Documente Academic

Documente Profesional

Documente Cultură

Electrode Booklet F Web 17

Încărcat de

satnam0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări1 paginăElectrode Booklet F Web 17

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentElectrode Booklet F Web 17

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

11 vizualizări1 paginăElectrode Booklet F Web 17

Încărcat de

satnamElectrode Booklet F Web 17

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

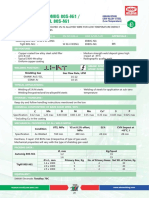

SUPABASE

C-Mn STEEL (Low Hydrogen)

Special Welding Electrode for Pressure Vessels and Bridges

CLASSIFICATION : EN ISO 2560-A AWS A/SFA 5.1 IS 814 APPROVALS :

E 42 3 B 32 H5 E 7018 E B5426H3JX ABS/BV/DNV/IRS/LRA/

IBR/BIS/NTPC/BHEL

KEY FEATURES :

• Basic type iron powder electrode • Radiographic weld deposit

• Metal recovery approx. 115% • Suitable for pipe welding in 5G & 6G

• All position capability positions

WELDING POSITION : AC (70 OCV)/ DCEP

TYPICAL APPLICATIONS :

• Pressure vessels, Pipes • Joining steel of ASTM SA 414/414M

• Storage tanks Gr.C/D, SA 516/516M Gr.55/60, IS 2002, IS

2062

• Bridges, Heavy structures

REDRYING CONDITION : 250-300OC for minimum 1 hr. (Also available in vacuum packed condition)

CHEMICAL COMPOSITION OF UNDILUTED WELD METAL, Wt % :

C Mn Si S P

Typical 0.06 1.1 0.4 0.02 0.02

Specification 0.04-0.09 0.8-1.6 0.35-0.7 0.03 max. 0.03 max.

MECHANICAL PROPERTIES OF ALL WELD METAL :

YS at 0.2% CVN Impact , J

Condition UTS, MPa EL%

offset, MPa -20°C -30°C

Typical 540 470 26 66 48

As Welded

Specification 500-600 440-550 24-30 50-80 30-70

Diffusible H2 Content: <5 ml/100 gm

PARAMETERS - PACKING DATA :

Approx. Approx. wt. of

Ø x L, mm Amperage, A Carton/Box

Pcs/Carton 1000 pcs, Kg.

2.5 x 350 60-90 225 4 22

3.15 x 450 100-130 110 4 45

4.0 x 450 140-180 75 4 66

5.0 x 450 180-240 50 4 98

EQUIVALENT: GMAW wire: Automig-70S-6 FCAW wire: Automig–FC-71T-1, Automig-FC-121

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

17

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 paginăAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamÎncă nu există evaluări

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 paginăAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamÎncă nu există evaluări

- Tigfil Cuni: Classification: ApprovalsDocument1 paginăTigfil Cuni: Classification: ApprovalssatnamÎncă nu există evaluări

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 paginăAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamÎncă nu există evaluări

- CWC-BookletF1 59Document1 paginăCWC-BookletF1 59satnamÎncă nu există evaluări

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 paginăAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamÎncă nu există evaluări

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 paginăAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamÎncă nu există evaluări

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 paginăAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamÎncă nu există evaluări

- Tiginox 385: Classification: en Iso 14343-ADocument1 paginăTiginox 385: Classification: en Iso 14343-AJagannath SahuÎncă nu există evaluări

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 paginăAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamÎncă nu există evaluări

- CWC-BookletF1 17Document1 paginăCWC-BookletF1 17satnamÎncă nu există evaluări

- CWC-BookletF1 10Document1 paginăCWC-BookletF1 10satnamÎncă nu există evaluări

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 paginăTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamÎncă nu există evaluări

- CWC-BookletF1 15Document1 paginăCWC-BookletF1 15satnamÎncă nu există evaluări

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 paginăAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamÎncă nu există evaluări

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 paginăAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamÎncă nu există evaluări

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 paginăAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamÎncă nu există evaluări

- CWC-BookletF1 12Document1 paginăCWC-BookletF1 12satnamÎncă nu există evaluări

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 paginăTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamÎncă nu există evaluări

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 paginăTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamÎncă nu există evaluări

- CWC-BookletF1 9Document1 paginăCWC-BookletF1 9satnamÎncă nu există evaluări

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 paginăAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamÎncă nu există evaluări

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 paginăTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamÎncă nu există evaluări

- CWC-BookletF1 9Document1 paginăCWC-BookletF1 9satnamÎncă nu există evaluări

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 paginăAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamÎncă nu există evaluări

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 paginăTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamÎncă nu există evaluări

- CWC-BookletF1 2Document1 paginăCWC-BookletF1 2satnamÎncă nu există evaluări

- CWC-BookletF1 4Document1 paginăCWC-BookletF1 4satnamÎncă nu există evaluări

- CWC-BookletF1 3Document1 paginăCWC-BookletF1 3satnamÎncă nu există evaluări

- CWC-BookletF1 5Document1 paginăCWC-BookletF1 5satnamÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- BOQ KosongDocument6 paginiBOQ Kosongkhairil mohdÎncă nu există evaluări

- Continuous Distillation Diagram ProcessDocument1 paginăContinuous Distillation Diagram ProcessSebastianÎncă nu există evaluări

- SP0793-0000-1M05-005 - Standard Specification For Welding Rev0 Marzo 2022Document19 paginiSP0793-0000-1M05-005 - Standard Specification For Welding Rev0 Marzo 2022Nestor De Jesus Pico TorresÎncă nu există evaluări

- Capstone Report On Wheel Chair Cum StretcherDocument40 paginiCapstone Report On Wheel Chair Cum StretcherRakesh Moparthi100% (1)

- Nanobiochar and Biochar Based NanocompositesDocument12 paginiNanobiochar and Biochar Based NanocompositesJaini FakhrudinÎncă nu există evaluări

- 2022 - 04 - 20 - VIVA-B-FIX Line TRG-PolymersDocument15 pagini2022 - 04 - 20 - VIVA-B-FIX Line TRG-PolymersJagdish PatelÎncă nu există evaluări

- Air Mite CatalogDocument56 paginiAir Mite Catalogtemoc128Încă nu există evaluări

- Camapana de Humo Sin DuctosDocument4 paginiCamapana de Humo Sin DuctosBRIAN JULIAN GARCIA ALFONSOÎncă nu există evaluări

- ARB220CW Tech SheetDocument2 paginiARB220CW Tech SheetJohn TrippÎncă nu există evaluări

- Hydraulic Brake SystemDocument11 paginiHydraulic Brake SystemRajKumawat100% (1)

- ACI 304R Guide For Meas., Mix., Transp., & Placing ConcDocument41 paginiACI 304R Guide For Meas., Mix., Transp., & Placing ConcVasanth KumarÎncă nu există evaluări

- Anugrah Raya: Shear ConnectorDocument6 paginiAnugrah Raya: Shear ConnectordedeÎncă nu există evaluări

- Static Tests On Complete StructuresDocument40 paginiStatic Tests On Complete StructuresZain AhmedÎncă nu există evaluări

- CAT8 EN 100dpi Gesamt PDFDocument391 paginiCAT8 EN 100dpi Gesamt PDFaleksandarpmauÎncă nu există evaluări

- AcryGuard TDS 2020Document3 paginiAcryGuard TDS 2020sarah magdyÎncă nu există evaluări

- Tape WrappingDocument8 paginiTape WrappingwalitedisonÎncă nu există evaluări

- Cabin Pressure:: ExampleDocument47 paginiCabin Pressure:: ExamplePrasanth ViratÎncă nu există evaluări

- Storage Tank DetailDocument22 paginiStorage Tank DetailRamu NallathambiÎncă nu există evaluări

- Polymer Processing Design Week 1Document53 paginiPolymer Processing Design Week 1Abdul RahmanÎncă nu există evaluări

- Rexnord Tabletop Mattop English 02Document215 paginiRexnord Tabletop Mattop English 02operationmanager100% (1)

- RF Series-Catalog 3800 - SectionADocument3 paginiRF Series-Catalog 3800 - SectionAStefan DinuÎncă nu există evaluări

- K-Tron Premier Rep Catalog Dec 2010 PDFDocument429 paginiK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- E831BDocument4 paginiE831BDenis JimenezÎncă nu există evaluări

- Process Engineering Toolkit SolutionsDocument71 paginiProcess Engineering Toolkit SolutionsTeymur RegenmaisterÎncă nu există evaluări

- API 600 Trim No.Document19 paginiAPI 600 Trim No.SUBHASISH BHATTACHARYYAÎncă nu există evaluări

- Final Project Report Natural CoagulationDocument48 paginiFinal Project Report Natural CoagulationSareeg Thomas0% (1)

- 0620 s13 Ms 32 PDFDocument6 pagini0620 s13 Ms 32 PDFShad muhammad KhanÎncă nu există evaluări

- Isolated Phase Busduct Ipb EnerbusDocument2 paginiIsolated Phase Busduct Ipb EnerbuszulryÎncă nu există evaluări

- L&T Pipeline Ball Valves PDFDocument19 paginiL&T Pipeline Ball Valves PDFSanjeev KachharaÎncă nu există evaluări

- Bible Saintgobain PamDocument742 paginiBible Saintgobain PamfrankytgÎncă nu există evaluări