Documente Academic

Documente Profesional

Documente Cultură

Boiler Plant Optimization Score Card: Company: Date: Contact Person: Location: Title: Phone: Email

Încărcat de

fauzi endraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Boiler Plant Optimization Score Card: Company: Date: Contact Person: Location: Title: Phone: Email

Încărcat de

fauzi endraDrepturi de autor:

Formate disponibile

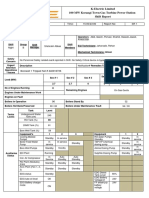

BOILER PLANT OPTIMIZATION

SCORE CARD

Company: Date:

Contact Person: Location:

Title: Phone: Email:

Please check the box where applicable for each task.

Already Do Not Does Not Action

Task Have Outdated Have Apply Required Responsible* Describe Action and Owner

Document Current State of Boiler Plant

Updated Boiler Plant Process and Instrumentation Diagram E

Updated Boiler Plant Standard Operating Procedures (SOPs) E

Boiler Room Valve & Instrument Tags E

Equipment List & Specifications E

Service Providers: Contact Info O

Daily Inspections/Checklist and Regular Log Book Entries O

Chemical Log by Service Provider - Weekly or Biweekly V

Chemical Log Test: Shift / Daily O

Total:

Operation & Maintenance

Comprehensive Preventative Program Including Weekly, Monthly and O, M

Annual Tasks

Record of Boiler & Equipment Maintenance History O, M

Quarterly or Semi-Annual Combustion Tuning O, V

Safety Relief Valve Test / Replacement Schedule O, V

Pressure Vessel Non-Destructive Tests: Deaerator Tank, High-Pressure O, V

Receiver, Blowdown Tank

Total:

Prepare Operational Recovery

Spare Parts List - Stock Items in Warehouse M

Spare Parts List - Long Lead Time Spare - Inventory M, W

Emergency Spares List M

“Boiler Down” - Contingency for Inoperable Boiler (Unplanned) P, O

Emergency Response Plan E, O

Total:

Opportunities for Improvement

Boiler & Boiler Plant Efficiency E, M, O

Condensate Recovery M, O

Flash Steam Venting E, M, O

Steam Trap Program M,O

Metering Including Steam, Fuel, Feedwater and Makeup Water E,O

Total:

Educational Training

Participation in Continuous Boiler Plant Education All

Total:

Grand Total:

*Responsible: E = Engineering, M = Maintenance, O = Operator, V = Vendor, W = Warehouse, P = Production

Contact Cleaver-Brooks for more information about these programs and other opportunities within the boiler plant

at marketing@cleaverbrooks.com

Printed in the USA

©2015 Cleaver-Brooks, Inc

CB-8531

6/15

S-ar putea să vă placă și

- Refrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsDe la EverandRefrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsEvaluare: 3 din 5 stele3/5 (2)

- Electrical Diagram Electric Duty Pump - DOL 1,1-45kWDocument11 paginiElectrical Diagram Electric Duty Pump - DOL 1,1-45kWMBMÎncă nu există evaluări

- PEC-TP-20231: E-7054 Tube Blockage & Baffle Plate Crack (DISCOVERY 036)Document23 paginiPEC-TP-20231: E-7054 Tube Blockage & Baffle Plate Crack (DISCOVERY 036)Natarajan MurugesanÎncă nu există evaluări

- Dry VRU Training Guide 2009 R2Document52 paginiDry VRU Training Guide 2009 R2lucashck100% (1)

- TCN PDFDocument66 paginiTCN PDFJahangir AlamÎncă nu există evaluări

- 415 - Dexler - QAP - 800V, 2200ADocument4 pagini415 - Dexler - QAP - 800V, 2200Asriram.5230Încă nu există evaluări

- Service Report: Specify Scope of WorkDocument3 paginiService Report: Specify Scope of WorkKevin QuijanoÎncă nu există evaluări

- 7 Auto Transformer Test ReportsDocument11 pagini7 Auto Transformer Test ReportsCOVER VERIFICACIONES ELECTRICAS, S.A.Încă nu există evaluări

- AMUDI EMEKA CV For ChevronDocument4 paginiAMUDI EMEKA CV For ChevronAMUDI EMEKAÎncă nu există evaluări

- Maintenance Schedule 1Document1 paginăMaintenance Schedule 1puwe qiheÎncă nu există evaluări

- 4011-REP-ABE-078-442-0001 - Rev01 - Emergency-Black Start Diesel Sizing CriteriaDocument18 pagini4011-REP-ABE-078-442-0001 - Rev01 - Emergency-Black Start Diesel Sizing CriteriatskumarÎncă nu există evaluări

- C 035 RW Vibrator12 Rev.1Document1 paginăC 035 RW Vibrator12 Rev.1slamet4riadiÎncă nu există evaluări

- B.Tech B.Pharm RC CV PCA Notification Extended CircularDocument1 paginăB.Tech B.Pharm RC CV PCA Notification Extended CircularJsjsjsjsjsjsjjÎncă nu există evaluări

- Commissioning Work Schedule-1Document2 paginiCommissioning Work Schedule-1kunjal mistryÎncă nu există evaluări

- E-380kVA KOEL DG Set drg.-R1 15.09.2022Document2 paginiE-380kVA KOEL DG Set drg.-R1 15.09.2022Electrical RadicalÎncă nu există evaluări

- JIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)Document6 paginiJIMT &NBSP Pre Com Water Plumbing System Punch List (Changing Room, Bin Centre, Grasswatering PT)GomathyselviÎncă nu există evaluări

- Technical Specification - 2023 01 16 18 50 06Document10 paginiTechnical Specification - 2023 01 16 18 50 06abhishekgupta9990Încă nu există evaluări

- Texas Sales Tax TableDocument12 paginiTexas Sales Tax TablepoopfeastÎncă nu există evaluări

- Img 20210910 0001Document1 paginăImg 20210910 0001YONG LINGÎncă nu există evaluări

- PPM 2017 2.0 LV System (Weekly)Document3 paginiPPM 2017 2.0 LV System (Weekly)Nazlie NasirÎncă nu există evaluări

- Installation Instructions Automatic Na Sensor Regeneration AMI Sodium PDocument8 paginiInstallation Instructions Automatic Na Sensor Regeneration AMI Sodium PCarmen LopezÎncă nu există evaluări

- Boiler Maintenance Log SheetDocument33 paginiBoiler Maintenance Log Sheetsohel rana0% (1)

- AC Motor Inspection/Testing & Commissioning Check ListDocument9 paginiAC Motor Inspection/Testing & Commissioning Check ListAdnan AhmadÎncă nu există evaluări

- It Cannot Be Used Without Prior Permission: Prof. Vaibhav V. GoudDocument176 paginiIt Cannot Be Used Without Prior Permission: Prof. Vaibhav V. GoudshubhamÎncă nu există evaluări

- NO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionDocument123 paginiNO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionYoseph Maulana0% (1)

- Contingency Program Objective: Emergency Response Organizational StructureDocument6 paginiContingency Program Objective: Emergency Response Organizational Structuremerimeri100% (2)

- L&T QapDocument2 paginiL&T Qapsriram.5230Încă nu există evaluări

- TDR 100 Portfolio Report ModifiedDocument5 paginiTDR 100 Portfolio Report ModifiedsirjamlesÎncă nu există evaluări

- Transformer Test Report FINALDocument21 paginiTransformer Test Report FINALStephenÎncă nu există evaluări

- Evening Shift Report 31-08-2019Document4 paginiEvening Shift Report 31-08-2019Baran ShafqatÎncă nu există evaluări

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 paginiAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilÎncă nu există evaluări

- Ultratech, AP Cement WorksDocument29 paginiUltratech, AP Cement WorksSanjeev PmÎncă nu există evaluări

- 1017 Itp 104 Rev. 01 Reinforced Concrete WorkDocument4 pagini1017 Itp 104 Rev. 01 Reinforced Concrete Workyasser elhousseiniÎncă nu există evaluări

- Sprinkler Report NFPA 25 03.27.13Document8 paginiSprinkler Report NFPA 25 03.27.13redbire100% (1)

- SRC FORM - MS and ITP FOR Raceway and Electrical BoxesDocument1 paginăSRC FORM - MS and ITP FOR Raceway and Electrical BoxesMoawia IbrahimÎncă nu există evaluări

- 9 20234 A A PPT 01 Well TestingDocument9 pagini9 20234 A A PPT 01 Well TestingkienlvÎncă nu există evaluări

- Bunkering ChecklisDocument1 paginăBunkering ChecklisgenghizregepÎncă nu există evaluări

- Public 866 PDFDocument4 paginiPublic 866 PDFJOSE GARCIAÎncă nu există evaluări

- Sangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraDocument2 paginiSangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraSANGEETHAÎncă nu există evaluări

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 paginăChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraÎncă nu există evaluări

- Isolator & Earth Switch - For SwitchayrdDocument6 paginiIsolator & Earth Switch - For SwitchayrdGopal KrishnanÎncă nu există evaluări

- LK 5 Sistem Pengapian OKDocument6 paginiLK 5 Sistem Pengapian OKNengah Saputra WijayaÎncă nu există evaluări

- 240 Pre Leach ThickeningDocument7 pagini240 Pre Leach ThickeningGUNTHERVEGAÎncă nu există evaluări

- Handling Over Epcmd 2 Qm00 FMT PP 010 - 00Document1 paginăHandling Over Epcmd 2 Qm00 FMT PP 010 - 00Muthu AlaguRajÎncă nu există evaluări

- Journal Pre-Proofs: Thermal Science and Engineering ProgressDocument60 paginiJournal Pre-Proofs: Thermal Science and Engineering ProgressMatheus M. DwinantoÎncă nu există evaluări

- PT Plant & Make Up WaterDocument5 paginiPT Plant & Make Up WaterPrudhvi RajÎncă nu există evaluări

- 009 - BoilerDocument2 pagini009 - BoilerRatu TyasÎncă nu există evaluări

- Adole Condensation of KetoneDocument30 paginiAdole Condensation of Ketoneashutosh kumarÎncă nu există evaluări

- Inspeksi Trafo - Sabtu SiangDocument24 paginiInspeksi Trafo - Sabtu SiangJAN OJANÎncă nu există evaluări

- Daily Inspection Checklist - Air CompressorDocument2 paginiDaily Inspection Checklist - Air Compressornadeem mallick78% (9)

- Crane 90 MeindoDocument11 paginiCrane 90 MeindoPrawiraÎncă nu există evaluări

- Fluid Phase Equilibria: Morteza Ardeshir Larijani, Mohamad Bayat, Hossein AfshinDocument14 paginiFluid Phase Equilibria: Morteza Ardeshir Larijani, Mohamad Bayat, Hossein AfshinManuel Andres Rivera GuerreroÎncă nu există evaluări

- Api StandardDocument6 paginiApi StandardYudhie RahmanÎncă nu există evaluări

- Presentationerectiongt9eavecliens 151003075321 Lva1 App6892Document108 paginiPresentationerectiongt9eavecliens 151003075321 Lva1 App6892dony ramdhaniÎncă nu există evaluări

- Cilar Checklist: Maintenance Job DeskDocument1 paginăCilar Checklist: Maintenance Job DeskedlistiantoÎncă nu există evaluări

- AE Overhaul Guidance & ReportingDocument49 paginiAE Overhaul Guidance & ReportingjoelandrewpintoÎncă nu există evaluări

- 3 Yrs Forward Plan, SRPCPL (Electrical)Document5 pagini3 Yrs Forward Plan, SRPCPL (Electrical)amjadÎncă nu există evaluări

- SPE 118709 The Pains and Gains of Experimental Design and Response Surface Applications in Reservoir Simulation StudiesDocument9 paginiSPE 118709 The Pains and Gains of Experimental Design and Response Surface Applications in Reservoir Simulation StudiesJosé Fernando TerronesÎncă nu există evaluări

- BP Shipping Questionnaire: New Build VesselDocument15 paginiBP Shipping Questionnaire: New Build Vesselmr mrÎncă nu există evaluări

- Pages From DRY POWDER EXTINGUIHSERS UL LISTED - PDF - Adobe Acrobat Pro ExtendedDocument1 paginăPages From DRY POWDER EXTINGUIHSERS UL LISTED - PDF - Adobe Acrobat Pro ExtendedAmeen Hamed AlwseyÎncă nu există evaluări

- Electric Drives - Brushless DC and Reluctance MotorsDocument5 paginiElectric Drives - Brushless DC and Reluctance Motorsfauzi endraÎncă nu există evaluări

- B6 CFHDocument44 paginiB6 CFHfauzi endraÎncă nu există evaluări

- 750-383 Master Panel 4Document60 pagini750-383 Master Panel 4fauzi endraÎncă nu există evaluări

- 750-386 Adac 1000 PDFDocument140 pagini750-386 Adac 1000 PDFfauzi endraÎncă nu există evaluări

- Alternative Fuel Systems - Sales and Technical GuideDocument7 paginiAlternative Fuel Systems - Sales and Technical GuideJDPSoaresÎncă nu există evaluări

- Clearfire - Model CFV: 9.5 - 60 HP Steam Vertical BoilerDocument39 paginiClearfire - Model CFV: 9.5 - 60 HP Steam Vertical Boilerfauzi endraÎncă nu există evaluări

- ADAC 4000 Boiler Book PDFDocument11 paginiADAC 4000 Boiler Book PDFfauzi endraÎncă nu există evaluări

- Advanced Tube DesignDocument2 paginiAdvanced Tube DesignBabu AravindÎncă nu există evaluări

- Hawk - Lead/Lag For Up To Eight Boilers System: Features and BenefitsDocument4 paginiHawk - Lead/Lag For Up To Eight Boilers System: Features and BenefitspikermiÎncă nu există evaluări

- BB Blowdown Separators Sept10Document12 paginiBB Blowdown Separators Sept10MaximilianoRodrigoCabestreroÎncă nu există evaluări

- BB Sample Coolers 11 2013 PDFDocument9 paginiBB Sample Coolers 11 2013 PDFfauzi endraÎncă nu există evaluări

- BB Condensate Return Systems Apr11Document4 paginiBB Condensate Return Systems Apr11fauzi endraÎncă nu există evaluări

- Blowdown System Boiler BookDocument16 paginiBlowdown System Boiler BookMatias MancillaÎncă nu există evaluări

- BB Chemical Feed Sept10Document4 paginiBB Chemical Feed Sept10fauzi endraÎncă nu există evaluări

- BB Spraymaster Duo Sept09Document15 paginiBB Spraymaster Duo Sept09fauzi endraÎncă nu există evaluări

- BFS Boiler Book PDFDocument4 paginiBFS Boiler Book PDFfauzi endraÎncă nu există evaluări

- CB Lcs-250E Level Control System: Features and BenefitsDocument4 paginiCB Lcs-250E Level Control System: Features and BenefitsMonirul IslamÎncă nu există evaluări

- BB ElectricBoilers Nov10Document40 paginiBB ElectricBoilers Nov10deztruktorÎncă nu există evaluări

- CB Lcs-150E.1 Level Control System: Features and BenefitsDocument3 paginiCB Lcs-150E.1 Level Control System: Features and Benefitsfauzi endraÎncă nu există evaluări

- CB Pcs-140E Pump Control System: Features and BenefitsDocument3 paginiCB Pcs-140E Pump Control System: Features and Benefitsfauzi endraÎncă nu există evaluări

- Boiler Book 2011Document1.140 paginiBoiler Book 2011gamronÎncă nu există evaluări

- Blowdown System Operating and Maintenance Manual BoilerDocument12 paginiBlowdown System Operating and Maintenance Manual BoilerMuhammad Muaddib LidinillahÎncă nu există evaluări

- Catálogo Boiler Book CBEX Elite 100-800Document20 paginiCatálogo Boiler Book CBEX Elite 100-800AndresCanoÎncă nu există evaluări

- Boiler Heating Square Footage PDFDocument2 paginiBoiler Heating Square Footage PDFfauzi endraÎncă nu există evaluări

- Boiler Book 2010 PDFDocument1.419 paginiBoiler Book 2010 PDFDiogenes TorresÎncă nu există evaluări

- Boiler Efficiency Guide PDFDocument24 paginiBoiler Efficiency Guide PDFAsnfiasnfd FenfeÎncă nu există evaluări

- Boiler Book CBEX Premium 100-800Document19 paginiBoiler Book CBEX Premium 100-800fauzi endraÎncă nu există evaluări

- Boiler Selection PDFDocument25 paginiBoiler Selection PDFShafqat AfridiÎncă nu există evaluări

- Boiler University: Certified Boiler Operation Class WBC Mechanical 4-Hour Boiler Training ClassDocument1 paginăBoiler University: Certified Boiler Operation Class WBC Mechanical 4-Hour Boiler Training Classfauzi endraÎncă nu există evaluări

- UopDocument3 paginiUopSean Davis100% (2)

- The Suitable Racking System For Any Demand: ProductsDocument18 paginiThe Suitable Racking System For Any Demand: ProductsSheel JhaÎncă nu există evaluări

- BUS827 - S2 - L4 - Feasability Writing A Business PlanDocument37 paginiBUS827 - S2 - L4 - Feasability Writing A Business PlanEli EspinozaÎncă nu există evaluări

- TOM Syllabus Recovered)Document130 paginiTOM Syllabus Recovered)Divakar RanjanÎncă nu există evaluări

- Design of Jigs and FixturesDocument3 paginiDesign of Jigs and FixturesRajueswarÎncă nu există evaluări

- Data Sheet - Mirafi® HPa (200 613-td-05-15)Document1 paginăData Sheet - Mirafi® HPa (200 613-td-05-15)khairul umamÎncă nu există evaluări

- Best Practices SAN IBMDocument338 paginiBest Practices SAN IBMJulio Rodanes MartinezÎncă nu există evaluări

- QP IAS Q3001 Instrumentation Technician (Control Valves)Document51 paginiQP IAS Q3001 Instrumentation Technician (Control Valves)armin heidariÎncă nu există evaluări

- Tata Indica v2 Xeta CarDocument89 paginiTata Indica v2 Xeta Carsantoshk165Încă nu există evaluări

- Corporate Entrepreneurship - HowDocument30 paginiCorporate Entrepreneurship - HowHoang Anh TuanÎncă nu există evaluări

- Lortz Manufacturing - Expansion Joints and Metal BellowsDocument3 paginiLortz Manufacturing - Expansion Joints and Metal Bellowssevero97Încă nu există evaluări

- Company Profile Balaji Defence Engineering Solutions 1 - 1Document29 paginiCompany Profile Balaji Defence Engineering Solutions 1 - 1Balaji DefenceÎncă nu există evaluări

- Ilovepdf MergedDocument30 paginiIlovepdf MergedKarthick S Mech KIOTÎncă nu există evaluări

- Automatic Metal PouringDocument4 paginiAutomatic Metal PouringOmar Mushtaq100% (1)

- MC ASN-GW Ver.3.5 System Manual 111207Document378 paginiMC ASN-GW Ver.3.5 System Manual 111207ابرهيم منصورÎncă nu există evaluări

- Effort EstimationDocument8 paginiEffort EstimationsrichandreddyÎncă nu există evaluări

- Copper Alloy Pipe (Amendments/Supplements To Astm B 111) : Technical SpecificationDocument7 paginiCopper Alloy Pipe (Amendments/Supplements To Astm B 111) : Technical SpecificationSalahuddin FarooquiÎncă nu există evaluări

- 1 Using FPC To Size Truck and Loader FleetsDocument201 pagini1 Using FPC To Size Truck and Loader Fleetsalfri121Încă nu există evaluări

- SAP Administration GuideDocument1.220 paginiSAP Administration GuidebigcoatlicueÎncă nu există evaluări

- Salesforce CRMconsultingDocument25 paginiSalesforce CRMconsultingksrajasekar100% (1)

- BQP ReportDocument5 paginiBQP ReportCristea RalucaÎncă nu există evaluări

- Evaluating The Green Supply Chain Management Barriers in A Sme: An Ahp ApproachDocument6 paginiEvaluating The Green Supply Chain Management Barriers in A Sme: An Ahp ApproachTJPRC PublicationsÎncă nu există evaluări

- FlightGlobal - Lightweight SeawolfDocument3 paginiFlightGlobal - Lightweight SeawolfAwesomeDeliteÎncă nu există evaluări

- Job Opportunities Kenya August 15 - August 20Document341 paginiJob Opportunities Kenya August 15 - August 20Rodney ABÎncă nu există evaluări

- Group 2 - Robert Street ImprovementsDocument92 paginiGroup 2 - Robert Street ImprovementsOctob Bhayu Hanggoro PutroÎncă nu există evaluări

- Preguntas de Certificación ABAPDocument61 paginiPreguntas de Certificación ABAPGabriel Gonzalez SalazarÎncă nu există evaluări

- SEC5 (1) WashpipeDocument22 paginiSEC5 (1) WashpipeCarlos Alberto PerdomoÎncă nu există evaluări

- ICC 2010 - Product Catalog PDFDocument78 paginiICC 2010 - Product Catalog PDFMIKHA2014Încă nu există evaluări

- Module 3 MANUALS OF PROFESSIONAL PRACTICE FOR CIVIL ENGINEERDocument2 paginiModule 3 MANUALS OF PROFESSIONAL PRACTICE FOR CIVIL ENGINEERRbcabajes ButalonÎncă nu există evaluări

- DFo 2 4 2 ProjectDocument2 paginiDFo 2 4 2 Projecthandoko.agusÎncă nu există evaluări