Documente Academic

Documente Profesional

Documente Cultură

PL Starting 8B - 1

Încărcat de

Pelis CloneDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PL Starting 8B - 1

Încărcat de

Pelis CloneDrepturi de autor:

Formate disponibile

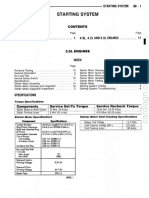

PL STARTING 8B - 1

STARTING

CONTENTS

page page

GENERAL INFORMATION STARTING SYSTEM TEST . . . . . . . . . . . . . . . . . 4

BOSCH STARTER . . . . . . . . . . . . . . . . . . . . . . . . 1 REMOVAL AND INSTALLATION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1 SAFETY SWITCHES . . . . . . . . . . . . . . . . . . . . . . 6

SUPPLY CIRCUIT AND CONTROL CIRCUIT . . . . 1 STARTER RELAY . . . . . . . . . . . . . . . . . . . . . . . . 7

DIAGNOSIS AND TESTING STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FEED CIRCUIT RESISTANCE TEST . . . . . . . . . . . 2 SPECIFICATIONS

FEED CIRCUIT TEST . . . . . . . . . . . . . . . . . . . . . . 2 STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

STARTER CONTROL CIRCUIT . . . . . . . . . . . . . . 1 TORQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GENERAL INFORMATION

INTRODUCTION

The starting system (Fig. 1) has:

• Ignition switch

• Starter relay

• Neutral starting and back up switch

• Clutch pedal position switch

• Wiring harness

• Battery

• Starter motor with an integral solenoid

BOSCH STARTER

The Bosch is a permanent magnet starter motor. A

planetary gear train transmits power between starter

motor and pinion shaft. The fields have six perma-

nent magnets. The starter system consists of two

separate circuits:

• A high amperage supply to feed the starter

motor.

• A low amperage circuit to control the starter

solenoid.

SUPPLY CIRCUIT AND CONTROL CIRCUIT

The starter system consists of two separate cir-

cuits:

• A high amperage supply to feed the starter

motor. Fig. 1 Starting System

• A low amperage circuit to control the starter

solenoid. • Neutral starting and back up switch with auto-

matic transmissions

• Clutch pedal position switch with manual trans-

DIAGNOSIS AND TESTING mission

• Ignition switch

STARTER CONTROL CIRCUIT • Battery

The starter control circuit has: • All related wiring and connections

• Starter solenoid

• Starter relay CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

8B - 2 STARTING PL

DIAGNOSIS AND TESTING (Continued)

To disable the ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for proper relay location.

FEED CIRCUIT RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition system also must be disabled

to prevent engine start while performing the follow-

ing tests.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

(a) Connect the negative lead of the voltmeter to Fig. 2 Test Battery Connection Resistance

the battery negative post, and positive lead to the

battery negative cable clamp (Fig. 2). Rotate and

hold the ignition switch in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp (Fig. 2). Rotate and hold

the ignition switch key in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between the cable clamp and

post.

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point (Fig.

3). Rotate and hold the ignition switch in the

START position. If voltage reads above 0.2 volt,

correct poor contact at ground cable attaching

point. If voltage reading is still above 0.2 volt after

correcting poor contacts, replace ground cable.

(3) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal (Fig. 4). Hold the ignition switch

key in the START position. If voltage reads above 0.2 Fig. 3 Test Ground Circuit Resistance

volt, correct poor starter to engine ground. (b) If resistance tests do not detect feed circuit

(a) Connect the positive voltmeter lead to the failures, replace the starter motor.

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid (Fig. 5). FEED CIRCUIT TEST

Rotate and hold the ignition switch in the START The following procedure will require a suitable

position. If voltage reads above 0.2 volt, correct volt-ampere tester (Fig. 6).

poor contact at battery cable to solenoid connec-

tion. If reading is still above 0.2 volt after correct- CAUTION: Before performing any starter tests, the

ing poor contacts, replace battery positive cable. ignition and fuel systems must be disabled.

PL STARTING 8B - 3

DIAGNOSIS AND TESTING (Continued)

Fig. 6 Volt Ampere Tester

Fig. 4 Test Starter Motor Ground

Fig. 7 Volt-Ampere Tester Connections

position or with the clutch pedal depressed and SET

parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(4) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

Fig. 5 Test Battery Positive Cable Resistance 6).

• If voltage reads above 9.6 volts, and amperage

(1) Connect a volt-ampere tester to the battery ter- draw reads above 280 amps or the Diesel engine

minals (Fig. 7). Refer to the operating instructions above 450 amps, check for engine seizing or faulty

provided with the tester being used. starter.

(2) To disable the ignition and fuel systems, dis- • If voltage reads 12.4 volts or greater and amper-

connect the Automatic Shutdown Relay (ASD). The age reads 0 to 10 amps, check for corroded cables

ASD relay is located in the Power Distribution Cen- and/or bad connections.

ter (PDC). Refer to the PDC cover for proper relay • Voltage below 9.6 volts and amperage draw

location. The 2.5L Diesel Engine, to disable the above 300 amps or Diesel engine above 500 amps,

engine from starting, disconnect wire connector from the problem is the starter. Replace the starter refer

the Fuel Solenoid. to starter removal.

(3) Verify that all lights and accessories are OFF, (5) After the starting system problems have been

and the transmission shift selector is in the PARK corrected, verify the battery state-of-charge and

8B - 4 STARTING PL

DIAGNOSIS AND TESTING (Continued)

charge battery if necessary. Disconnect all testing • Ignition Switch - Visually inspect the ignition

equipment and connect ASD relay or the Fuel Sole- switch for indications of physical damage and loose

noid. Start the vehicle several times to assure the or corroded wire harness connections.

problem has been corrected. • Clutch Pedal Position Switch - Visually

inspect the clutch pedal position switch for indica-

STARTING SYSTEM TEST tions of physical damage and loose or corroded wire

For circuit descriptions and diagrams, refer to harness connections.

8W-21, Starting System in Group 8W, Wiring Dia- • Park/Neutral Position Switch - Visually

grams. inspect the park/neutral position switch for indica-

tions of physical damage and loose or corroded wire

WARNING: ON VEHICLES EQUIPPED WITH AIR- harness connections.

BAGS, REFER TO GROUP 8M - PASSIVE • Starter Relay - Visually inspect the starter

RESTRAINT SYSTEMS BEFORE ATTEMPTING relay for indications of physical damage and loose or

STEERING WHEEL, STEERING COLUMN, OR corroded wire harness connections.

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR • Starter - Visually inspect the starter for indica-

SERVICE. FAILURE TO TAKE THE PROPER PRE- tions of physical damage and loose or corroded wire

CAUTIONS COULD RESULT IN ACCIDENTAL AIR- harness connections.

BAG DEPLOYMENT AND POSSIBLE PERSONAL • Starter Solenoid - Visually inspect the starter

INJURY. solenoid for indications of physical damage and loose

or corroded wire harness connections.

• Wiring - Visually inspect the wire harness for

INSPECTION

damage. Repair or replace any faulty wiring, as

Before removing any unit from the starting system

required.

for repair or diagnosis, perform the following inspec-

tions:

• Battery - Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer to Group 8A, Battery

for more information.

PL STARTING 8B - 5

DIAGNOSIS AND TESTING (Continued)

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO 1. Battery discharged or faulty. 1. Refer to Group 8A, Battery. Charge or replace

ENGAGE. 2. Starting circuit wiring faulty. battery, if required.

3. Starter relay faulty. 2. Refer to Feed Circuit Resistance Test and

4. Ignition switch faulty. Feed Circuit Test in this section.

5. Park/Neutral position switch 3. Refer to Relay Test, in this section. Replace

(auto trans) faulty or mis-adjusted. relay, if necessary.

6. Clutch pedal position switch 4. Refer to Ignition Switch Test, in Group 8D

(man trans) faulty. Ignition System or Group 8W, Wiring Diagrams.

7. Starter solenoid faulty. Replace switch, if necessary.

8. Starter assembly faulty. 5. Refer Park/Neutral Position Switch Test, in

Group 21, Transaxle. Replace switch, if

necessary.

6. Refer to Clutch Pedal Position Switch Test, in

Group 6, Clutch. Replace switch, if necessary.

7. Refer to Solenoid Test, in this section.

Replace starter assembly, if necessary.

8. If all other starting system components and

circuits check OK, replace starter assembly.

STARTER ENGAGES, 1. Battery discharged or faulty. 1. Refer to Group 8A, Battery. Charge or replace

FAILS TO TURN 2. Starting circuit wiring faulty. battery as necessary.

ENGINE. 3. Starter assembly faulty. 2. Refer to the Feed Circuit Resistance Test and

4. Engine seized. the Feed Circuit Test in this section. Repair as

necessary.

3. If all other starting system components and

circuits check OK, replace starter assembly.

4. Refer to Group 9 Engine, for diagnostic and

service procedures.

STARTER ENGAGES, 1. Broken teeth on starter ring gear. 1. Remove starter. Inspect ring gear and replace

SPINS OUT BEFORE 2. Starter assembly faulty. if necessary.

ENGINE STARTS. 2. If all other starting system components and

circuits check OK, replace starter assembly.

STARTER DOES NOT 1. Starter improperly installed. 1. Install starter. Tighten starter mounting

DISENGAGE. 2. Starter relay faulty. hardware to correct torque specifications.

3. Ignition switch faulty. 2. Refer to Relay Test, in this section. Replace

4. Starter assembly faulty. relay, if necessary.

3. Refer to Ignition Switch Test, in Group 8D,

Ignition System. Replace switch, if necessary.

4. If all other starting system components and

circuits check OK, replace starter assembly.

8B - 6 STARTING PL

REMOVAL AND INSTALLATION

SAFETY SWITCHES

For Removal and Installation of the:

• Clutch Position Switch, refer to Group 6, Clutch.

• Park/Neutral Switch, refer to Group 21, Tran-

saxle.

STARTER

REMOVAL

(1) Disconnect battery negative cable (Fig. 8).

(2) Raise vehicle.

(3) Vehicles equipped with A/C:

(a) Using a floor jack or jack stand, support the

engine and transmission assembly so they will not Fig. 9 Front Engine Mount Bolt Removal

rotate.

(b) Remove the front engine mount bolt from the

insulator and front crossmember mounting bracket

(Fig. 9).

(c) Lower the front of the engine, rotate the

engine forward, allowing easier removal of starter

motor.

(4) For easier servicing, do not remove the wiring

from starter at this time.

(5) Remove two bolts attaching starter to trans-

mission housing (Fig. 10).

(6) Remove starter/starter solenoid assembly from

transmission housing. Position the starter to gain

access to the wiring connectors.

(7) Remove the battery positive cable nut and

remove the battery positive and generator output

wire from the starter (Fig. 11).

(8) Disconnect push-on solenoid connector. Pull

back on slide and push down on rear tab to release

lock.

(9) Position the starter vertically such that the

pinion end faces downward.

(10) Remove the starter through the bottom of the

vehicle. Move aside A/C plumbing as necessary. Fig. 10 Starter Removal

(2) Connect the battery positive and generator out-

put wire to the starter solenoid post (Fig. 11).

CAUTION: It is critical that the generator output ter-

minal be connected to the battery positive terminal

of the starter solenoid, for proper operation of the

charging and cranking systems.

(3) Connect the push-on until fully engaged.

(4) Position the starter face into transmission

housing. Support starter in pilot and start the top

bolt (Fig. 10).

(5) Attach ground cable to lower mounting bolt

Fig. 8 Battery Cable Removal and Installation and start bolt.

INSTALLATION (6) Ensure the proper starter alignment before

(1) Clean corrosion/dirt from the cable and wire tightening the starter mounting bolts to 54 N·m (40

terminals before installing wiring to the solenoid. ft. lbs.) torque.

PL STARTING 8B - 7

REMOVAL AND INSTALLATION (Continued)

SPECIFICATIONS

STARTER

Manufacturer BOSCH

Engine Application 2.0L OHC - DOHC

Power rating 0 .95 Kw

Voltage 12 VOLTS

No. of Fields 6

No. of Poles 6

Brushes 4

Drive Planetary Gear Train

Cranking Amperage Draw 150 - 280 Amps.

test

Fig. 11 Wire Connection

(7) Vehicles equipped with A/C: Engine should be up to operating temperature.

(a) Using a floor jack or jack stand, raise the Extremely heavy oil or tight engine will increase

engine and transmission assembly to the original starter amperage draw.

position.

(b) Install the front engine mount bolt through TORQUE

the insulator and front crossmember mounting

bracket (Fig. 9). DESCRIPTION TORQUE

(c) Tighten bolt to 54 N·m (40 ft. lbs.) torque. Starter Mounting Bolts. . . . . . . . .54 N·m (40 ft. lbs.)

(8) Lower vehicle and connect battery cables. Starter Solenoid Battery Nut . . . .10 N·m (90 in. lbs.)

STARTER RELAY

The relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for relay location.

S-ar putea să vă placă și

- Group 14 Starting SystemDocument10 paginiGroup 14 Starting SystemMister_YÎncă nu există evaluări

- 98DN - 8B Starting SystemsDocument8 pagini98DN - 8B Starting SystemsylescorÎncă nu există evaluări

- TJ Starting Systems 8B - 1Document10 paginiTJ Starting Systems 8B - 1Art DoeÎncă nu există evaluări

- 6-06 Starting SystemDocument23 pagini6-06 Starting SystemJ.A.G.AÎncă nu există evaluări

- ZG Starting Systems 8B - 1Document14 paginiZG Starting Systems 8B - 1ensmartisÎncă nu există evaluări

- 1988 Chrysler LeBaron Convert/Coupe Starter GuideDocument6 pagini1988 Chrysler LeBaron Convert/Coupe Starter GuideJames PonzoÎncă nu există evaluări

- Voltage During CrankingDocument5 paginiVoltage During CrankingGomzalez Bin GembozÎncă nu există evaluări

- Starting System Diagnosis GuideDocument10 paginiStarting System Diagnosis GuideSomphorsÎncă nu există evaluări

- ChassisElectrical PDFDocument111 paginiChassisElectrical PDFDhany SiregarÎncă nu există evaluări

- Starting System Guide for Complete Diagnosis and RepairDocument14 paginiStarting System Guide for Complete Diagnosis and RepairLiliana Rebeca Santos santosÎncă nu există evaluări

- 1999 Jeep TJ Wrangler Service Manual - 08. Electrical SystemsDocument434 pagini1999 Jeep TJ Wrangler Service Manual - 08. Electrical Systemsbfranklin3390% (10)

- Testing The Starter On The Engine (1453,1450,1401)Document6 paginiTesting The Starter On The Engine (1453,1450,1401)Cristopher LaosÎncă nu există evaluări

- 1g Charging Starting System-1Document21 pagini1g Charging Starting System-1Anthony DizonÎncă nu există evaluări

- Basic TroubleshootingDocument3 paginiBasic TroubleshootingJeremy RydmanÎncă nu există evaluări

- Venox 16-18Document22 paginiVenox 16-18Fernando HenaoÎncă nu există evaluări

- WJ - 00 - 08B - Starting SystemDocument12 paginiWJ - 00 - 08B - Starting SystemCesar BartzÎncă nu există evaluări

- Maintenance Instruction For Superlight Sl-2Document15 paginiMaintenance Instruction For Superlight Sl-2Scripd4dogsonlyÎncă nu există evaluări

- BW125 - 150 Cap 16 (Imp Ricarica)Document8 paginiBW125 - 150 Cap 16 (Imp Ricarica)Franckie HyacintheÎncă nu există evaluări

- Start TestDocument2 paginiStart Testhelp3rÎncă nu există evaluări

- ZJ Starting Systems 8B - 1Document10 paginiZJ Starting Systems 8B - 1Dalton WiseÎncă nu există evaluări

- Hyundai Elantra 1.6 Engine Electrical1Document55 paginiHyundai Elantra 1.6 Engine Electrical1MANUALES2000CLÎncă nu există evaluări

- AGILITY50 Cap 16 (Imp Avviamento)Document6 paginiAGILITY50 Cap 16 (Imp Avviamento)api-3759317Încă nu există evaluări

- KXR50 Cap 14 (Imp Ricarica)Document12 paginiKXR50 Cap 14 (Imp Ricarica)tutifruti649Încă nu există evaluări

- Keeway Focus Matrix Electrical System SchemaDocument12 paginiKeeway Focus Matrix Electrical System SchemaugoranÎncă nu există evaluări

- Engine Electrical System OverviewDocument28 paginiEngine Electrical System Overview2791957Încă nu există evaluări

- Cb750 Service 2Document136 paginiCb750 Service 2gabimaier31Încă nu există evaluări

- Experiment Laboratory Report No.3 DraftDocument8 paginiExperiment Laboratory Report No.3 DraftSherwin CaringalÎncă nu există evaluări

- Starter Circuit TroubleshootingDocument5 paginiStarter Circuit Troubleshootingeshopmanual limaÎncă nu există evaluări

- Power Seats: Aa BodyDocument20 paginiPower Seats: Aa BodyChristian MartinezÎncă nu există evaluări

- Danger Warning Caution: Safety InformationDocument7 paginiDanger Warning Caution: Safety InformationcombaheeÎncă nu există evaluări

- Engine Electrical System: General Ignition System Starting SystemDocument33 paginiEngine Electrical System: General Ignition System Starting SystemEduardo OlmosÎncă nu există evaluări

- Onan RV Troubleshooing GuideDocument17 paginiOnan RV Troubleshooing GuideJohn Larson100% (3)

- TS 15.12.1.3Document8 paginiTS 15.12.1.3frankhil ramosÎncă nu există evaluări

- Aprilia 3-Phase Recharging System DiagnosisDocument15 paginiAprilia 3-Phase Recharging System DiagnosisManuallesÎncă nu există evaluări

- Fuel Shutoff - TestDocument7 paginiFuel Shutoff - TestAdolfo Dario SaavedraÎncă nu există evaluări

- Cat 950GDocument10 paginiCat 950GManuel BarahonaÎncă nu există evaluări

- ChassisElectrical PDFDocument111 paginiChassisElectrical PDFdhanysiregarÎncă nu există evaluări

- Chassis ElectricalDocument111 paginiChassis Electricaltruckman1000Încă nu există evaluări

- Electric Starting System - Test: Testing and AdjustingDocument5 paginiElectric Starting System - Test: Testing and Adjustingmanuel100% (1)

- Technical Vocational Livelihood (TVL) : Automotive Servicing 9Document28 paginiTechnical Vocational Livelihood (TVL) : Automotive Servicing 9YvetteÎncă nu există evaluări

- Battery, Charging & AC Generator GuideDocument14 paginiBattery, Charging & AC Generator GuideStojanov MarjanÎncă nu există evaluări

- SM - 5 Jeep ElectricoDocument32 paginiSM - 5 Jeep Electricoedgar danielÎncă nu există evaluări

- ChargingDocument17 paginiChargingSJElliÎncă nu există evaluări

- Testes SensoresDocument8 paginiTestes SensoresArtur ValÎncă nu există evaluări

- STARTER MOTOR TEST PROCEDURE GUIDEDocument13 paginiSTARTER MOTOR TEST PROCEDURE GUIDEwei fooÎncă nu există evaluări

- Systems OperationDocument29 paginiSystems OperationCristopher LaosÎncă nu există evaluări

- Alternator and RegulatorDocument6 paginiAlternator and Regulatorsonny1234Încă nu există evaluări

- Engine Electrical SystemDocument14 paginiEngine Electrical SystemMatthew Robert QuinnÎncă nu există evaluări

- Manual - Alternador Honda gx610Document3 paginiManual - Alternador Honda gx610Crisz Giovanny Toapanta MedinaÎncă nu există evaluări

- DG Diagnosticsheet Eng3Document1 paginăDG Diagnosticsheet Eng3Alexander David Pino SalazarÎncă nu există evaluări

- Piaggio 3 Phase Charging CheckingDocument15 paginiPiaggio 3 Phase Charging Checkingminekkell1Încă nu există evaluări

- Actuator Calibration GEN IV - en-GBDocument5 paginiActuator Calibration GEN IV - en-GBIsos CellÎncă nu există evaluări

- Diagnosis and Testing BlazerDocument308 paginiDiagnosis and Testing BlazerAli Castillo100% (1)

- Diesel Engine Care and Repair: A Captain's Quick GuideDe la EverandDiesel Engine Care and Repair: A Captain's Quick GuideEvaluare: 5 din 5 stele5/5 (1)

- Op Amps: Design, Application, and TroubleshootingDe la EverandOp Amps: Design, Application, and TroubleshootingEvaluare: 5 din 5 stele5/5 (2)

- Switching in Electrical Transmission and Distribution SystemsDe la EverandSwitching in Electrical Transmission and Distribution SystemsÎncă nu există evaluări

- Transaxle: Description and Operation Brake Transmission Shift Interlock (Btsi) SystemDocument4 paginiTransaxle: Description and Operation Brake Transmission Shift Interlock (Btsi) SystemPelis CloneÎncă nu există evaluări

- Fig. 1 Vehicle Identification NumberDocument10 paginiFig. 1 Vehicle Identification NumberPelis CloneÎncă nu există evaluări

- PL Electrically Heated Systems 8N - 1Document4 paginiPL Electrically Heated Systems 8N - 1Pelis CloneÎncă nu există evaluări

- PL Horns 8G - 1Document4 paginiPL Horns 8G - 1Pelis CloneÎncă nu există evaluări

- Wheel Alignment Guide for Front and Rear SuspensionDocument54 paginiWheel Alignment Guide for Front and Rear SuspensionGuillermo UcÎncă nu există evaluări

- Transaxle: NV T350 (A-578) Manual TransaxleDocument120 paginiTransaxle: NV T350 (A-578) Manual TransaxlePelis CloneÎncă nu există evaluări

- PL Instrument Panel and Systems 8E - 1Document14 paginiPL Instrument Panel and Systems 8E - 1Pelis CloneÎncă nu există evaluări

- Lamps: Lamp DiagnosisDocument14 paginiLamps: Lamp DiagnosisPelis CloneÎncă nu există evaluări

- Epl 8w PDFDocument322 paginiEpl 8w PDFPelis CloneÎncă nu există evaluări

- Epl 22 PDFDocument14 paginiEpl 22 PDFPelis CloneÎncă nu există evaluări

- MANUFACTURER PLATE - . - . - . - . - . - . - . - . - . 2 Vehicle Identification Number - . - . - . - . - 1Document2 paginiMANUFACTURER PLATE - . - . - . - . - . - . - . - . - . 2 Vehicle Identification Number - . - . - . - . - 1CARLOSÎncă nu există evaluări

- Audio System Diagnostics and Repair GuideDocument6 paginiAudio System Diagnostics and Repair GuidePelis CloneÎncă nu există evaluări

- Guide to Clutch System Components, Diagnosis, and RepairDocument12 paginiGuide to Clutch System Components, Diagnosis, and RepairPelis CloneÎncă nu există evaluări

- Chrysler Neon 99 - Immobiliser SystemDocument4 paginiChrysler Neon 99 - Immobiliser SystemeephantomÎncă nu există evaluări

- PL Heating and Air Conditioning 24 - 1Document30 paginiPL Heating and Air Conditioning 24 - 1Pelis CloneÎncă nu există evaluări

- How to Replace Headlight Bulbs and Fog LampsDocument8 paginiHow to Replace Headlight Bulbs and Fog LampsPelis CloneÎncă nu există evaluări

- Power Door Lock and Remote Keyless Entry Troubleshooting GuideDocument6 paginiPower Door Lock and Remote Keyless Entry Troubleshooting GuidePelis CloneÎncă nu există evaluări

- PL Charging System 8C - 1Document12 paginiPL Charging System 8C - 1Pelis CloneÎncă nu există evaluări

- Windshield Wipers and WashersDocument10 paginiWindshield Wipers and WashersPelis CloneÎncă nu există evaluări

- Body Component Removal and Installation GuideDocument52 paginiBody Component Removal and Installation GuidePelis CloneÎncă nu există evaluări

- Epl 8m PDFDocument12 paginiEpl 8m PDFPelis CloneÎncă nu există evaluări

- PL Differential and Driveline 3 - 1Document16 paginiPL Differential and Driveline 3 - 1Pelis CloneÎncă nu există evaluări

- Optimize Your Braking KnowledgeDocument90 paginiOptimize Your Braking KnowledgePelis CloneÎncă nu există evaluări

- Epl 14 PDFDocument58 paginiEpl 14 PDFPelis CloneÎncă nu există evaluări

- PL Ignition System 8D - 1Document20 paginiPL Ignition System 8D - 1Pelis CloneÎncă nu există evaluări

- Emission Control Systems Guide for Diagnosing On-Board DiagnosticsDocument22 paginiEmission Control Systems Guide for Diagnosing On-Board DiagnosticsPelis CloneÎncă nu există evaluări

- Battery Charging Guide and Diagnosis TipsDocument10 paginiBattery Charging Guide and Diagnosis TipsPelis CloneÎncă nu există evaluări

- PL Cooling 7 - 1Document24 paginiPL Cooling 7 - 1Pelis CloneÎncă nu există evaluări

- Frame and BumpersDocument10 paginiFrame and BumpersPelis CloneÎncă nu există evaluări

- Wireless Battery ChargerDocument13 paginiWireless Battery ChargerAkshay Kashyap71% (7)

- High-Voltage Safety Improvement Design For ElectriDocument15 paginiHigh-Voltage Safety Improvement Design For ElectriVăn BảoÎncă nu există evaluări

- Sager - m72s EsmDocument88 paginiSager - m72s EsmDonÎncă nu există evaluări

- Bird ManualDocument144 paginiBird ManualVijay KumarÎncă nu există evaluări

- Toyota Intelligent Tester II User ManualDocument131 paginiToyota Intelligent Tester II User Manualjorge morilloÎncă nu există evaluări

- Emergency Power Battery PDFDocument23 paginiEmergency Power Battery PDFJanitha HettiarachchiÎncă nu există evaluări

- Batteries - ppt-56543312Document18 paginiBatteries - ppt-56543312fuobvjogbÎncă nu există evaluări

- User Guide: Battery Diagnostic Service SystemDocument21 paginiUser Guide: Battery Diagnostic Service SystemМихаил КулигинÎncă nu există evaluări

- User Guide: Trimble Netr9 Gnss Reference ReceiverDocument32 paginiUser Guide: Trimble Netr9 Gnss Reference ReceiverTony AzizÎncă nu există evaluări

- Brosur Battery Enersys 12 TD 100F4Document2 paginiBrosur Battery Enersys 12 TD 100F4Lawas UnikÎncă nu există evaluări

- Cembre Tools 203,205Document2 paginiCembre Tools 203,205Amol PATILÎncă nu există evaluări

- Install BatteryDocument3 paginiInstall BatteryTawatchai BoonpermÎncă nu există evaluări

- Service MA0235-01 CE-AS EnglishDocument77 paginiService MA0235-01 CE-AS EnglishРоманÎncă nu există evaluări

- VRLA Battery Specification and Performance GuideDocument2 paginiVRLA Battery Specification and Performance GuidelordkurÎncă nu există evaluări

- G5 Plus Troubleshooting Guide v0.1Document124 paginiG5 Plus Troubleshooting Guide v0.1Manuel ChavesÎncă nu există evaluări

- Zapi FC2125 CodesDocument9 paginiZapi FC2125 CodesDaniel PopescuÎncă nu există evaluări

- Datron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualDocument28 paginiDatron PRC-BC4 Multiple Battery Charger - Operator and Technical ManualAlexander J RokowetzÎncă nu există evaluări

- Enmind: Instruction ManualDocument66 paginiEnmind: Instruction ManualElectromedicina CatanÎncă nu există evaluări

- Truealert Addressable Notification: FeaturesDocument6 paginiTruealert Addressable Notification: FeaturesJorge InostrozaÎncă nu există evaluări

- Panther-I Handheld Breathalyzer User GuideDocument36 paginiPanther-I Handheld Breathalyzer User GuideUlises Piscoya100% (1)

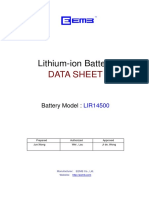

- EEMB LIR14500 Li-ion Battery Spec SheetDocument6 paginiEEMB LIR14500 Li-ion Battery Spec SheetFloyd PriceÎncă nu există evaluări

- Ev ChecklistDocument6 paginiEv Checklistsachin wankhedeÎncă nu există evaluări

- MSDS - Lsi 2022Document11 paginiMSDS - Lsi 2022rpkj7wysmvÎncă nu există evaluări

- Testo 175 H1 Data SheetDocument2 paginiTesto 175 H1 Data SheetMohammadIsmailÎncă nu există evaluări

- CMVR Type Approval - Vehicle Level Tests: 2 Wheeler Battery Operated Vehicle (BOV)Document1 paginăCMVR Type Approval - Vehicle Level Tests: 2 Wheeler Battery Operated Vehicle (BOV)anandganesÎncă nu există evaluări

- Fuzetec 2023 PPTC CatalogDocument76 paginiFuzetec 2023 PPTC Catalogmichael'mic' samsonÎncă nu există evaluări

- Revolt UM RV400 91219 PDFDocument48 paginiRevolt UM RV400 91219 PDFjohnloganmac100% (1)

- ZHZ Industry LTD.: Model Description Picture Specification FOB Price (Usd) Package Pc/carto N Carton Size N.w/G. WDocument2 paginiZHZ Industry LTD.: Model Description Picture Specification FOB Price (Usd) Package Pc/carto N Carton Size N.w/G. WSamy ChemalaÎncă nu există evaluări

- CR1-3N Li-MnO2 Battery (FDK America CR1 - 3N)Document1 paginăCR1-3N Li-MnO2 Battery (FDK America CR1 - 3N)MedSparkÎncă nu există evaluări

- Narada 12NDT190 ArgDocument2 paginiNarada 12NDT190 ArgAriel PerezÎncă nu există evaluări