Documente Academic

Documente Profesional

Documente Cultură

Daily Sanitation Inspection Checklist

Încărcat de

James Christian Hermetanio LopezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Daily Sanitation Inspection Checklist

Încărcat de

James Christian Hermetanio LopezDrepturi de autor:

Formate disponibile

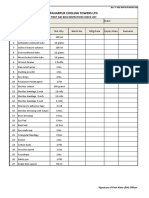

DAILY SANITATION INSPECTION CHECKLIST

Date: ________________

District/Pltn:________________ 30 mins. before start follow-up inspection

PPlant No.: ________________ Inspection Time ->>>

A. GROUNDS AND SURROUNDINGS Y N REMARKS Y N REMARKS

1 No stray animals in the surroundings.

No tall grass and weeds 1m distance from the immediate vicinity of packing

2

plant.

3 No excessive dust on paved roads, yards and parking lots.

4 Drainage canal clear of debris/wastes and provided with gratings.

5 No stagnant waters that attract pests.

6 Garbage containers have covers, segregated, and disposed regularly.

7 Equipment stored properly in designated areas.

8 Perimeter lights functional.

9 Clean and functional of footbath (entrance and exit).

10 Disinfection of 200ppm inside & outside the pp premises, recorded.

Rating/Section:

B. HANDWASH & FOOTBATH FACILITIES AT ENTRANCE AREA

1 Area is clean.

2 Supply of water is adequate.

3 Supply of liquid soap and paper towel or hand dryer.

4 Handwash/Footbath reminders are strategically posted.

5 Clean footbath with disinfectant solution.

6 Garbage containers have covers, segregated, and disposed regularly.

Rating/Section:

C. FRUIT PATIO/FRUIT RECEIVING AREA

1 Clean and in good condition harvest trucks.

2 Clean harvesting crates and bruise protection materials, replaced regularly.

3 No excess grease or oil along cablelines and equipment.

4 Drawers/cabinets for documents/records in the fruit receiving section properly

arranged & no items that may cause potential risk to food safety.

5 Garbage containers have covers, segregated, and disposed regularly.

6 No rejected bananas and stalk left overnight.

7 No plastics and banana debris scattered on floor.

8 No dirt & mud on unloading area & under washtanks.

9 Drainage canal clear of debris/wastes and provided with gratings.

10 Fluorescent lights are protected/covered, cleaned and functional.

11 Traylines and soaking tanks clean and not corroded.

12 Clean and calibrated weighing scale.

Rating/Section:

D. PROCESSING AREA

1 Debris are removed underneath washtanks.

2 Stains from washtanks are removed regularly.

3 Sharp selector's knife, no broken knife. Container for spare knife is provided.

4 Traypans clean, sanitized and in good condition (no cracks/broken).

5 PE foams are in good condition, cleaned and sanitized.

6 Crown treatment eqpt clean and in good condition. No temporary fixing.

7 Conveyors, traylines clean, no latex stain and kept in good repair.

8 Weighing scales labeled, clean and calibration updated.

9 Propybag, stickers segregated per SKU in the line.

10 White background matting for propy bag checking.

11 No unused stickers, ID cards and other materials in the packing lines.

12 OPM containers free from stuff not used in the processing zone.

13 Loose items (crayons, ballpen, scissors) are tied.

14 Packers' table & trodat receptacle clean, free of dust and stains.

15 Ethylene scrubbers stored in clean and closed container.

16 No packaging materials placed directly on floor.

17 Processing area floor is clean,not slimy/muddy, no stagnant water or dusty.

18 Fluorescent lights are protected/covered, cleaned and functional.

19 No cobwebs/ insects thriving in the processing zone.

20 Garbage containers have covers, segregated, and disposed regularly.

Rating/Section:

BN-FM-PP01; Rev. No.:5; Eff. Date: Aug 21, 2017 Page 1 of 3

DAILY SANITATION INSPECTION CHECKLIST

Date: ________________

District/Pltn:________________ 30 mins. before start follow-up inspection

PPlant No.: ________________ Inspection Time ->>>

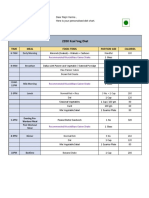

E. KD/OPM BODEGA

1 Area is clean and not dusty.

2 Bodega is not over-crowded. First-In-First-Out basis is followed.

3 Materials are stored on pallets.

4 Packaging materials are protected from dust and other elements.

5 Materials are stored 0.5-1.0 meter against walls.

6 Propybag, stickers segregated per SKU.

7 Reject materials are labeled, segregated and recorded.

8 Rat traps are properly installed/monitored. Trapped rodents are promptly

disposed.

9 No cracks or holes on walls that will serve as entry points for pests.

10 No birds or pests found inside the bodega and no materials contaminated.

11 Fluorescent lights are protected/covered, cleaned and functional.

12 No cobwebs/ insects thriving inside KD bodega

13 Fire Protection facilities available and inspected.

14 Bodega floor plan complied.

15 Drawers/cabinets are stored with items only for PP use, properly arranged and

no items that may cause potential risk to food safety

16 Box forming machine clean and in good condition.

17 Garbage containers have covers, segregated, and disposed regularly.

Rating/Section:

F. PALLETIZING/LOADING AREA

1 Clean and organized area, not dusty.

2 Pallets used are cleaned, no contaminated pallets inside PP.

3 Pallets are protected against sunlight, rain & other source of contamination.

4 Clean van/shuttler/stationary reefer van.

5 Enclosed with net, no gaps and torn portions that serve as entry point of

pests/insects.

6 Fluorescent lights are protected/covered, cleaned and functional.

7 No cobwebs. No pest and insect.

8 Palletizing materials labeled, functional, contained and no loose metals within

its premises.

9

Drawers/cabinets for documents and records in the Palletizing/Loading section

are properly arranged and no items that may cause potential risk to food safety

10 Use of BANEX STICKERS. Enough inventory (1 period) is maintained

11 Use of PALLET TAGS. Enough inventory (1 period) is maintained

12 Garbage containers have covers, segregated, and disposed regularly.

Rating/Section:

G. EMPLOYEE HYGIENE AND PRACTICES

1 No smoking inside the PP premises.

2 Clean footwear/close shoes and working attire, no pocket shirt, no

buttons.

3 No wearing of jewelry inside the PP.

4 Hair restraint is worn properly.

5 No associates w/infected wounds or lesions or w/contagious disease.

6 Hands are washed before going to the processing area and after using

the toilet

7 All personnel pass through body frisking, PPE inspection and personal hygiene

before entering the processing zone after signifying their attendance in a

logbook placed at the PP entrance.

8 No personal effects/lunch boxes stored in production areas.

9 No evidence of eating/chewing in working area.

10 No associates with unsanitary habit such as touching, nose, mouth, or

scratching head and not washing hands before touching the product.

11 No spitting on floor of the production area.

12 No lying or sitting on top of product or packaging materials.

13 Checking on the proper wearing of hair restraint is done hourly.

Rating/Section:

H. WTS

1 Clean water at washtank

2 Area is clean and organized.

3 Operator wearing appropriate PPEs.

4 Chlorine monitoring kit available. Color chart not faded

5 WTS chemicals are labeled and MSDS readily available. Measuring

equipment labeled (test tube, graduated cylinder, weighing scale,

collector cup) and calibrated.

BN-FM-PP01; Rev. No.:5; Eff. Date: Aug 21, 2017 Page 2 of 3

DAILY SANITATION INSPECTION CHECKLIST

Date: ________________

District/Pltn:________________ 30 mins. before start follow-up inspection

PPlant No.: ________________ Inspection Time ->>>

6 Processing chemicals covered, secured, not in wet area, and stored away from

pesticides and fertilizers.

7 Ortho-tolidine waste container labeled and disposed properly.

8 Chlorine level is monitored and recorded hourly.

Rating/Section:

I. MESS HALL

1 Clean and organized area.

2 Handwash station have adequate supply of water and in good repair.

3 Fluorescent lights are protected/covered, cleaned and functional.

4 Lockers are clean, used only for lunch box and personal effects.

5 Fluorescent lights are protected/covered, cleaned and functional.

6 Garbage containers have covers, segregated, and disposed regularly.

Rating/Section:

J. TOILET FACILITIES

1 Toilets clean, dry and no foul odor.

2 Toilet facility in good repair (door, window, faucet, bowl)

3 Supply of water is adequate.

4 Provided with toilet paper.

Handwash station posted with 'proper washing of hands reminders' and

5

provided with liquid soap.

6 Fluorescent lights are protected/covered, cleaned and functional.

7 Garbage containers have covers, segregated, and disposed regularly.

Rating/Section:

K. PACKING PLANT OFFICE

1 Clean and organized area.

2 No cobwebs, pest and insects.

3 Garbage containers have covers, segregated, and disposed regularly.

4 Deployed with First Aider; first aid kit available.

Rating/Section:

L. POSTHARVEST

1 PH Processing Line Crew and Chemical Mixer wear appropriate PPEs.

2 Clean, organized with appropriate signages storage and packing line are

segregated.

3 Post Harvest chemicals and materials labeled w/ PH and calibrated. MSDS

readily available.

4 Post Harvest chemicals covered, secured, stored in a secondary containment

and away from product/packaging materials and separated from other

chemicals.

5 Empty chemical containers are triple rinsed before storing. Returned to Lead

Warehouse for proper disposal. Recorded.

6 Post harvest treatment application Report, recorded.

7 Spray equipment clean, functional and labeled with PH

8

Provision of chemical containment for spill and drippings at spray line.

Rating/Section:

OVER-ALL RATING ->

Inspected by: __________________________ Acknowledge by: __________________________

QC Inspector PP Coach

BN-FM-PP01; Rev. No.:5; Eff. Date: Aug 21, 2017 Page 3 of 3

S-ar putea să vă placă și

- First Aid Box Fill ListDocument34 paginiFirst Aid Box Fill Listzam110Încă nu există evaluări

- SOP - Cleaning-Disinfecting After Incidents Involving Body FluidsDocument4 paginiSOP - Cleaning-Disinfecting After Incidents Involving Body FluidsJohn Kah Heng OngÎncă nu există evaluări

- RSHS Food Safety ChecklistDocument2 paginiRSHS Food Safety ChecklistMohammed YahyaÎncă nu există evaluări

- Sanitation SOP PDFDocument2 paginiSanitation SOP PDFbetterthandrugsÎncă nu există evaluări

- Food and Safety & Sanitary Inspection ChecklistDocument6 paginiFood and Safety & Sanitary Inspection ChecklistChristian TorrijosÎncă nu există evaluări

- House Keeping Check ListDocument11 paginiHouse Keeping Check ListSushil RautÎncă nu există evaluări

- Daily Pre Use Inspection Checklist For John Deere Backhoe LoaderDocument2 paginiDaily Pre Use Inspection Checklist For John Deere Backhoe Loaderqhse.bpkhazzan.int.tec100% (1)

- Audit Catering ChecklistDocument3 paginiAudit Catering ChecklistMuataz Alkhateeb100% (3)

- FMS - EOC ChecklistDocument6 paginiFMS - EOC Checklisthany winihastutiÎncă nu există evaluări

- Control MeasuresDocument4 paginiControl MeasuresCharlie Dela RosaÎncă nu există evaluări

- Air Compressor Inspection Checklist Global EHS 029Document1 paginăAir Compressor Inspection Checklist Global EHS 029Safety Mohini100% (1)

- IMS-08 First Aid Box ChecklistDocument1 paginăIMS-08 First Aid Box ChecklistRísês ÃfrözÎncă nu există evaluări

- Hygiene Inspection ChecklistDocument3 paginiHygiene Inspection ChecklistRonachai Fuangfoong100% (5)

- Housekeeping Checklist for Offices and Production AreasDocument1 paginăHousekeeping Checklist for Offices and Production AreasAndi YanuarÎncă nu există evaluări

- Safety Committee Meeting Minutes TemplateDocument3 paginiSafety Committee Meeting Minutes TemplateKashémÎncă nu există evaluări

- Housekeeping Checklist 015 To 017Document5 paginiHousekeeping Checklist 015 To 017ankit sharmaÎncă nu există evaluări

- Bodily Fluids Spillage: Standard Operating ProcedureDocument5 paginiBodily Fluids Spillage: Standard Operating ProcedureLinda Setya Wati100% (1)

- SOP For Cleaning & SanitationDocument4 paginiSOP For Cleaning & Sanitationgmby100% (2)

- Site Safety OrientationDocument19 paginiSite Safety OrientationKrischaEverÎncă nu există evaluări

- Daily Health Inspection ChecklistDocument3 paginiDaily Health Inspection ChecklistThandabantu MagengeleleÎncă nu există evaluări

- Induction Training - 2021Document95 paginiInduction Training - 2021Fajar PrasetyoÎncă nu există evaluări

- Daily Equipment Maintenance Checklist: Items Evaluators CommentDocument1 paginăDaily Equipment Maintenance Checklist: Items Evaluators CommentCarwill TesdaÎncă nu există evaluări

- Food Act 2006 Audit ReportDocument3 paginiFood Act 2006 Audit ReportHOtaru LoveyouÎncă nu există evaluări

- Ehs - Chemical Storage Area Inspection Checklist: Tower: Floor: Wing: Area/Location: Date: Audit TeamDocument12 paginiEhs - Chemical Storage Area Inspection Checklist: Tower: Floor: Wing: Area/Location: Date: Audit TeamLakshmi BalaÎncă nu există evaluări

- Audit Sheet Tracks 5S ImplementationDocument5 paginiAudit Sheet Tracks 5S ImplementationMaintenance BawalÎncă nu există evaluări

- SOP-PRP-E - Waste Mgt.Document2 paginiSOP-PRP-E - Waste Mgt.SEED SEEDÎncă nu există evaluări

- SPC Microtech Lab Waste Disposal GuideDocument3 paginiSPC Microtech Lab Waste Disposal GuideBernardoÎncă nu există evaluări

- Allergen Cleaning Validation GuideDocument4 paginiAllergen Cleaning Validation Guidengoc98Încă nu există evaluări

- Portable Toilet Inspection Checklist TemplateDocument1 paginăPortable Toilet Inspection Checklist TemplateJulia Wibawa HaryantoÎncă nu există evaluări

- Worker Camp Inspection ChecklistDocument2 paginiWorker Camp Inspection ChecklistSatya NaiduÎncă nu există evaluări

- IMS-ADM-02 Housekeeping Cleaning ChecklistDocument2 paginiIMS-ADM-02 Housekeeping Cleaning ChecklistKarthi ThiyagarajanÎncă nu există evaluări

- Facility Hygienic Design ChecklistDocument6 paginiFacility Hygienic Design ChecklistEyad Al-Jeezani100% (1)

- Cleaning Check List For Discharge or Empty RoomDocument4 paginiCleaning Check List For Discharge or Empty RoomsaadÎncă nu există evaluări

- Hazardous Substances & Dangerous Goods WHSPRO-007 CMDocument7 paginiHazardous Substances & Dangerous Goods WHSPRO-007 CMJason McIntoshÎncă nu există evaluări

- 5S Audit Checklist FactoryDocument2 pagini5S Audit Checklist FactoryGaneshÎncă nu există evaluări

- Clean Tank WaterDocument1 paginăClean Tank Waterblahblah100% (1)

- Weekly Food Safety AuditDocument4 paginiWeekly Food Safety AuditNina YoungÎncă nu există evaluări

- GMP Policy ManualDocument3 paginiGMP Policy ManualAgnes_Agnes_AgnesÎncă nu există evaluări

- Daily Vehicle Inspection Checklist.1Document2 paginiDaily Vehicle Inspection Checklist.1Twin BullsÎncă nu există evaluări

- Daily Audit ReportDocument3 paginiDaily Audit ReportJames MathaiÎncă nu există evaluări

- Food Safety ChecklistDocument4 paginiFood Safety Checklistjalali007Încă nu există evaluări

- SQ Mark & 100ppm ChecklistDocument14 paginiSQ Mark & 100ppm Checklistkarpags100% (2)

- Audit Checklist 2012 Revised 090412 CJBDocument13 paginiAudit Checklist 2012 Revised 090412 CJBJason TiongcoÎncă nu există evaluări

- Thawing FoodDocument2 paginiThawing FoodAddress HotelÎncă nu există evaluări

- Section 6: Monitoring Records: Good 2 Eat Catering Food Safety ProgrammeDocument33 paginiSection 6: Monitoring Records: Good 2 Eat Catering Food Safety Programmeruthushan namasivayam100% (1)

- Eye Wash Checklist - WeeklyDocument1 paginăEye Wash Checklist - WeeklyFarooq MohammadÎncă nu există evaluări

- Free Food Safety VideosDocument22 paginiFree Food Safety VideosnelsonÎncă nu există evaluări

- Supervisor Daily Toilet Cleaning ChecklistDocument1 paginăSupervisor Daily Toilet Cleaning ChecklistFULL,HALF AND QUARTERÎncă nu există evaluări

- Cleaning Schedule Charts - SFLBDocument7 paginiCleaning Schedule Charts - SFLBiorharris100% (1)

- Inspection Checklist: A. Tools and Equipment YES NODocument1 paginăInspection Checklist: A. Tools and Equipment YES NOHENJEL PERALESÎncă nu există evaluări

- Quality SOP Manual in Catering and RestaurantsDocument88 paginiQuality SOP Manual in Catering and RestaurantsMohamed100% (4)

- 1S2S3S - Check SheetDocument1 pagină1S2S3S - Check SheetManoj KaushikÎncă nu există evaluări

- Daily Inspection Checklist (Revised 02)Document14 paginiDaily Inspection Checklist (Revised 02)Dlraje DlrajeÎncă nu există evaluări

- F-S-21.04-030-02 (Visitor Screening Quistionnaire)Document1 paginăF-S-21.04-030-02 (Visitor Screening Quistionnaire)Ratna SariÎncă nu există evaluări

- Food Facility Self Inspection ChecklistDocument2 paginiFood Facility Self Inspection Checklistmelisizwe2016Încă nu există evaluări

- Facilities Internal Audit ChecklistDocument2 paginiFacilities Internal Audit Checklistslynchcpna100% (2)

- Factory Hygiene ProcedureDocument5 paginiFactory Hygiene ProcedureGsr MurthyÎncă nu există evaluări

- Example-Self Safety Inspection Checklist - QADocument3 paginiExample-Self Safety Inspection Checklist - QAHehok Hehe100% (1)

- Workplace Safety Audit ChecklistDocument4 paginiWorkplace Safety Audit Checklistloveanbu24Încă nu există evaluări

- 02.CGV Safety Day Checklist MonthlyDocument3 pagini02.CGV Safety Day Checklist MonthlyYudhi PratamaÎncă nu există evaluări

- When He Comes, Close Your Eyes PDFDocument613 paginiWhen He Comes, Close Your Eyes PDFRiza Alvarez93% (14)

- Wicking Bed Gardening For Drought GardeningDocument5 paginiWicking Bed Gardening For Drought GardeningU8x58Încă nu există evaluări

- How To Grow Ground Cherries ( Physalis SPP.) : Frost CalendarDocument2 paginiHow To Grow Ground Cherries ( Physalis SPP.) : Frost CalendarKCMG FoundationÎncă nu există evaluări

- Trickster ReadingsDocument47 paginiTrickster ReadingsNoemi CaladoÎncă nu există evaluări

- Outlook for World Vegoils in 2016Document11 paginiOutlook for World Vegoils in 2016Usman MahmoodÎncă nu există evaluări

- Drip Irrigation BenefitsDocument8 paginiDrip Irrigation BenefitsJignesh ChaudharyÎncă nu există evaluări

- New Coke Market BlunderDocument8 paginiNew Coke Market BlunderAnkit KumarÎncă nu există evaluări

- PRAN Enters Milk Market with UHT InnovationDocument13 paginiPRAN Enters Milk Market with UHT InnovationAsif FaiyedÎncă nu există evaluări

- Simple Present Tense ExamplesDocument2 paginiSimple Present Tense Examplesyrynuka yrysÎncă nu există evaluări

- Better Late Than NeverDocument2 paginiBetter Late Than NeverAshley MorganÎncă nu există evaluări

- The Complete Crafter - GM BinderDocument26 paginiThe Complete Crafter - GM BinderPhạm Quang0% (1)

- Salted Caramel Chocolate Vegan CupcakesDocument5 paginiSalted Caramel Chocolate Vegan CupcakesShieldon Vic Senajon PinoonÎncă nu există evaluări

- Department of Animal Husbandry and Dairying Institute of Agricultural Sciences Banaras Hindu University Varanasi - 221005Document2 paginiDepartment of Animal Husbandry and Dairying Institute of Agricultural Sciences Banaras Hindu University Varanasi - 221005Yamini GowdaÎncă nu există evaluări

- Final Feasibility LonganisaDocument12 paginiFinal Feasibility LonganisaJerickson MauricioÎncă nu există evaluări

- California Beef Recall Updated List With AddressesDocument210 paginiCalifornia Beef Recall Updated List With Addressesapi-249687736Încă nu există evaluări

- Northwestern Michigan Trav-O-GuideDocument27 paginiNorthwestern Michigan Trav-O-GuideHarbor Springs Area Historical SocietyÎncă nu există evaluări

- Royalton Resort MapDocument1 paginăRoyalton Resort MapJean-Michel LeclercÎncă nu există evaluări

- Riga Travel Guide (2007) by RyanairDocument10 paginiRiga Travel Guide (2007) by RyanairisrgffÎncă nu există evaluări

- 1 - 3 September 2016: Hall 101-102 Bangkok International Trade and Exhibition Center (BITEC)Document60 pagini1 - 3 September 2016: Hall 101-102 Bangkok International Trade and Exhibition Center (BITEC)TBS Máy Phát ĐiệnÎncă nu există evaluări

- List Phrasal VerbsDocument16 paginiList Phrasal Verbsjsuarezp705311Încă nu există evaluări

- The Luncheon Is A Satirical Story That The Writer Uses Humor and Irony To Depict TheDocument5 paginiThe Luncheon Is A Satirical Story That The Writer Uses Humor and Irony To Depict TheDard TongÎncă nu există evaluări

- French Gastronomy Seminar Focuses on History and DishesDocument15 paginiFrench Gastronomy Seminar Focuses on History and DishesElena GonzalezÎncă nu există evaluări

- Complete The Chart: Present Perfect Infinitive Past Simple Past ParticipleDocument10 paginiComplete The Chart: Present Perfect Infinitive Past Simple Past ParticipleYamilaPMÎncă nu există evaluări

- Rajni Verma's Diet PlanDocument2 paginiRajni Verma's Diet PlanPiyushÎncă nu există evaluări

- Activity - BHEL: Swami ShreejiDocument2 paginiActivity - BHEL: Swami ShreejiANAnD PatelÎncă nu există evaluări

- I. General Information: Family Survery FormDocument9 paginiI. General Information: Family Survery FormAnonymous h2EnKyDbÎncă nu există evaluări

- Characterisation of Cassava Varieties For Appropriate UtilisationDocument87 paginiCharacterisation of Cassava Varieties For Appropriate UtilisationLiyaliLibonda100% (1)

- SantaDocument1 paginăSantaRajesh VermaÎncă nu există evaluări

- Raise Organic ChickensDocument47 paginiRaise Organic Chickensjames lacanilao100% (3)

- 3 Column Notes Ecology Vocab AnswersDocument2 pagini3 Column Notes Ecology Vocab AnswersmceldowneaÎncă nu există evaluări