Documente Academic

Documente Profesional

Documente Cultură

Machines Application Notes Ask Application Submit Case History

Încărcat de

Nguyen ChuyenTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Machines Application Notes Ask Application Submit Case History

Încărcat de

Nguyen ChuyenDrepturi de autor:

Formate disponibile

Applications: Horizontal Pumps

Machines

Application Notes

Ask Application

Question

Submit Case History

A pump is a device that moves a gas or liquid from one area to an

This can be done by accelerating the liquid using centrifugal force

(centrifugal/rotodynamic pumps) or by grabbing a certain amoun

liquid and physically pushing it towards where it needs to go (pos

displacement pumps).

Pumps are perhaps the most widely used mechanical devices and

designs vary as much as their applications. They are used in dom

applications for washing machines, in municipalities for sewage a

water treatment management, in HVAC systems to control conde

collection, in industrial steam systems to return cooled water to th

(boiler feed pump), for irrigation, flood control, and even pumpin

out of your sinking ship. Some types of pumps are:

Centrifugal Pumps Positive Displacement Pumps

Overhung pump Reciprocating pump

Vertical pump Lobe pump

Split Case pump Helical pump

Between Bearing pump Screw pump

Diaphragm pump

Scroll pump

Peristaltic pump

Gear Pump

Nodding Donkey Pump

Centrifugal Pumps

Centrifugal pumps use a spinning propeller to increase the velocit

liquid. The propeller spins inside a chamber that has a larger volu

the outgoing pipes so that when the water, which is at an increas

velocity, enters the outgoing pipe it is funneled down, and thus

compressed. These pumps are generally classified as horizontal (p

above) or vertical (picture at top of page). Another common

classification/ nomenclature for these pumps is single stage versu

stage. The pump above is a single stage pump because the water

one impeller and then is ejected. In a multistage pump, the wate

pressure will be increased by one impeller and is then fed to anot

impeller to increase the pressure even more.

Centrifugal Pump Monitoring Options

440 Switch with External Sensor (Above)

Provides local contacts as well as 4-20mA output for interface wit

Sensor is located on pump while 440 switch is located in a more

electronic friendly environment.

SA6200 and 5535

Provides 4-20mA output for interface with a PLC / DCS. Dynamic

available from front panel for vibration analysis purposes. Provide

options for custom filters, local display/indication, or galvanic isola

ST5484E / ST5491E

The ST5484E provides for the simplest installation available. Since

loop-powered device, only two wires are needed for full operation

ST5484E is connected directly to a PLC / DCS. Optional filtering a

dynamic outputs are available. The ST5491E has a local indicator

Special Case - Large Vertical Pumps

Large pump applications, such as the one shown above, require a

thorough monitoring scheme than smaller applications. For exam

while it may be beneficial to monitor bearing temperatures of sma

pumps, it is a necessity for larger applications.

The Metrix solution provides a vibration sensor for all bearings, an

sensor to detect cavitations, and a DATAWATCH monitor. The

DATAWATCH monitors all vibration and temperature readings (inc

bearing RTDs and Motor Winding Temperatures [provided by oth

and compares them to pre-programmed setpoints in order to cha

state of Alarm and Danger relay outputs.

The DATAWATCH also provides trending of all signals, audit track

Ethernet and RS232/485 communications (Modbus/TCP), remova

memory storage, USB ports, and a color touch screen interface. M

can also provide junction boxes for wiring convenience as well as

DATAWATCH enclosures that are environmentally rated and have

inputs and outputs pre-wired to rear panel mounted terminal bloc

Special Case - Pumps with Journal Bearings

Some pumps, especially pumps that run at high speeds and / or h

loads, use journal bearings as opposed to rolling element bearing

Journal bearings use a layer of oil to isolate the shaft from the be

Therefore, the shaft is actually floating on a cushion of oil and ha

contact with any other metal. Because of the oil layer, a vibration

produced by the shaft does not have a path to travel to the mach

casing. That means that a seismic sensor placed on the case of th

cannot properly sense what is going on with the shaft.

This makes it necessary to use proximity sensors to detect shaft f

proximity probe mounts through the case of the machine and sen

position of the shaft relative to the probe tip. The pump casing ho

probe steady so that any movement in the shaft will cause the pr

probe / transmitter to give an indication. This type of measureme

termed “relative” because the shaft movement is being measured

relation to the machine casing.

Positive Displacement Pumps

Positive Displacement pumps handle liquids or gases in a much m

direct manner. These pumps use one of several methods to physi

grab a quantity of liquid and push it to where it needs to go. A

reciprocating pump operates in much the same way as a reciproc

compressor in that it uses a chamber filled with liquid (or gas) wh

compressed by a moving cylinder before the liquid is released into

delivery system (piping). Gear pumps, vane pumps, helical pumps

Peristaltic pumps all use interlocking / rotating parts between whi

is trapped between and then pushed out of.

Generally speaking, positive displacement pumps are too small to

damaging vibration or are so inexpensive that a vibration monitor

system is un-economical. That’s not to say that a situation will ne

come up in which a positive displacement pump needs to be mon

for vibration. In this case, please consult the Metrix factory for

monitoring options.

Products | Applications | Global Services | Customer Service | Quote Request | Contact Us |

Copyright ©2014 - Metrix Instrument Co., LP.

http://hardyinst.com/Applications/HorizontalPumps.aspx

S-ar putea să vă placă și

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesDe la EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesEvaluare: 5 din 5 stele5/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowDe la EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowEvaluare: 2 din 5 stele2/5 (1)

- Fluid machinery-2024S-CH342-2Document19 paginiFluid machinery-2024S-CH342-2ahmedhammad7838Încă nu există evaluări

- Process EquipmentsDocument277 paginiProcess EquipmentsnatarajaÎncă nu există evaluări

- Title: Introduction To Compressors, Fans and BlowersDocument74 paginiTitle: Introduction To Compressors, Fans and BlowersRishi Gethu MassÎncă nu există evaluări

- Different Types of Pumps - Centrifugal Pumps - Process Industry ForumDocument8 paginiDifferent Types of Pumps - Centrifugal Pumps - Process Industry ForumWin AlcaideÎncă nu există evaluări

- Pumps: Applications, Components, Types, WorkingDocument19 paginiPumps: Applications, Components, Types, WorkingHassan KafilÎncă nu există evaluări

- Performance Analysis of Reciprocating PumpDocument8 paginiPerformance Analysis of Reciprocating PumpMohamed HassanÎncă nu există evaluări

- Pumps TypesDocument14 paginiPumps TypesAbdallah Mansour100% (1)

- Pump Cuplings:: Centrifugal PumpsDocument5 paginiPump Cuplings:: Centrifugal PumpsSaswata PradhanÎncă nu există evaluări

- Pumps, Valves and CompressorDocument52 paginiPumps, Valves and CompressorAnonymous zUreJLmN100% (1)

- Term Paper: Fluid MechanicsDocument13 paginiTerm Paper: Fluid Mechanicsdharmendrarj_3Încă nu există evaluări

- Fluid Mechanics-1 Lab: Types of PumpsDocument5 paginiFluid Mechanics-1 Lab: Types of PumpsHamza MateenÎncă nu există evaluări

- PumpsDocument141 paginiPumpsissam elmoharirÎncă nu există evaluări

- Marine Auxiliary Machinery PDFDocument7 paginiMarine Auxiliary Machinery PDFReginÎncă nu există evaluări

- Centrifugal PumpsDocument4 paginiCentrifugal PumpsKalyani SSECÎncă nu există evaluări

- Study of A Centrifugal Pump, Pipe Fittings and Valves - Ch.E 206Document30 paginiStudy of A Centrifugal Pump, Pipe Fittings and Valves - Ch.E 206Synthia100% (1)

- Positive Displacement Pumps Selection Guide - Types, Features, ApplicationsDocument11 paginiPositive Displacement Pumps Selection Guide - Types, Features, Applicationsarunima04Încă nu există evaluări

- 1.2 Pumps PresentationDocument25 pagini1.2 Pumps PresentationKristian UretaÎncă nu există evaluări

- 1.2 Pumps PresentationDocument25 pagini1.2 Pumps PresentationKristian UretaÎncă nu există evaluări

- Pumps Fan BlowerDocument20 paginiPumps Fan BlowerUma GoÎncă nu există evaluări

- Pumps Fan BlowerDocument20 paginiPumps Fan BlowerUma GoÎncă nu există evaluări

- Project 2Document7 paginiProject 2Lalaine RamosÎncă nu există evaluări

- Hydraulics Microproject FinalDocument10 paginiHydraulics Microproject FinalVedant “21CE067 Vedant C. Khawale” KhawaleÎncă nu există evaluări

- Useful Information On Positive Displacement Pumps: 3wiseDocument1 paginăUseful Information On Positive Displacement Pumps: 3wisehumaÎncă nu există evaluări

- Useful Information On Centrifugal Pumps: 3wiseDocument1 paginăUseful Information On Centrifugal Pumps: 3wisehumaÎncă nu există evaluări

- PumpsDocument5 paginiPumpsMonicaa BautistaÎncă nu există evaluări

- A Small, Electrically Powered Pump: Positive Displacement PumpsDocument6 paginiA Small, Electrically Powered Pump: Positive Displacement PumpsabduÎncă nu există evaluări

- Waste WaterDocument18 paginiWaste WaterJelou SibiÎncă nu există evaluări

- Pumps: Tayyab-Ul-Islam 2K17-ESE-22 Muhammad Bilal 2K17-ESE-23 M. Fakhar Hayat 2K17-ESE-24Document22 paginiPumps: Tayyab-Ul-Islam 2K17-ESE-22 Muhammad Bilal 2K17-ESE-23 M. Fakhar Hayat 2K17-ESE-24Tayyab IslamÎncă nu există evaluări

- Pumps 04Document19 paginiPumps 04agrimÎncă nu există evaluări

- Types of Pumps: Working Principle of PumpDocument12 paginiTypes of Pumps: Working Principle of PumpFe CaprichoÎncă nu există evaluări

- Pumps N MechDocument17 paginiPumps N MechmeerhatÎncă nu există evaluări

- Fluid Mechanics Final Rep PDFDocument9 paginiFluid Mechanics Final Rep PDFGamal Ezat100% (1)

- Dosing Pumps (Metering Pumps) - Star Pump AllianceDocument2 paginiDosing Pumps (Metering Pumps) - Star Pump Alliancedattu33Încă nu există evaluări

- Introduction To Fluid PowerDocument55 paginiIntroduction To Fluid PowerAhmed MohamedÎncă nu există evaluări

- Report #2: The Disc FiltersDocument8 paginiReport #2: The Disc FiltersAli SharifÎncă nu există evaluări

- Auxiliary Machinery 1: L.O. 1.1 PumpsDocument54 paginiAuxiliary Machinery 1: L.O. 1.1 PumpsCharles VillaricoÎncă nu există evaluări

- PumpsDocument12 paginiPumpsFuatÎncă nu există evaluări

- Pumps MRPLDocument10 paginiPumps MRPLAnnamalai PalaniappanÎncă nu există evaluări

- Debre Berhan University: Instructor:-Ashenafi ADocument25 paginiDebre Berhan University: Instructor:-Ashenafi AhayliyesusÎncă nu există evaluări

- Group 4 Hydraulics 1Document14 paginiGroup 4 Hydraulics 1STOCK MSOWOYAÎncă nu există evaluări

- Pump Part 1Document82 paginiPump Part 1Amit KhadkaÎncă nu există evaluări

- Marine Auxiliary Machinery PDFDocument7 paginiMarine Auxiliary Machinery PDFMahmoud ElNaggar50% (2)

- Liquid Handling Pumps Information - Engineering360Document9 paginiLiquid Handling Pumps Information - Engineering360cristi.nicolaehotmail.comÎncă nu există evaluări

- Positive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitDocument9 paginiPositive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitMerie Ann Aumentado CallejaÎncă nu există evaluări

- 1) Hi Everyone. Today We Start A New Chapter Which Is Dedicated To Pumps. in ThisDocument4 pagini1) Hi Everyone. Today We Start A New Chapter Which Is Dedicated To Pumps. in ThisIdris IbrahimovÎncă nu există evaluări

- Experiment No. 1 Performance Test of Centrifugal PumpDocument24 paginiExperiment No. 1 Performance Test of Centrifugal PumpAli Requiso MahmudÎncă nu există evaluări

- Classification of PumpsDocument4 paginiClassification of Pumpsccmc.devmarineacademyÎncă nu există evaluări

- Introduction To FPSDocument32 paginiIntroduction To FPStmohanrajkecÎncă nu există evaluări

- Hydraulics MicroprojectDocument17 paginiHydraulics MicroprojectAkash ChourasiaÎncă nu există evaluări

- NOTES 9 (2023) TurbomachineryDocument22 paginiNOTES 9 (2023) TurbomachineryVinn GTÎncă nu există evaluări

- JJ 615 Mechanical Components & MaintenanceDocument36 paginiJJ 615 Mechanical Components & Maintenancedaussz60% (5)

- Rotary PumpsDocument3 paginiRotary Pumpspulkitkakkar998Încă nu există evaluări

- Pumps: Prepared by Rohit G. Sorte M.TechDocument33 paginiPumps: Prepared by Rohit G. Sorte M.TechdjeutcheuÎncă nu există evaluări

- What Is A Pump?Document11 paginiWhat Is A Pump?John John MarfalÎncă nu există evaluări

- Emergency Steering in ShipDocument34 paginiEmergency Steering in ShipMayilai AshokÎncă nu există evaluări

- Pumps Notes Level 1 REV 3Document10 paginiPumps Notes Level 1 REV 3Collins Obari AdiyeÎncă nu există evaluări

- Hydraulic Pumps: BY Abeesh Kiran A M-Tech Design and Precision Engineering Nitk Surathkal, KarnatakaDocument62 paginiHydraulic Pumps: BY Abeesh Kiran A M-Tech Design and Precision Engineering Nitk Surathkal, KarnatakaFaisal Rafique100% (1)

- Motor Data For 55798Document1 paginăMotor Data For 55798Nguyen ChuyenÎncă nu există evaluări

- Practices For Lurbricating Bearing in APIDocument6 paginiPractices For Lurbricating Bearing in APINguyen ChuyenÎncă nu există evaluări

- LGLT 2: Grease SelectionDocument4 paginiLGLT 2: Grease SelectionNguyen ChuyenÎncă nu există evaluări

- Pump PerformanceDocument25 paginiPump PerformanceNguyen ChuyenÎncă nu există evaluări

- Sound Pressure: Pa (20 Micro Pascal, 0.02 Mpa)Document3 paginiSound Pressure: Pa (20 Micro Pascal, 0.02 Mpa)Nguyen ChuyenÎncă nu există evaluări

- You Can Use The Following Formula For Determining Stiffening Frame SizeDocument1 paginăYou Can Use The Following Formula For Determining Stiffening Frame SizeNguyen ChuyenÎncă nu există evaluări

- 1,4-Butanediol: From Wikipedia, The Free EncyclopediaDocument11 pagini1,4-Butanediol: From Wikipedia, The Free EncyclopediaNguyen ChuyenÎncă nu există evaluări

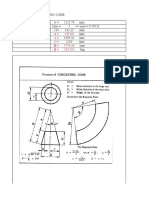

- Khai Trien Hinh ConeDocument4 paginiKhai Trien Hinh ConeNguyen ChuyenÎncă nu există evaluări

- Dynamic, Absolute and Kinematic ViscosityDocument8 paginiDynamic, Absolute and Kinematic ViscosityNguyen ChuyenÎncă nu există evaluări

- Specific Heat Capacities of AirDocument13 paginiSpecific Heat Capacities of AirNguyen ChuyenÎncă nu există evaluări

- Driving SystemDocument8 paginiDriving SystemNguyen ChuyenÎncă nu există evaluări

- DEMISTERDocument6 paginiDEMISTERNguyen ChuyenÎncă nu există evaluări

- 650-645 Design Requirements For Self-Supporting Roofs 9/24/07Document5 pagini650-645 Design Requirements For Self-Supporting Roofs 9/24/07Nguyen ChuyenÎncă nu există evaluări

- Catalog - Extrusion Piston Pump PDFDocument76 paginiCatalog - Extrusion Piston Pump PDFNguyen ChuyenÎncă nu există evaluări

- External Pressure: 1 - The Basics - Failure MechanismsDocument18 paginiExternal Pressure: 1 - The Basics - Failure MechanismsNguyen ChuyenÎncă nu există evaluări

- Demister (Vapor)Document6 paginiDemister (Vapor)Nguyen ChuyenÎncă nu există evaluări

- A203Grf, A203 GR.F, A203 GR F, Steel Plate - SteelmaterialDocument2 paginiA203Grf, A203 GR.F, A203 GR F, Steel Plate - SteelmaterialNguyen ChuyenÎncă nu există evaluări

- Compact Exchangers For Demanding ApplicationsDocument4 paginiCompact Exchangers For Demanding ApplicationsNguyen ChuyenÎncă nu există evaluări

- PumpDocument9 paginiPumpNguyen ChuyenÎncă nu există evaluări

- Heat Losses From Bare and Lagged Pipe: Ii. MaterialsDocument6 paginiHeat Losses From Bare and Lagged Pipe: Ii. MaterialsRyan VasquezÎncă nu există evaluări

- 2 3Document2 pagini2 3Nhimrod SanjoseÎncă nu există evaluări

- Process Flow DiagramDocument19 paginiProcess Flow DiagramKaycelyn Bacay100% (1)

- Glycol Dehydration Unit English A4 PDFDocument4 paginiGlycol Dehydration Unit English A4 PDFM Luthfi JundiaturridwanÎncă nu există evaluări

- Irs qb1Document4 paginiIrs qb1PachaiyappanRangaNathanÎncă nu există evaluări

- Seminar Om MBRDocument7 paginiSeminar Om MBRઅવિનાશ મીણા100% (1)

- What Is MatterDocument3 paginiWhat Is MatterGraziella Wayne MabulacÎncă nu există evaluări

- Parts Price ListDocument5.325 paginiParts Price ListAlva100% (1)

- Griffin 1976Document21 paginiGriffin 1976Manu K VasudevanÎncă nu există evaluări

- Polyethylene: Section GuideDocument31 paginiPolyethylene: Section GuidemjinspectorÎncă nu există evaluări

- Fundamentals of Pump and Fundamentals of Pump and Compressor Systems - ME-Compressor Systems - ME - 44 44Document4 paginiFundamentals of Pump and Fundamentals of Pump and Compressor Systems - ME-Compressor Systems - ME - 44 44Hayderr HassÎncă nu există evaluări

- Sewer Systems, Appurtenances, Construction and MaintenanceDocument16 paginiSewer Systems, Appurtenances, Construction and MaintenanceDexter Dwight Mendoza100% (1)

- AV-ME-WI-02 Operation Instruction For Fluid Bed DryerDocument4 paginiAV-ME-WI-02 Operation Instruction For Fluid Bed DryerjfejfeÎncă nu există evaluări

- Flow in PipesDocument35 paginiFlow in Pipesbernabas100% (1)

- SUEZ Brochure FGD ENDocument4 paginiSUEZ Brochure FGD ENKumarrathinamÎncă nu există evaluări

- Leaflet S23 2020 - Cavagna Pressure RegulatorDocument4 paginiLeaflet S23 2020 - Cavagna Pressure RegulatorWND PRTMÎncă nu există evaluări

- WATER SUPPLY (PDF - Io)Document34 paginiWATER SUPPLY (PDF - Io)Maher Abdullah100% (1)

- Rheology of Cross-Linked Poly (Sodium Acrylate) /sodium Silicate HydrogelsDocument9 paginiRheology of Cross-Linked Poly (Sodium Acrylate) /sodium Silicate HydrogelsRatri HiusenaÎncă nu există evaluări

- 11502Document9 pagini11502balajivangaruÎncă nu există evaluări

- 09-0217 Rev 1 Barber Safety Systems BrochureDocument4 pagini09-0217 Rev 1 Barber Safety Systems Brochure2009tamer100% (1)

- 03 Well CompletionDocument31 pagini03 Well Completionhfdshy12Încă nu există evaluări

- Chemical Engineering Science: Pawe" Sobieszuk, Ryszard Pohorecki, Pawe" Cygan Ski, Jacek GrzelkaDocument9 paginiChemical Engineering Science: Pawe" Sobieszuk, Ryszard Pohorecki, Pawe" Cygan Ski, Jacek GrzelkajayashriÎncă nu există evaluări

- 05 Seat and o Ring TemperatureDocument1 pagină05 Seat and o Ring TemperatureAndri AjaÎncă nu există evaluări

- Ahe Lab QuestionDocument3 paginiAhe Lab QuestionVijay A HwreÎncă nu există evaluări

- Soil Physics ExerciseDocument14 paginiSoil Physics ExerciseChanako DaneÎncă nu există evaluări

- Combustion FundamentalsDocument30 paginiCombustion FundamentalsPrem SagarÎncă nu există evaluări

- Asme b31.8 Comp Iso 13623Document7 paginiAsme b31.8 Comp Iso 13623tss13723100% (2)

- Valve / Actuator Sizing Summary: Quotation No: FEQ-20-60010-A-1 Customer: 纽威 Project Name: 尼日利亚项目Document6 paginiValve / Actuator Sizing Summary: Quotation No: FEQ-20-60010-A-1 Customer: 纽威 Project Name: 尼日利亚项目RajÎncă nu există evaluări

- Valvula Solenoide SV13-20Document2 paginiValvula Solenoide SV13-20roqueÎncă nu există evaluări

- Breather ValveDocument27 paginiBreather ValveMohamad IwanÎncă nu există evaluări