Documente Academic

Documente Profesional

Documente Cultură

3.fluid Power Engineering

Încărcat de

snemo30Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

3.fluid Power Engineering

Încărcat de

snemo30Drepturi de autor:

Formate disponibile

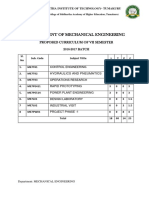

Government of Karnataka

Department of Technical Education

Board of Technical Examinations, Bengaluru

Course Title: Fluid Power Engineering Course Code: 15MC33T

Mode (L:T:P) : 4:0:0 Credits:4 Core/ Elective: Core

Type of Course: Lectures & Student Activities Total Contact Hours: 52

CIE= 25 Marks SEE= 100 Marks

Prerequisites: Knowledge of Applied Science

Course Objectives: Understand the properties of fluid, Components of fluid power system,

Engineering application of hydraulic and pneumatic systems

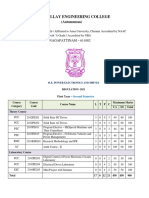

Course Outcome: At the end of the semester the students will be able to

1. Understand various technical terms associated with properties of fluid

2. Know the various components of fluid power system

3. Develop a hydraulic circuits for engineering applications

4. Develop a pneumatic circuits for engineering applications

Cognitive Linked Teaching Hours

Course Outcome with PO

Level

Understand various technical terms

associated with properties of fluid R/U 1,2 4

CO1

Know the various components of fluid

CO2 U 1,2 12

power system

Develop a hydraulic circuits for

CO3 engineering applications U/A 1,2 18

Develop a pneumatic circuits for

CO4 U/A 1,2 18

engineering applications

Total sessions 52

Legend: R; Remember, U: Understand A: Application

Directorate Of Technical Education Karnataka State 15MC33T Page 1

Mapping of Course Outcomes with Program Outcomes

Course Programme Outcomes

1 2 3 4 5 6 7 8 9 10

Fluid Power Engineering 3 3 - - - - - - - -

Level 3- Highly Addressed, Level 2-Moderately Addressed, Level 1-Low Addressed.

Method is to relate the level of PO with the number of hours devoted to the COs which address the given PO.

If >40% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 3

If 25 to 40% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 2

If 5 to 25% of classroom sessions addressing a particular PO, it is considered that PO is addressed at Level 1

If < 5% of classroom sessions addressing a particular PO, it is considered that PO is considered not-addressed.

Course Content and Weightage For SEE

Unit CO Hour Marks allocated for Marks

No Unit Name different Cognitive Weightage (%)

level Questions

R U A

Introduction to Fluid power 1 4 05 10 - 10.34

1

system

Components of fluid power 2 - 40 - 27.6

2

12

system

Basic oil power circuits 3 08 - 05 10 10.34

3

Engineering applications of 3 - 10 20 20.69

4

10

oil power system

5

Basic pneumatic circuits 4 08 05 10 10.34

Engineering applications of 4 - 10 20 20.69

6

10

pneumatic system

Total 52 145 Marks 100

Directorate Of Technical Education Karnataka State 15MC33T Page 2

Contents

Unit –I

Introduction to Fluid power system

Properties of fluids: Density, specific gravity, pressure, absolute pressure, gauge pressure, Kinetic

viscosity, absolute viscosity, Capillarity, surface tension. PASCAL’s law and Bernoulli’s theorem (No

derivation) applications of Bernoulli’s theorem, major losses and minor losses as fluid flows through a

pipe, Types of fluid power system: Oil power fluid system, Pneumatic system, Comparison of oil power

Fluid system and pneumatic system. .Advantages and applications of fluid power, Fluidics, coanda effect,

Fluid logic: AND and NOR Function, Pneumatic sensors: Interruptible jet sensor, Reflex sensor, Back

pressure sensor. 4Hours

Unit –II

Components of fluid power system

Single acting reciprocating pump, Centrifugal pump, vane pump and Gear pump, fluid reservoir, single

stage reciprocating air compressor, Centrifugal air compressors, Rotary vanes compressor, axial flow air

compressor, Twin lobe air compressor, screw compressor, filter, pressure regulator, lubricator, FLR Unit

in combination,2/2 spool type DC valves, 3/2 spool type DC valves, 5/2 spool type Dc valves, 5/2 pilot

operated DC valve, 5/3 Spool type DC valves, pressure reducing valve, pressure relief valve, pressure

intensifier, twin pressure valve, shuttle valve, flow control valves ,quick exhaust valve, time delay valve,

needle valve, check valve, DC valve actuation mechanism, spring ,lever, push button, solenoid, Gas

loaded accumulator, single acting and double fluid power cylinders.

12Hours

Unit –III

Basic oil power circuits

Circuit symbols for; Cylinders, Direction control valves, flow control valves, pressure control valves,

actuations such as mechanical control, electrical control, pressure control, actuation of single acting

cylinder, double acting cylinder. Circuit to actuate single acting and double acting cylinders, Circuit to

control speed of a single acting and double acting cylinder,(meter in meter out),

8Hours

Directorate Of Technical Education Karnataka State 15MC33T Page 3

Unit –IV

Engineering applications of oil power system

Pump unloading circuit, circuit to achieve faster extension as in drilling machine, counter balance valve

application as in power press to avoid free fall of hammer due to gravity, circuit to lock the cylinder using

pilot check valve to protect the piston rod from external forces on that, application of sequencing of

circuit as in case of punching machine to clamp the work piece and to perform punching operation, to

obtain automatic reciprocating of cylinders, fail safe circuit against over loading and to prevent injury to

the operator, accumulator circuit to store energy and supply when needed.

10Hours

Unit – V

Basic pneumatic circuits

Circuit to actuate single acting and double acting pneumatic cylinders ,Circuit to control speed of a single

acting and double acting cylinder,(meter in meter out),Pilot controlled double acting cylinder, circuit

for Double acting cylinder to advance by actuation of a solenoid valve and it’s retract

movements is delayed by time lag through a timer, 8Hours

Unit – VI

Engineering applications of pneumatic system

Circuit to Press fit a pin to a hole with a pre-condition that while actuating of the cylinder, both

the hands of the operator should be engaged (two handed safety circuits),A piston rod of a

double acting cylinder is to extend when two 3/2 DC valves are actuated if one of the 3/2DC

valve is released the cylinder returns to its initial position(AND function), A double acting

cylinder extends if one or both 3/2DC valve are operated. If both 3/2 DC valves are released then

cylinder retracts (OR function)

10Hours

Directorate Of Technical Education Karnataka State 15MC33T Page 4

References

1: Fluid power with applications - Anthony Esposito: Pearson prince hall,

2: Engineering fluid Mechanics - K L Kumar Eurasia publishing house private Ltd.( S Chand)

3: Hydraulics, Fluid Mechanics and Hydraulic Machines – Khurmi, S Chand and company

4: Pneumatic systems principles and maintenance – S.R. majumdar, tata McGraw hill education private

Ltd, New Delhi.

5. Hydraulic and pneumatic controls – K.Shanmuga sundaram,S. CHAND publications

6: Hydraulic and pneumatic – R.K. Hegde, Niranjan murthy, SAPNA Publication

e-References

1. http://www.nptel.ac.in/courses/112106175/Module%201/Lecture%201.pdf

2. http://www.asconumatics.eu/images/site/upload/_en/pdf1/00482gb.pdf

3. http://www.mdfirst.org/images/stories/documents_2012/Pneumatics-basics.pdf

4. http://www.festo.com/cat/en-in_in/products

5. http://www.janatics.com/products.htm

6. http://www.lagos.udg.mx/sites/default/files/Electroneumaticabasica(eng).pdf

Student Activity

Activity No Description of the Student Activity

1 Build a oil power circuit for an application beyond the curriculum and submit 2 to

3 pages hand written report

2 Build a pneumatic circuit for an application beyond the curriculum and submit 2 to

3 pages hand written report

Note:

1. Group of max four students should do any one of the above activity or any other similar

activity related to the course COs and get it approved from concerned Teacher and HOD.

2. No group should have activity repeated or similar

3. Teacher should ensure activities by group must cover all COs

4. Teacher should asses every student by using suitable Rubrics approved by HOD

Directorate Of Technical Education Karnataka State 15MC33T Page 5

Rubrics

Dimension

Exemplary Accomplished Developing Beginning Roll No. of the Student

5/4 3 2 1 1 2 3 4 5

Information Information in Difficult to Cannot Ex:

presented in logical follow understand

Organization logical, sequence presentation-- presentation-- 2

interesting student jumps no sequence

sequence around of

information

Subject Demonstrates At ease with Uncomfortable Does not 3

Knowledge full expected with have a grasp

knowledge by answers to information of the

answering all questions but and is able to information.

class does not answer only Cannot

questions with elaborate rudimentary answer

explanations questions questions

and about subject

elaborations

Explain and Relate to text Occasionally Uses 4

reinforce and uses graphics superfluous

Graphics screen text presentation that rarely graphics or

and support text no graphics

presentation and

presentation

Oral Maintains eye Maintains eye Occasionally Reads with 5

Presentation contact and contact most of uses eye no eye

pronounces all the time and contact, mostly contact and

terms pronounces reading incorrectly

precisely. All most words presentation, pronounces

audience correctly. Most and incorrectly terms. Speaks

members can audience pronounces too quietly

hear members can terms.

hear Audience

presentation members have

difficulty

hearing

Total Score=2+3+4+5=14/4=3.5=4

Directorate Of Technical Education Karnataka State 15MC33T Page 6

Institutional Activity

Activity No Description of the Institutional Activity

1 Organise seminar, workshop, lecture from eminent person in the following domain:

a) Recent trends in Low Cost Automation

b) Modern trends in Hydraulics and Pneumatics

c) Safety issues in Fluid Power System

b) Impact of oil power hydraulic systems on environment

c) Design for safety

e) Role of professional bodies in Automation such as institute of

engineers.

2 Organise nearby industrial visit

3 Motivate student to take case study on Low Cost Automation to inculcate self and

continuous learning

Course Assessment Pattern

Particulars Max Evidence Course

Marks outcomes

Direct Assessment CIE Three test 20 Blue books 1,2,3,4

(Average of

three tests)

Student 05 Student 1,2,3,4

Activity Activity

Sheets

SEE End of the 100 Answer scripts 1,2,3,4

course at BTE

Indirect Assessment Student Middle of the Feedback 1&2

Feedback course forms

on course

End of the Feedback 3&4

course forms

Note: I.A. test shall be conducted for 20 marks. Average marks of three tests shall be rounded off to

the next higher digit.

Directorate Of Technical Education Karnataka State 15MC33T Page 7

FORMAT OF I A TEST QUESTION PAPER (CIE)

Test/Date and Time Semester/year Course/Course Code Max Marks

Ex: I test/6 th weak of I/II SEM

20

sem 10-11 Am Year:

Name of Course coordinator : Units:__

CO’s:____

Question

Question MARKS CL CO PO

no

1

2

3

4

Note: Internal Choice may be given in each CO at the same cognitive level (CL).

Model Question Paper (CIE)

Date and Time Semester/year Course Max Marks

th

1 Test (6 weak of III SEM Fluid Power Engineering

20

sem) 10-11 Am Year: 2015-16 Course code:15MC33T

Name of Course coordinator : Units:1,2 CO: 1,2

All questions carries equal marks

Question

Question CL CO PO

No

1 Define kinematic and absolute viscosity of a fluid R 1 1,2

OR

Define density and specific gravity of a fluid

2 Explain the bernoulli’s theorem. U 1 1,2

OR

Compare oil power hydraulic system and pneumatic system

3 With a neat sketch explain working of single acting reciprocating pump U 2 1,2

OR

What is the necessity of fluid reservoir in oil power hydraulic system

4 With a neat sketch explain 3/2 spool type DC valve U 2 1,2

OR

With a neat sketch explain twin pressure valve

Directorate Of Technical Education Karnataka State 15MC33T Page 8

Model Question Paper

III Semester Diploma in Mechatronics Engineering

Fluid Power Engineering

Instructions: Answer any six questions from part A and Seven full questions from part B

PART-A

Answer any six questions. 5X6=30 marks

1. Define density and specific gravity of a fluid

2. Write a block diagram showing the components of oil power hydraulic system

3. With a neat sketch explain working of single acting reciprocating pump

4. Write a Circuit symbols for; Double acting Cylinders, 2/3Direction control valves, flow control

valves, pressure, compressor ,accumulator

5. Build a circuit to control forward speed of a single acting Hydraulic cylinder

6. Build a circuit to control forward speed of a Double acting Hydraulic cylinder

7. Build a circuit to actuate single acting Pneumatic cylinder

8. Build a circuit to control forward speed of a Double acting Pneumatic cylinder

9. Build a circuit for Pilot controlled double acting cylinder

PART- B

Answer any seven full questions. 10X7=70M

1. a) Explain Bernoulli’s theorem

b) Explain coanda effect

2. a) With a neat sketch explain pressure regulator

b) With a neat sketch explain working of centrifugal air compressor

3. a) With a neat sketch explain 2/2 spool type DC valve

b) With a neat sketch explain oil lubricator

4. Identify the different components used in the given circuit

Directorate Of Technical Education Karnataka State 15MC33T Page 9

5. a) Build a Pump unloading circuit

b) Develop a circuit to control reverse speed of a double acting hydraulic cylinder

6. a) Build a circuit counter balance valve application as in power press to avoid free fall of hammer

due to gravity

b) Build a circuit to obtain automatic reciprocating of cylinders

7. a) Build a accumulator circuit to store energy and supply when needed

b) Build a circuit to lock the cylinder using pilot check valve to protect the piston rod from

External forces

8. Build a circuit for a piston rod of a double acting cylinder is to extend when two 3/2 DC

9. valves are actuated if one of the 3/2DC valve is released the cylinder returns to its initial

position(AND function)

10. Build a circuit for a double acting cylinder extends if one or both 3/2DC valve are

Operated. If both 3/2 DC valves are released then cylinder retracts (OR function)

*******************************************************

Directorate Of Technical Education Karnataka State 15MC33T Page 10

Model Question Bank

III Semester Diploma in Mechatronics Engineering

Fluid Power Engineering

Unit -I

Introduction to Fluid power system

Cognitive level- Remember

1. Define density and specific gravity of a fluid

2. Define capillarity and surface tension

3. State pascal’s law

4. State Bernoulli’s theorem

5. List applications of bernoulli’s theorem

6. List the advantages of fluid power system

7. List the applications of fluid power system in engineering

Cognitive level-Understanding

1. Explain absolute pressure and gauge pressure

2. Explain kinematic and absolute viscosity of a fluid

3. Explain the major losses and minor losses as fluid flows through a pipe

4. Compare oil power hydraulic system and pneumatic system

5. Explain coanda effect

6. With a neat sketch explain how AND logic function can be achieved using fluid

7. With a neat sketch explain how NOR logic function can be achieved using fluid

8. With a neat sketch explain interruptable jet sensor

9. With a neat sketch explain reflex sensor

10. With a neat sketch explain back pressure sensor

Unit -II

Components of fluid power system

Cognitive level-Understanding

1. Write a block diagram showing the components of oil power hydraulic system

2. Write a block diagram showing the components of pneumatic power system

3. With a neat sketch explain working of single acting reciprocating pump

4. With a neat sketch explain working of centrifugal pump

5. With a neat sketch explain working of vane pump

6. With a neat sketch explain working of gear pump

7. What is the necessity of fluid reservoir in oil power hydraulic system

8. With a neat sketch explain working of single acting reciprocating air compressor

9. With a neat sketch explain working of centrifugal air compressor

10. With a neat sketch explain working of rotary vane air compressor

11. With a neat sketch explain working of axial flow air compressor

12. With a neat sketch explain working of twin lobe air compressor

13. With a neat sketch explain working of screw air compressor

14. With a neat sketch explain air filter

15. With a neat sketch explain pressure regulator

16. With a neat sketch explain oil lubricator

Directorate Of Technical Education Karnataka State 15MC33T Page 11

17. Explain the necessity of the FRL Unit in a pneumatic system

18. With a neat sketch explain 2/2 spool type DC valve

19. With a neat sketch explain 3/2 spool type DC valve

20. With a neat sketch explain 5/2 spool type DC valve

21. With a neat sketch explain 5/2 pilot operated DC valve

22. With a neat sketch explain 5/3 spool type DC valve

23. With a neat sketch explain flow control valve

24. With a neat sketch explain pressure reducing valve

25. With a neat sketch explain pressure relief valve

26. With a neat sketch explain pressure intensifier

27. With a neat sketch explain twin pressure valve

28. With a neat sketch explain shuttle valve

29. With a neat sketch explain quick exhaust valve

30. With a neat sketch explain time delay valve

31. With a neat sketch explain needle valve

32. With a neat sketch explain check valve

33. Explain the various mechanical actuation of DC valve

34. Sketch and explain the solenoid actuation of DC valve

35. Explain is the purpose of accumulator in fluid power system

36. With a neat sketch explain gas loaded accumulator

37. With a neat sketch explain single acting fluid power cylinder

38. With a neat sketch explain double acting fluid power cylinder

Unit -III

Basic oil power circuits

Cognitive level-Understanding

1. Write a Circuit symbols for; Cylinders, Direction control valves, flow control valves, pressure

control valves, actuations such as mechanical control, electrical control, pressure control,

actuation of single acting cylinder, double acting cylinder

Cognitive level-Application

1. Build a circuit to actuate single acting Hydraulic cylinder

2. Build a circuit to control forward speed of a single acting Hydraulic cylinder

3. Build a circuit to control reverse speed of a single acting Hydraulic cylinder

4. Build a circuit to actuate Double acting Hydraulic cylinder

5. Build a circuit to control forward speed of a Double acting Hydraulic cylinder

6. Build a circuit to control reverse speed of a Double acting Hydraulic cylinder

7. Build a circuit for meter in and meter out of a Double acting Hydraulic cylinder

8. Build a circuit for meter in and meter out of a single acting Hydraulic cylinder

Directorate Of Technical Education Karnataka State 15MC33T Page 12

Unit -IV

Engineering applications of oil power system

Cognitive level-Application

1. Build a Pump unloading circuit

2. Build a circuit to achieve faster extension as in drilling machine

3. Build a circuit counter balance valve application as in power press to avoid free fall of hammer

due to gravity

4. Build a circuit to lock the cylinder using pilot check valve to protect the piston rod from external

forces

5. Build a circuit for an application of sequencing of circuit as in case of punching machine to clamp

the work piece and to perform punching operation

6. Build a circuit to obtain automatic reciprocating of cylinders

7. Build a fail safe circuit against over loading and to prevent injury to the operator

8. Build a accumulator circuit to store energy and supply when needed

Unit -V

Basic pneumatic circuits

Cognitive level-Application

1. Build a circuit to actuate single acting Pneumatic cylinder

2. Build a circuit to control forward speed of a single acting Pneumatic cylinder

3. Build a circuit to control reverse speed of a single acting Pneumatic cylinder

4. Build a circuit to actuate Double acting Pneumatic cylinder

5. Build a circuit to control forward speed of a Double acting Pneumatic cylinder

6. Build a circuit to control reverse speed of a Double acting Pneumatic cylinder

7. Build a circuit for meter in and meter out of a Double acting Pneumatic cylinder

8. Build a circuit for meter in and meter out of a single acting Pneumatic cylinder

9. Build a circuit for Pilot controlled double acting cylinder

10. Build a circuit for Double acting cylinder to advance by actuation of a solenoid valve and

it’s retract movements is delayed by time lag through a timer

Unit -VI

Engineering applications of pneumatic system

Cognitive level-Application

1. Build a Circuit to Press fit a pin to a hole with a pre-condition that while actuating of the

cylinder, both the hands of the operator should be engaged (two handed safety circuits)

2. Build a circuit for a piston rod of a double acting cylinder is to extend when two 3/2 DC

valves are actuated if one of the 3/2DC valve is released the cylinder returns to its initial

position(AND function)

3. Build a circuit for a double acting cylinder extends if one or both 3/2DC valve are

operated. If both 3/2 DC valves are released then cylinder retracts (OR function)

Directorate Of Technical Education Karnataka State 15MC33T Page 13

S-ar putea să vă placă și

- Aeronautical Engineering Units 130710Document63 paginiAeronautical Engineering Units 130710maitham1000% (1)

- Gas-Liquid And Liquid-Liquid SeparatorsDe la EverandGas-Liquid And Liquid-Liquid SeparatorsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Course Outcome CL: CIE-25 Marks SEE-100 MarksDocument15 paginiCourse Outcome CL: CIE-25 Marks SEE-100 MarksSreedhar MÎncă nu există evaluări

- 2.industrial ElectronicsDocument12 pagini2.industrial ElectronicsNIKHIL ASÎncă nu există evaluări

- Hydraulics and Pneumatics SyllabusDocument2 paginiHydraulics and Pneumatics SyllabusMulu Girmay67% (3)

- Government of Karnataka Course on Transmission Distribution and UtilisationDocument24 paginiGovernment of Karnataka Course on Transmission Distribution and UtilisationVijaya BhaskerÎncă nu există evaluări

- 1.elements of Mechanical Engineering Science-1Document17 pagini1.elements of Mechanical Engineering Science-1Ashrit sarurÎncă nu există evaluări

- Industrial Drives CourseDocument22 paginiIndustrial Drives CourseVijaya BhaskerÎncă nu există evaluări

- Course Outcome CL: Board of Technical Examinations, BangaloreDocument13 paginiCourse Outcome CL: Board of Technical Examinations, BangaloreDarklightÎncă nu există evaluări

- Fluid Mechanics and Hydraulic Machines SyllabusDocument55 paginiFluid Mechanics and Hydraulic Machines SyllabusDeedad SaleemÎncă nu există evaluări

- Vel Tech High Tech DR - Ranagarajan DR - Sakunthala Engineering College - Department of ECEDocument27 paginiVel Tech High Tech DR - Ranagarajan DR - Sakunthala Engineering College - Department of ECEkarthikapecÎncă nu există evaluări

- Gujarat Technological University: W.E.F. AY 2018-19Document3 paginiGujarat Technological University: W.E.F. AY 2018-19Chandler BingÎncă nu există evaluări

- Lab Manual Hydraulics and Pneumatics .Document56 paginiLab Manual Hydraulics and Pneumatics .Aniket ChavanÎncă nu există evaluări

- Hyd & Pneumatics LabDocument6 paginiHyd & Pneumatics LabPepe AkashÎncă nu există evaluări

- Automotive Electrical and Elctronics SystemsDocument15 paginiAutomotive Electrical and Elctronics SystemsAmrithÎncă nu există evaluări

- Hyd& PneumaticsDocument18 paginiHyd& PneumaticssathishÎncă nu există evaluări

- BE MechanicalDocument162 paginiBE Mechanicalsatish kurraÎncă nu există evaluări

- Marine Electrical Control Systems Eto PDFDocument2 paginiMarine Electrical Control Systems Eto PDFMohapatra Coaching centreÎncă nu există evaluări

- Gujarat Technological University: Semester - IV Subject Name: Oil Hydraulics and PneumaticsDocument4 paginiGujarat Technological University: Semester - IV Subject Name: Oil Hydraulics and PneumaticsNisarg ShahÎncă nu există evaluări

- 2 Basic Thermal Engg.Document19 pagini2 Basic Thermal Engg.Pepe AkashÎncă nu există evaluări

- UG Mechatronics Course Combines Mechanics & ElectronicsDocument3 paginiUG Mechatronics Course Combines Mechanics & ElectronicsAshutosh KumarÎncă nu există evaluări

- Hydraulic & Pneumatic Systems in Automotive VehiclesDocument2 paginiHydraulic & Pneumatic Systems in Automotive VehiclesWork WearautoÎncă nu există evaluări

- 3 (B) .Automotive Electronics (Elective)Document10 pagini3 (B) .Automotive Electronics (Elective)NIKHIL ASÎncă nu există evaluări

- 4360504Document9 pagini4360504Abhishek ThummarÎncă nu există evaluări

- Department of Technical EducationDocument21 paginiDepartment of Technical EducationVijaya BhaskerÎncă nu există evaluări

- 5th Sem Ee SyllabusDocument179 pagini5th Sem Ee SyllabusNeelakanth BenakalÎncă nu există evaluări

- Power Electronics Course OverviewDocument332 paginiPower Electronics Course OverviewpradeepÎncă nu există evaluări

- Birla Institute of Technology and Science-Pilani - Hyderabad CampusDocument3 paginiBirla Institute of Technology and Science-Pilani - Hyderabad CampusAgtÎncă nu există evaluări

- SONA COLLEGE LAB MANUAL FOR HYDRAULIC AND PNEUMATIC SYSTEMSDocument41 paginiSONA COLLEGE LAB MANUAL FOR HYDRAULIC AND PNEUMATIC SYSTEMSKanishk KannaÎncă nu există evaluări

- Course Title Advanced Fluid Mechanics Course Level: UG Credit Units: 04 Course Code: MAE304Document4 paginiCourse Title Advanced Fluid Mechanics Course Level: UG Credit Units: 04 Course Code: MAE304Surjit DuttaÎncă nu există evaluări

- Course Outline-Hydraulics and PneumaticsDocument2 paginiCourse Outline-Hydraulics and Pneumaticsmuru0105100% (1)

- Advanced Automotive SystemsDocument14 paginiAdvanced Automotive SystemsVikram Athreya VÎncă nu există evaluări

- GTU Bachelor Engineering Oil Hydraulics PneumaticsDocument3 paginiGTU Bachelor Engineering Oil Hydraulics PneumaticsPratik VishwakarmaÎncă nu există evaluări

- Building A DroneDocument15 paginiBuilding A DroneVarun RanaÎncă nu există evaluări

- 2171912Document3 pagini2171912Krupal VithlaniÎncă nu există evaluări

- SY BTech Mech Syllabus AutonomousDocument30 paginiSY BTech Mech Syllabus Autonomousjeetupatilp7Încă nu există evaluări

- 1 AC 200 282C ILT 001 Syllabus Introduction AppendicesDocument36 pagini1 AC 200 282C ILT 001 Syllabus Introduction AppendicesaaaguilarmÎncă nu există evaluări

- 3rd Year Copy 2Document43 pagini3rd Year Copy 2sai jaswanth putturuÎncă nu există evaluări

- Electrical Estimation and CostingDocument23 paginiElectrical Estimation and CostingPoojaym PoojaÎncă nu există evaluări

- Industrial Fluid Power (12242)Document23 paginiIndustrial Fluid Power (12242)gotu123Încă nu există evaluări

- B.Tech Chemical Engineering Syllabus 3rd SemesterDocument49 paginiB.Tech Chemical Engineering Syllabus 3rd SemesterAbhishek PaloÎncă nu există evaluări

- Minor Degree BE Electric-VehiclesDocument16 paginiMinor Degree BE Electric-VehiclesArun C DixitÎncă nu există evaluări

- Mechatronics 7th Sem PDFDocument3 paginiMechatronics 7th Sem PDFSourav Shukla100% (1)

- Lab No 7 - Introduction To Electro PneumaticsDocument4 paginiLab No 7 - Introduction To Electro PneumaticsMuhammad RafayÎncă nu există evaluări

- 2018 Syllabus 7th SEMDocument25 pagini2018 Syllabus 7th SEM18ME045Încă nu există evaluări

- EE428 Course Outline - IPC Spring 2022Document4 paginiEE428 Course Outline - IPC Spring 2022Skiwordy MediaÎncă nu există evaluări

- Fluid Power Engineering FPE 18ME55 Syllabus 2018 19Document3 paginiFluid Power Engineering FPE 18ME55 Syllabus 2018 19ChinthanÎncă nu există evaluări

- Progress Report on Auto Fuel Valve AnalysisDocument31 paginiProgress Report on Auto Fuel Valve AnalysisIkramÎncă nu există evaluări

- Automotive Electrical and Electronic SystemsDocument4 paginiAutomotive Electrical and Electronic SystemsVikram Athreya VÎncă nu există evaluări

- 20ME901 Automobile Engineering Unit 4Document90 pagini20ME901 Automobile Engineering Unit 46044 sriramÎncă nu există evaluări

- Nowledge of Science,: Course Outcome CLDocument15 paginiNowledge of Science,: Course Outcome CLAbhishek DadhichÎncă nu există evaluări

- R2021 PED 2 SemDocument18 paginiR2021 PED 2 SemStudents Xerox ChidambaramÎncă nu există evaluări

- Electrical Technical OfficerDocument35 paginiElectrical Technical Officerjefftec005Încă nu există evaluări

- Bachelor of Technology (Mechanical Engineering) Kurukshetra University, KurukshetraDocument12 paginiBachelor of Technology (Mechanical Engineering) Kurukshetra University, KurukshetraAaushKumarÎncă nu există evaluări

- Mech 2022Document476 paginiMech 2022Rahul HansdahÎncă nu există evaluări

- Computational Flow Modeling for Chemical Reactor EngineeringDe la EverandComputational Flow Modeling for Chemical Reactor EngineeringEvaluare: 3 din 5 stele3/5 (3)

- Process System Value and Exergoeconomic Performance of Captive Power PlantsDe la EverandProcess System Value and Exergoeconomic Performance of Captive Power PlantsÎncă nu există evaluări

- MecsyllDocument149 paginiMecsyllArun Kumar K NÎncă nu există evaluări

- Mecschsyll PDFDocument161 paginiMecschsyll PDFVinay V GowdaÎncă nu există evaluări

- METROLOGYDocument28 paginiMETROLOGYsnemo30Încă nu există evaluări

- Home Remedies For Gallstones - Top 10 Home RemediesDocument6 paginiHome Remedies For Gallstones - Top 10 Home Remediessnemo30Încă nu există evaluări

- Physics March 2014 Kannada Version PDFDocument8 paginiPhysics March 2014 Kannada Version PDFPrasad C MÎncă nu există evaluări

- Matlab ManualDocument43 paginiMatlab ManualvenkyeeeÎncă nu există evaluări

- Solid SolutionsDocument20 paginiSolid Solutionssnemo30Încă nu există evaluări

- Introduction To Modelling and SimulationDocument18 paginiIntroduction To Modelling and Simulationsnemo30Încă nu există evaluări

- Power Density FunctionDocument2 paginiPower Density Functionsnemo30Încă nu există evaluări

- History of Wind UsesDocument55 paginiHistory of Wind Usessnemo30Încă nu există evaluări

- Modeling & SimulationDocument51 paginiModeling & Simulationsnemo300% (1)

- Weibull StatisticsDocument5 paginiWeibull Statisticssnemo30Încă nu există evaluări

- An Open Letter - The HinduDocument3 paginiAn Open Letter - The Hindusnemo30Încă nu există evaluări

- An Open Letter - The HinduDocument3 paginiAn Open Letter - The Hindusnemo30Încă nu există evaluări

- Homebuilt Aircraft Drag ReductionDocument15 paginiHomebuilt Aircraft Drag ReductionYvess100% (2)

- HydraulicskoDocument12 paginiHydraulicskoJestan MagatÎncă nu există evaluări

- Butterfly Vale LossesDocument12 paginiButterfly Vale LossesNguyễn Thống NhấtÎncă nu există evaluări

- BaumannDocument5 paginiBaumannSergio RiveraÎncă nu există evaluări

- Conformal Mapping Techniques for Designing Efficient Wing ProfilesDocument13 paginiConformal Mapping Techniques for Designing Efficient Wing Profileschristos032Încă nu există evaluări

- PoF 15 High Speed Aerodynamics IDocument43 paginiPoF 15 High Speed Aerodynamics IglorfindelptÎncă nu există evaluări

- SATIP S 060 04 Plumbing FixturesDocument2 paginiSATIP S 060 04 Plumbing FixturesMuhammad Farukh ManzoorÎncă nu există evaluări

- Piping Isometric DrawingDocument90 paginiPiping Isometric DrawingAmi PutraÎncă nu există evaluări

- History and Trends of Fluid MechanicsDocument8 paginiHistory and Trends of Fluid MechanicsMd. Rahimul IslamÎncă nu există evaluări

- Inspection Form For Fire PumpDocument6 paginiInspection Form For Fire PumpRonny Aja100% (1)

- WGM MPFMDocument16 paginiWGM MPFMahcenenÎncă nu există evaluări

- Chemical Engineering Portal - How to Calculate NPSH of Pump with ExamplesDocument5 paginiChemical Engineering Portal - How to Calculate NPSH of Pump with ExamplesSo VonÎncă nu există evaluări

- Anexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Document1 paginăAnexo 2 - Hoja de Datos Valvula de Diagragma (30-XV-4069)Antezana RodriguezÎncă nu există evaluări

- Analysis of Compressible Flow in FUNDAMENTALS OF FLUID MECHANICSDocument210 paginiAnalysis of Compressible Flow in FUNDAMENTALS OF FLUID MECHANICSAjay kumar100% (1)

- Revised hydraulic suction lines parts listDocument3 paginiRevised hydraulic suction lines parts listOscar ItzolÎncă nu există evaluări

- Addenda Nominal - Composition Product - Form Spec - NoDocument12 paginiAddenda Nominal - Composition Product - Form Spec - NoAngelo MinatiÎncă nu există evaluări

- Torricelli's Theorem & Orifice Equation ExplainedDocument2 paginiTorricelli's Theorem & Orifice Equation ExplainedRoadmaster911Încă nu există evaluări

- Gear Pump Troubleshooting GuideDocument3 paginiGear Pump Troubleshooting GuideRALPH JULES SARAUSÎncă nu există evaluări

- Dryers, Fans Blowers, PumpsDocument31 paginiDryers, Fans Blowers, PumpsJay Pee Zey100% (1)

- Nsce 65-160 - 150 - P25VCC4Document4 paginiNsce 65-160 - 150 - P25VCC4Weird StrangerÎncă nu există evaluări

- Module HydraulicsDocument62 paginiModule HydraulicsTricia Mae CatapangÎncă nu există evaluări

- Abreviaturas de la Industria de VálvulasDocument3 paginiAbreviaturas de la Industria de VálvulasCarlos Alberto Pascual QuezadaÎncă nu există evaluări

- Sa (Valves and Fittings Exam)Document6 paginiSa (Valves and Fittings Exam)rajaksekar100% (2)

- Velocity MeasurementDocument3 paginiVelocity MeasurementSHERWIN MOSOMOSÎncă nu există evaluări

- Class 11422 Piping Design Limits and Component MaterialsDocument15 paginiClass 11422 Piping Design Limits and Component Materialsbsnegi111Încă nu există evaluări

- Checklist For Installation For Fire Fighting Piping System and Accessories Under GroundDocument1 paginăChecklist For Installation For Fire Fighting Piping System and Accessories Under Groundvishalkadam57Încă nu există evaluări

- Flow Through A Pipe Orifice Meter LabDocument8 paginiFlow Through A Pipe Orifice Meter LabHenDricky MagosiÎncă nu există evaluări

- Group 2 Main Circuit: 1. Suction and Delivery CircuitDocument3 paginiGroup 2 Main Circuit: 1. Suction and Delivery CircuitĐạt VươngÎncă nu există evaluări

- Hydril Blowout Preventers Ram Seal KitsDocument1 paginăHydril Blowout Preventers Ram Seal KitsJIN WANGÎncă nu există evaluări

- How Adding Drag Affects Paper Plane Flight DistanceDocument19 paginiHow Adding Drag Affects Paper Plane Flight DistancesuthasenasendramÎncă nu există evaluări