Documente Academic

Documente Profesional

Documente Cultură

X20 (C) PS2100

Încărcat de

Claiton Costa NunesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

X20 (C) PS2100

Încărcat de

Claiton Costa NunesDrepturi de autor:

Formate disponibile

X20(c)PS2100

X20(c)PS2100

1 General information

The supply module is used for the internal I/O supply.

• 24 VDC supply module for internal I/O supply

2 Coated modules

Coated modules are X20 modules with a protective coating for the electronics component. This coating protects

X20c modules from condensation and corrosive gases.

The modules' electronics are fully compatible with the corresponding X20 modules.

For simplification purposes, only images and module IDs of uncoated modules are used in this data

sheet.

The coating has been certified according to the following standards:

• Condensation: BMW GS 95011-4, 2x 1 cycle

• Corrosive gas: EN 60068-2-60, method 4, exposure 21 days

3 Order data

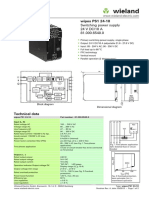

Model number Short description Figure

Power supplies

X20PS2100 X20 power supply module, for internal I/O supply

X20cPS2100 X20 power supply module, coated, for internal I/O supply

Required accessories

Bus modules

X20BM01 X20 power supply bus module, 24 VDC keyed, internal I/O sup-

ply interrupted to the left

X20BM05 X20 power supply bus module, with node number switch, 24

VDC keyed, internal I/O supply interrupted to the left

X20cBM01 X20 power supply bus module, coated, 24 VDC keyed, internal

I/O supply interrupted to the left

Terminal blocks

X20TB12 X20 terminal block, 12-pin, 24 VDC keyed

Table 1: X20PS2100, X20cPS2100 - Order data

Data sheet V3.16 1

X20(c)PS2100

4 Technical data

Model number X20PS2100 X20cPS2100

Short description

Power supply module 24 VDC supply module for internal I/O supply

General information

B&R ID code 0x1BBF 0xE23C

Status indicators Operating state, module status

Diagnostics

Module run/error Yes, using status LED and software

Power consumption of X2X Link power supply 1) 0.2 W

Power consumption 1)

Internal I/O 0.6 W

Additional power dissipation caused by actuators -

(resistive) [W]

Certifications

CE Yes

KC Yes -

UL cULus E115267

Industrial control equipment

HazLoc cCSAus 244665

Process control equipment

for hazardous locations

Class I, Division 2, Groups ABCD, T5

ATEX Zone 2, II 3G Ex nA nC IIA T5 Gc

IP20, Ta (see X20 user's manual)

FTZÚ 09 ATEX 0083X

DNV GL Temperature: B (0 - 55°C)

Humidity: B (up to 100%)

Vibration: B (4 g)

EMC: B (Bridge and open deck)

LR ENV1

GOST-R Yes

Input I/O power supply

Input voltage 24 VDC -15% / +20%

Fuse Required line fuse: Max. 10 A, slow-blow

Reverse polarity protection No

Output I/O power supply

Nominal output voltage 24 VDC

Behavior on short circuit Required line fuse

Permissible contact load 10 A

Electrical characteristics

Electrical isolation I/O supply not isolated from I/O power supply

Operating conditions

Mounting orientation

Horizontal Yes

Vertical Yes

Installation elevation above sea level

0 to 2000 m No limitations

>2000 m Reduction of ambient temperature by 0.5°C per 100 m

Degree of protection per EN 60529 IP20

Environmental conditions

Temperature

Operation

Horizontal mounting orientation -25 to 60°C

Vertical mounting orientation -25 to 50°C

Derating -

Storage -40 to 85°C

Transport -40 to 85°C

Relative humidity

Operation 5 to 95%, non-condensing Up to 100%, condensing

Storage 5 to 95%, non-condensing

Transport 5 to 95%, non-condensing

Mechanical properties

Note Order 1x X20TB12 terminal block separately Order 1x X20TB12 terminal block separately

Order 1x X20BM01 supply bus module separately Order 1x X20cBM01 supply bus module separately

Spacing 12.5+0.2 mm

Table 2: X20PS2100, X20cPS2100 - Technical data

1) The specified values are maximum values. For examples of the exact calculation, see section "Mechanical and electrical configuration" of the X20 system

user's manual.

2 Data sheet V3.16

X20(c)PS2100

5 LED status indicators

For a description of the various operating modes, see section "Additional information - Diagnostic LEDs" of the

X20 system user's manual.

Figure LED Color Status Description

r Green Off No power to module

Single flash RESET mode

Blinking PREOPERATIONAL mode

On RUN mode

e Red Off No power to module or everything OK

Double flash LED indicates one of the following states:

• I/O supply too low

• X2X link voltage too low

e+r Red on / Green single flash Invalid firmware

6 Pinout

r e

X20 PS 2100

+24 V I/O

+24 V I/O

GND

7 Connection example

PS

10 A slow-blow

+ I/O

_ Power supply

+24 VDC

GND

8 Safe shutdown of potential group

In safety-related applications, it must be guaranteed that the potential group is safely shut down in order to achieve

a category 4 shutdown in accordance with EN ISO 13849-1. An X20PS2100 (rev.F0 or higher) or X20PS2110

(rev.C0 or higher) supply module must be used to do this.

Important notes on "Safe shutdown" are listed in the X20 system user's manual, section"Mechanical and electrical

configuration - Safe shutdown". The user's manual is available in the Downloads section of the B&R website

(www.br-automation.com).

Data sheet V3.16 3

X20(c)PS2100

9 Register description

9.1 General data points

In addition to the registers listed in the register description, the module also has other more general data points.

These registers are not specific to the module but contain general information such as serial number and hardware

version.

General data points are described in section "Additional information - General data points" of the X20 system user's

manual.

9.2 Function model 0 - Standard

Register Fixed offset Name Data type Read Write

Cyclic Non-cyclic Cyclic Non-cyclic

0 1 Module status USINT ●

StatusInput01 Bit 0

StatusInput02 Bit 2

4 3 SupplyVoltage USINT ●

Fixed modules require their data points to be in a specific order in the X2X frame. Cyclic access occurs according

to a predefined offset, not based on the register address.

Acyclic access continues to be based on the register numbers.

9.3 Function model 254 - Bus controller

Register Offset1) Name Data type Read Write

Cyclic Non-cyclic Cyclic Non-cyclic

0 0 Module status UINT ●

StatusInput01 Bit 0

StatusInput02 Bit 2

4 4 SupplyVoltage UINT ●

1) The offset specifies the position of the register within the CAN object.

9.3.1 Using the module on the bus controller

Function model 254 "Bus controller" is used by default only by non-configurable bus controllers. All other bus

controllers can use other registers and functions depending on the fieldbus used.

For detailed information, see section "Additional information - Using I/O modules on the bus controller" of the X20

user's manual (version 3.50 or later).

9.3.2 CAN I/O bus controller

The module occupies 1 analog logical slot on CAN I/O.

9.4 Module status

Name:

Module status

The following module supply voltages are monitored in this register:

Bus supply voltage: Bus supply voltage <4.7 V is displayed as a warning.

24 VDC I/O supply voltage: I/O supply voltage <20.4 V is displayed as a warning.

Function model Data type Value

0 - Standard USINT See bit structure.

254 - Bus controller UINT See bit structure.

Bit structure:

Bit Name Value Information

0 StatusInput01 0 No error

1 Bus supply warning - Undervoltage (<4.7 V)

1 Reserved 0

2 StatusInput02 0 I/O power supply above the warning limit of 20.4 V

1 I/O power supply below the warning limit of 20.4 V

3-x Reserved 0

4 Data sheet V3.16

X20(c)PS2100

9.5 Bus supply voltage

Name:

SupplyVoltage

This register displays the bus supply voltage measured at a resolution of 0.1 V.

Function model Data type

0 - Standard USINT

254 - Bus controller UINT

9.6 Minimum cycle time

The minimum cycle time defines how far the bus cycle can be reduced without communication errors occurring.

It is important to note that very fast cycles reduce the idle time available for handling monitoring, diagnostics and

acyclic commands.

Minimum cycle time

100 μs

9.7 Minimum I/O update time

The minimum I/O update time defines how far the bus cycle can be reduced while still allowing an I/O update to

take place in each cycle.

Minimum I/O update time

2 ms

Data sheet V3.16 5

S-ar putea să vă placă și

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- 100% NATEF Task Coverage: Automotive TechnologyDocument88 pagini100% NATEF Task Coverage: Automotive TechnologynhathoaÎncă nu există evaluări

- GT ManualDocument10 paginiGT Manualsoldatbr4183Încă nu există evaluări

- X20CM0985 1 Eng - V1.42Document72 paginiX20CM0985 1 Eng - V1.42rushaÎncă nu există evaluări

- BHEL - Agitator Specification PDFDocument68 paginiBHEL - Agitator Specification PDFRiyaz100% (1)

- Large Field Refrigeration System-USMC Technical ManualDocument228 paginiLarge Field Refrigeration System-USMC Technical ManualbusybusybusyÎncă nu există evaluări

- IC200MDL640Document2 paginiIC200MDL640s_waqarÎncă nu există evaluări

- X20 (C) DO8332: 1 General InformationDocument12 paginiX20 (C) DO8332: 1 General InformationKader SllÎncă nu există evaluări

- X20do9322-Eng V3.15Document8 paginiX20do9322-Eng V3.15dhiyaulhaq05071991Încă nu există evaluări

- X20di9371-Eng V3.23Document7 paginiX20di9371-Eng V3.23smdsahinÎncă nu există evaluări

- X20 (C) DC1198: 1 General InformationDocument8 paginiX20 (C) DC1198: 1 General InformationOmar AzzainÎncă nu există evaluări

- X20BC0083-cabeça Rede AutomaçãoDocument5 paginiX20BC0083-cabeça Rede AutomaçãoWillian ErthalÎncă nu există evaluări

- X20 (C) BC0083-ENG V2.33Document6 paginiX20 (C) BC0083-ENG V2.33Teh Boon SiangÎncă nu există evaluări

- X20bc0083-Eng V2.40Document6 paginiX20bc0083-Eng V2.40dalitso ngomaÎncă nu există evaluări

- 1 General Information: Nettime Timestamp For OutputDocument8 pagini1 General Information: Nettime Timestamp For OutputOscar Enríquez MorenoÎncă nu există evaluări

- 1 General Information: Model Number Short Description Counter Functions Required Accessories Bus ModulesDocument11 pagini1 General Information: Model Number Short Description Counter Functions Required Accessories Bus Modulesroni kurniawanÎncă nu există evaluări

- X20dc1376-Eng V2.31Document19 paginiX20dc1376-Eng V2.31Lajos SütőÎncă nu există evaluări

- X20 (C) BB80: 1 General InformationDocument3 paginiX20 (C) BB80: 1 General InformationOscar Enríquez MorenoÎncă nu există evaluări

- 1 General InformationDocument45 pagini1 General InformationNikolayÎncă nu există evaluări

- X20di9371-Eng V3.11Document7 paginiX20di9371-Eng V3.11Behzad MirzaeiÎncă nu există evaluări

- X20at4222-Eng V3.12Document10 paginiX20at4222-Eng V3.12Asif MehmoodÎncă nu există evaluări

- X20AT4222-Entrada RTDDocument10 paginiX20AT4222-Entrada RTDWillian ErthalÎncă nu există evaluări

- X20 (C) BM11: 1 General InformationDocument3 paginiX20 (C) BM11: 1 General Informationroni kurniawanÎncă nu există evaluări

- X20if1072-Eng V2.34Document4 paginiX20if1072-Eng V2.34ВладимирÎncă nu există evaluări

- 1 General Information: Model Number Short Description Analog InputsDocument32 pagini1 General Information: Model Number Short Description Analog InputsOscar Enríquez MorenoÎncă nu există evaluări

- X20do9322 EngDocument8 paginiX20do9322 Engbarbisan.fabioÎncă nu există evaluări

- X20 (C) AT6402: 1 General InformationDocument12 paginiX20 (C) AT6402: 1 General InformationOscar Enríquez MorenoÎncă nu există evaluări

- Catalog SurseDocument16 paginiCatalog Sursedaniiely4643Încă nu există evaluări

- CATALOGUEDocument27 paginiCATALOGUEparahu ariefÎncă nu există evaluări

- X20ao4622 EngDocument8 paginiX20ao4622 Engbarbisan.fabioÎncă nu există evaluări

- Atem 81.000.6120.0Document2 paginiAtem 81.000.6120.0WILLYÎncă nu există evaluări

- Wieland - 81.000.6540.0 - Hoja de Datos Tecnicos - Fragmento de Catalogo PDFDocument2 paginiWieland - 81.000.6540.0 - Hoja de Datos Tecnicos - Fragmento de Catalogo PDFJason Galvis JimenezÎncă nu există evaluări

- Information:: Model Number Short Description Image Bus TransmitterDocument7 paginiInformation:: Model Number Short Description Image Bus TransmitterOSAMAÎncă nu există evaluări

- If1020 (RS232)Document3 paginiIf1020 (RS232)Mikhail PetuninÎncă nu există evaluări

- X20bc8084-Eng V2.42Document9 paginiX20bc8084-Eng V2.42tori widayatÎncă nu există evaluări

- X20 (C) PS9400: 1 General InformationDocument7 paginiX20 (C) PS9400: 1 General InformationAgus SuwardonoÎncă nu există evaluări

- Hitachi 2000kVA DatasheetDocument1 paginăHitachi 2000kVA DatasheetYusuke OkudairaÎncă nu există evaluări

- 1 General Information: Nettime Timestamp of The Position and Trigger TimeDocument51 pagini1 General Information: Nettime Timestamp of The Position and Trigger TimeСтив АааÎncă nu există evaluări

- 8V1320.001-2 en V1.8Document14 pagini8V1320.001-2 en V1.8JlavieraÎncă nu există evaluări

- 3 Training Manual of 81-PBL024-PW2印刷版 (兼容模式)Document30 pagini3 Training Manual of 81-PBL024-PW2印刷版 (兼容模式)WILIAM RODRIGUEZÎncă nu există evaluări

- 8B0C0160HW00.001-1: 1 General InformationDocument6 pagini8B0C0160HW00.001-1: 1 General InformationИльнур ТагировÎncă nu există evaluări

- FC250H1 Power Module: DC-DC Converter 18 VDC To 36 VDC Input, 24 VDC Output 250 WDocument20 paginiFC250H1 Power Module: DC-DC Converter 18 VDC To 36 VDC Input, 24 VDC Output 250 WNicolás HeiliÎncă nu există evaluări

- Tosc S A0002811465 1Document8 paginiTosc S A0002811465 1Raul Damian MamaniÎncă nu există evaluări

- Modular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Document2 paginiModular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Charmer JiaÎncă nu există evaluări

- InteliCharger 120 12 24 DatasheetDocument2 paginiInteliCharger 120 12 24 Datasheetjean sanchezÎncă nu există evaluări

- 2CDC114054D0201 - Data Sheet Power Supply CP-D 24-0.42Document9 pagini2CDC114054D0201 - Data Sheet Power Supply CP-D 24-0.42adelone23Încă nu există evaluări

- 520PSD01 DS enDocument3 pagini520PSD01 DS enDJ ThangÎncă nu există evaluări

- Datasheet PMC-24V050W1AADocument12 paginiDatasheet PMC-24V050W1AARulo Hdez LazoÎncă nu există evaluări

- X20TB06/X20TB12: 1 General InformationDocument3 paginiX20TB06/X20TB12: 1 General Informationroni kurniawanÎncă nu există evaluări

- 8V1640.001-2 en V1.8Document14 pagini8V1640.001-2 en V1.8JlavieraÎncă nu există evaluări

- Epsitron - Capacitive Buffer Modules: DescriptionDocument1 paginăEpsitron - Capacitive Buffer Modules: DescriptionHector bonillaÎncă nu există evaluări

- 1 General Information: Model Number Short Description Servo DrivesDocument14 pagini1 General Information: Model Number Short Description Servo DrivesMr.K ch100% (1)

- Single-Phase Power Supply Unit, Primary Switched For Universal Use QUINT-PS-100-240AC/48DC/20Document10 paginiSingle-Phase Power Supply Unit, Primary Switched For Universal Use QUINT-PS-100-240AC/48DC/20toseruÎncă nu există evaluări

- TC7SH04F, TC7SH04FU: InverterDocument6 paginiTC7SH04F, TC7SH04FU: InverterMario Rosas VargasÎncă nu există evaluări

- Eaton 269471 Emt6 KDB en GBDocument4 paginiEaton 269471 Emt6 KDB en GBAriel TorresÎncă nu există evaluări

- 74HCU04D Datasheet en 20201111-981095Document9 pagini74HCU04D Datasheet en 20201111-981095Faisal OsamaÎncă nu există evaluări

- Isolated 48VDC/24VDC ConverterDocument3 paginiIsolated 48VDC/24VDC ConverterOPENWIFI MIKROTIKÎncă nu există evaluări

- 0PS1020.0 Powersupply, 1phase, 24VDC, 2A - EnG - V2.11Document14 pagini0PS1020.0 Powersupply, 1phase, 24VDC, 2A - EnG - V2.11Edson VargasÎncă nu există evaluări

- 74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicDocument8 pagini74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicAssistec TecÎncă nu există evaluări

- Product Di810Document4 paginiProduct Di810rogeliobarÎncă nu există evaluări

- 4 Rpi-M20a Data Sheet v4Document3 pagini4 Rpi-M20a Data Sheet v4KARTIKÎncă nu există evaluări

- 74HC4066D Datasheet en 20201124-1128579Document13 pagini74HC4066D Datasheet en 20201124-1128579cesar gaiborÎncă nu există evaluări

- Delphi Series H48SC3R325, 85W Half Brick Family DC/DC Power Modules: 48V In, 3.3V/25A OutDocument13 paginiDelphi Series H48SC3R325, 85W Half Brick Family DC/DC Power Modules: 48V In, 3.3V/25A OutRODRIGO ALVES DA COSTAÎncă nu există evaluări

- LM2480NADocument5 paginiLM2480NAFranklin JimenezÎncă nu există evaluări

- IT Chem F5 Mid-Year Examination (E)Document10 paginiIT Chem F5 Mid-Year Examination (E)Norzawati NoordinÎncă nu există evaluări

- Transformers and Rectifiers IndiaDocument26 paginiTransformers and Rectifiers IndiaPravesh RaoÎncă nu există evaluări

- Aula Balancim DifusaoDocument29 paginiAula Balancim DifusaoGabrielAntoniazziÎncă nu există evaluări

- Slope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseDocument34 paginiSlope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseRIzwanaÎncă nu există evaluări

- The Hazards of Pork ScratchingsDocument1 paginăThe Hazards of Pork ScratchingsSteve ForsterÎncă nu există evaluări

- DatasheetDocument13 paginiDatasheetkishore kumarÎncă nu există evaluări

- Southwark Schools For The FutureDocument59 paginiSouthwark Schools For The FuturewilliamsaminÎncă nu există evaluări

- General Catalogue: Compressors & Condensing UnitsDocument88 paginiGeneral Catalogue: Compressors & Condensing UnitsJader Leon100% (1)

- Unit 1 Solar EnergyDocument176 paginiUnit 1 Solar EnergyAkhil Dayalu100% (1)

- York Chiller Specifications (14654)Document11 paginiYork Chiller Specifications (14654)Игорь ДергачевÎncă nu există evaluări

- Design HydSysDocument1 paginăDesign HydSysManikandan RamalingamÎncă nu există evaluări

- Catalog Solar-PV String Inverters Hopewind V4.3.1Document14 paginiCatalog Solar-PV String Inverters Hopewind V4.3.1Atiq SaberÎncă nu există evaluări

- Снимок экрана 2023-03-01 в 09.16.43Document48 paginiСнимок экрана 2023-03-01 в 09.16.43Maksim ZolotarjovÎncă nu există evaluări

- NACHI Full Catalog Small RevDocument468 paginiNACHI Full Catalog Small RevSombat MahamadÎncă nu există evaluări

- Manual Grindex - Bravo400.Document26 paginiManual Grindex - Bravo400.Roque LlamoccaÎncă nu există evaluări

- Solar Panel Thesis PhilippinesDocument6 paginiSolar Panel Thesis Philippinesmelanierussellvirginiabeach100% (2)

- MegaFlex - 480V UL UPS Brochure - 041720Document9 paginiMegaFlex - 480V UL UPS Brochure - 041720GeorgeÎncă nu există evaluări

- 1.diesel Engine AssemblyDocument22 pagini1.diesel Engine Assemblypepenapao1217Încă nu există evaluări

- Fluid MechanicsDocument35 paginiFluid MechanicsJohn Ely Collado Bantog0% (1)

- Aktuator Diapraghm Fisher 30i-70iDocument12 paginiAktuator Diapraghm Fisher 30i-70iUntoro Adi NugrohoÎncă nu există evaluări

- Refrig - Samsung RF23J9011SR - v2 - User ManualDocument108 paginiRefrig - Samsung RF23J9011SR - v2 - User ManualadamsusaÎncă nu există evaluări

- Investigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantDocument5 paginiInvestigation Into The Probable Cause of Failure of Economizer Tube of A Thermal Power PlantKR PAÎncă nu există evaluări

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Document7 paginiAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluÎncă nu există evaluări

- EPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFDocument50 paginiEPSRC Thermal Management Sheffield Drying Tech Feb 2010 PDFVampireSuicideÎncă nu există evaluări

- Physics Thermal Chemical Current MCQDocument5 paginiPhysics Thermal Chemical Current MCQAyan GhoshÎncă nu există evaluări

- CALEFACCION Combitronic - 22297Document20 paginiCALEFACCION Combitronic - 22297AlbertoÎncă nu există evaluări