATOMiguel RojasÎncă nu există evaluări

- 01EJ3051Document3 pagini01EJ3051ForteLubÎncă nu există evaluări

- EI3920Document4 paginiEI3920Pali SimónÎncă nu există evaluări

- Test injection pump specifications Toyota 4Runner Hilux dieselDocument3 paginiTest injection pump specifications Toyota 4Runner Hilux dieselJaqueline S. S. Maicá100% (1)

- 9320A093GDocument4 pagini9320A093GKevin TtitoÎncă nu există evaluări

- 0599Document2 pagini0599Edinson Ariel Chavarro Quintero100% (1)

- Test Plan: 9320A530: Pump SpecificationDocument4 paginiTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovÎncă nu există evaluări

- Test PlanDocument4 paginiTest PlanOFFICE DANACÎncă nu există evaluări

- ZEXEL test values for diesel fuel-injection equipmentDocument5 paginiZEXEL test values for diesel fuel-injection equipmentMihai-Eugen PopaÎncă nu există evaluări

- 9320a225g Plano LHDocument3 pagini9320a225g Plano LHForteLubÎncă nu există evaluări

- 8522a090 Delphi PDFDocument7 pagini8522a090 Delphi PDFBaytolgaÎncă nu există evaluări

- Dpico: Inj. Pump Calibration DataDocument2 paginiDpico: Inj. Pump Calibration Datamurillo_rodriguez8382Încă nu există evaluări

- Bosch EP test values for diesel fuel injection equipmentDocument3 paginiBosch EP test values for diesel fuel injection equipmentTamer Moustafa100% (1)

- 3042f843 Plano de TesteDocument1 pagină3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- Testing Specifications for Isuzu 6HK1-TC Injection PumpDocument2 paginiTesting Specifications for Isuzu 6HK1-TC Injection Pumpคุณชายธวัชชัย เจริญสุข75% (4)

- EH4890Document4 paginiEH4890aaa bbbÎncă nu există evaluări

- Ei4060 1Document4 paginiEi4060 1Miguel RojasÎncă nu există evaluări

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pagini096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungÎncă nu există evaluări

- Injection P Ump Test Specifications 196000-327#Document4 paginiInjection P Ump Test Specifications 196000-327#Manuel João JoãoÎncă nu există evaluări

- Fuel Injection Pump Parts ListDocument5 paginiFuel Injection Pump Parts ListJunior Iung100% (1)

- Denso Original CatalogueDocument16 paginiDenso Original CatalogueегорÎncă nu există evaluări

- Fuel Injection Pump Parts ListDocument5 paginiFuel Injection Pump Parts ListJunior Iung100% (1)

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pagini096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungÎncă nu există evaluări

- Solenóides Bomba CP BoschDocument5 paginiSolenóides Bomba CP BoschJunior Iung50% (2)

- 095000-5801 ExplodidoDocument1 pagină095000-5801 ExplodidoJunior IungÎncă nu există evaluări

- CASE 956 1056XL PreviewDocument41 paginiCASE 956 1056XL PreviewRaúl CacharrónÎncă nu există evaluări

- Lubi Permeate Pump DatasheetDocument2 paginiLubi Permeate Pump DatasheetVenkatesh SivaramanÎncă nu există evaluări

- Price List Vacuum Pumps 2-2022 PDFDocument26 paginiPrice List Vacuum Pumps 2-2022 PDFЭльшад АскеровÎncă nu există evaluări

- Unit - II: Environmental Engineering-I: TopicDocument53 paginiUnit - II: Environmental Engineering-I: Topicbharatiya technologyÎncă nu există evaluări

- Experimental Study On CI Engine Fuel Injector Assemble and TestingDocument9 paginiExperimental Study On CI Engine Fuel Injector Assemble and TestingSai KiranÎncă nu există evaluări

- Workshop Manual Octavia Engine Mechanics 1Document72 paginiWorkshop Manual Octavia Engine Mechanics 1Shriram Iyer100% (2)

- Smarter Washing Solutions: Modular Wash RangeDocument5 paginiSmarter Washing Solutions: Modular Wash RangeSujesh AnÎncă nu există evaluări

- Hitachi Sumitomo Scx2800 2 Hydraulic Crawler Crane SpecificationsDocument2 paginiHitachi Sumitomo Scx2800 2 Hydraulic Crawler Crane Specificationsedward100% (43)

- VRF Outdoor Unit InstallationDocument25 paginiVRF Outdoor Unit Installationtyberius7Încă nu există evaluări

- FM 3 0 Mk3 - EN - 1R - Tech DataDocument6 paginiFM 3 0 Mk3 - EN - 1R - Tech DataOrhan HasanogluÎncă nu există evaluări

- Suspension Test RigDocument13 paginiSuspension Test RigPoonam Mankar100% (1)

- Technical Note Rosemount 8700 Series Flowmeter in Fire Pump System Applications en 87722Document9 paginiTechnical Note Rosemount 8700 Series Flowmeter in Fire Pump System Applications en 87722pinkcityÎncă nu există evaluări

- ECONOMIC SURGE TANK DESIGN WITH REVERSE FLOW THROTTLEDocument6 paginiECONOMIC SURGE TANK DESIGN WITH REVERSE FLOW THROTTLEcsimsekÎncă nu există evaluări

- Hump Hydraulics CalculationsDocument13 paginiHump Hydraulics CalculationsrutujaÎncă nu există evaluări

- Manual Hydracore 2000 PDFDocument47 paginiManual Hydracore 2000 PDFlabortorio100% (2)

- Summary of Test Reports For The Year 2016Document37 paginiSummary of Test Reports For The Year 2016subyÎncă nu există evaluări

- TD Ec225Document36 paginiTD Ec225Tien Hong Do100% (1)

- Thesis On Turbo PumpDocument5 paginiThesis On Turbo Pumppak0t0dynyj3100% (2)

- End Suction Centrifugal Pumps Data SheetDocument2 paginiEnd Suction Centrifugal Pumps Data Sheetgangruka67% (3)

- XY-1A Core Drilling RigDocument3 paginiXY-1A Core Drilling RigAnu Pathak75% (4)

- Atlas Copco Centrifugal CompressorsDocument24 paginiAtlas Copco Centrifugal Compressorsthunder100% (1)

- John Deere Rain Simulator Final ReportDocument61 paginiJohn Deere Rain Simulator Final Reportswm5376Încă nu există evaluări

- Sulzer Ahlstar PP E00545Document16 paginiSulzer Ahlstar PP E00545Benicio Joaquín Ferrero Brebes100% (1)

- Systems Operation Testing Adjusting 3500 Generator Set Engine AttachmentsDocument34 paginiSystems Operation Testing Adjusting 3500 Generator Set Engine Attachmentsale alvarezÎncă nu există evaluări

- Pumping Stations Design Lecture 5Document60 paginiPumping Stations Design Lecture 5Misama NedianÎncă nu există evaluări

- Asme A13.1 - 1996Document27 paginiAsme A13.1 - 1996lohv100% (1)

- Purpose of This Manual: Gasboy UHF Pump, Blackmer Xu2A Rebuild Kit Installation Manual June 2004Document26 paginiPurpose of This Manual: Gasboy UHF Pump, Blackmer Xu2A Rebuild Kit Installation Manual June 2004Juan Carlos MuñozÎncă nu există evaluări

- Against Water Hummer PDFDocument36 paginiAgainst Water Hummer PDFDenstar Ricardo SilalahiÎncă nu există evaluări

- Bilge Water Separator: Mpeb-VtDocument16 paginiBilge Water Separator: Mpeb-VtSezer Deniz ZağlıÎncă nu există evaluări