Documente Academic

Documente Profesional

Documente Cultură

Ch.8 - Exhaust Flow Elements and Problems

Încărcat de

John Joseph AmoresDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ch.8 - Exhaust Flow Elements and Problems

Încărcat de

John Joseph AmoresDrepturi de autor:

Formate disponibile

8-1. A six-cylinder SI engine, with a compression ratio of rc = 8.5, Δm = 0.000697 kg - 0.000265 kg = 0.

= 0.000697 kg - 0.000265 kg = 0.000432 kg mass flow rate of exhaust through turbine = mass flow rate of air

operates on an air-standard Otto cycle at WOT. Cylinder %Δ = (0.000432 kg / 0.000697 kg) 100 = 62.0% + mass flow rate of fuel

temperature and pressure when the exhaust valve opens are 1000 (c) Exit velocity at the start of blowdown, assuming choked flow mex = ma + mf = ma (1+FA)

K and 520 kPa. Exhaust pressure is 100 kPa and air temperature in occurs. [m/sec] mex = 0.0361 kg/sec (1+0.068) = 0.0386 kg/sec

the intake manifold is 35°C. Calculate: Vd=(𝜋/4)B2S = 600cm3 =(𝜋/4)B2(0.85B) (c) Inlet air temperature at turbocharger exit. [0C]

(a) Exhaust temperature during exhaust stroke. [0C] B=9.65cm Eq. 5-15 Isentropic Process

Tex=TEVO(Pex/PEVO)(k-1)/k = S=0.85B =0.85(9.65cm) =8.20cm T2 = T1 (P2/P1)k-1/k = (300 K)(120/96)1.4-1/1.4 = 320

Tex=1000K(100kPa/520kPa)(1.35-1)/1.35 = 652K = 379 oC Crankshaft offset K

(b) Exhaust residual. [%] a= S/2 = (8.2cm)/2 =4.1cm Eq. 5-13 Isentropic Power

xr = (1/rc)(T4/Tex)(Pex/P4) = R= r/a = (16.4cm)/(4.10cm) = 4.0 Wcomp = ma(hout - hin) = maCp(Tout-Tin)

(1/8.5)(1000K/652K)(100kPa/520kPa) = 0.035 = 3.5% Ɵ=180o-56o = 124o = (0.0361 kg/sec)(1.005

(c) Cylinder temperature at the start of compression. [0C] Vevo/Vc = 1+ ½(rc - 1) [R+1 - cos Ɵ - kJ/kg-K)(320 K – 300 K)

(T)1 = xrTex + (1-xr)Ta = (0.035)(652K) + (1- √𝑅2 − 𝑠𝑖𝑛2 Ɵ] Wcomp = 0.726 kW

0.035)(308K) = 302K = 29 oC = 1+ ½(10.1- 1) [4+1 - cos Wactual comp = Wcomp / ni = 0.726 kW / 0.78 = 0.931

(d) Peak temperature of cycle. [0C] 124 - √42 − 𝑠𝑖𝑛2 124] kW

T4 = 1000K = T3(1/rc)k-1 = T3(1/8.5)0.035 => T3 = = 8.490 Wactual comp = maCp(Tout-Tin)

2115K = 1842 oC Tevo = T3 (V3/Vevo)k-1 = Tc (Vc / Vevo)k-1 =2700K = (0.0361 kg/sec)(1.005

(e) Cylinder temperature when the intake valve opens. [0C] (1/8.490)1.35-1 kJ/kg-K)(Tout – 300 K)

TEVO = Tex = 379 °C Tevo = 1277K Tout = 326 K = 53 oC

-------------------------------------------------------------------------------

8-2. A four-cylinder SI engine, with a

v = c = √𝑘𝑅𝑇 =

(d) Exhaust temperature at turbocharger exit. [0C]

J 𝑘𝑔

compression ratio of rc = 9, operates on an air-standard Otto cycle √1.35 ∗ 287 kgK ∗ 1277𝐾 ∗ (1 𝑁𝑠𝑒𝑐 2) Tout = Tin (Pout/Pin)k-1/k = (770 K)(98/119)1.35-1/1.35 =

at part throttle. Conditions in the cylinders when the exhaust valve 732 K

opens are 70 psia and 2760°F. Exhaust pressure is 14.6 psia and v = 703 m/sec Wturb = mex(hin – hout) = mexCp(Tin-Tout) = (0.0386

conditions in the intake manifold are 8.8 psia and 135°F. ------------------------------------------------------------------------------- kg/sec)(1.108 kJ/kg-K)(770 K – 732 K)

Calculate: 8-7. Exhaust manifold pressure of the engine in Wturb = 1.625 kW

(a) Exhaust temperature during exhaust stroke. [OF] Problem 8-6 is 98 kPa. In the manifold, the high kinetic energy of Wactual turb = Wturbnt = (1.625 kW)(0.80) = 1.30 kW

Tex=TEVO(Pex/PEVO)(k-1)/k = the exhaust flow during blowdown is quickly dissipated and Wactual turb = mexCp(Tin-Tout)

Tex=3220R(100psi/520psi)(1.35-1)/1.35 = 2145R = 1685 oF converted to an increase in specific enthalpy. Calculate: = (0.0386 kg/sec)(1.108

(b) Exhaust residual. [%] (a) Pseudo-steady-state exhaust temperature in the exhaust stroke. kJ/kg-K)(770 K – Tout)

xr = (1/rc)(T4/Tex)(Pex/P4) = [0C] Tout = 740 K = 467 oC

(1/9)(3220R/2145R)(14.6psi/70psi) = 0.035 = 3.5% Tex =T7 = 857 K

(c) Cylinder temperature and pressure at the start of compression (b) Theoretical peak temperature experienced in the exhaust flow.

stroke. [OF,psia] [0C]

Txr = Tex(Tintake/Tex)k/k-1 = When velocity is dissipated, KE is changed to

2145R(8.8psi/14.6psi)1.35-1/1.35 = 1881R enthalpy increase

(T)1 = xrTex + (1-xr)Ta = (0.035)(1881R) + (1- v2/2gc = ∆H = Cp∆T

0.035)(595K) = 640R ∆T = v2 / 2gcCp

P1 = Given = 8.8 psia = (703 m/s)2 / (2(1 kg-m / N-s)(1.108 kJ / kg-

------------------------------------------------------------------------------- K)(1000 J / 1 kJ))

8-3. A three-cylinder, two-stroke cycle SI automobile engine, = 223 K

operating at 3600 RPM, has peak cycle operating conditions of Tex = 857 K + 223 K

2900°C and 9000 kPa. Cylinder temperature when the exhaust port Tex = 1080 K = 807 oC

opens is 1275°C. Calculate: ------------------------------------------------------------------------------

(a) Cylinder pressure when the exhaust port opens. [kPa] 8-8. A four-cylinder, 2.5-liter, four-stroke cycle

P2 = P1(T2/T1)k/k-1 = SI engine with a compression ratio rc = 9.6 operates at 3200 RPM.

9000kPa(1548K/3173K)1.35/1.35-1 = 565 kPa Peak cycle temperature is 2227°C, peak cycle pressure is 6800

(b) Maximum flow velocity through the exhaust port. [m/sec] kPa, and exhaust pressure is 101 kPa. The engine operates at part

c = throttle with inlet air at 60°C and 75 kPa. An exhaust residual

remains in the cylinders at the end of the exhaust stroke. In

√1.35(287 𝐽/𝑘𝑔𝐾)(1548𝐾)(1 𝑘𝑔𝑚/𝑁𝑠2)= 774m/s addition, 12% EGR at exhaust temperature and pressure is diverted

------------------------------------------------------------------------------- back into the intake manifold, where it mixes with the inlet air

8-4. An SI Otto cycle engine has a compression before the intake valve. Calculate:

ratio of rc = 8.5, and a CI Diesel cycle engine has a compression

ratio of rc = 20.5. Both engine cycles have a maximum temperature (a) Exhaust temperature during exhaust stroke. [0C]

of 2400 K and maximum pressure of 9800 kPa. The diesel engine T7 = T3(P7/P3)k-1/k = 2500 K (101/6800)1.35-1/1.35 =

has a cutoff ratio β = 1.95. Calculate the cylinder temperature 839 K = 566 oC

when the exhaust valve opens on each engine. [0C] (b) Exhaust residual before EGR is added. [%]

Otto Cycle Engine T4 = T3(1/rc)k-1 = 2500 K (1/9.6)1.35-1 = 1133 K

P4 = P3 (1/rc)k-1 = 6800 kPa (1/9.6)1.35-1 = 321 kPa

Tevo = T4 = T3(1/rc)k-1 xr = (1/rc)(T4/Tex)(Pex/P4) =

T4 = 2400 K (1/8.5)1.35-1 (1/9.6)(1133/839)(101/321) = 0.044 = 4.4%

T4 = 1135 K = 862 oC (c) Cylinder temperature at the start of compression stroke. [0C]

Diesel Cycle Engine Total Exhaust in the cycle = xr + EGR = 4.4% +

12% = 16.4%

β = V3/ V2 Tex after intake valve opens and expansion cooling

V3 = βV2 Tex = 839 K (75/101)1.35-1/1.35 = 777 K

T4 = T3(V3/ V4)k-1 T1 = xrTex + (1-xr)Ta = (0.164)(777) + (1 -

T4 = T3(βV2/ V4)k-1, V4 = V1 and rc = V1/V2 0.164)(333 K) = 406 K = 133 oC

T4 = T3(β/ rc)k-1 (d) Theoretical design ratio of exhaust valve diameter to intake

T4 = 2400 K (1.95/20.5)1.35-1 valve diameter.

T4 = 1053 K = 780 oC Ti = (0.12)(777 K) + (1 – 0.12)(333 K) = 386 K

------------------------------------------------------------------------------ Eq.8-6, ἀ = (Ti/Tex)1/2 = (386/839)1/2 = 0.678

8-6. A 1.8-liter, three-cylinder SI engine ἀ = (Aex/Ai) = ((π/4)dex2)/( (π/4)di2) = dex/di =

produces brake power of 42 kW at 4500 RPM, with a compression (0.678)1/2 = 0.82

ratio rc = 10.1:1 and bore and stroke related by S = 0.85 B. ------------------------------------------------------------------------------

Maximum temperature in the cycle is 2700 K and maximum 8-9. A 5.6-liter V8 engine, with a compression

pressure is 8200 kPa. Exhaust pressure is 98 kPa. The exhaust ratio of Tc = 9.4:1, operates on an airstandard Otto cycle at 2800

valve effectively opens at 56° BDC. Calculate: RPM, with a volumetric efficiency ηv = 90% and a stoichiometric

(a) Time of exhaust blowdown. [sec] air-fuel ratio using gasoline. The exhaust gas flow undergoes a

Exhaust blowdown last for 56o of engine temperature drop of 44°C as it passes through the turbine of the

rotation time turbocharger. Calculate:

Time = (56o) / [(4500/60 rev/sec)(360o/rev)] = (a) Mass flow rate of exhaust gas. [kg/sec]

0.0021 sec Eq. 2-70. ma = ρaVdηVN/n = ((1.181 kg/m3)(0.0056

(b) Percent of exhaust gas that exits cylinder during blowdown. m3)(0.90)(2800/60 rev/sec))/2

[%] ma = 0.1389 kg/s

T4 = T3(1/rc)k-1 = (2700 K)(1/10.1)1.35-1 = 1202 K mass flow rate of exhaust gas = mass flow rate of air + mass flow

P4 = P3(1/rc)k-1 = (8200 kPa)(1/10.1)1.35-1 = 361 rate of fuel

kPa mex = ma + mf = ma (1+FA)

For 1 cylinder FA = 1 : 14.7 = 1/14.7

Vd = (1.8L/3) =0.6L =600cm3 = 0.0006 m3 FA = 0.068

Eq.2-12 mex = 0.1389 kg/sec (1+0.068) = 0.148 kg/sec

rc = V1 / V2 (b) Power available to drive the turbocharger compressor. [kW]

rc = (Vd + VC)/Vc

10.1 = (0.0006 m3 + Vc) / Vc Eq. 8-9, Wt = mCpΔT = (0.148kg/s) (1.108 kJ/kg-K) (44 K)

Vc = 0.0000659 m3 =7.22kW

Eq.2-11 ------------------------------------------------------------------------------

VBDC = V1 = Vd + Vc 8-10. A turbocharged, three-cylinder, four-

VBDC = 0.0006 m3 + 0.0000659 m3 = 0.0006659 stroke cycle, 1.5-liter, multipoint port-injected SI engine using

m3 stoichiometric gasoline operates at 2400 RPM with a volumetric

mEVO = m4 = (PV/RT)4 = (361 kPa)(0.0006659 efficiency of 88%. The turbocharger has a turbine isentropic

m3) / (0.287 kJ/kg-K)(1202 K) efficiency of 80% and a compressor isentropic efficiency of 78%.

= 0.000697 Exhaust flow enters the turbine at 770 K and 119 kPa, and exits at

kg at start of blowdown 98 kPa. Air enters the compressor at 27°C and 96 kPa, and exits at

After blowdown at state 7 120 kPa. Calculate:

P7 = Pex = 98kPa V = VBDC = (a) Mass flow rate through the tubocharger compressor. [kg/sec]

0.0006659 m3 Eq. 2-71,

Eq. 3-37 ρ = P / RT = 96 kPa / (0.287 kJ/kg-K)(300 K) = 1.115 kg/m3

(k-1)/k

Tex =T7 = T3(P7/P3) Eq. 2-70 mass flow rate through the compressor

Tex = 2700K (98/8200)(1.35-1)/1.35 = 857 K ma = ρVdηVN/n = (1.115 kg/m3)(0.0015 m3)(1.08)(2400/60

m = PV/RT = (98kPa)(0.0006659 m3) / (0.287 rev/sec) / 2

kJ/kg-K)(857 K) = 0.000265 kg ma = 0.0361 kg/sec

mass that exits cylinder during blowdown (b) Mass flow rate through the turbocharger turbine. [kg/sec]

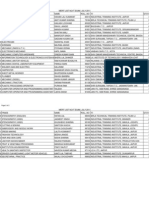

S-ar putea să vă placă și

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDe la EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsÎncă nu există evaluări

- Colligative Property and Solution ObjectiveDocument6 paginiColligative Property and Solution ObjectivenoelÎncă nu există evaluări

- 8.3 Colligative Properties - Tutorial (Lecturer) EDITDocument8 pagini8.3 Colligative Properties - Tutorial (Lecturer) EDITsufiaÎncă nu există evaluări

- ERRORLESS CHEMISTRY Edujournal - in - Pages-293-339 PDFDocument47 paginiERRORLESS CHEMISTRY Edujournal - in - Pages-293-339 PDFtasnimÎncă nu există evaluări

- Features of Microsoft WordDocument9 paginiFeatures of Microsoft Wordمحمد TVÎncă nu există evaluări

- BreadboardsDocument3 paginiBreadboardschelseablues100% (2)

- Importance of Productivity MeasurementDocument4 paginiImportance of Productivity MeasurementrajatÎncă nu există evaluări

- The Commonwealth of The PhilippinesDocument7 paginiThe Commonwealth of The PhilippinesRenalyn de LimaÎncă nu există evaluări

- Reflective Essay Final DraftDocument11 paginiReflective Essay Final Draftapi-405135320Încă nu există evaluări

- Major Religions of The WorldDocument24 paginiMajor Religions of The WorldPrashantÎncă nu există evaluări

- 01-Solution & Colligative Properties - Theory-FinalDocument10 pagini01-Solution & Colligative Properties - Theory-FinalAnkit MishraÎncă nu există evaluări

- Colligative PropertiesDocument61 paginiColligative PropertiesSubhasish Sau100% (1)

- Case-Friedland Timbers CompanyDocument2 paginiCase-Friedland Timbers Companytalented guy0% (1)

- Solutions and Colligative Proprties in 1 Shot PDFDocument75 paginiSolutions and Colligative Proprties in 1 Shot PDFAbhishek YadavÎncă nu există evaluări

- The 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsDocument6 paginiThe 8 Deadly Lean Wastes - DOWNTIME: #1 DefectsRam KumarÎncă nu există evaluări

- 11 Stoichiometry Calculations Based On Chemical EquationsDocument38 pagini11 Stoichiometry Calculations Based On Chemical EquationsMohamed TarekÎncă nu există evaluări

- Dilute Solution & Colligative Properties-Assignment PDFDocument25 paginiDilute Solution & Colligative Properties-Assignment PDFggk201375% (4)

- Ch3 Process CostingDocument4 paginiCh3 Process CostingmahendrabpatelÎncă nu există evaluări

- Taylor's Scientific Management Principles in Current Organizational Management PracticesDocument11 paginiTaylor's Scientific Management Principles in Current Organizational Management Practicesashji10Încă nu există evaluări

- SERRANO RR22 Final Module STSDocument11 paginiSERRANO RR22 Final Module STSRenie SerranoÎncă nu există evaluări

- Affirmative Action in EducationDocument48 paginiAffirmative Action in EducationSushman DasÎncă nu există evaluări

- Analysing NAPLAN Results Using SMARTDocument36 paginiAnalysing NAPLAN Results Using SMARTFiras AlameddineÎncă nu există evaluări

- Calculus II SyllabusDocument2 paginiCalculus II SyllabusHa PhamÎncă nu există evaluări

- Indus Valley CivilizationDocument31 paginiIndus Valley CivilizationMunivenkata KrishnaÎncă nu există evaluări

- San Carlos College: The Contemporary World Renato JR, D. Ursua LPTDocument2 paginiSan Carlos College: The Contemporary World Renato JR, D. Ursua LPTmawiÎncă nu există evaluări

- StarbucksDocument3 paginiStarbucksMonika SharmaÎncă nu există evaluări

- 1 PsychologyDocument2 pagini1 PsychologySyahaneez A JamilÎncă nu există evaluări

- Economic Order QuantityDocument10 paginiEconomic Order QuantityZafar IqbalÎncă nu există evaluări

- CHED Launches Free Tuition Law IRRDocument32 paginiCHED Launches Free Tuition Law IRRRenz AbadÎncă nu există evaluări

- Peña, Eufie & Ocampo, Cherrylyn ADocument5 paginiPeña, Eufie & Ocampo, Cherrylyn AJemimah A. AlgarÎncă nu există evaluări

- Pre-Calculus ProjectDocument3 paginiPre-Calculus Projectapi-348365155Încă nu există evaluări

- Lesson 7 - Hard To ImagineDocument25 paginiLesson 7 - Hard To ImagineakerraÎncă nu există evaluări

- Case StudiesDocument25 paginiCase StudiesAguilan, Alondra JaneÎncă nu există evaluări

- Biochemical Tests For Neisseria and MoraxellaDocument2 paginiBiochemical Tests For Neisseria and MoraxellaJoshua Ty CayetanoÎncă nu există evaluări

- Food Preservation FoodDocument5 paginiFood Preservation FoodSumaiyaÎncă nu există evaluări

- Social Learning Towards A Sustainable WorldDocument541 paginiSocial Learning Towards A Sustainable WorldGabriela Santos Tibúrcio100% (1)

- CH 3 StoichiometryDocument30 paginiCH 3 StoichiometryGhina Nur FadhilahÎncă nu există evaluări

- Aquatic EcosystemsDocument16 paginiAquatic Ecosystemsapi-323141584Încă nu există evaluări

- Phenol Water System-Libre PDFDocument7 paginiPhenol Water System-Libre PDFManuel Esteban Videla BustosÎncă nu există evaluări

- Lecture Notes (Plane and Solid Geometry)Document51 paginiLecture Notes (Plane and Solid Geometry)LIAJOY BONITES100% (1)

- Decisions Whether. This Is The Yes/no, Either/or Decision That Must Be Made BeforeDocument16 paginiDecisions Whether. This Is The Yes/no, Either/or Decision That Must Be Made BeforeJaseem Pk0% (1)

- Breadboard and Circuit Diagram Basics PDFDocument3 paginiBreadboard and Circuit Diagram Basics PDFRajesh MurugesanÎncă nu există evaluări

- Solutions & Colligative Properties - (Lecture Notes)Document35 paginiSolutions & Colligative Properties - (Lecture Notes)mrdldwivedi100% (2)

- Approaches To EntrepreneurshipDocument40 paginiApproaches To Entrepreneurshipm umair zahirÎncă nu există evaluări

- Colligative Properties NotesDocument22 paginiColligative Properties NotesAbilash murali100% (1)

- Jhon Sammuel - 110401044 - Tugas Motor BakarDocument5 paginiJhon Sammuel - 110401044 - Tugas Motor BakarAkhun NastiÎncă nu există evaluări

- Additional ProblemsDocument5 paginiAdditional ProblemsPJ PerezÎncă nu există evaluări

- Fajril Ar Rahman 100401014Document4 paginiFajril Ar Rahman 100401014Fajril Ar-rahmanÎncă nu există evaluări

- Problem Solving (Adrian Recamadas) : FindDocument9 paginiProblem Solving (Adrian Recamadas) : FindPJ PerezÎncă nu există evaluări

- Applied Mechanical Engineering Engine Power Cycle: SolutionDocument6 paginiApplied Mechanical Engineering Engine Power Cycle: SolutionAlteaAlÎncă nu există evaluări

- Solved ProblemsDocument15 paginiSolved ProblemsMichaelle Angela Arnedo70% (10)

- CalculationDocument4 paginiCalculationaoauaz2000Încă nu există evaluări

- Renewable Energy Resources HW 2Document4 paginiRenewable Energy Resources HW 2Ajit KanaleÎncă nu există evaluări

- Cycle Engine PDFDocument6 paginiCycle Engine PDFk marcusÎncă nu există evaluări

- InDocument25 paginiInMiko Ong TanÎncă nu există evaluări

- Plinske Turbine 2015Document13 paginiPlinske Turbine 2015Aleksandar NikolićÎncă nu există evaluări

- Assignment 5 - Jagonos, Ariel PDFDocument7 paginiAssignment 5 - Jagonos, Ariel PDFleno voiÎncă nu există evaluări

- ch08 41 85Document52 paginich08 41 85Giuseppe TestarossaÎncă nu există evaluări

- Gas Turbines Worked Out ExamplesDocument33 paginiGas Turbines Worked Out ExamplesShankarMukherjeeÎncă nu există evaluări

- Thermal CyclesDocument6 paginiThermal CyclesSathish Kasilingam0% (1)

- Michael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972Document13 paginiMichael J. Flynn - Some Computer Organizations and Their Effectiveness, 1972earthcrosserÎncă nu există evaluări

- NA BR 1177 EN Dematic AutoStore SubsystemDocument8 paginiNA BR 1177 EN Dematic AutoStore SubsystemDaniel Garnando KristianÎncă nu există evaluări

- SF DumpDocument17 paginiSF DumpBeatríz YañezÎncă nu există evaluări

- Mae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3Document38 paginiMae 1202: Aerospace Practicum: Lecture 4: Introduction To Basic Aerodynamics 3زهديابوانسÎncă nu există evaluări

- TLE Curriculum MatrixDocument3 paginiTLE Curriculum MatrixJerrymi TandogÎncă nu există evaluări

- HTTPHeader LiveDocument199 paginiHTTPHeader LiveDenys BautistaÎncă nu există evaluări

- Review Chapter 2Document46 paginiReview Chapter 2JennysanÎncă nu există evaluări

- An Automated Test and Measurement System For Calibration of Industrial FlowmetersDocument2 paginiAn Automated Test and Measurement System For Calibration of Industrial FlowmetersfredpintoÎncă nu există evaluări

- Sebu6100-02 MDocument74 paginiSebu6100-02 MSa CruCerÎncă nu există evaluări

- Pardoseli PVCDocument72 paginiPardoseli PVCnasuemilÎncă nu există evaluări

- Painting and Weathering Unlocked PDFDocument91 paginiPainting and Weathering Unlocked PDFWrensEye100% (6)

- Belbin's Team ModelDocument2 paginiBelbin's Team Modelsonu_saisÎncă nu există evaluări

- JRX118SP SpecsheetDocument2 paginiJRX118SP SpecsheetLuisÎncă nu există evaluări

- STRUCTUREDocument26 paginiSTRUCTUREJulia RatihÎncă nu există evaluări

- European Foundation Design For Seasonally Frozen GroundDocument127 paginiEuropean Foundation Design For Seasonally Frozen GroundLevente SikoÎncă nu există evaluări

- AquaMapPublic v202Document26 paginiAquaMapPublic v202engfeupÎncă nu există evaluări

- Chapter 5 (6) Concrete MaterialDocument134 paginiChapter 5 (6) Concrete Materialraju_420034520Încă nu există evaluări

- APAVE Tiger CP - UK - FINAL2Document1 paginăAPAVE Tiger CP - UK - FINAL2AdrewhassTechnicaÎncă nu există evaluări

- Computer Typing History of TypingDocument9 paginiComputer Typing History of TypingRamÎncă nu există evaluări

- BCO120Document3 paginiBCO120erwin_simsensohnÎncă nu există evaluări

- Staffing ProcessDocument18 paginiStaffing ProcessEbtesam EliasÎncă nu există evaluări

- Ballsim DirectDocument58 paginiBallsim DirectDiego GaliciaÎncă nu există evaluări

- FINAL THESIS DOC LastDocument114 paginiFINAL THESIS DOC LastMulat ShierawÎncă nu există evaluări

- Acm 003Document5 paginiAcm 003Roan BÎncă nu există evaluări

- Cultural Competence Refers To An Ability To Interact Effectively With People of Different CulturesDocument5 paginiCultural Competence Refers To An Ability To Interact Effectively With People of Different CulturesKim EliotÎncă nu există evaluări

- Ass AsDocument2 paginiAss AsMukesh BishtÎncă nu există evaluări

- Product Leaflet Seawater ElectrochlorinationDocument4 paginiProduct Leaflet Seawater Electrochlorinationgkdora574Încă nu există evaluări

- PT2 Exam CLASS XI CS 2023Document2 paginiPT2 Exam CLASS XI CS 2023Aditya AurangeÎncă nu există evaluări

- 78-SAFETY - QUESTIO in PDFDocument21 pagini78-SAFETY - QUESTIO in PDFIndermohan MehtaÎncă nu există evaluări

- Antennas and Wave Propagation - Nov - 2015Document8 paginiAntennas and Wave Propagation - Nov - 2015Jyothi SamanthulaÎncă nu există evaluări