Documente Academic

Documente Profesional

Documente Cultură

APH Data Sheet Format 1

Încărcat de

Joydev GangulyDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

APH Data Sheet Format 1

Încărcat de

Joydev GangulyDrepturi de autor:

Formate disponibile

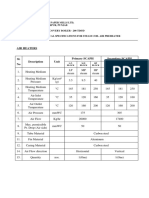

FORMAT – 1

Unit :Capacity : 250 MW Date : 22.03.2018

Load :200 MW Steam flow : 650 TPH

Coal fired :100 % Indian coal / Indian coal blended with ...0.. % imported coal

APH size : 27.5 VIMT 2000 (720 PA)

Heating elements - Hot end : 0.8 mm- DU profile, Carbon steel, 850 mm element height.

Hot intermediate : 0.8 mm- DU profile, Carbon steel, 850 mm element height.

Cold end : 1.2 mm- NF6 profile, Corten steel, 300 mm element height.

Drive unit : 11 KW, 1500 RPM, 415 V, 3Phase, 50 Hz.

No. of sectors in Rotor : Trisector

SCAPH : Not available

(please get APH data sheet for our reference).

Sl. PARAMETERS Design Actual

TEMPERATURES - C APH A APH B

01 Flue gas – Inlet 293 270

02 Flue gas - Outlet 142 140

03 Primary Air – Inlet 44 44

04 Primary Air - Outlet 260 262

05 Secondary Air – Inlet 36 36

06 Secondary Air - Outlet 265 264

PRESSURE - mmwc

07 Flue gas – Inlet -45 to -51 -31 to -49

08 Flue gas - outlet -172 to -179 -173 to -177

09 Primary air – inlet 755 to 768 758 to 773

10 Primary air - outlet 713 to 732 708 to 734

11 Secondary air - inlet 244 to 257 253 to 264

12 Secondary air side - outlet 80 to 108 81 to 102

13 Primary air – Header Pressure 687 to 711

FANS A B

14 PA Fan Current & GV Position 53 Amps / 10.3 % 53 Amps / 32.9 %

15 FD Fan Current & GV Position 26 Amps / 47.6 % 26 Amps / 46.8 %

16 ID Fan IGV %, VFD Current & speed 52.3%/145Amps/65% scoop 55%/83Amps/26% scoop

17 MILLS

Mills in Operation A B C

Mill Current - Amps 36 40 39

Mill inlet air temperature - C 121 171 170

Mill outlet temperature - C 76 77 79

Bharat Heavy Electricals Limited Page 1 of 2

FORMAT – 1

Unit :Capacity : 250 MW Date : 22.03.2018

Load :200 MW Steam flow : 650 TPH

Coal fired :100 % Indian coal / Indian coal blended with ...0.. % imported coal

Mill air Flow - T/Hr 61 66 67

18 Total secondary air flow - T/hr 505

19 Total coal flow – T/hr 90

20 O2 at APH inlet 4.55% 3.76%

20.8% (suspected error

21 O2 at APH outlet 4.65%

value)

SL Equipments Design Actual

Soot blower Assy

21 Steam pressure – kg / sqcm

22 Steam temperature – Deg.C

23 Duration of operation – minutes

24 Frequency of operation per day

25 Condition of Condensate auto drain

26.Indian coal analysis

Moisture: SM = 2.4 % , TM = 5.0 % Ash = 32.6% Volatile Matter= 26.4 %

GCV (TM Basis) = 5143

Fixed carbon = % S%=

Kcal/Kg

27. Imported coal analysis

Moisture: SM = % ,TM= % Ash = % Volatile Matter= %

GCV(TM Basis) =

Fixed carbon= % S%=

Kcal/Kg

Signature

Bharat Heavy Electricals Limited Page 2 of 2

S-ar putea să vă placă și

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- VT Report SampleDocument38 paginiVT Report SampleRohit BaruaÎncă nu există evaluări

- Udaipur Cement Works LimitedDocument17 paginiUdaipur Cement Works LimitedBülent BulutÎncă nu există evaluări

- Boiler Operating ParametersDocument1 paginăBoiler Operating ParametersAmbati Siva Kumar Reddy100% (1)

- Traning Material Gatecycle LabuanDocument48 paginiTraning Material Gatecycle LabuanyoyoÎncă nu există evaluări

- DatasheetsDocument10 paginiDatasheetsArslan NisarÎncă nu există evaluări

- Air-Cooled Series R (TM) Product ReportDocument2 paginiAir-Cooled Series R (TM) Product ReportBernard Bonnin CervantesÎncă nu există evaluări

- Boiler MIURA - LX-300-16Document2 paginiBoiler MIURA - LX-300-16LuizPauloCostaÎncă nu există evaluări

- Wärtsilä 18V50DF engine technical dataDocument3 paginiWärtsilä 18V50DF engine technical dataAniket Gaikwad100% (1)

- 0694-VU-40-PE.xlsxDocument2 pagini0694-VU-40-PE.xlsxRufus D SÎncă nu există evaluări

- Boiler & Turbine Efficiency: Rohit Verma Dy - Director NPTI, FaridabadDocument77 paginiBoiler & Turbine Efficiency: Rohit Verma Dy - Director NPTI, FaridabadLakshya Soni100% (3)

- 005.heat Balance - New - 22.06.2023hoDocument31 pagini005.heat Balance - New - 22.06.2023hoGauranka MoranÎncă nu există evaluări

- Presentation - Ruby II - Fso Bd01 - Fpso Lam SonDocument127 paginiPresentation - Ruby II - Fso Bd01 - Fpso Lam SonRubyÎncă nu există evaluări

- Operation Procedure: 1 P.B.MohapatraDocument8 paginiOperation Procedure: 1 P.B.MohapatraSanjay SharmaÎncă nu există evaluări

- Vocational Training at CESC's 750MW Budge Budge Power PlantDocument45 paginiVocational Training at CESC's 750MW Budge Budge Power PlantRohit BaruaÎncă nu există evaluări

- Basic-01 - General Description of CCPPDocument18 paginiBasic-01 - General Description of CCPPMohammed LamineÎncă nu există evaluări

- Model: C2250 D5 Frequency: 50 HZ Fuel Type: Diesel: Generator Set Data SheetDocument3 paginiModel: C2250 D5 Frequency: 50 HZ Fuel Type: Diesel: Generator Set Data Sheetarshadtabassum782Încă nu există evaluări

- CESC LTD Converted 1Document40 paginiCESC LTD Converted 1Sparsh GuptaÎncă nu există evaluări

- Thermal performances for one boilerDocument1 paginăThermal performances for one boilerJosé Pedro MagalhãesÎncă nu există evaluări

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFDocument24 paginiV94.2 Beggenum Experience & Improve Concept For Syngas Application PDFEliyanto E BudiartoÎncă nu există evaluări

- Rah 563 Ce Heating Element 35 Non Enamelled 1566626618Document4 paginiRah 563 Ce Heating Element 35 Non Enamelled 1566626618Senthil KumarÎncă nu există evaluări

- 200 MWDocument36 pagini200 MWphilocloudÎncă nu există evaluări

- GT Class TKGTPSDocument84 paginiGT Class TKGTPSGnanaseharan Arunachalam100% (1)

- Performance GNC 350 HP BarrickDocument2 paginiPerformance GNC 350 HP BarrickEnrique RafaelÎncă nu există evaluări

- VU 40 Bi-drum Boiler SpecificationDocument27 paginiVU 40 Bi-drum Boiler SpecificationNatarajan AÎncă nu există evaluări

- Boiler Control Room Data for NALCO Damanjodi 200 TPH UnitsDocument1 paginăBoiler Control Room Data for NALCO Damanjodi 200 TPH Unitskoushikdey_2011Încă nu există evaluări

- Che 455 Fall 2009 Major 1 Phthalic Anhydride Production: BackgroundDocument20 paginiChe 455 Fall 2009 Major 1 Phthalic Anhydride Production: Backgroundاحمد الدلالÎncă nu există evaluări

- Cargo Oil Pump TurbineDocument16 paginiCargo Oil Pump TurbineNikolay KirovÎncă nu există evaluări

- Document Submission Status for Auxiliary Equipment SelectionDocument8 paginiDocument Submission Status for Auxiliary Equipment SelectionHai NguyenÎncă nu există evaluări

- UntitledDocument8 paginiUntitledPhepheronÎncă nu există evaluări

- MGS2800B (2.500 - 2.750 kVA)Document4 paginiMGS2800B (2.500 - 2.750 kVA)kesitiÎncă nu există evaluări

- Motor Scania 6cil B PDFDocument1 paginăMotor Scania 6cil B PDFEnzo MassagliaÎncă nu există evaluări

- Gen-Seal&cool-New - 500 MWDocument98 paginiGen-Seal&cool-New - 500 MWharisankar100% (2)

- Data Sheet - CompressorDocument2 paginiData Sheet - CompressorPruthviraj JuniÎncă nu există evaluări

- BPGDE - 15 Tons - Consolidated Customer PackageDocument7 paginiBPGDE - 15 Tons - Consolidated Customer Packagetc01Încă nu există evaluări

- Qatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1Document23 paginiQatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1varatharajan g rÎncă nu există evaluări

- R2 00 MGS2800HV (50Hz 10kV)Document4 paginiR2 00 MGS2800HV (50Hz 10kV)luat1983Încă nu există evaluări

- Celanova Faza 2 Chilleri: Selection: Compact Screw Compressors CS // CSVDocument3 paginiCelanova Faza 2 Chilleri: Selection: Compact Screw Compressors CS // CSVSladjan UgrenovicÎncă nu există evaluări

- RTAF - Air-Cooled Series R (TM) Product ReportDocument2 paginiRTAF - Air-Cooled Series R (TM) Product ReportRafaelDutraÎncă nu există evaluări

- 6FA CC UnitDocument10 pagini6FA CC UnittonytrujilloÎncă nu există evaluări

- Super Critical Boiler Cycle GuideDocument32 paginiSuper Critical Boiler Cycle GuideJayaraman Kamaraj100% (1)

- Second Annual Conference on Carbon Sequestration Focuses on Hydrogen ProductionDocument27 paginiSecond Annual Conference on Carbon Sequestration Focuses on Hydrogen ProductionBangrivÎncă nu există evaluări

- Energy Performance Assessment of BoilersDocument17 paginiEnergy Performance Assessment of BoilersLohith KumarÎncă nu există evaluări

- Air-Cooled Series R (TM) CRTAG145 Product Report - Rev01aDocument2 paginiAir-Cooled Series R (TM) CRTAG145 Product Report - Rev01aUrsula MottaÎncă nu există evaluări

- BIOGAS DRYER Technical ENrev5Document4 paginiBIOGAS DRYER Technical ENrev5Manikandan SWMSÎncă nu există evaluări

- Cooler-2 DiagramDocument3 paginiCooler-2 DiagramPraveen Singh Chouhan100% (1)

- Engineering Declaration Unit # 2 JindalDocument16 paginiEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- Datos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Document1 paginăDatos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Julio César Samamé VegaÎncă nu există evaluări

- Skikda Training CDU (Goal Content)Document26 paginiSkikda Training CDU (Goal Content)Mohamed OuichaouiÎncă nu există evaluări

- CDU IV Highlights 21-Feb'2024Document2 paginiCDU IV Highlights 21-Feb'2024Manjunath GangaramÎncă nu există evaluări

- Screenshot 2020-08-31 at 10.10.39 AMDocument24 paginiScreenshot 2020-08-31 at 10.10.39 AMS.SHANMUGA SABAREESANÎncă nu există evaluări

- Fuel Firing - Feeder SystemDocument335 paginiFuel Firing - Feeder Systemsrbehera1987Încă nu există evaluări

- AVU Critical EquipmentsDocument55 paginiAVU Critical EquipmentsmujeebtalibÎncă nu există evaluări

- Copeland 4re2-200a-Tsk-800 Article 1377777674228 en SsDocument1 paginăCopeland 4re2-200a-Tsk-800 Article 1377777674228 en SsGhulam HussainÎncă nu există evaluări

- Scaph SpecnDocument3 paginiScaph SpecnV U P RaoÎncă nu există evaluări

- T4900 T41200Document2 paginiT4900 T41200Grover CondoriÎncă nu există evaluări

- 2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Document59 pagini2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Tiara Noir100% (2)

- Boost Plant Efficiency and Reduce Emissions with Combustion OptimisationDocument88 paginiBoost Plant Efficiency and Reduce Emissions with Combustion OptimisationDSGÎncă nu există evaluări

- Inspection of Unfired Pressure Vessel Std-128Document34 paginiInspection of Unfired Pressure Vessel Std-128dyke_engg100% (1)

- Api 1104Document13 paginiApi 1104luisorduz70Încă nu există evaluări

- Inspection of Fans, Blowers, Gear Boxes & Agitators: Amended EditionDocument14 paginiInspection of Fans, Blowers, Gear Boxes & Agitators: Amended EditionJoydev GangulyÎncă nu există evaluări

- TCEQ 0724 Form InstructionsDocument7 paginiTCEQ 0724 Form InstructionsJoydev GangulyÎncă nu există evaluări

- Inspection of Rotating Equipment Components: Amended EditionDocument12 paginiInspection of Rotating Equipment Components: Amended EditionJoydev GangulyÎncă nu există evaluări

- Standard Procedure For Registration of E-Deed Through E-Registration ModuleDocument2 paginiStandard Procedure For Registration of E-Deed Through E-Registration ModuleShell VenkatÎncă nu există evaluări

- STD 126Document18 paginiSTD 126Joydev GangulyÎncă nu există evaluări

- Inspection OF Pipes, Valves and Fittings: OISD - 130Document28 paginiInspection OF Pipes, Valves and Fittings: OISD - 130Jesse Garcia OlmosÎncă nu există evaluări

- Recommended Spares for Electrostatic Precipitator AnnexureDocument1 paginăRecommended Spares for Electrostatic Precipitator AnnexureJoydev GangulyÎncă nu există evaluări

- Fire Protection Facilities FOR Port Oil Terminals: OISD-Guidelines-156 For Restricted Circulation OnlyDocument35 paginiFire Protection Facilities FOR Port Oil Terminals: OISD-Guidelines-156 For Restricted Circulation OnlyJoydev GangulyÎncă nu există evaluări

- Oisd List PDFDocument5 paginiOisd List PDFJoydev GangulyÎncă nu există evaluări

- STD 125Document18 paginiSTD 125Joydev GangulyÎncă nu există evaluări

- Annex 3 AphDocument2 paginiAnnex 3 AphJoydev GangulyÎncă nu există evaluări

- Name of EquipmentDocument3 paginiName of EquipmentJoydev GangulyÎncă nu există evaluări

- Annexure: Ii Recommended Spares (Mill Spares)Document2 paginiAnnexure: Ii Recommended Spares (Mill Spares)Joydev GangulyÎncă nu există evaluări

- ANNEXURE-I RECOMMENDED SPARES (BOILERDocument4 paginiANNEXURE-I RECOMMENDED SPARES (BOILERJoydev GangulyÎncă nu există evaluări

- (Supply Glow, Rectifier Blink) (Rectifier Glow) (Bat Charging & Bat Glow) (Aux Supply Glow) (Output Glow) (Inv & Static Switch Glow)Document1 pagină(Supply Glow, Rectifier Blink) (Rectifier Glow) (Bat Charging & Bat Glow) (Aux Supply Glow) (Output Glow) (Inv & Static Switch Glow)Joydev GangulyÎncă nu există evaluări

- Enq. SL - No. Offer SL - No. Item Description DRAWING NO Unit Qty Unit Rate Total PriceDocument1 paginăEnq. SL - No. Offer SL - No. Item Description DRAWING NO Unit Qty Unit Rate Total PriceJoydev GangulyÎncă nu există evaluări

- Note: Initial Cold Values Shall Be Taken Before Hydraulic Test and Hot Values Shall Be Taken at Near Full ParametersDocument5 paginiNote: Initial Cold Values Shall Be Taken Before Hydraulic Test and Hot Values Shall Be Taken at Near Full ParametersJoydev GangulyÎncă nu există evaluări

- Chemical CleaningDocument32 paginiChemical Cleaningkae kae100% (2)

- Turbine VDocument1 paginăTurbine VJoydev GangulyÎncă nu există evaluări

- Ventilation MCC - OSB-REARDocument1 paginăVentilation MCC - OSB-REARJoydev GangulyÎncă nu există evaluări

- Turbine VDocument3 paginiTurbine VJoydev GangulyÎncă nu există evaluări

- All Drawings 14.05.2013Document107 paginiAll Drawings 14.05.2013Joydev GangulyÎncă nu există evaluări

- PID feed water, auxiliary steam, and blowdown systemsDocument3 paginiPID feed water, auxiliary steam, and blowdown systemsJoydev GangulyÎncă nu există evaluări

- Blr. InsulationDocument2 paginiBlr. InsulationJoydev GangulyÎncă nu există evaluări

- Colour codes for Tubes & Pipes (BHEL) standardsDocument1 paginăColour codes for Tubes & Pipes (BHEL) standardsJoydev GangulyÎncă nu există evaluări

- Ventilation MCC - OSB-FRONTDocument1 paginăVentilation MCC - OSB-FRONTJoydev GangulyÎncă nu există evaluări

- Turbine MCC - 8ka (Front)Document1 paginăTurbine MCC - 8ka (Front)Joydev GangulyÎncă nu există evaluări

- Turbine MCC - 8ka (Rear)Document1 paginăTurbine MCC - 8ka (Rear)Joydev GangulyÎncă nu există evaluări

- Champagne Making Process: Benjamin CochainDocument13 paginiChampagne Making Process: Benjamin CochainSrikanth ReddyÎncă nu există evaluări

- Waste Management: Spoilage of LandscapeDocument7 paginiWaste Management: Spoilage of Landscapeshauryasahu2004Încă nu există evaluări

- Black Soldier Fly Larvae ManualDocument14 paginiBlack Soldier Fly Larvae ManualLeonardo Shibata100% (1)

- NPD High Level Status: Concept Development FeasibilityDocument22 paginiNPD High Level Status: Concept Development FeasibilityRaviÎncă nu există evaluări

- The Payment of Bonus Act 1965 PDFDocument30 paginiThe Payment of Bonus Act 1965 PDFappu kunda100% (1)

- Product and Service Costing: Job-Order System: Questions For Writing and DiscussionDocument22 paginiProduct and Service Costing: Job-Order System: Questions For Writing and Discussionsetiani putriÎncă nu există evaluări

- Chapter 11 Blood Specimen Handling: Phlebotomy, 5e (Booth)Document35 paginiChapter 11 Blood Specimen Handling: Phlebotomy, 5e (Booth)Carol Reed100% (2)

- Spring Creek Sun August 27Document24 paginiSpring Creek Sun August 27amoses88Încă nu există evaluări

- 4th QUARTER EXAMINATION IN TLE 8Document3 pagini4th QUARTER EXAMINATION IN TLE 8judy ann sottoÎncă nu există evaluări

- Cooking - Sauces and Marinade RecipesDocument96 paginiCooking - Sauces and Marinade Recipesagape_1st7100% (3)

- Multiple Bank Accounts Registration FormDocument2 paginiMultiple Bank Accounts Registration FormAjith JainÎncă nu există evaluări

- Honey Nut Baklava Filo Pastry TreatsDocument2 paginiHoney Nut Baklava Filo Pastry TreatsiantperÎncă nu există evaluări

- OECD Guideline Toxicokinetics StudyDocument20 paginiOECD Guideline Toxicokinetics StudyChirag PatelÎncă nu există evaluări

- Rockaway Times 11-21-19Document44 paginiRockaway Times 11-21-19Peter MahonÎncă nu există evaluări

- UntitledDocument77 paginiUntitledVedranL84Încă nu există evaluări

- Herbal Abortifacient Drugs A ReviewDocument6 paginiHerbal Abortifacient Drugs A Reviewyogesh ushirÎncă nu există evaluări

- Bio Project-Polymerase Chain ReactionDocument21 paginiBio Project-Polymerase Chain ReactionS.AbiniveshÎncă nu există evaluări

- Household Chemical Poisoning GuideDocument9 paginiHousehold Chemical Poisoning GuideAshley DayagÎncă nu există evaluări

- Practical Laser Diodes GuideDocument4 paginiPractical Laser Diodes GuideM Xubair Yousaf XaiÎncă nu există evaluări

- Bar7 Menu 2023Document24 paginiBar7 Menu 2023Diana GamoteÎncă nu există evaluări

- Wheel Horse by YearDocument14 paginiWheel Horse by YearNeil SmallwoodÎncă nu există evaluări

- Cooling & Heating: ShellmaxDocument3 paginiCooling & Heating: Shellmaxvijaysirsat2007Încă nu există evaluări

- Vodafone Idea Limited: PrintDocument2 paginiVodafone Idea Limited: PrintPrakhar KapoorÎncă nu există evaluări

- Airtel's Africa Growth: Surviving CompetitionDocument9 paginiAirtel's Africa Growth: Surviving CompetitionSagar RiazÎncă nu există evaluări

- Evonik-BREAK THRU Brochure Microbials EN Asset 2214205Document5 paginiEvonik-BREAK THRU Brochure Microbials EN Asset 2214205李雷Încă nu există evaluări

- Children's Test Anxiety Scale (CTASDocument10 paginiChildren's Test Anxiety Scale (CTASSchahyda ArleyÎncă nu există evaluări

- PDI Quality Manual Rev 4 - 1.0 Table of ContentsDocument1 paginăPDI Quality Manual Rev 4 - 1.0 Table of ContentslouieÎncă nu există evaluări

- Silver Chloride Dissolution in ARDocument5 paginiSilver Chloride Dissolution in ARAFLAC ............Încă nu există evaluări

- Adapted Sports & Recreation 2015: The FCPS Parent Resource CenterDocument31 paginiAdapted Sports & Recreation 2015: The FCPS Parent Resource CenterkirthanasriÎncă nu există evaluări

- Frontline ArticleDocument7 paginiFrontline Articleapi-548946265Încă nu există evaluări