Documente Academic

Documente Profesional

Documente Cultură

Louver Spec

Încărcat de

Cyril J PadiyathDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Louver Spec

Încărcat de

Cyril J PadiyathDrepturi de autor:

Formate disponibile

Abu Dhabi Airports Company PJSC Specification, Section 089100

SECTION 089100

LOUVERS

1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 01 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Contractor shall provide all labour, Materials, Contractor’s Equipment and Plant to fully

execute the requirements to furnish, deliver, and install the Works as expressly described in

the Drawings and Specification, or implied therefrom, and in accordance with the Contract.

It is the intent of this Specification section that the work performed pursuant hereto be

complete and acceptable in every respect for its intended purpose. It is further required that

the provisions of this Specification section shall be complementary to, and shall be

correlated with, the requirements of the Contract. Nothing in this Specification section shall

limit the scope of work as required by the Contract.

B. Section Includes:

1. Fixed, extruded-aluminum louvers.

a. (ref LRV-01 is not used)

b. Sand louvers (ref LRV-02): Sand trap louvers

c. Internal louvers (ref LRV-06).

d. Architectural louvers and doors (ref LRV-07).

2. Fixed stainless-steel louvers.

a. Architectural louvers (ref LRV-09).

3. Louver blanking panels (ref LRV-03: Blank-off panels.

4. Louver screens:

a. Bird screening (ref LRV-04).

b. Insect screening (ref LRV-05).

5. Architectural decorative louver (grille) (ref LRV-08).

C. Related Sections include, but are not limited to, the following. This paragraph cross-

references requirements a reader might expect to find in this Section but are specified in

another section. It is not intended to be, and shall not be interpreted as, a listing of every

other section that has a relationship to this Section.

1. Division 05 Section "Metal Fabrications" for steel framing and supports for louvers.

2. Division 08 Section "Door Hardware" for hardware for hinged louver assembly as

part of LRV-07.

3. Division 23 Sections for louvers that are a part of mechanical equipment

1.3 DEFINITIONS

A. Louver Terminology: Definitions of terms for metal louvers contained in AMCA 501 apply

to this Section unless otherwise defined in this Section or in referenced standards.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 1 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

B. Horizontal Louver: Louver with horizontal blades; i.e., the axes of the blades are horizontal.

C. Drainable-Blade Louver: Louver with blades having gutters that collect water and drain it

to channels in jambs and mullions, which carry it to bottom of unit and away from opening.

D. Sand Trap Louvers: Louvers specifically designed to separate sand and dust from the air.

E. Architectural Decorative Louvers (Grilles): Architectural grille designed to serve as vision

barrier.

1.4 PERFORMANCE REQUIREMENTS

A. General:

1. Contractor is responsible for the design of connections and fixings for louvers and

related elements, including interfaces and interfaces and coordination with work of

adjoining trades, to satisfy aesthetic effects and performance requirements in

accordance with the Contract Documents.

2. The Specification together with the Drawings establish requirements for aesthetic

effects and performance requirements. As scope and performance documents, the

Drawings and Specifications do not necessarily indicate or describe in detail all work

required for the full performance and completion of the Works. Contractor is

responsible for developing and completing the design in accordance with the Contract

Documents, and shall provide all items required for proper completion of the Works

without adjustment to the Contract price.

a. Aesthetic effects are indicated by dimensions, arrangements, alignment, and

profiles of components and assemblies as they relate to sightlines, to one

another, and to adjoining construction.

b. Performance requirements are indicated by criteria, conformance with which

may be subject to verification by preconstruction testing, field testing, or in-

service performance as determined by Engineer. Scheduling and procedures

for such testing that may be required to verify that the design complies with

performance requirements shall be agreed with Engineer prior to commencing

Work.

c. Do not revise intended aesthetic effects, as judged solely by Engineer, except

with Engineer's approval. If revisions are proposed, submit comprehensive

explanatory data to Engineer for review.

B. Structural Performance: Louvers shall withstand the effects of gravity loads and the

following loads and stresses within limits and under conditions indicated without permanent

deformation of louver components, noise or metal fatigue caused by louver blade rattle or

flutter, or permanent damage to fasteners and anchors. Wind pressures shall be considered

to act normal to the face of the building.

1. Wind Loads – Exterior Louvers - Sand Louvers (LRV-02) and Architectural Louvers

and Doors (ref LRV-07).

a. Refer to report titled “Wind Tunnel Testing Cladding Pressure Studies” by

BMT Fluid Mechanics.

1) The mean hourly wind speed for this area is 23.3 meters per second.

2) Calculate wind loads in accordance with SEI/ASCE 7 or BS 6399 Pt 2.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 2 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

b. When tested at both positive and negative applications of design wind loads,

multiplied by a factor of 1.5, there shall be no permanent damage to louvers,

framing, or anchors. Framing members shall not be buckled.

2. Seismic Loads: Withstand the effects of earthquake motions in accordance with 1997

UBC Division IV-Earthquake Design. The following factors shall be used:

a. The seismic classification for the area is 2A of UBC 1997.

b. The building is classified as a Seismic Use Group II, Occupancy Importance

factor I = 1.25, Design Category C, structure in accordance with the NEHRP

Recommended Provisions for New Buildings and Other Structures: Part 1:

Provisions (FEMA 450).

c. Design louvers, associated framing, and connections to sustain the induced

load acceleration factors associated with seismic actions in accordance with

UBC 1997.

d. Louvers, associated framing, and connections shall be assigned a component

importance factor, Ip, of 1.0, as indicated in Section 13.1.3 of SEI/ASCE 7.

C. Thermal Movements – Exterior Louvers: Allow for thermal movements from ambient and

surface temperature changes without buckling, opening of joints, overstressing of

components, failure of connections, and other detrimental effects.

1. Ambient Temperature Range: 0 deg C to 70 deg C.

2. Metal Surfaces Temperature Range: 0 deg C to 85 deg C.

D. Louver Performance Ratings: Provide louvers complying with requirements specified in

Part 2 below for each type of louver, as demonstrated by testing manufacturer's stock units

identical to those provided, except for length and width according to AMCA 500-L.

1.5 SUBMITTALS

A. Product Data: For each type of product indicated.

1. For louvers specified to bear AMCA seal, include printed catalog pages showing

specified models with appropriate AMCA Certified Ratings Seals.

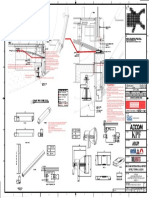

B. Visual Mockup Shop Drawings: Showing fabrication and installation details for visual

mockups.

C. Shop Drawings: For louvers and accessories. Include plans, elevations, sections, details,

and attachments to other work. Show frame profiles and blade profiles, angles, and spacing.

1. Indicate locations, dimensions, tolerances, and details of steel framing and support

required for support of louvers.

2. Show weep paths, gaskets, flashing, sealant, and other means of preventing water

intrusion.

3. Show mullion profiles and locations.

D. Samples for Verification: For each type of metal finish required.

E. Certification: Signed and sealed by Contractor, certifying that products and systems to be

provided comply with performance requirements in the Contract Documents. Include

calculations and structural analysis including comprehensive engineering analysis (limited

to the extent of the defined Performance Requirements in this Section) signed and sealed by

the qualified professional engineer responsible for their preparation.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 3 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

1. Should there be proposed deviations from specified requirements, submit

calculations, loads, standards and other factors used to establish compliance with

performance requirements, for review and acceptance by Engineer.

2. Should there be proposed deviations from aesthetic effects, submit drawings

indicating such proposed deviations, for review and acceptance by Engineer.

F. Product Test Reports: Based on evaluation of comprehensive tests performed according to

AMCA 500-L by a qualified testing agency or by manufacturer and witnessed by a qualified

testing agency, for each type of louver and showing compliance with performance

requirements specified.

G. Warranties: Sample of special warranties.

1.6 QUALITY ASSURANCE

A. Source Limitations: Obtain louvers and vents from single source from a single

manufacturer where indicated to be of same type, design, or factory-applied color finish.

B. Visual Mockups: After approval of samples, build visual mockups for louvers, complete

with framing, anchors, and connections, to comply with the following requirements, using

materials indicated in the Contract Documents for the completed Work:

1. Provide components for mockups as indicated on the A12 Series Drawings and as

specified in Division 01 Section “Mock-Ups, Mock-Up Area & Facility and Other

Requirements.” Build visual mockups of size and extent indicated on Drawings, in

location as directed by Engineer.

2. Purpose of visual mockups is to verify selections made under sample submittals and

to demonstrate aesthetic effects and set quality standards for materials and execution.

3. Obtain Engineer’s approval of visual mockups before starting work, fabrication, or

construction.

4. Maintain visual mockups during construction in an undisturbed condition as a

standard for judging the completed Work.

5. Demolish and remove visual mockups when directed by Engineer.

C. SMACNA Standard: Comply with recommendations in SMACNA's "Architectural Sheet

Metal Manual" for fabrication, construction details, and installation procedures.

1.7 REFERENCES

A. Product manufacture, testing and installation shall comply with the following references

unless otherwise stated in the specification or otherwise approved by the Engineer.

B. Air Movement and Control Association International, Inc.

1. AMCA 500-L-1999: Test Methods for Louvers, Dampers

2. AMCA 501-2003: Application Manual for Air Louvers

C. American Architectural Manufacturers Association

1. AAMA 2603-2002: Voluntary Specification, Performance Requirements and Test

Procedures for Pigmented Organic Coatings on Aluminum Extrusions and Panels

2. AAMA 2605-2002: Voluntary Specification, Performance Requirements and Test

Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and

Panels

D. American Society of Civil Engineers:

1. SEI/ASCE 7: Minimum Design Loads for Buildings and Other Structures.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 4 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

E. ASTM International

1. ASTM B 26/B 26M-03: Specification for Aluminum-Alloy Sand Castings

2. ASTM B 209M-04: Specification for Aluminum and Aluminum-Alloy Sheet and

Plate [Metric]

3. ASTM B 221M-04: Specification for Aluminum and Aluminum-Alloy Extruded

Bars, Rods, Wire, Profiles and Tubes [Metric]

4. ASTM E 488-96 (Reapproved 2003): Test Methods for Strength of Anchors in

Concrete and Masonry Elements

F. International Code Council

1. Uniform Building Code (UBC) 1997

G. National Association of Architectural Metal Manufacturers

1. Metal Finishes Manual for Architectural and Metal Products. 1988.

H. Sheet Metal and Air Conditioning Contractors' National Association

1. Architectural Sheet Metal Manual. 2003.

1.8 PROJECT CONDITIONS

A. Field Measurements: Verify actual dimensions of openings by field measurements before

fabrication.

1.9 WARRANTY

A. Special Finish Warranty: Manufacturer's standard form in which manufacturer agrees to

repair or replace components on which finishes do not comply with requirements or that fail

in materials or workmanship within specified warranty period. Warranty does not include

normal weathering.

1. Warranty Periods: See Division 01 Section “Warranties” for commencement date of

warranty period.

a. Fluoropolymer finish: 20 years.

b. Powder-coat finish: Five years.

2 - PRODUCTS

2.1 MATERIALS

A. Aluminum Extrusions: ASTM B 221M, Alloy 6063-T5, T-52, or T6.

B. Aluminum Sheet: ASTM B 209M, Alloy 3003 or 5005 with temper as required for

forming, or as otherwise recommended by metal producer for required finish.

C. Aluminum Castings: ASTM B 26/B 26M, Alloy 319.

D. Stainless-Steel Sheet: ASTM A 240/A 240M, Type 304, No. 4 finish, with grain running

parallel to length of blades and frame members.

E. Fasteners: Use types and sizes to suit unit installation conditions.

1. Use Phillips flat-head tamper-resistant screws for exposed fasteners unless otherwise

indicated on Drawings.

2. For fastening aluminum, use aluminum or 300 series stainless-steel fasteners.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 5 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

3. For fastening stainless steel, use 300 series stainless-steel fasteners.

4. For color-finished louvers, use fasteners with heads that match color of louvers.

F. Postinstalled Fasteners for Concrete and Masonry: Torque-controlled expansion anchors,

made from stainless-steel components, with capability to sustain, without failure, a load

equal to 4 times the loads imposed, for concrete, or 6 times the load imposed, for masonry,

as determined by testing per ASTM E 488, conducted by a qualified independent testing

agency.

2.2 FABRICATION, GENERAL

A. Assemble louvers in factory to minimize field splicing and assembly. Disassemble units as

necessary for shipping and handling limitations. Clearly mark units for reassembly and

coordinated installation.

B. Vertical Assemblies: Where height of louver units exceeds fabrication and handling

limitations, fabricate units to permit field-bolted assembly with close-fitting joints in jambs

and mullions, reinforced with splice plates.

1. Horizontal Mullions: Provide horizontal mullions at joints unless continuous vertical

assemblies are indicated on Drawings.

C. Maintain equal louver blade spacing to produce uniform appearance.

D. Fabricate frames, including integral sills, to fit in openings of sizes indicated, with

allowances made for fabrication and installation tolerances, adjoining material tolerances,

and perimeter sealant joints.

1. Frame Type: Interior flange unless otherwise indicated on Drawings.

E. Include supports, anchorages, and accessories required for complete assembly.

F. Provide vertical mullions of type and at spacings indicated on Drawings, but not more than

recommended by manufacturer, or 1800 mm o.c., whichever is less.

1. Fully Recessed Mullions – Interior Louvers: Where indicated, provide mullions fully

recessed behind louver blades. Where length of louver exceeds fabrication and

handling limitations, fabricate with close-fitting blade splices designed to permit

expansion and contraction.

2. Exposed Mullions – Exterior Louvers: Where indicated, provide units with exposed

mullions of same width and depth as louver frame. Where length of louver exceeds

fabrication and handling limitations, provide interlocking split mullions designed to

permit expansion and contraction.

G. Provide subsills made of same material as louvers for recessed louvers.

H. Join frame members to each other and to fixed louver blades with fillet welds, threaded

fasteners, or both, as standard with louver manufacturer, or size of louver assembly makes

bolted connections between frame members necessary.

2.3 SAND TRAP LOUVERS (ref LRV-02)

A. Louver Type: Sand trap louver; extruded aluminum frames and blades.

1. Louver Depth: As standard with manufacturer, but not less than 75 mm.

2. Configuration: Two rows of opposing extruded aluminum vertical channels, spaced to

allow indirect air flow, and staggered, with sand removed from louver by

manufacturer’s standard method.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 6 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

3. Frame Profile: Channel, or as otherwise indicated on Drawings.

B. Louver Performance Ratings:

1. Free Area: 18 percent free area.

2. Air Performance: 60 Pa maximum at 0.8 m/s.

3. Sand Removal Efficiency: 70 percent using standard sand having grains sized

between 100 and 1000 microns, with 90 percent between 150 and 425 microns.

2.4 INTERIOR LOUVERS (ref LRV-06)

A. Louver Type: Horizontal, nondrainable-blade louver; extruded or roll-formed aluminum

frames and blades.

1. Louver Depth: 50 mm.

2. Frame and Blade Nominal Thickness: Not less than 2.0 mm.

3. Blade Profile: Plain blade without center baffle.

4. Mullion Type: Fully recessed.

B. Louver Performance Ratings: Based on testing 1000 mm x 3400 mm size unit in accordance

with AMCA 500.

1. Free Area: 60 percent, nominal.

2. Air Performance: 4.5 cu. m./s at 20 Pa.

2.5 ARCHITECTURAL LOUVERS AND DOORS (ref LRV-07).

A. Louver Type: Horizontal, nondrainable-blade louver; extruded aluminum frames and blades.

Design louver for fixed installation, and for factory-installation outboard of blanking panel

for doors, as indicated on Drawings.

1. Louver Depth: As indicated on Drawings.

2. Frame and Blade Nominal Thickness: Not less than 2.0 mm.

3. Blade Profile: Plain blade without center baffle.

4. Mullion Type: Fully recessed.

B. Louver Performance Ratings: Based on testing 1219 mm x 1219 mm size unit in accordance

with AMCA 500.

1. Free Area: 54 percent, nominal.

2. Free Area Size: 0.8 sq. m.

3. Maximum Recommended Air Flow Velocity Thru Free Area: 4.5 m/s.

4. Maximum Pressure Drop: 0.04 kPa.

5. Water Penetration: Maximum of 3.1 g/sq. m. of free area at an air flow of 4.5 m/s

free area velocity when tested for 15 minutes.

C. Doors:

1. Doors within architectural louvers are assemblies of louver factory-installed outboard

of blanking panel. See Division 08 Section "Door Hardware" for hardware for these

hinged louver assemblies.

2. Fasten louver to blanking panel using concealed stainless clips, such that louver

blades on door align with louver blades on adjoining wall to provide continuous

appearance.

3. Fabricate profiles and alignments of vertical edges of door, and of adjoining louvers

and wall, as indicated on Drawings, such that door will clear adjoining construction

when door is operated.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 7 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

2.6 ARCHITECTURAL DECORATIVE LOUVERS (GRILLES) (ref LRV-08).

A. Louver Type: Vertical wall screen grille; extruded aluminum blades and supports. Louver

blades secured to manufacturer’s continuous extruded aluminum supports.

1. Louver Depth: As indicated on Drawings.

2. Frame and Blade Nominal Thickness: Not less than 2.0 mm.

3. Blade Profile: Y-shaped, sight-proof blade.

4. Blade Spacing: 114 mm o.c.

2.7 ARCHITECTURAL LOUVER (ref LRV-09).

A. Louver Type: Horizontal, nondrainable blade louver; stainless-steel frames and blades.

1. Louver Depth: As indicated on Drawings.

2. Frame and Blade Nominal Thickness: Not less than 3.00 mm.

3. Blade Profile: Custom blade without center baffle.

4. Mullion Type: Fully recessed.

B. Louver Performance Ratings: Based on testing 1000 mm x 1000 mm size unit in accordance

with AMCA 500.

1. Free Area: 40 percent nominal.

2. Air performance 1.2 cu. m/s at 50 Pa.

2.8 LOUVER SCREENS

A. General: Provide screen for louvers as follows.

1. Exterior Louvers:

a. Screening Type: Bird screening and insect screening.

b. Screen Location: Interior face of louvers, with insect screening inboard of bird

screening.

2. Interior Louvers:

a. Screening Type: Insect screening.

b. Screen Location: Interior face of louvers.

B. Secure screen frames to louver frames with stainless-steel machine screws with heads

finished to match louver, spaced a maximum of 150 mm from each corner and at 300 mm

o.c.

C. Louver Screen Frames: Fabricate with mitered corners to louver sizes indicated.

1. Metal: Same kind and form of metal as specified for louver to which screens are

attached. Reinforce extruded-aluminum screen frames at corners with clips.

2. Finish: Same finish as louver frames to which louver screens are attached.

3. Type:

a. For use with insect screen: Rewirable frames with a driven spline or insert.

b. For use with bird screen: Non-rewirable, U-shaped frames.

D. Bird Screening (ref LRV-04): Stainless steel, Type 316L; 13-mm- square mesh, 1.19-mm

wire.

E. Insect Screening (ref LRV-05): Stainless steel, type 316L; 1.4-by-1.4-mm mesh, 0.23-mm

wire.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 8 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

2.9 LOUVER BLANKING PANELS (REF LRV-03)

A. Laminated panels consisting of insulating core surfaced on back and front with metal sheets

and attached to back of louver.

1. Thickness: 50 mm.

2. Metal Facing Sheets: Aluminum sheet, not less than 0.81-mm nominal thickness.

3. Insulating Core: Rigid, glass-fiber-board insulation or extruded-polystyrene foam.

4. Edge Treatment: Trim perimeter edges of blank-off panels with louver

manufacturer's standard channel frames, with corners mitered and with same finish as

panels.

5. Seal perimeter joints between panel faces and louver frames with gaskets or sealant.

6. Panel Finish: Same type of finish applied to louvers, but black color.

7. Attach blank-off panels with clips.

B. For blanking panels associated with doors in LRV-07, fabricate blankoff panels with

perimeter and internal framing as required to resist door operating stresses, and as required

for attachment of door hardware.

C. Provide insulated, blank-off panels for louvers for portions of louvers not connected to

ducts.

2.10 ALUMINUM FINISHES

A. General: Comply with NAAMM's "Metal Finishes Manual for Architectural and Metal

Products" for recommendations for applying and designating finishes.

B. 2-Coat High-Performance Organic Finish: 2-coat fluoropolymer finish complying with

AAMA 2605 and containing not less than 70 percent PVDF resin by weight in color coat.

Prepare, pretreat, and apply coating to exposed metal surfaces to comply with coating and

resin manufacturers' written instructions.

1. Sand trap louvers, other than to receive 3-coat high-performance organic finish (ref

LRV-02): Dark grey color to be selected by Engineer.

2. Louver blanking panels, other than to receive 3-coat high-performance organic finish

(ref LRV-07): Matte black color.

C. 3-Coat High-Performance Organic Finish: 3-coat fluoropolymer finish complying with

AAMA 2605 and containing not less than 70 percent PVDF resin by weight in both color

coat and clear topcoat. Prepare, pretreat, and apply coating to exposed metal surfaces to

comply with coating and resin manufacturers' written instructions.

1. Sand trap louvers on roofs (ref LRV-02): RAL color 9006 Metallic Silver.

2. Internal louvers (ref LRV-06): RAL color 9006 Metallic Silver.

3. Architectural louvers and doors (ref LRV-07), including edges and both faces of

blanking panels associated with doors: RAL color 9006 Metallic Silver.

4. Architectural decorative louver (ref LRV-08): RAL colour 9006 Metallic Silver.

3 - EXECUTION

3.1 EXAMINATION

A. Examine substrates and openings, with Installer present, for compliance with requirements

for installation tolerances and other conditions affecting performance.

B. Proceed with installation only after unsatisfactory conditions have been corrected.

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 9 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

Abu Dhabi Airports Company PJSC Specification, Section 089100

3.2 PREPARATION

A. Coordinate setting drawings, diagrams, templates, instructions, and directions for

installation of anchorages that are to be embedded in concrete or masonry construction.

Coordinate delivery of such items to Project site.

3.3 INSTALLATION

A. Locate and place louvers and vents level, plumb, and at indicated alignment with adjacent

work.

1. Refer to Division 05 Section “Structural Steel Framing” for limitations on sizes and

locations of site-drilled holes in structural steel.

B. Install doors within architectural louvers such that louver blades on door align with louver

blades on adjoining wall to provide continuous appearance. Adjust hardware for hinged

louvers for proper operation. Coordinate with Division 08 Section "Door Hardware".

C. Use concealed anchorages where possible. Provide brass or lead washers fitted to screws

where required to protect metal surfaces and to make a weathertight connection.

D. Form closely fitted joints with exposed connections accurately located and secured.

E. Provide perimeter reveals and openings of uniform width for sealants and joint fillers, as

specified or as indicated on Drawings.

F. Repair finishes damaged by cutting, welding, soldering, and grinding. Restore finishes so

no evidence remains of corrective work. Return items that cannot be refinished in the field

to the factory, make required alterations, and refinish entire unit or provide new units.

G. Protect unpainted nonferrous-metal surfaces that will be in contact with concrete, masonry,

or dissimilar metals from corrosion and galvanic action by separating surfaces with

waterproof gaskets or nonmetallic flashing.

H. Install concealed gaskets, flashings, joint fillers, and insulation as louver installation

progresses, where weathertight louver joints are required. Comply with Division 07 Section

"Joint Sealants" for sealants applied during louver installation.

3.4 ADJUSTING AND CLEANING

A. Clean exposed surfaces of louvers and vents that are not protected by temporary covering, to

remove fingerprints and soil during construction period. Do not let soil accumulate during

construction period.

B. Before final inspection, clean exposed surfaces with water and a mild soap or detergent not

harmful to finishes. Thoroughly rinse surfaces and dry.

C. Restore louvers and vents damaged during installation and construction so no evidence

remains of corrective work. If results of restoration are unsuccessful, as determined by

Engineer, remove damaged units and replace with new units.

1. Touch up minor abrasions in finishes with air-dried coating that matches color and

gloss of, and is compatible with, factory-applied finish coating.

END OF SECTION

Contract: Midfield Terminal Building - General Contractor, AUH.06.10.0401 Page 10 of 10

145 Rev. 01

Construction Bulletins: Bulletin No. XXX; 31 January 2015

S-ar putea să vă placă și

- Compliance Statement - MakanDocument23 paginiCompliance Statement - MakanJaouad Id BoubkerÎncă nu există evaluări

- QCS 2014 Glass UvalueDocument1 paginăQCS 2014 Glass UvalueRaoofÎncă nu există evaluări

- Method Statement FOR Artificial Rock WorkDocument9 paginiMethod Statement FOR Artificial Rock Workbhupsjangir100% (2)

- Chilled Water Ceiling Cassette Fan Coil UnitDocument6 paginiChilled Water Ceiling Cassette Fan Coil UnitZhen Sin0% (1)

- Fire Piping Astm A795Document3 paginiFire Piping Astm A795sinahimsÎncă nu există evaluări

- U Value Calculations 11Document3 paginiU Value Calculations 11onspsnonsÎncă nu există evaluări

- ACP Standards Saudi ArabiaDocument29 paginiACP Standards Saudi ArabiaRoland James Arimado50% (2)

- Uaefirecode Eng September 2018Document1.348 paginiUaefirecode Eng September 2018Sheik Peer Mohideen100% (1)

- Compliance StatementDocument2 paginiCompliance Statementshajeer1982Încă nu există evaluări

- Where To Install?: Chute Size Plastic Bag Capacity (LTRS) Apartments Per ChuteDocument2 paginiWhere To Install?: Chute Size Plastic Bag Capacity (LTRS) Apartments Per ChuteMoloy Das100% (1)

- Fire Fighting Building B O QDocument10 paginiFire Fighting Building B O QJurie_sk3608Încă nu există evaluări

- Dowel Data SheetDocument2 paginiDowel Data SheetalsvsuryaÎncă nu există evaluări

- Sandwich PanelDocument23 paginiSandwich Panel1DC20AT033 Kaarthik N.Încă nu există evaluări

- Boq Final NewDocument77 paginiBoq Final NewAburvarajÎncă nu există evaluări

- Terracotta Rainscreen CladdingDocument9 paginiTerracotta Rainscreen CladdingAbdul Hafeez100% (1)

- FCA Foam ChamberDocument5 paginiFCA Foam ChamberN AfiyahÎncă nu există evaluări

- Outline SpecsDocument171 paginiOutline Specsmohamed fawzyÎncă nu există evaluări

- Uniform Plumbing Code of Abu Dhabi Emirate - CleanoutDocument1 paginăUniform Plumbing Code of Abu Dhabi Emirate - Cleanouturssulthan4416Încă nu există evaluări

- Dubai Municipality - Local Order No. 8 of 2002Document35 paginiDubai Municipality - Local Order No. 8 of 2002Muhanad SalemÎncă nu există evaluări

- Woqod Guideline For Fuel Tank SetupDocument1 paginăWoqod Guideline For Fuel Tank SetupRamiAl-fuqaha100% (1)

- Plumbing and Fire Fighting Sample BoqDocument30 paginiPlumbing and Fire Fighting Sample BoqNajeeb Ahmad Khan100% (2)

- 03 DM BLDG U-Value+Calculation V01Document1 pagină03 DM BLDG U-Value+Calculation V01AburvarajÎncă nu există evaluări

- Gutmann Curtain Wall Systems f50 Plus f60 Plus enDocument1 paginăGutmann Curtain Wall Systems f50 Plus f60 Plus enNacer IzriÎncă nu există evaluări

- Commerical Stair and Handrail Guard Requirements Compressed PDFDocument4 paginiCommerical Stair and Handrail Guard Requirements Compressed PDFMohd parvezÎncă nu există evaluări

- Amca 501Document25 paginiAmca 501Erwin Maldo100% (2)

- Technical Data SheetDocument15 paginiTechnical Data SheetHari Stars Aluminium50% (2)

- Astmc864 05Document11 paginiAstmc864 05pandey0080% (1)

- Bill No. 1 General Requirements Item Description Qty. Unit Unit Rate Amount Numbers Words SR GeneralDocument59 paginiBill No. 1 General Requirements Item Description Qty. Unit Unit Rate Amount Numbers Words SR Generalmohamed nawwarÎncă nu există evaluări

- BOQ For Solar Water HeatersDocument2 paginiBOQ For Solar Water Heaterssolpower_epl100% (2)

- Submital & Method Statement - Loading BracketsDocument1 paginăSubmital & Method Statement - Loading BracketsvtalexÎncă nu există evaluări

- BOQDocument2 paginiBOQManish Goyal100% (1)

- Air and Water Permeability of Sandwich Panel JointsDocument43 paginiAir and Water Permeability of Sandwich Panel JointsThiên BìnhÎncă nu există evaluări

- ChutesDocument48 paginiChutesSema Jain100% (1)

- BOQ AppartmentDocument78 paginiBOQ AppartmentAbdalah OsamaÎncă nu există evaluări

- C162-05 (2010) Standard Terminology of Glass and Glass ProductsDocument16 paginiC162-05 (2010) Standard Terminology of Glass and Glass ProductsAhmed AlzubaidiÎncă nu există evaluări

- Fan Coil Units (DX-COIL With Heat Pump) : High WallDocument9 paginiFan Coil Units (DX-COIL With Heat Pump) : High WallSTANDARD EDUCATION ACADEMY M.E.P CENTERÎncă nu există evaluări

- Rate Analysis of Fire Fighting SystemDocument6 paginiRate Analysis of Fire Fighting SystemNagendra Mishra Aiims BhopalÎncă nu există evaluări

- Air Terminal CatalogeDocument114 paginiAir Terminal CatalogeRamadan RashadÎncă nu există evaluări

- Reynaers Product Overview CURTAIN WALLDocument80 paginiReynaers Product Overview CURTAIN WALLyantoÎncă nu există evaluări

- HILTI Firestop and Fire Protection SystemsDocument9 paginiHILTI Firestop and Fire Protection Systemsfrikkie@100% (1)

- BS en 10088-4-2009Document48 paginiBS en 10088-4-2009khanhÎncă nu există evaluări

- SPECIFICATIONDocument213 paginiSPECIFICATIONnadeem UddinÎncă nu există evaluări

- Kerala BOQDocument47 paginiKerala BOQSmith SivaÎncă nu există evaluări

- BOQ Fire Detail NetDocument10 paginiBOQ Fire Detail NetrajuÎncă nu există evaluări

- Architect / Consultant Sandeep Govalkar Design Associates Client: Central Bank of India Project: - Proposed Air Conditioning Work of Vikhroli BranchDocument2 paginiArchitect / Consultant Sandeep Govalkar Design Associates Client: Central Bank of India Project: - Proposed Air Conditioning Work of Vikhroli BranchSantosh ThakurÎncă nu există evaluări

- Appendix 1 Estidama EN PDFDocument108 paginiAppendix 1 Estidama EN PDFAulia Rahman FahmiliÎncă nu există evaluări

- Fire FightDocument4 paginiFire Fightkiran raghukiranÎncă nu există evaluări

- Iso 717 1 2020Document12 paginiIso 717 1 2020Antonia Cordeiro100% (1)

- BOQDocument47 paginiBOQAbdullah.N FAAliÎncă nu există evaluări

- Construction Specification Chain Link FenceDocument2 paginiConstruction Specification Chain Link Fenceyamanta_rajÎncă nu există evaluări

- Fire-Suppression Piping System-13915 PDFDocument21 paginiFire-Suppression Piping System-13915 PDFMohammad Jugnu100% (1)

- Easy Duct PDFDocument8 paginiEasy Duct PDFSameera Sri VidurangaÎncă nu există evaluări

- Afdb Abuja Hvac Boq - Lot2-1Document48 paginiAfdb Abuja Hvac Boq - Lot2-1Dee RajaÎncă nu există evaluări

- Seismic Design Specification For Buildings, Structures, Equipment, and Systems: 2020Document10 paginiSeismic Design Specification For Buildings, Structures, Equipment, and Systems: 2020AndreaAlberoÎncă nu există evaluări

- Facade-Alumimum & Glazing Works Scope-Technical SpecificationsDocument5 paginiFacade-Alumimum & Glazing Works Scope-Technical SpecificationsHasnain SafdarÎncă nu există evaluări

- BOQ CanteenDocument35 paginiBOQ Canteendimuthu lasinthaÎncă nu există evaluări

- Sample BOQDocument17 paginiSample BOQThushan MaduÎncă nu există evaluări

- V04 (Decorative Metal)Document25 paginiV04 (Decorative Metal)Cyril J PadiyathÎncă nu există evaluări

- Metal Fabrications - Edited 02062023Document26 paginiMetal Fabrications - Edited 02062023Raymond John TomasÎncă nu există evaluări

- SECTION 076200 Sheet Metal Flashing and Trim: 1 - GeneralDocument10 paginiSECTION 076200 Sheet Metal Flashing and Trim: 1 - GeneralCyril J PadiyathÎncă nu există evaluări

- Tokio QuoteDocument5 paginiTokio QuoteCyril J PadiyathÎncă nu există evaluări

- FANR - RG007 Ver1Document64 paginiFANR - RG007 Ver1Cyril J PadiyathÎncă nu există evaluări

- RN-02-00001-07-11-IR-NBH-MI-000145 (01) - M.Sub For Steel Elements For Irrigation Pump StationDocument2 paginiRN-02-00001-07-11-IR-NBH-MI-000145 (01) - M.Sub For Steel Elements For Irrigation Pump StationCyril J PadiyathÎncă nu există evaluări

- Inside WeldingDocument1 paginăInside WeldingCyril J PadiyathÎncă nu există evaluări

- Comments Resolution Sheet (CRS)Document27 paginiComments Resolution Sheet (CRS)Cyril J PadiyathÎncă nu există evaluări

- Form Radiation Work Permit Free TemplateDocument1 paginăForm Radiation Work Permit Free TemplateCyril J PadiyathÎncă nu există evaluări

- V1 V2 Cal PRCDocument5 paginiV1 V2 Cal PRCCyril J PadiyathÎncă nu există evaluări

- Stylish Teaching Cover LetterDocument1 paginăStylish Teaching Cover LetterCyril J PadiyathÎncă nu există evaluări

- FANR-RG-019 Radiation Safety in Industrial RadiographyDocument31 paginiFANR-RG-019 Radiation Safety in Industrial RadiographyCyril J PadiyathÎncă nu există evaluări

- Queen Street Local Rules June 2011Document10 paginiQueen Street Local Rules June 2011Cyril J PadiyathÎncă nu există evaluări

- JSC "Zaporizhstal" (Ukraine) : Company's Business ProfileDocument8 paginiJSC "Zaporizhstal" (Ukraine) : Company's Business ProfileCyril J PadiyathÎncă nu există evaluări

- SULB Product Catalogue PDFDocument46 paginiSULB Product Catalogue PDFCyril J PadiyathÎncă nu există evaluări

- Allianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMDocument2 paginiAllianz Middle East Ship Mangament LLC: "WWE 210" 210ft Positioning (Crane) Barge 4PMCyril J PadiyathÎncă nu există evaluări

- National Guard Epoxy Red Oxide PrimerDocument3 paginiNational Guard Epoxy Red Oxide PrimerCyril J PadiyathÎncă nu există evaluări

- National Red Oxide Primer PDFDocument3 paginiNational Red Oxide Primer PDFCyril J Padiyath100% (1)

- Penguard Special: Technical Data SheetDocument5 paginiPenguard Special: Technical Data SheetCyril J PadiyathÎncă nu există evaluări

- General: SECTION 01 78 36 WarrantiesDocument3 paginiGeneral: SECTION 01 78 36 WarrantiesCyril J PadiyathÎncă nu există evaluări

- Emirates Steel BrochureDocument92 paginiEmirates Steel BrochureCyril J PadiyathÎncă nu există evaluări

- 401 An e 07 Ge 0.00 LT SD 071 v00.c (Typical Lighting Detail Plan Lighting Fixture Type l2b & Xs1 S)Document1 pagină401 An e 07 Ge 0.00 LT SD 071 v00.c (Typical Lighting Detail Plan Lighting Fixture Type l2b & Xs1 S)Cyril J PadiyathÎncă nu există evaluări

- Sanitory Works SpecDocument10 paginiSanitory Works SpecCyril J PadiyathÎncă nu există evaluări

- Project SpecDocument5 paginiProject SpecCyril J PadiyathÎncă nu există evaluări

- Safety Analysis of Trailing CablesDocument28 paginiSafety Analysis of Trailing CablesMaikPortnoyÎncă nu există evaluări

- Deepwell Submersible Motor 50HzDocument38 paginiDeepwell Submersible Motor 50HzSujanto WidjajaÎncă nu există evaluări

- Annual Report 2010-11Document188 paginiAnnual Report 2010-11Suryanath Gupta100% (1)

- Justeq07 Product BulletinDocument1 paginăJusteq07 Product BulletinjusteqÎncă nu există evaluări

- Jettty DesignDocument14 paginiJettty DesignNnamani ajÎncă nu există evaluări

- Barossa ATV - Quaterback 250 E - Spare Parts List PDFDocument45 paginiBarossa ATV - Quaterback 250 E - Spare Parts List PDFgabysurfÎncă nu există evaluări

- Datavideo Dac10Document2 paginiDatavideo Dac10misliosÎncă nu există evaluări

- How-To Guide: Transaction Launcher (SAP CRM 7.0) .0Document22 paginiHow-To Guide: Transaction Launcher (SAP CRM 7.0) .0Satish DhondalayÎncă nu există evaluări

- Datasheet - HK f7313 39760Document7 paginiDatasheet - HK f7313 39760niko67Încă nu există evaluări

- أثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFDocument146 paginiأثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFNezo Qawasmeh100% (1)

- DatasheetDocument17 paginiDatasheetErnesto SuarezÎncă nu există evaluări

- Emission Test Station - Workshop: Multi-FuelDocument2 paginiEmission Test Station - Workshop: Multi-FuelARMANDO HERNANDEZÎncă nu există evaluări

- MEEN461 - FA17 - LAB01 - Intro To PLCs and LogixProDocument10 paginiMEEN461 - FA17 - LAB01 - Intro To PLCs and LogixProAngel Exposito100% (1)

- Cruise Control (3RZ-FE)Document6 paginiCruise Control (3RZ-FE)Esteban LefontÎncă nu există evaluări

- 7.4.1.2 Packet Tracer - Skills Integration Challenge InstructionsDocument3 pagini7.4.1.2 Packet Tracer - Skills Integration Challenge InstructionsJerry FullerÎncă nu există evaluări

- Background of UNITAR International UniversityDocument3 paginiBackground of UNITAR International UniversityAin NadiaÎncă nu există evaluări

- Dental Chair: A-Dec Service Guide, Vol. IIDocument40 paginiDental Chair: A-Dec Service Guide, Vol. IIQuang Định ĐinhÎncă nu există evaluări

- Ansi z245 2 1997Document31 paginiAnsi z245 2 1997camohunter71Încă nu există evaluări

- Travel Fellowship Application FormDocument4 paginiTravel Fellowship Application FormAsma100% (1)

- Shot PeeningDocument5 paginiShot Peeningcaddcentre velacheryÎncă nu există evaluări

- ABS Buckling Requirements For OffshoreDocument94 paginiABS Buckling Requirements For Offshorecurvedbrain100% (1)

- API Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug ValvesDocument15 paginiAPI Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug Valveskaveh-bahiraeeÎncă nu există evaluări

- CH 01Document28 paginiCH 01Deepu MaroliÎncă nu există evaluări

- Electrophoretic Display Technology The Beginnings, The Improvements, and A Future in Flexible ElectronicsDocument15 paginiElectrophoretic Display Technology The Beginnings, The Improvements, and A Future in Flexible Electronicsslysoft.20009951Încă nu există evaluări

- Mechanical Engineering Manufacturing.149Document1 paginăMechanical Engineering Manufacturing.149Anonymous QvIxEazXGdÎncă nu există evaluări

- ATB Riva Calzoni Gianluca RaseniDocument35 paginiATB Riva Calzoni Gianluca RaseniDiana QuinteroÎncă nu există evaluări

- Second Edition Handbook of PE Pipe - HDPE HandbookDocument3 paginiSecond Edition Handbook of PE Pipe - HDPE HandbooklucianoÎncă nu există evaluări

- Ample Sound Basics #1 ArpeggiosDocument37 paginiAmple Sound Basics #1 ArpeggiosWesleyÎncă nu există evaluări

- Sewa bill-AED 559Document1 paginăSewa bill-AED 559muhdazarÎncă nu există evaluări

- Pressure Vessel PDFDocument8 paginiPressure Vessel PDFdanielreyeshernandezÎncă nu există evaluări

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsDe la EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsÎncă nu există evaluări

- Civil Engineer's Handbook of Professional PracticeDe la EverandCivil Engineer's Handbook of Professional PracticeEvaluare: 4.5 din 5 stele4.5/5 (2)

- Real Life: Construction Management Guide from A-ZDe la EverandReal Life: Construction Management Guide from A-ZEvaluare: 4.5 din 5 stele4.5/5 (4)

- Even More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsDe la EverandEven More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsÎncă nu există evaluări

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationDe la EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettEvaluare: 4 din 5 stele4/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDe la EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyEvaluare: 4 din 5 stele4/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- Piping Engineering Leadership for Process Plant ProjectsDe la EverandPiping Engineering Leadership for Process Plant ProjectsEvaluare: 5 din 5 stele5/5 (1)

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessDe la EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessEvaluare: 5 din 5 stele5/5 (3)

- Estimating Construction Profitably: Developing a System for Residential EstimatingDe la EverandEstimating Construction Profitably: Developing a System for Residential EstimatingÎncă nu există evaluări

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDe la EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesÎncă nu există evaluări

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsDe la EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsEvaluare: 4.5 din 5 stele4.5/5 (6)

- Construction Management: Document to Reduce RiskDe la EverandConstruction Management: Document to Reduce RiskÎncă nu există evaluări

- Fire Protection Engineering in Building DesignDe la EverandFire Protection Engineering in Building DesignEvaluare: 4.5 din 5 stele4.5/5 (5)

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- The Homeowner's DIY Guide to Electrical WiringDe la EverandThe Homeowner's DIY Guide to Electrical WiringEvaluare: 5 din 5 stele5/5 (2)

- EMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeDe la EverandEMOTIONAL EATING: How To Stop Emotional Eating Naturally And Live A Better LifeEvaluare: 4 din 5 stele4/5 (14)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDe la EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyEvaluare: 4 din 5 stele4/5 (1)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesDe la EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesÎncă nu există evaluări