Documente Academic

Documente Profesional

Documente Cultură

Rego Cryo Regulator

Încărcat de

dhaktodesatyajitTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Rego Cryo Regulator

Încărcat de

dhaktodesatyajitDrepturi de autor:

Formate disponibile

Cryogenic Pressure Regulating Valve

Installation, Operation and

Maintenance Manual

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 1 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

WARNING!

BEFORE ANY INSTALLATION AND MAINTENANCE WORK CAN

COMMENCE ENSURE THE VALVE AND SURROUNDING SYSTEM

IS DRAINED OF PRESSURE AND ISOLATED.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 2 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Contents

Disclaimer ....................................................................................................................... 4

Introduction ..................................................................................................................... 5

Outline ............................................................................................................... 5

Safety ................................................................................................................ 5

Cleanliness ........................................................................................................ 6

Service Intervals ................................................................................................ 7

Installation ......................................................................................................... 7

Installation Overview ......................................................................................... 7

Preparation ........................................................................................................ 9

Hardware Description ...................................................................................... 10

Features and Benefits ..................................................................................... 10

Operation......................................................................................................... 11

Technical Data / Description............................................................................ 13

Installation and Maintenance ..................................................................................... 14

Spares Kit ........................................................................................................ 14

Installation Method .......................................................................................... 15

Refit / Refurbishment Method .......................................................................... 17

Troubleshooting ........................................................................................................... 23

Contact Details ............................................................................................................. 24

Service Record ............................................................................................................. 25

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 3 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Disclaimer

PLEASE NOTE:

If the valves produced by Bestobell Valves/LNG are refurbished by a third party organisation that is

not approved by Bestobell Valves/LNG, then the safety and performance will not be guaranteed and

the warranty may be invalid.

If unsure about the installation and operation procedures for this valve, please contact Bestobell

Valves/LNG.

Bestobell Valves has produced this manual in order to provide engineering personnel with sufficient

general information to enable the operation, installation and effective maintenance of the valve

manufactured by Bestobell Valves.

In the interest of product development, the designs and specifications for our products are

constantly under review and we therefore reserve the right to make changes and improvements

without notice.

This manual and the copyright therein are the property of PRESIDENT ENGINEERING GROUP

and all information that it contains is confidential.

This manual must not be reproduced or disclosed nor must any information taken there from be

disclosed, without prior consent in writing of PRESIDENT ENGINEERING GROUP.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 4 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Introduction

Outline

This manual is broken down into separate sections:

Introduction

This section provides information about important safety requirements as well as highlighting

the precautions taken at Bestobell Valves to ensure the cleanliness of products. Details

regarding servicing are also introduced.

Installation

This details the method of installing the valve on site, and includes information on storage,

unpacking and inspection. Preparation of the valve and site is also discussed to allow ease of

installation and operation.

Hardware Description

Introduces the product as well as providing a more detailed description including operating

conditions and suitable media. Any further requirements for the effective operation of the

valve are also discussed.

Operation

Provides information on how to operate the valve.

Maintenance

Provides information relating to the on-site maintenance of the supplied valve, as well as

discussing common problems and solutions.

Safety

Read and understand these instructions before installing the valve. Improper installation,

operation or maintenance by the owner or operator of this valve can result in personal injury.

Only use genuine Bestobell Valves spares to ensure safe and optimum performance.

Prior to the installation of the valve into the system, ensure the system is de-pressurised and

isolated for the duration of the installation and during any subsequent maintenance.

The valve must be installed within a system that has adequate draining and venting provisions.

In cryogenic applications the area of pipe-work to receive the valve must be allowed to reach

ambient temperature.

It is essential that the installers and operators are conversant with all of the safety issues relating to

the medium within the system, and are fully trained to an adequate standard.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 5 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Wear safety glasses and gloves during any installation or operation of the valve.

Valves must only be used in a circuit protected by suitable equipment.

The valve should be inspected for wear as part of a regular system maintenance programme.

Cryogenic burns can occur if the valve is handled during or after the valve has operated.

Minor leaks from the outlet side of the valve, if allowed to build up in a confined area, can be

hazardous. This can be avoided by dissipating into the atmosphere or a well ventilated area.

If valve is to be installed in hazardous climatic conditions or seismic areas, please inform Bestobell

Valves Ltd.

Identify the intended flow direction and match the valve orientation with its flow direction arrow.

Ensure that all end connections to the valve are in line and that the pipe work is supported to reduce

unwanted stresses, loading and vibration on the valve and system pipe work.

Ensure that all joining materials / components used during the installation of the valve are

compatible, and will not cause any deterioration to the valve structure.

When using on CO2, the internal atmosphere must be dry and moisture free as any bronze

components could be affected by carbonic acid.

DO NOT check leaks with hands.

Cleanliness

Immediately after assembly in a controlled clean room, the valve is sealed in an airtight plastic bag

to maintain cleanliness. As such, it is essential to maintain this cleanliness throughout all stages of

installation. Particular care should be taken not to contaminate the internals of the valve with

grease, moisture, grinding dust, weld/brazing spatter etc.

Clean practices will save time later with reduced ‘flushing’ and maintenance.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 6 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Service Intervals

Bestobell Valves recommends that a major service is carried out on its valves in line with

the procedures contained in this manual every 2 years.

In addition to this, a regular inspection should take place to ensure correct operational

condition.

Regular inspections are suggested on a monthly basis and maintenance work should be

carried out in line with this service manual.

It is recommended that the Service Record Sheet enclosed be fully completed at every

service interval.

Installation

Personnel carrying out Assembly / Joining / Welding / Inspection must be adequately trained and

hold the necessary approvals.

Ensure that environmental conditions (atmospheric pollution) are compatible with the valve

materials.

(NOTE: Ensure there is enough space around the valves installed position to allow the removal and

refit of the headwork / valve)

Installation Overview

The quality of performance in service is a function of the care taken to ensure good installation. A

careful study of these instructions is therefore recommended, as properly installed equipment will

normally operate for long periods without problems.

The most critical point in the lifetime of a valve is the time of installation, therefore, proper care at

this stage and during any maintenance will increase the probability of trouble free valve service.

It is important to maintain cleanliness throughout all stages of the installation, with particular care

being taken not to contaminate the internals of the valve with grease, moisture, grinding dust, weld /

brazing spatter or other foreign matter.

Clean practices will save time later with reduced ‘flushing’ and maintenance.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 7 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

STORAGE:

The equipment packing cases are NOT waterproof and should be stored in a weatherproof location

before use.

UNPACKING:

It is recommended that before any item is unpacked, it should be moved as close as possible to its

installed position. This will minimise the possibility of damage during handling.

It is further recommended that each item should only be unpacked immediately before it is required.

Before installation the engineer should check for:

Damaged Packaging

Bent or Distorted Items

Scratches, Dents or Damage

Particular attention should be paid to the sealing faces on the end connection flanges.

TOOLS REQUIRED:

No special tooling is required for the installation of this valve.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 8 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Preparation

WARNING!

BEFORE ANY INSTALLATION AND MAINTENANCE WORK CAN

COMMENCE ENSURE THE VALVE AND SURROUNDING SYSTEM

IS DRAINED OF PRESSURE AND ISOLATED.

Identify the intended flow direction and match the valve orientation with its flow direction arrow.

Ensure that all end connections to the valve are in line and that the pipe work is supported to reduce

unwanted stresses, loading and vibration on the valve and system pipe work.

Ensure that all joining materials / components used during the installation of the valve are

compatible, and will not cause any deterioration to the valve structure.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 9 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Hardware Description

The Cryogenic Pressure Regulating Valve (Cryoreg) is designed to provide all pressure regulator

functions within one valve.

The standard body material is bronze; however, stainless steel bodies are also available.

Designed for use on all cryogenic pressure vessels including static and transportable tanks; the

Cryoreg valve combines each of the following functions in one unit:

1. Pressure build up regulator

2. Economiser valve

3. Thermal relief* on two of the ports

* The Cryoreg provides thermal relief for the PBU inlet and vents this to the economiser outlet. If a

stop valve is fitted on all three lines and were all closed then liquid lock would occur, therefore a

thermal relief valve must be fitted to the economiser line or the gas (outlet) side of the Cryoreg.

Features and Benefits

• Combined pressure build-up regulator and economiser functions for simpler pipe work and fewer

joints.

• High flow characteristics – for closer control of tank pressure.

• Operates on liquid or gas – to suit every installation.

• Single adjustment for both functions – for simpler tank setting.

• High accuracy/low dead band allows higher tank pressure – reduced boil-off in pipelines.

• Dual thermal relief valve action – for added system protection.

• Strainer fitted as standard on inlet and outlet.

• Ball check fitted to economiser outlet as standard.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 10 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Operation

In the following explanation, it is assumed that the Cryoreg is fitted downstream of the pressure

build-up coil and will therefore be controlling a gaseous flow during the pressure build-up phase of

its operation. Operation is identical when fitted upstream of the PBU coil except that liquid will be

passed during the pressure build-up phase.

C

Function One – Pressure Build-up Regulator

B

As liquid or gas is drawn from the tank, the pressure inside the tank A

will fall. To compensate for this, the Cryoreg will open to allow liquid

to pass through the pressure build-up coil. Sufficient gas will thus be

generated to bring the tank back to its normal working pressure.

In this phase of operation, flow is from port A to port B via the

pressure build-up seat on the multi-function disc away from the main

seat. This upward movement arises as a result of the force in the

pressure setting spring overcoming the pressure force acting over the C

sensing diaphragm. As soon as the pressure in the tank has B

recovered, the diaphragm assembly is pushed back down again,

A

stopping the flow.

Function Two – Economiser Valve

When heat leaks into a cryogenic storage tank, liquid will revert to its gas

phase leading to a pressure rise in the tank. Left unchecked, the process

may continue until the relief valve lifts, wastefully venting gas to the

atmosphere.

The function of an economiser valve is to divert excess gas into the supply line. Providing the

customer is drawing gas, diverting the flow in this manner will prevent the relief valve lifting,

avoiding waste and reducing the overall cost of storing the liquefied gas.

To accomplish this, a flow path is formed within the Cryoreg to allow gas to pass from port B, up

through the centre of the valve to exit via the economiser port C. The flow path is formed from the

downward movement of the diaphragm (which senses tank pressure), having overcome over the

force in the pressure setting spring. This occurs when the tank pressure exceeds the valve set

pressure by more than 0.54 barg.

Note that this mechanism is also used to provide thermal relief into the economiser from outlet B.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 11 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Function 3 – Thermal Relief

C

Inadvertent closure of the valve supplying the pressure build-up coil could

lead to liquid being trapped between the coil and the Cryoreg.

B

A thermal relief valve would normally be required to protect the coil A

associated pipe work from the high pressures generated by warming of the

trapped liquid. This function, however, is built into the Cryoreg, which will

automatically vent the gas into either the economiser line (port C) or the gas

supply line to the tank (port B).

This function is accomplished by the differential pressure across the bellows

assembly forcing it to compress, leaving the multi-function disc in place. This

allows a flow path to form from port A, up through the centre of the bellows

to exit from the economiser port.

Remember that thermal relief is provided on port B by the economiser function described above,

giving protection under all foreseeable circumstances.

The Cryoreg is also seen in its ability to control the flow of liquid when fitted upstream of the

pressure build-up coil, or gas when fitted downstream. Typical pipe work layouts are shown.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 12 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Technical Data / Description

Stainless

Steel Bellows

Bellows

Return Spring

Port B

Pressure Build-

up Outlet / Port A

Economiser Pressure Build-

Inlet up Inlet

Multi-Layer

Diaphragm

Valve Disc Pressure Control

Spring

A choice of four ranges

up to 40 bar.

Maximum working pressure: 40 bar.

Designed and engineered for use with O2, N2, Ar, CO2, CH4, He, CHF, Kr, Ne, He, H2, C2H4, N2O,

SF6, LPG, LNG.

ISO 9001 accreditation – designed and manufactured to ASTM B31.3 and BSEN1626.

Optional full material traceability backed by BSEN 10204 3.1/3.2 certification.

Marking according to Pressure Equipment Directive 97/23/EC.

Marking to Directive 99/36/EC only on written request complete with purchase order.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 13 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

The Cryoreg is available with a choice of springs to give optimum control in all applications. Set

pressure tolerance will normally be held on gas +/- 3% and liquid side +/- 5%.

DN15 – DN25 bull nose end connections available.

Installation and Maintenance

Spares Kit

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 14 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Kit Number Name Contents

1 SEAL

CKCSP1 SEAL KIT

2 GASKETS

1 BELLOWS

BELLOWS/SEAL 1 SPRING

CKCSP2

KIT 1 SEAL

2 GASKETS

DIAPHRAGM KIT 1 DIAPHRAGM ASSY

CKCSP3 (HP)

(10.0 - 25.0 BAR) 1 GASKET NOTE:

DIAPHRAGM KIT 1 DIAPHRAGM ASSY Please ensure that when ordering

CKCSP4 (LP) Spares the parts being ordered match

(1.5 to 12.0 BAR) 1 GASKET

MAINSPRING KIT 1 SPRING the pressure rating of parts either

CKCSP5 (HP) fitted, or being fitted.

10.0 top 25.0 BAR) 1 GASKET

MAINSPRING KIT 1 SPRING

CKCSP6 (MP)

E.g.

(4.0 to 12.0 BAR) 1 GASKET CK30A1REPKITHP or CKCSP3 must

MAINSPRING KIT 1 SPRING only be used in conjunction with

CKCSP7 (LP) CKCSP5.

(1.5 to 4.0 BAR) 1 GASKET

2 GASKETS

CKCSP8 GASKET SET

1 GASKET

1-CKCSP3

REPAIR KIT (HP)

CK30A1REPKITHP 1 SEAL

(10.0 to 25.0 BAR)

2 GASKETS

1-CKCSP4

REPAIR KIT (LP)

CK30A1REPKITLP 1 SEAL

(1.5 to 12.0 BAR)

2 GASKETS

Installation Method

Install the valve in the pipe work with the connections as shown in either of the figures on the

following page.

Ensure that the direction arrows on the valve are pointing in the correct direction.

Ensure that the physical environment will not cause the drain hole in the cover to become

blocked.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 15 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

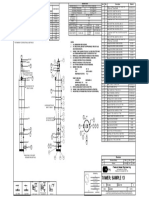

Gas Side Liquid Side

The valve may be fitted on either the liquid or gas side of the pressure build up coil at the

discretion of the customer.

Ensure that there is a minimum of 200mm head between the highest liquid level and the

point at which the economiser outlet joins the customer supply line.

Install the Cryoreg with the pressure setting screw downwards; this prevents ice formation

inside the cover which would impede correct operation of the valve.

To set the valve at the correct pressure (it is usually supplied with the pressure setting

screw at mid spring range unless otherwise requested) slacken off the setting screw

locknut. Screw the pressure setting screw into the valve until the correct working pressure

is obtained.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 16 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Care should be taken to ensure that safe working pressures are not exceeded.

As an indication and to assist in the initial setting of the valve the approximate rates of

adjustment shown below apply for the three available springs.

Spring Range Bar) Sensitivity (Bar/Turn)

1.5 to 5 0.75

4.0 to 12.0 2

10.0 to 25.0 5

Refit / Refurbishment Method

STEP 1:

Unscrew the Setscrew from the top of the valve.

Leave the lock nut at its current setting.

Step 2:

Unscrew each of the six socket cap screws and lift off the cover.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 17 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

STEP 3:

Remove the large spring and thrust plate over the top of the

diaphragm assembly.

STEP 4:

Remove the diaphragm assembly from the body.

STEP 5:

Remove the lock nut from over the top of the diaphragm discs.

NOTE: Hold the square below the diaphragm discs in a vice with

soft jaws to prevent damage to this end; take care not to damage

the lapped seat face.

STEP 6:

Remove the diaphragms and replace the gasket. If the

diaphragms are in good condition re-use, if not replace. Tighten

the lock nut back on top to 33Nm (24 lb.ft).

Valve Operating Pressure: Number of Diaphragms

Required:

1.5 – 5.0 3

4.0 – 12.0 3

10.0 – 25.0 4

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 18 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

STEP 7:

Unscrew each socket cap screw from the coupling.

STEP 8:

Remove the circlip from the groove inside the threads of the

coupling.

STEP 9:

Remove the ball from the coupling – replace this if worn with the

one from the spares kit.

STEP 10:

Remove the small spring from inside the bellows.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 19 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

STEP 11:

Remove the bellows and discard the gasket underneath. Replace

it with the new one from the spares kit.

STEP 12:

Remove the seal with pliers and discard. Replace the seal with the

new one from the spares kit and place back inside the body.

Place the seal with the two raised seat faces downwards into the

body and the single seat face upwards towards the bellows.

STEP 13:

Replace the bellows with the one from the spares kit if it is

damaged or excessively worn.

STEP 14:

Insert the small spring inside the bellows.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 20 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

STEP 15:

Reinsert the ball into the coupling.

Secure the ball in place by re-attaching the circlip.

STEP 16:

Replace the coupling ensuring that the gasket is in position.

Tighten the socket cap screws to 12NM (9 lb.ft), working

alternately on opposite corners to apply equal pressure to the

face, to secure the coupling to the body.

STEP 17:

Invert the body. Remove and discard the main body gasket and

replace with the new one from the spares kit.

STEP 18:

Replace the diaphragm assembly into the body.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 21 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

STEP 19:

Replace the large spring and thrust plate over the top of the

diaphragm assembly.

STEP 20:

Place the cover onto the spring. Screw each of the six socket cap

screws back into the body.

Do not initially fully tighten each screw; gradually tighten each one

until all the screws are tightened to the specified torque.

STEP 21:

Screw the setscrew back into the valve down to the lock nut.

Ensure the lock nut is then secured in this position.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 22 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Troubleshooting

SYMPTOM: FAULT: SOLUTION:

SET THE PRESSURE

PRESSURE SETTING

PRESSURE CONTINUES TO BUILD SETTING SCREW TO THE

SCREW NOT SET

UP. CORRECT PRESSURE

CORRECTLY.

(SEE PAGE 9).

IF LINES A AND B AND THE

OUTSIDE OF THE VALVE

ENSURE THAT ALL

AT THESE PORTS ARE

MAINTENANCE IS

FROSTY BUT THE

CARRIED OUT IN A CLEAN

PRESSURE CONTINUES TO BUILD ECONOMISER OUTLET

ENVIRONMENT AND THAT

UP. (PORT C) IS NOT FROSTY

NO FOREIGN MATTER IS

THIS COULD INDICATE

ALLOWED INTO THE

THAT FOREIGN MATTER

SYSTEM.

OR ICE IS PRESENT

AROUND THE SEAL.

IF PORTS B AND C ARE

FROSTED BUT PORT A IS

NOT, THIS COULD

PRESSURE CONTINUES TO BUILD INDICATE THAT REVERSE REPAIR OR REPLACE THE

UP. FLOW OR SIPHONING IS FAULTY CHECK VALVE.

OCCURRING. EITHER THE

CHECK VALVE OR THE

ECONOMISER IS FAULTY.

PRESSURE CONTINUES TO BUILD A CHECK VALVE IS NOT

FIT A CHECK VALVE

UP. FITTED.

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 23 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Contact Details

For further maintenance instructions and spares contact:

United Kingdom Enquiries:

Bestobell Valves/LNG

President Park,

President Way,

Sheffield,

South Yorkshire,

S4 7UR,

England.

Tel: +44(0)114 2240263

Fax: +44(0)114 2784974

Email: info@lngvalves.com / info@bestobellvalves.com

Web: www.bestobell-lng.com / www.bestobellvalves.com

United States Enquiries:

Bestobell Valves Inc

270 Meadowlands Blvd,

Washington,

PA 15301.

Tel: +1 724 746 3750

Fax: +1 724 746 0940

Email: sales@conflowusa.com

Web: www.bestobellvalves.com

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 24 of 25 QF 80: Issue 2

Cryogenic Pressure Regulating Valve

Reference Number: IOM_003 Date: 28 July 2010 Issue: A

Service Record

Valve Tag Number: Date: Date: Date: Date:

Bestobell Valves, President Park, President Way, Bestobell Valves Inc, 270 Meadowlands Blvd

Sheffield, South Yorkshire, S4 7UR Washington, PA 15301

Tel: +44 (0) 114 224 0000 Fax: +44 (0) 114 278 4974 Tel: +1 724 746 3750 Fax: +1 724 746 0940

info@bestobellvalves.com www.bestobellvalves.com sales@conflowusa.com www.bestobellvalves.com

Date of Issue: 4 August 2010 Page 25 of 25 QF 80: Issue 2

S-ar putea să vă placă și

- Unvented Indirect Hot Water Cylinders Systemfit: Megaflo Product GuideDocument40 paginiUnvented Indirect Hot Water Cylinders Systemfit: Megaflo Product GuideaaneezÎncă nu există evaluări

- Kinesis One M5800-00Document34 paginiKinesis One M5800-00powerliftermiloÎncă nu există evaluări

- TP128 UserManual RevCDocument68 paginiTP128 UserManual RevCsudheesh k nair100% (1)

- Janus Probe st-500 ManualDocument30 paginiJanus Probe st-500 ManualSiddharthTrivediÎncă nu există evaluări

- Uniflux™ System: Operating InstructionsDocument164 paginiUniflux™ System: Operating InstructionsOlger Renan PulamarinÎncă nu există evaluări

- Triple 7s Field Service Mpu6 Base Manual 2 2 1Document96 paginiTriple 7s Field Service Mpu6 Base Manual 2 2 1Charlotte SpainÎncă nu există evaluări

- Watts 2011 Price List: Backflow Prevention Products Repair Kits & Service PartsDocument56 paginiWatts 2011 Price List: Backflow Prevention Products Repair Kits & Service Partskohatian27796105Încă nu există evaluări

- Classic 321gl Operating Manual enDocument23 paginiClassic 321gl Operating Manual enNicolae JulaÎncă nu există evaluări

- OfficialManualOCA 203 EDocument122 paginiOfficialManualOCA 203 ETiffany RusÎncă nu există evaluări

- Piezoelectric Sound Components: Application ManualDocument12 paginiPiezoelectric Sound Components: Application ManualNicola VirgilioÎncă nu există evaluări

- Ols4a, Ols2 Instruction ManualDocument88 paginiOls4a, Ols2 Instruction ManualBadaiLautChinaÎncă nu există evaluări

- Croma 19572 User Manual PDFDocument65 paginiCroma 19572 User Manual PDFRaul InzunzaÎncă nu există evaluări

- Panasonic KX-TGA110EX User ManualDocument24 paginiPanasonic KX-TGA110EX User ManualpanfokÎncă nu există evaluări

- RAS Spec For UD686 - Rev00Document74 paginiRAS Spec For UD686 - Rev00СеменÎncă nu există evaluări

- DR 633 833 1233 (1) BarraDocument15 paginiDR 633 833 1233 (1) BarraJhonatan Bejarano BazanÎncă nu există evaluări

- Chapter 5 - Plug and Abandonment of Subsea WellsDocument23 paginiChapter 5 - Plug and Abandonment of Subsea WellsSalvador Morales LeónÎncă nu există evaluări

- Instruction Manual: Permeability Plugging TesterDocument27 paginiInstruction Manual: Permeability Plugging TesterDukilson PersyÎncă nu există evaluări

- 171-193 - Permeability Plugging Tester, 5000 PSIDocument27 pagini171-193 - Permeability Plugging Tester, 5000 PSIJessica Matos TacuriÎncă nu există evaluări

- Lnlet ValveDocument9 paginiLnlet ValveZewduErkyhunÎncă nu există evaluări

- ZXSDR BS8900A GU360 Outdoor GSMUMTS Dual Mode Macro BTS Documentation Guide - 396600Document9 paginiZXSDR BS8900A GU360 Outdoor GSMUMTS Dual Mode Macro BTS Documentation Guide - 396600ErangaÎncă nu există evaluări

- Ecotec Installation and Servicing Manual 261417Document88 paginiEcotec Installation and Servicing Manual 261417adrgrÎncă nu există evaluări

- Teac LEDV2282FHD Service ManualDocument46 paginiTeac LEDV2282FHD Service Manualbawbaw1Încă nu există evaluări

- Potterton Kingfisher MF RS 50 Installation Manual GCNo 41 393 95Document39 paginiPotterton Kingfisher MF RS 50 Installation Manual GCNo 41 393 95lenin6737Încă nu există evaluări

- 02-A Kinetico Owners Manual - Commercial Plus Softener SeriesDocument32 pagini02-A Kinetico Owners Manual - Commercial Plus Softener SeriesCastoriadisÎncă nu există evaluări

- SpearsDocument96 paginiSpearsatnkpr_vn9368Încă nu există evaluări

- Manuale Tecnico Ferro Da Stiro Elettronico 703Document25 paginiManuale Tecnico Ferro Da Stiro Elettronico 703Andrea GiavenniÎncă nu există evaluări

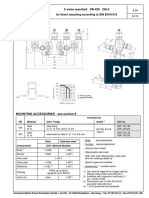

- 5 Valve Manifold PN 420 DN 5: For Direct Mounting According To DIN EN 61518Document1 pagină5 Valve Manifold PN 420 DN 5: For Direct Mounting According To DIN EN 61518Murat KodalÎncă nu există evaluări

- Oring Sizes AS568Document5 paginiOring Sizes AS568최승원Încă nu există evaluări

- Nioec SP 50 59Document9 paginiNioec SP 50 59aminÎncă nu există evaluări

- Appendix A - Technical Specification - Not CompleteDocument27 paginiAppendix A - Technical Specification - Not CompletepetroÎncă nu există evaluări

- Un 40 Ku 630 DFDocument153 paginiUn 40 Ku 630 DFRafael Jaime GonçalvesÎncă nu există evaluări

- Revc FinalDocument12 paginiRevc FinalHasan KamalÎncă nu există evaluări

- SL-M5370 M4370 MS v02Document375 paginiSL-M5370 M4370 MS v02Talles TaysonÎncă nu există evaluări

- Lead-Free Repairing SystemDocument14 paginiLead-Free Repairing SystemRoy Muy GolfoÎncă nu există evaluări

- M71 (NTSC) Service Manual: Model 14Dn3Wyd-By Li ChangzhengDocument56 paginiM71 (NTSC) Service Manual: Model 14Dn3Wyd-By Li ChangzhengEdilberto Avila100% (1)

- NXE1 ManualDocument124 paginiNXE1 ManualDorival Junior Ferreira de Mello0% (1)

- Datamax I Class Parts ListDocument24 paginiDatamax I Class Parts ListJason JacobsÎncă nu există evaluări

- Sup Eq CatalogDocument18 paginiSup Eq CatalogHendrias Ari SujarwoÎncă nu există evaluări

- G501 MSDSDocument6 paginiG501 MSDSucb51525354Încă nu există evaluări

- CTS Esh-Psh-Swh 2108-2109 RF Series NMS V1.2 20101112 PDFDocument110 paginiCTS Esh-Psh-Swh 2108-2109 RF Series NMS V1.2 20101112 PDFCristea Horea TomaÎncă nu există evaluări

- Servicemanual Samsung 4-VägskassettDocument136 paginiServicemanual Samsung 4-VägskassettLuz UribeÎncă nu există evaluări

- SC/V - Valve Actuator Spring Return: Instruction Manual 5018Document49 paginiSC/V - Valve Actuator Spring Return: Instruction Manual 5018kaicyemÎncă nu există evaluări

- SI500.11r5e - GrafoilDocument5 paginiSI500.11r5e - GrafoilHumayun NawazÎncă nu există evaluări

- Grundfosliterature 3979032 PDFDocument110 paginiGrundfosliterature 3979032 PDFIslam FawzyÎncă nu există evaluări

- HUAWEI Quidway AR 29-21&29-41 Routers System Description PDFDocument61 paginiHUAWEI Quidway AR 29-21&29-41 Routers System Description PDFninoslavnÎncă nu există evaluări

- Vip Planopt ManualDocument70 paginiVip Planopt ManualArif MuslimÎncă nu există evaluări

- TM 750-254 Cooling Systems Tactical Vehicles 1972Document73 paginiTM 750-254 Cooling Systems Tactical Vehicles 1972Wurzel1946Încă nu există evaluări

- gxdp-700 User Manual English 207723-r4 PDFDocument130 paginigxdp-700 User Manual English 207723-r4 PDFVera KomalasariÎncă nu există evaluări

- Abschreckmedien EDocument24 paginiAbschreckmedien EhsemargÎncă nu există evaluări

- PR3100 TSC User Manual EN (English)Document149 paginiPR3100 TSC User Manual EN (English)shaimaa11133Încă nu există evaluări

- JIC-3 Injector Connector PDFDocument6 paginiJIC-3 Injector Connector PDFmoorpvrÎncă nu există evaluări

- Deh 2780 2750Document62 paginiDeh 2780 2750jcgabbiÎncă nu există evaluări

- Im50 Service ManualDocument59 paginiIm50 Service ManualJAVIER100% (1)

- Instruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerDocument20 paginiInstruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerLuis Gomez JimenezÎncă nu există evaluări

- Select List of Deep Shaft and VERTREAT - VERTAD PlantsDocument1 paginăSelect List of Deep Shaft and VERTREAT - VERTAD PlantsFabio NascimentoÎncă nu există evaluări

- Zp5 Gcu2 ManualDocument144 paginiZp5 Gcu2 ManualMiguel PintoÎncă nu există evaluări

- Delta - Ia-Mds - VFD-C2000 - Um - en - 201606 PDFDocument684 paginiDelta - Ia-Mds - VFD-C2000 - Um - en - 201606 PDFFelipe Raul Chumpitaz GuevaraÎncă nu există evaluări

- Cryo Regulator RegValve PDFDocument25 paginiCryo Regulator RegValve PDFdhaktodesatyajitÎncă nu există evaluări

- 140-60 - Instructions Filtrado APIDocument8 pagini140-60 - Instructions Filtrado APIMyrnaÎncă nu există evaluări

- Dynamic Filter Press ManualDocument23 paginiDynamic Filter Press ManualMobeen MurtazaÎncă nu există evaluări

- Chapter ObjectivesDocument30 paginiChapter ObjectivesdhaktodesatyajitÎncă nu există evaluări

- Bined LoadingDocument8 paginiBined LoadingdhaktodesatyajitÎncă nu există evaluări

- 3602 Drawing R0Document1 pagină3602 Drawing R0dhaktodesatyajitÎncă nu există evaluări

- CT 120 Designing High Perf TraysDocument13 paginiCT 120 Designing High Perf TraysdhaktodesatyajitÎncă nu există evaluări

- Brochure PT Ethylene RippleTray WEBDocument8 paginiBrochure PT Ethylene RippleTray WEBdhaktodesatyajitÎncă nu există evaluări

- 4500 Series: Bellows Sealed Valves (0.156"/3.962 MM Orifice)Document2 pagini4500 Series: Bellows Sealed Valves (0.156"/3.962 MM Orifice)dhaktodesatyajitÎncă nu există evaluări

- P04 Stainless Steel Corrugated Hoses and Metal Bellows Expansion Joints CleanDocument11 paginiP04 Stainless Steel Corrugated Hoses and Metal Bellows Expansion Joints CleandhaktodesatyajitÎncă nu există evaluări

- Dokumen - Tips 03 e 4 Static EqptDocument316 paginiDokumen - Tips 03 e 4 Static EqptdhaktodesatyajitÎncă nu există evaluări

- Cryogenic Pressure RegulatorDocument4 paginiCryogenic Pressure RegulatordhaktodesatyajitÎncă nu există evaluări

- Ti01221den 0921Document126 paginiTi01221den 0921dhaktodesatyajitÎncă nu există evaluări

- Material Safety Data Sheet (MSDS) : Extremely Unpleasant OdourDocument2 paginiMaterial Safety Data Sheet (MSDS) : Extremely Unpleasant OdourdhaktodesatyajitÎncă nu există evaluări

- Intech-Natural Gas OdorizationDocument20 paginiIntech-Natural Gas OdorizationdhaktodesatyajitÎncă nu există evaluări

- Avaleha Criticalreview PDFDocument9 paginiAvaleha Criticalreview PDFArunÎncă nu există evaluări

- Solid State - Study Material - Yak9Document33 paginiSolid State - Study Material - Yak9Amrit Kumar BiswasÎncă nu există evaluări

- Energy and Power Ib2Document24 paginiEnergy and Power Ib2Gkid GkidÎncă nu există evaluări

- Expansion Vessels enDocument32 paginiExpansion Vessels enahmed100% (1)

- MITOCHONDRIADocument3 paginiMITOCHONDRIAAbid RazaÎncă nu există evaluări

- Control of Corrosion On Underwater Piles: J Santhosh Kumar CH Kusuma KeerthiDocument7 paginiControl of Corrosion On Underwater Piles: J Santhosh Kumar CH Kusuma KeerthiSaurav Patil100% (1)

- 5031 Acid Base WorksheetDocument5 pagini5031 Acid Base WorksheetSaima Usman/TCHR/MGBÎncă nu există evaluări

- Performance Enhancing Substances and TechniquesDocument2 paginiPerformance Enhancing Substances and Techniquesapi-391714949Încă nu există evaluări

- Carbon Dioxide Levels Are at A Record High-Article From National Geografic 29387904Document5 paginiCarbon Dioxide Levels Are at A Record High-Article From National Geografic 29387904Matias Riera LópezÎncă nu există evaluări

- HamzaDocument20 paginiHamzaHamza KhakwaniÎncă nu există evaluări

- Modes of Occurrence and Provenance of Gemstones of Sri Lanka (Mineralium Deposita, Vol. 15, Issue 1) (1980)Document6 paginiModes of Occurrence and Provenance of Gemstones of Sri Lanka (Mineralium Deposita, Vol. 15, Issue 1) (1980)StarScourgeÎncă nu există evaluări

- GGBSDocument20 paginiGGBSratnakar0% (1)

- Pitting Corrosion Due To Deposits in Cooling Water SystemsDocument12 paginiPitting Corrosion Due To Deposits in Cooling Water SystemsAnonymous 1XHScfCIÎncă nu există evaluări

- Structural Composite Material. FinalDocument43 paginiStructural Composite Material. Finalআলবার্ট হালদার100% (3)

- Which Instrument Is Used To Tell DirectionDocument12 paginiWhich Instrument Is Used To Tell DirectionLousy MoÎncă nu există evaluări

- Ammonia Based Refrigeration SystemsDocument19 paginiAmmonia Based Refrigeration SystemsHoainam NguyenÎncă nu există evaluări

- Chemistry For Engineers: Assignment 1Document4 paginiChemistry For Engineers: Assignment 1Thanh Tan PhamÎncă nu există evaluări

- Iso 19229 2019Document10 paginiIso 19229 2019laythÎncă nu există evaluări

- Electrolux RM 4400Document10 paginiElectrolux RM 4400LorenzoCapochiani100% (1)

- ConcreteDocument11 paginiConcretesiddhi gangwalÎncă nu există evaluări

- Egyptian Blue Cuprorivaite A Window To Ancient Egyptian TechnologyDocument13 paginiEgyptian Blue Cuprorivaite A Window To Ancient Egyptian TechnologyDοмenıκ CaesarÎncă nu există evaluări

- A New Methodology For Determining The Moisture Diffusion Coefficient of Transformer Solid InsulationDocument4 paginiA New Methodology For Determining The Moisture Diffusion Coefficient of Transformer Solid InsulationabetieÎncă nu există evaluări

- TDS Mil-Prf-23377 PPGDocument6 paginiTDS Mil-Prf-23377 PPGCarlos Alberto Rozo R.Încă nu există evaluări

- Introduction To TextileDocument30 paginiIntroduction To Textileumar.niift3049100% (1)

- Bruice Organic Chemistry 6eDocument26 paginiBruice Organic Chemistry 6esdfasf asdasdasd100% (1)

- Us 4570540Document3 paginiUs 4570540erwerÎncă nu există evaluări

- Well Control MethodsDocument4 paginiWell Control MethodsVassilios KelessidisÎncă nu există evaluări

- NW6Document10 paginiNW6Mamidala HarithaÎncă nu există evaluări

- FINAL Spec 8.0 TR LHB RMPUDocument71 paginiFINAL Spec 8.0 TR LHB RMPUdivisional electrical engg63% (8)