Documente Academic

Documente Profesional

Documente Cultură

High Build Epoxy Coating For Pipelines: Product Data Sheet

Încărcat de

demi bajakan0 evaluări0% au considerat acest document util (0 voturi)

22 vizualizări2 paginicanusa HB-5

Titlu original

canusa HB-5

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentcanusa HB-5

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

22 vizualizări2 paginiHigh Build Epoxy Coating For Pipelines: Product Data Sheet

Încărcat de

demi bajakancanusa HB-5

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

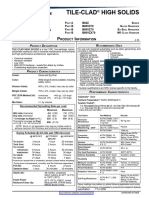

HBE-95

High Build Epoxy coating for pipelines

The Canusa HBE-95 is an advanced two-component epoxy

coating system which has been specifically formulated for

moderate temperature pipelines. Applied to bare steel, HBE-95 has

proven to withstand operating temperatures up to 95°C (203°F)

with superior performance. HBE-95 is used for protection of field

joint girth welds, valves and fittings, as a holiday repair material on

FBE coated pipe or for rehabilitation projects. This environmentally

friendly, 100% solids, novolac epoxy system can either be spray

applied or brush applied to the intended substrate.

Applications

Corrosion Protection up to 95°C

Oil & Gas

• HBE-95 coating system was designed to protect operating

pipelines up to 95°C with exceptional performance.

Repair & Rehab

Exceeds FBE Performance Requirements

• Exceeds FBE coating performance requirements, including impact

resistance, hot water soak adhesion and resistance to cathodic Abrasion Coating

disbonding, as specified in USA (NACE RP0394), British (CW6),

and Canadian (CSA Z245.20) standards.

Girth-Weld Joints

Fast, Medium and Slow Cure Options

• HBE-95 brush grade comes with three different cure speed

Fittings & Bends

options: Fast, Medium and Slow. Cure speed options present pot-

life flexibility based on ambient temperatures and cycle

cle time

requirements.

High Build in Single Coat

• A single pass application direct-to-metal will achieve

e a high

build coating thickness of 20-40mils (500-1000microns).

rons).

Variety of Uses

• Mainline pipelines, rehabilitation projects, girth weld field joints,

damage and holiday repair to FBE coated pipe, pipeline ne

valves, fittings and bends, or directional drilling

applications.

PRODUCT DATA SHEET canusacps.com

The product information

shown here is intended as a guide

HBE-95 for standard products.

Consult your Canusa

High Build Epoxy coating for pipelines representative for specific

projects or unique applications.

Performance All performance testing followed CSA-Z245.20-10 unless specified.

Service Temp. Up to 95°C (203°F)

Typical Thickness > 20 mils (500 microns)

Mixing Ratio 3:1 (by volume)

Percent Solids 100%

Base: 1.49

Specific Gravity

Cure: 1.048

Hardness (ASTM D2240) > 85 Shore D

Adhesion to Steel > 2300 psi

Adhesion to FBE > 2000 psi

Cathodic Disbondment @ 28 days, 23°C < 3 mm

Cathodic Disbondment @ 28 days, 80°C < 8 mm Canusa-CPS

A division of Shawcor Ltd.

Cathodic Disbondment @ 28 days, 95°C < 8 mm

Head Office

Impact Resistance @ -30°C > 3.0 J

25 Bethridge Road

Impact Resistance @ 25°C > 3.0 J Toronto, ON, Canada M9W 1M7

Tel: +1 416 743 7111

Hot Water Immersion @ 28 days, 75°C Rating 1 Fax: +1 416 743 5927

Hot Water Immersion @ 28 day, 95°C Rating 1 Canada

Dome Tower St. 2200, 333-7th Avenue SW

Water Absorption (ASTM D570) < 0.1 % Calgary, AB, Canada T2P 2Z1

Chemical Resistance (ASTM D543) Excellent in various pH solutions Tel: +1 403 218 8207

Fax: +1 403 264 3649

3 years when stored in original packaging Americas

Shelf Life

between 5°C and 40°C.

5875 N. Sam Houston Pkwy W., Suite 200

Cure Speed Options1 Houston, TX, USA 77086

Tel: +1 281 886 2350

SuperFast Cure2 (SFT) Gel Time = Forced Cure Fax: +1 281 886 2353

Fast Cure (WG) Gel Time = < 10 minutes Middle East

ADPC - Mussafah Port, P.O. Box 2621

Medium Cure (XG) Gel Time = < 15 minutes Abu Dhabi, UAE

Tel: +971 2 496 3500

Slow Cure (RG) Gel Time = < 20 minutes Fax: +971 2 496 3501

3

Typical Kit Size Required by Pipe Diameter Europe, Africa & Russia

4.5” – 16” 0.5 Liter Kit Dellaertweg 9-E, Gebouw “Le Carrefour”

2316 WZ Leiden, The Netherlands (NL)

18” – 32” 1.0 Liter Kit Tel: +31 71 80 802 70

Fax: +31 71 80 802 71

34” to 50” 1.5 Liter Kit

Asia-Pacific

1 Gel times were measured @ 23°C (73°F). For more information please refer to Canusa’s Technical Bulletin – High Build Epoxy Cure Profiles. 101 Thomson Road, #11-03 United Square

2 SuperFast Technology (SFT) is used as repair material in FBE coating plants. 307591 Singapore

3 Based on 400 mm coating width, 25 mils (635 micron) average thickness and 50% wastage factor. Tel: +65 6749 8918

Fax: +65 6749 8919

Quality Management system

registered to ISO 9001

Safety Canusa warrants that the product conforms to its

chemical and physical description and is appropriate

for the use stated on the product data sheet when

Handle with care. Before and during use, observe all safety labels on packaging used in compliance with Canusa’s written instructions.

Since many installation factors are beyond our control,

containers, consult with Canusa-CPS Material Safety Data Sheets and abide by all the user shall determine the suitability of the products

for the intended use and assume all risks and liabilities

local or national safety regulations. in connection therewith. Canusa’s liability is stated

in the standard terms and conditions of sale. Canusa

makes no other warranty either expressed or implied.

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings All information contained in this data sheet is to be

used as a guide and is subject to change without

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high notice. This data sheet supersedes all previous data

sheets on this product. E&OE

performance products are manufactured to the highest quality standards and are available in a number

of configurations to accommodate many specific project applications. PDS_HBE-95_rev024

S-ar putea să vă placă și

- HBE-HT Product Application Procedure With Install Guide and TDSDocument13 paginiHBE-HT Product Application Procedure With Install Guide and TDSNuSpec Consulting75% (4)

- CBT QuestionsDocument20 paginiCBT Questionsmohammed amjad ali100% (1)

- TSPP8Document76 paginiTSPP8Ian Naylor100% (1)

- PDS Purethane NXT Rev 04 PolyurethaneDocument4 paginiPDS Purethane NXT Rev 04 PolyurethaneGilbert Lim100% (1)

- Slide 1: Pipeline Ancillary EquipmentDocument46 paginiSlide 1: Pipeline Ancillary EquipmentadesloopÎncă nu există evaluări

- SP-2034 Ver 1 Specification For Internal FBE Coating of Line Pipe (Amendment - Suppliment To API RP 5L7) (Sep 05)Document21 paginiSP-2034 Ver 1 Specification For Internal FBE Coating of Line Pipe (Amendment - Suppliment To API RP 5L7) (Sep 05)Devam RajÎncă nu există evaluări

- CV-Navaneethan-Vendor Inspection CoordinatorDocument12 paginiCV-Navaneethan-Vendor Inspection CoordinatorShanmuga NavaneethanÎncă nu există evaluări

- High Build Epoxy Coating For Pipelines: Product Data SheetDocument2 paginiHigh Build Epoxy Coating For Pipelines: Product Data SheetChegg ChemÎncă nu există evaluări

- Hbe-Os: High Build Epoxy Coating For Offshore Corrosion ProtectionDocument2 paginiHbe-Os: High Build Epoxy Coating For Offshore Corrosion Protectionsamkarthik47Încă nu există evaluări

- Pds Na Hbeht HssDocument2 paginiPds Na Hbeht HssdakidofdaboomÎncă nu există evaluări

- Hbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsDocument2 paginiHbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsMohammad Mehdi JafariÎncă nu există evaluări

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 paginiWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanÎncă nu există evaluări

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 paginiWrapidcoat PVC: Superior Mechanical ProtectionsenthilkumarÎncă nu există evaluări

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 paginiWrapidcoat PVC: Superior Mechanical ProtectioncocoaÎncă nu există evaluări

- HBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsDocument2 paginiHBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsolalekanÎncă nu există evaluări

- Pds Na Gts65Document2 paginiPds Na Gts65Yan FerizalÎncă nu există evaluări

- Poly-Cote 110 (Aug'22)Document4 paginiPoly-Cote 110 (Aug'22)David cÎncă nu există evaluări

- Technical Data Sheet Product 406: Worldwide Version, February 1996Document3 paginiTechnical Data Sheet Product 406: Worldwide Version, February 1996Muhammad irtizaÎncă nu există evaluări

- Canusa GTS 80Document2 paginiCanusa GTS 80ZainudinÎncă nu există evaluări

- Nitoproof 600: Constructive SolutionsDocument22 paginiNitoproof 600: Constructive SolutionsMazen AlRefaaiÎncă nu există evaluări

- NXTDocument4 paginiNXTSam HuangÎncă nu există evaluări

- Wall Bushings: STB Series: 40.5 252 KV Combined Wall Bushings With Current Transformer: STB-L Series: 40.5 252kVDocument4 paginiWall Bushings: STB Series: 40.5 252 KV Combined Wall Bushings With Current Transformer: STB-L Series: 40.5 252kVRamesh PatelÎncă nu există evaluări

- Marco Material Datasheet M1005 PDFDocument2 paginiMarco Material Datasheet M1005 PDFRose VillaÎncă nu există evaluări

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 paginiProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraÎncă nu există evaluări

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 paginiWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanÎncă nu există evaluări

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 paginiWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanÎncă nu există evaluări

- Fluteck P7500 CA v01.19Document2 paginiFluteck P7500 CA v01.19fprovitaliÎncă nu există evaluări

- DTM Acrylic Pimer Finish B66W1Document4 paginiDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaÎncă nu există evaluări

- Product 266: Technical Data SheetDocument2 paginiProduct 266: Technical Data SheetFabio ParceroÎncă nu există evaluări

- Epofine 556 FR/ FInehard 951Document3 paginiEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- Canusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSDocument2 paginiCanusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSozcanÎncă nu există evaluări

- LR-C-VentureClad Catalogue 01Document16 paginiLR-C-VentureClad Catalogue 01himanshu desaiÎncă nu există evaluări

- PDS - Na - Klon-KlnnDocument2 paginiPDS - Na - Klon-Klnndemi bajakanÎncă nu există evaluări

- Manta Canusa - GTS65 - en InglesDocument2 paginiManta Canusa - GTS65 - en IngleserwinvillarÎncă nu există evaluări

- PDS - NA - PRP Repair Data SheetDocument2 paginiPDS - NA - PRP Repair Data SheetHendra AwanÎncă nu există evaluări

- Marco Material Datasheet M1002Document2 paginiMarco Material Datasheet M1002Chang MikeÎncă nu există evaluări

- TDS L2057216Document3 paginiTDS L2057216erolsarÎncă nu există evaluări

- Scotchkote Coatings BrochureDocument8 paginiScotchkote Coatings BrochureDarren PerryÎncă nu există evaluări

- Fosroc Nukote BLDocument4 paginiFosroc Nukote BLm.elsanee.cubicÎncă nu există evaluări

- MeCaTeC MeCaCorr 710 Surface Polymer Ceramic CoatingDocument1 paginăMeCaTeC MeCaCorr 710 Surface Polymer Ceramic CoatingjaviermvsÎncă nu există evaluări

- ShaliPoxy CTE 103Document4 paginiShaliPoxy CTE 103Prashant BaruaÎncă nu există evaluări

- Proton PF-15Document1 paginăProton PF-15HirenÎncă nu există evaluări

- 638 - New-EnDocument4 pagini638 - New-EnKan Sang MokÎncă nu există evaluări

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 paginiPintura Epoxica Sherwin Willians Hoja Seguridad1Încă nu există evaluări

- Tideguard 182: Product Data/ Application InstructionsDocument2 paginiTideguard 182: Product Data/ Application InstructionsPablo Ahumada G.Încă nu există evaluări

- Initial Ring BendingDocument13 paginiInitial Ring BendingmdabdullaÎncă nu există evaluări

- Marco Material Datasheet B1083 PDFDocument2 paginiMarco Material Datasheet B1083 PDFAlaa SaadÎncă nu există evaluări

- HDPE-100 Catalogue PDFDocument9 paginiHDPE-100 Catalogue PDFkumar sandeepÎncă nu există evaluări

- SubseaLV DatasheetDocument1 paginăSubseaLV DatasheetPablo TorresÎncă nu există evaluări

- Chemthane 2265Document1 paginăChemthane 2265VICTOR RESENDIZÎncă nu există evaluări

- Marco Material Datasheet B1105 PDFDocument2 paginiMarco Material Datasheet B1105 PDFAlaa SaadÎncă nu există evaluări

- Belex Wireline LubricantDocument2 paginiBelex Wireline LubricantdhowardjÎncă nu există evaluări

- Scar Guard EnglishDocument2 paginiScar Guard EnglishVismael SantosÎncă nu există evaluări

- Urethane Coating 165 PWDocument3 paginiUrethane Coating 165 PWANIBALLOPEZVEGAÎncă nu există evaluări

- Parche CRP 65 - Ficha Técnica - en InglesDocument2 paginiParche CRP 65 - Ficha Técnica - en IngleserwinvillarÎncă nu există evaluări

- Ceilcote 2000 Flakeline+td+engDocument2 paginiCeilcote 2000 Flakeline+td+engMohamed NouzerÎncă nu există evaluări

- 4622 Product InfoDocument4 pagini4622 Product InfoVendy KurniawanÎncă nu există evaluări

- Marco Material Datasheet E1097Document3 paginiMarco Material Datasheet E1097phoenixenggworkÎncă nu există evaluări

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocument4 paginiArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoÎncă nu există evaluări

- Wrapidtape: Primerless Crosslinked Protective TapeDocument2 paginiWrapidtape: Primerless Crosslinked Protective TapeHendra AwanÎncă nu există evaluări

- Polylon HP PDSDocument4 paginiPolylon HP PDSJose MachadoÎncă nu există evaluări

- Technical Data Sheet: Heavy Duty GreaseDocument1 paginăTechnical Data Sheet: Heavy Duty GreaseDon HowardÎncă nu există evaluări

- Marco Material Datasheet N1000 PDFDocument2 paginiMarco Material Datasheet N1000 PDFAlaa SaadÎncă nu există evaluări

- Loctite PC 7227™: Technical Data SheetDocument3 paginiLoctite PC 7227™: Technical Data SheetMohsin ModiÎncă nu există evaluări

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyDe la EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinÎncă nu există evaluări

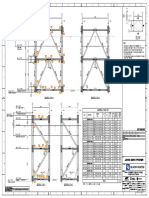

- Drawing STR PDFDocument47 paginiDrawing STR PDFdemi bajakanÎncă nu există evaluări

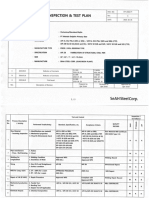

- Inspection and Test Plan - Rev.C (Draft)Document3 paginiInspection and Test Plan - Rev.C (Draft)demi bajakanÎncă nu există evaluări

- PDS - Na - Klon-KlnnDocument2 paginiPDS - Na - Klon-Klnndemi bajakanÎncă nu există evaluări

- A2V2D6 - Condition 17 - Field Joining Program - Appendix B4 - Magnetic Part PDFDocument11 paginiA2V2D6 - Condition 17 - Field Joining Program - Appendix B4 - Magnetic Part PDFaditya rahmanÎncă nu există evaluări

- Jfesp: JFE Steel Sheet PilesDocument15 paginiJfesp: JFE Steel Sheet Pilesbtcong93Încă nu există evaluări

- Uji Coba Parkir Tamu: Jl. TB Sima TUP ANGDocument1 paginăUji Coba Parkir Tamu: Jl. TB Sima TUP ANGdemi bajakanÎncă nu există evaluări

- Drill de EntranceDocument1 paginăDrill de Entrancedemi bajakanÎncă nu există evaluări

- Pip Ctsu1000-2018Document59 paginiPip Ctsu1000-2018antonio diazÎncă nu există evaluări

- SAMSS New StandardDocument25 paginiSAMSS New Standardlhanx2100% (1)

- Technical Specification For FJCDocument8 paginiTechnical Specification For FJCĐiệnBiênNhâmÎncă nu există evaluări

- 3lpe CoatingDocument30 pagini3lpe CoatingMohan Kumar SÎncă nu există evaluări

- Fire Protection Control ValvesDocument20 paginiFire Protection Control ValvesDaniel Eduardo RodriguezÎncă nu există evaluări

- TS-C4Gas-COATMEX001 - Rev3 (Official)Document18 paginiTS-C4Gas-COATMEX001 - Rev3 (Official)Reynol Mejía OlmosÎncă nu există evaluări

- NACE CIP Part II - (6) Coatings For Industry - (Qs - As)Document23 paginiNACE CIP Part II - (6) Coatings For Industry - (Qs - As)Almagesto QuenayaÎncă nu există evaluări

- External Pipe CoatingsDocument15 paginiExternal Pipe Coatingsupesddn2010100% (3)

- Jindal Saw - Steel SW - Pipe Presentation - Rev 6 - July 2013Document34 paginiJindal Saw - Steel SW - Pipe Presentation - Rev 6 - July 2013Claudio GallardoÎncă nu există evaluări

- Piping FBE Spool MethodologyDocument28 paginiPiping FBE Spool MethodologyHariharan MÎncă nu există evaluări

- TDS - Pipeclad HOT 120Document2 paginiTDS - Pipeclad HOT 120Long ChenÎncă nu există evaluări

- (201207) (TDS) Ig4848Document2 pagini(201207) (TDS) Ig4848Abdelrahman AwadallahÎncă nu există evaluări

- Fusion Bonded Epoxy-Coated Pipe Piles: Standard Specification ForDocument4 paginiFusion Bonded Epoxy-Coated Pipe Piles: Standard Specification ForRamzi BEN AHMEDÎncă nu există evaluări

- Pipeline Construction Specification (Pcs-01) Sp-1208Document80 paginiPipeline Construction Specification (Pcs-01) Sp-1208samkarthik47100% (1)

- South Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Document19 paginiSouth Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Kingsley BaptistaÎncă nu există evaluări

- Effect of Ultraviolet Exposure On Corrosion Performance of Fusion Bonded Epoxy (FBE) Coated Steel RebarsDocument8 paginiEffect of Ultraviolet Exposure On Corrosion Performance of Fusion Bonded Epoxy (FBE) Coated Steel RebarsnagarajuÎncă nu există evaluări

- Sol Epoxy Epoxy Coating Powder - Product Selector GuidesDocument14 paginiSol Epoxy Epoxy Coating Powder - Product Selector GuidesAlexandreÎncă nu există evaluări

- Napca Bulletins 1-65-94 Thru 17-98Document72 paginiNapca Bulletins 1-65-94 Thru 17-98lemuel bacsaÎncă nu există evaluări

- ISO21809-3 2008 Fiel Joint CoatingsDocument108 paginiISO21809-3 2008 Fiel Joint CoatingsUsable Tools100% (1)

- Icaiea 2018Document174 paginiIcaiea 2018csrajmohan2924Încă nu există evaluări

- Fusion Bonded Epoxy For External Pipeline Coating-EGDocument15 paginiFusion Bonded Epoxy For External Pipeline Coating-EGChozha RajanÎncă nu există evaluări

- C153 Di Compact MJ Fittings: Domestic Price ListDocument28 paginiC153 Di Compact MJ Fittings: Domestic Price Listgabriel240371Încă nu există evaluări

- Astm A 884 PDFDocument5 paginiAstm A 884 PDFMuhammad NaumanÎncă nu există evaluări

- 50-Plus Years of Proven Corrosion Protection Performance With Thousands of Miles of Pipelines Operating in A Broad Range of Service ConditionsDocument2 pagini50-Plus Years of Proven Corrosion Protection Performance With Thousands of Miles of Pipelines Operating in A Broad Range of Service ConditionsNebu MathewÎncă nu există evaluări