Documente Academic

Documente Profesional

Documente Cultură

Ttacacac

Încărcat de

Yorvic GodoyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ttacacac

Încărcat de

Yorvic GodoyDrepturi de autor:

Formate disponibile

RING INSTALLATION RING INSTALLATION

Most Powroll piston rings are purposely oversize to enable re-

Most Powroll piston rings are purposely oversize to enable re-ringing of

ringing of cylinders which have worn within certain acceptable

cylinders which have worn within certain acceptable limits. Because of

limits. Because of this, ring ends must usually be filed down

this, ring ends must usually be filed down before installation.

before installation.

FAILURE TO FILE RINGS TO APPROPRIATE END GAP WILL CAUSE FAILURE TO FILE RINGS TO APPROPRIATE END GAP WILL

ENGINE DAMAGE. CAUSE ENGINE DAMAGE.

Excess gap is not critical. Excess gap is not critical

Insufficient gap can be ruinous! Insufficient gap can be ruinous!

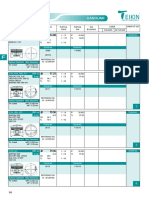

Ring Diameter Ring Diameter Min. End Ring Diameter Ring Diameter Min. End

Inches Millimeters Gap Inches Millimeters Gap

1.731” to 1.968” 44mm to 50mm .004” 1.731” to 1.968” 44mm to 50mm .004”

1.969” to 2.675” 50.25mm to 68mm .007” 1.969” to 2.675” 50.25mm to 68mm .007”

2.676” to 3.120” 68.10mm to 79.25mm .010” 2.676” to 3.120” 68.10mm to 79.25mm .010”

3.121” to 4.000” 79.35mm to 102mm .013” 3.121” to 4.000” 79.35mm to 102mm .013”

In. mm In. mm

#

#

Dia.

Dia.

Part

Ring

Part

Ring

ALWAYS INSTALL RINGS WITH ALWAYS INSTALL RINGS WITH

MARKINGS FACING UP. MARKINGS FACING UP.

TOP RING – COMPRESSION RING TOP RING – COMPRESSION RING

May either be square or grooved like the scraper design below. May either be square or grooved like the scraper design below.

Chromed face always installs in the top ring land. Engraved “top”, Chromed face always installs in the top ring land. Engraved “top”,

“N”, or other markings, or paint mark denote top of ring. “N”, or other markings, or paint mark denote top of ring.

CENTER RING – SCRAPER RING CENTER RING – SCRAPER RING

Usually has either an inside groove (installs up), or an outside Usually has either an inside groove (installs up), or an outside

groove (installs down). If no grooves or markings, install either groove (installs down). If no grooves or markings, install either

side up. Face may be chrome. side up. Face may be chrome.

OIL RING OIL RING

May be a one piece, or three piece design. One Piece: Unless May be a one piece, or three piece design. One Piece: Unless

marked, install with either side up. marked, install with either side up.

Three Piece: Install corrugated spacer first, then lower rail, then Three Piece: Install corrugated spacer first, then lower rail, then

upper rail. Locate gaps approximately 1” apart. (Note: there is no upper rail. Locate gaps approximately 1” apart. (Note: there is no

“top” to any of the three oil rings). Ends of corrugated center rail “top” to any of the three oil rings). Ends of corrugated center rail

must butt together, not overlap. must butt together, not overlap.

BASIC RE-RINGING PROCEDURES BASIC RE-RINGING PROCEDURES

¾ When re-ringing, follow this procedure for testing piston-to- ¾ When re-ringing, follow this procedure for testing piston-to-

cylinder wall clearance: First, bathe piston and cylinder in diesel or cylinder wall clearance: First, bathe piston and cylinder in diesel or

stove oil (lubricates as it cleans) and leave wet. Nest, place a long- stove oil (lubricates as it cleans) and leave wet. Nest, place a long-

type feeler gauge in the cylinder (NOTE: If thickness of gauge type feeler gauge in the cylinder (NOTE: If thickness of gauge

required to complete this test is .002” or more greater than required to complete this test is .002” or more greater than

original clearance specifications, boring to an oversize is advised). original clearance specifications, boring to an oversize is advised).

Insert piston, without rings, so the gauge contact is made on the Insert piston, without rings, so the gauge contact is made on the

thrust side (at right angles to the piston pin holes). The correct thrust side (at right angles to the piston pin holes). The correct

amount of force required to move the piston, measured by a amount of force required to move the piston, measured by a

spring scale should be 5 to 6 lbs. spring scale should be 5 to 6 lbs.

¾ Inspect cylinder wall for wear. Boring to an oversize generally ¾ Inspect cylinder wall for wear. Boring to an oversize generally

is advisable whenever there’s a ridge of .oo1” or more. is advisable whenever there’s a ridge of .oo1” or more.

¾ Don’t re-use pistons which have seized. Such overheating ¾ Don’t re-use pistons which have seized. Such overheating

invariably causes partial collapse of the piston skirt. This allows invariably causes partial collapse of the piston skirt. This allows

slight rocking of the piston within the cylinder, with resultant slight rocking of the piston within the cylinder, with resultant

poor ring seal. poor ring seal.

¾ Remove any carbon and inspect piston ring lands for wear. If ¾ Remove any carbon and inspect piston ring lands for wear. If

it is possible to insert a .005” feeler gauge between the top ring it is possible to insert a .005” feeler gauge between the top ring

land and the upper surface of the ring, the piston should be land and the upper surface of the ring, the piston should be

replaced. Also check for possible piston pin wear. replaced. Also check for possible piston pin wear.

¾ Before installation, be certain you have the correct ring set. ¾ Before installation, be certain you have the correct ring set.

Ring width must be the same as the piston ring groove. Ring Ring width must be the same as the piston ring groove. Ring

thickness must not be greater than piston ring groove depth. thickness must not be greater than piston ring groove depth.

Misfitted rings can cause severe engine damage. Misfitted rings can cause severe engine damage.

¾ Lightly hone cylinder to remove glaze (with 320 to 360 grit). ¾ Lightly hone cylinder to remove glaze (with 320 to 360 grit).

Thoroughly clean everything in solvent, then with hot, soapy Thoroughly clean everything in solvent, then with hot, soapy

water – then immediately wipe dry and oil to prevent rust. water – then immediately wipe dry and oil to prevent rust.

¾ Check the end gap of each ring by positioning it squarely in ¾ Check the end gap of each ring by positioning it squarely in

the lower, unworn portion of the cylinder (push in place with the the lower, unworn portion of the cylinder (push in place with the

piston). This clearance must not be less than the minimums piston). This clearance must not be less than the minimums

specified above. specified above.

¾ Be sure ring gaps are spaced equally around the piston. Gaps ¾ Be sure ring gaps are spaced equally around the piston. Gaps

falling one above the other can result in a compression leak. falling one above the other can result in a compression leak.

IF YOU HAVE ANY QUESTIONS, GIVE US A CALL! IF YOU HAVE ANY QUESTIONS, GIVE US A CALL!

POWROLL inc. POWROLL inc.

4115 SW 19th. - PO Box 920 4115 SW 19th. - PO Box 920

Redmond OR 97756 Redmond OR 97756

Phone: 541-923-1290 Phone: 541-923-1290

Fax: 541-923-5637 E-Mail mail@powroll.com Fax: 541-923-5637 E-Mail mail@powroll.com

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Manual de Alarma Prestige Aps95bt3 PDFDocument2 paginiManual de Alarma Prestige Aps95bt3 PDFYorvic GodoyÎncă nu există evaluări

- Tie Rod End Failures: 2001-2004 General Motors 1500/2500/3500 TrucksDocument1 paginăTie Rod End Failures: 2001-2004 General Motors 1500/2500/3500 TrucksYorvic GodoyÎncă nu există evaluări

- Installation Manual: Model APS 400Document24 paginiInstallation Manual: Model APS 400Yorvic GodoyÎncă nu există evaluări

- Starting & Starter Clucth SystemDocument9 paginiStarting & Starter Clucth SystemYorvic GodoyÎncă nu există evaluări

- Daqarta - Sound Card Engine Crank and Cam Sensor Simulator Mini-AppDocument26 paginiDaqarta - Sound Card Engine Crank and Cam Sensor Simulator Mini-AppYorvic GodoyÎncă nu există evaluări

- Druid 4 ArduinoDocument8 paginiDruid 4 ArduinoYorvic GodoyÎncă nu există evaluări

- Engine Compression TestingsDocument2 paginiEngine Compression TestingsYorvic GodoyÎncă nu există evaluări

- FCCCGGGGDocument4 paginiFCCCGGGGYorvic GodoyÎncă nu există evaluări

- Ignition Troubleshooting: No Spark: Red R RedDocument2 paginiIgnition Troubleshooting: No Spark: Red R RedYorvic GodoyÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Diesel Generator n14 PDFDocument4 paginiDiesel Generator n14 PDFRobles Jmr100% (1)

- Automotive Maintenance Chapter 3&4Document22 paginiAutomotive Maintenance Chapter 3&4MeleseÎncă nu există evaluări

- 302 EMD Parts Manual 1 - Part2 - 1630037002851Document117 pagini302 EMD Parts Manual 1 - Part2 - 1630037002851Ashish JhaÎncă nu există evaluări

- Part Catalog Es22d5 Es28d5 X3engineDocument96 paginiPart Catalog Es22d5 Es28d5 X3engineSugeng Ariyadi100% (1)

- SD313-2 MFI Control System (G4FC-GSL 1.6L)Document1 paginăSD313-2 MFI Control System (G4FC-GSL 1.6L)Luis GarcíaÎncă nu există evaluări

- Palmarola Joan Masoneria de PerfeccionDocument792 paginiPalmarola Joan Masoneria de PerfeccionIgorCencičÎncă nu există evaluări

- Valenta RP200 12Y3J - Maintenance ScheduleDocument437 paginiValenta RP200 12Y3J - Maintenance SchedulesxturboÎncă nu există evaluări

- Teknik Pengukuran Terbang Tugas I Alat Ukur Di Pesawat TerbangDocument25 paginiTeknik Pengukuran Terbang Tugas I Alat Ukur Di Pesawat TerbangrikiÎncă nu există evaluări

- RM85K7 01a PDFDocument206 paginiRM85K7 01a PDFJames RacingÎncă nu există evaluări

- SMS2008 DX33Document4 paginiSMS2008 DX33Imam DinÎncă nu există evaluări

- Civic 2001 1.7LDocument307 paginiCivic 2001 1.7LIng Luis RojasÎncă nu există evaluări

- 501-KB5, KB5S Illus Parts Cat, 3rd Ed, Rev 1, 12-1-02 (CATALOGO DE PARTES) PDFDocument523 pagini501-KB5, KB5S Illus Parts Cat, 3rd Ed, Rev 1, 12-1-02 (CATALOGO DE PARTES) PDFoperador master 1Încă nu există evaluări

- Service Station Manual Vespa LX 125 - 150 4t Euro 3Document241 paginiService Station Manual Vespa LX 125 - 150 4t Euro 3Adèle Standard100% (1)

- MTU Series 10V1600 ESN 6601002253 PDFDocument154 paginiMTU Series 10V1600 ESN 6601002253 PDFRath Asypaden100% (1)

- Motion Pro Leak Test 2TDocument1 paginăMotion Pro Leak Test 2TLeandro CaraccioliÎncă nu există evaluări

- Iveco UnifluxDocument7 paginiIveco Unifluxal_capone_mkÎncă nu există evaluări

- ICE Handout 2 PDFDocument14 paginiICE Handout 2 PDFFaizan AhmedÎncă nu există evaluări

- Manual Honda Bf25Document138 paginiManual Honda Bf25Printer ProvencalÎncă nu există evaluări

- EB8870Document2 paginiEB8870Miguel RojasÎncă nu există evaluări

- Mazda 2 1.4 16V FXJB: Timing Belt: Removal/installation With Eccentric TensionerDocument11 paginiMazda 2 1.4 16V FXJB: Timing Belt: Removal/installation With Eccentric Tensionermarquin84Încă nu există evaluări

- AP Application Guide PDFDocument5 paginiAP Application Guide PDFLuisYFer1Încă nu există evaluări

- C4 CACTUS 1,6D BlueHDi-BHY (DV6FD) 1.6 - (17-18) DIAGRADocument6 paginiC4 CACTUS 1,6D BlueHDi-BHY (DV6FD) 1.6 - (17-18) DIAGRAFabian Carrasco Naula100% (1)

- Teikin Catalog Vol 18-Automotive FordDocument6 paginiTeikin Catalog Vol 18-Automotive FordBolívar FuentesÎncă nu există evaluări

- 06 CatDocument17 pagini06 CatAntonio Renato CrespoÎncă nu există evaluări

- Chapter-1 Steam Turbine TheoryDocument17 paginiChapter-1 Steam Turbine TheorybhaskarÎncă nu există evaluări

- Man Diesel Engine D 2866 e D 2866 D 2866 Le D 2866 Lxe Operating InstructionsDocument6 paginiMan Diesel Engine D 2866 e D 2866 D 2866 Le D 2866 Lxe Operating InstructionsEstela100% (49)

- PRD Assignment 1Document5 paginiPRD Assignment 1sulthan shadiqahÎncă nu există evaluări

- Chapter 9 GAS Power CycleDocument87 paginiChapter 9 GAS Power CyclezabidullahÎncă nu există evaluări

- Blow Off Valve Presentation: Supervised By: DR - Forat Yasir Prepared byDocument10 paginiBlow Off Valve Presentation: Supervised By: DR - Forat Yasir Prepared byحسين الخزاعيÎncă nu există evaluări

- Kia J3Document6 paginiKia J3ANTONIO RUGAMA100% (1)