Documente Academic

Documente Profesional

Documente Cultură

Opel Corsa C Oil Filter Replacement

Încărcat de

AndrásBakosTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Opel Corsa C Oil Filter Replacement

Încărcat de

AndrásBakosDrepturi de autor:

Formate disponibile

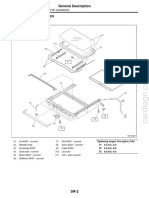

Corsa C

J Engine and Engine Aggregates > DOHC Petrol Engine > Cylinder Head > Camshaft > Repair Instructions > Remove and install both camshafts (Z 12 XE, Z 12 XEP, Z 14

XEP, with air conditioning, LHD)

Remove and install both camshafts (Z 12 XE, Z 12 XEP, Z 14 XEP, with air

conditioning, LHD)

Remove

1. Open bonnet

2. Remove air cleaner housing (1)

• Disconnect 2 wiring harness plugs

– Hot film mass air flow sensor (3), tank

vent valve (2)

• Unclip tank vent valve

• Remove suction pipe (4)

– Unscrew 2 nuts

– Detach engine vent hose (5)

• For Z 12 XEP, Z 14 XEP: detach air intake

hose

– Release clamp

• Remove bolt (arrow)

3. Disconnect 4 cable management wiring harness

plugs

• Oil pressure switch (2), coolant temperature

sensor (3), camshaft sensor (4) and ignition

module (1)

• Unclip wiring trough (5)

• Set wiring harness to one side

4. Remove ignition module

• Remove ignition module cover

– Move to the right

• Unscrew 2 bolts

• Extract using KM-6009 (1)

Note: Do not tilt

5. Remove cylinder head cover

• Detach 2 engine vent hoses

• Unclip coolant hose

• Unscrew 13x bolt

6. Raise vehicle

7. Remove ribbed V-belt cover

• Unscrew 3 bolts (1)

• Remove clip (arrow)

8. Unscrew crankshaft bearing bridge closure bolt (1)

9. Set no.1 cylinder to TDC

• Insert KM-952 (2)

• Turn crankshaft uniformly until KM-952 engages

– Mark on crankshaft belt pulley (4) must line up with lug (3) on timing case

10. Insert KM-953

• KM-953 must engage in camshaft groove

• Remove KM-953

11. Lock chain tensioner

• Unscrew closure bolt (1)

• Load intake camshaft in direction of arrow

via hexagonal section using an open-ended

spanner

• Insert KM-955-1 (2)

12. Remove sliding rail (1)

• Unscrew 2 bolts

13. Detach camshaft sprockets

• Unscrew 2 bolts (2)

– Counterhold camshafts at hexagonal section (3)

• Remove phase sensor disc

14. Remove exhaust camshaft

• Remove camshaft bearing cap

– Note identification

• Release camshaft bearing cap working in

inward spiral from outside in steps of 1/2 to 1

turn

– Camshaft must be evenly released from

the bearing seats

15. Remove intake camshaft

• Remove camshaft bearing cap

– Note identification

• Release camshaft bearing cap working in

inward spiral from outside in steps of 1/2 to 1

turn

– Camshaft must be evenly released from

the bearing seats

Install

16. Inspect components

Note: If cylinder head is to be checked and

overhauled : Remove all outer attaching parts

from cylinder head.

• Camshafts, cylinder head

17. Install intake camshaft

• Coat sliding surfaces with MoS2 lubricating

paste

• Insert camshaft, camshaft bearing cap

– Observe installation position and

allocations

• Install camshaft bearing cap

– Tighten 8 camshaft bearing cap bolts 8

Nm

Note: Tighten in stages in a spiral

from inside to outside

18. Install exhaust camshaft

• Coat sliding surfaces with MoS2 lubricating

paste

• Insert camshaft, camshaft bearing cap

– Observe installation position and

allocations

• Install camshaft bearing cap

– Tighten 8 camshaft bearing cap bolts 8

Nm

Note: Tighten in stages in a spiral

from inside to outside

19. Adjust camshafts

• Insert KM-953 (1)

– "Turn" the camshafts at hexagonal section (arrows)

20. Attach camshaft sprockets

• Renew bolts

• Attach intake camshaft sprocket with phase

sensor disc (2)

– Bolt in bolt

Note: It must be possible to rotate

phase sensor disk by hand

• Attach exhaust camshaft sprocket

– Bolt in bolt

21. Attach sliding rail

• Tighten bolt 8 Nm

22. Remove KM-955-1

• Replace seal ring

• Tighten chain tensioner closure bolt 50 Nm

23. Attach KM-954

• Rotate phase sensor disk (2) until KM-

954 (1) can be attached to timing case

24. Fasten camshaft sprockets

Note: Tightening torque of 10 Nm is used to

secure the camshaft sprockets and the phase

sensor disk

• Tighten 2 bolts (2) 10 Nm

Note: First tighten intake camshaft sprocket

bolt

– Counterhold camshafts at hexagonal

section (1)

25. Remove retaining tools

• KM-952 , KM-953 , KM-954

Note: Retaining tools must not be used for

counterholding

26. Fasten camshaft sprockets

Note: Second person required

• Tighten 2 bolts 50 Nm + 60°

Note: First tighten intake camshaft sprocket

bolt

– Counterhold camshafts at hexagonal

section

27. Timing, Check

• Turn crankshaft (720°)

• Insert KM-952

• Insert KM-953

• Attach KM-954

28. Remove retaining tools

• KM-952 , KM-953 , KM-954

29. Attach closure bolt of crankshaft bearing bridge

• Replace seal ring

• Tighten bolt 50 Nm

30. Install ribbed V-belt cover

• Tighten 3 bolts

• Install clip

31. Lower vehicle

32. Attach cylinder head cover (1)

• Renew gasket (2) and seal rings

• Apply sealant (dimension I = 2 mm)

Note: Complete assembly operations within

10 minutes

• Tighten 13 bolts 8 Nm

33. Attach 2 engine vent hoses

34. Attach ignition module

• Unscrew 2 KM-6009

• Tighten 2 bolts 8 Nm

• Attach ignition module cover

35. Install engine management wiring harness

• Route wiring harness

• Clip-in wiring trough

• Connect 4 wiring harness plugs

36. Install air cleaner housing

• Tighten bolt

• Attach suction pipe

– Replace seal ring

– Tighten 2 nuts

• For Z 12 XEP, Z 14 XEP: attach air intake hose

– Tighten clamp 3.5 Nm

• Attach engine vent hose

• Clip in tank vent valve

• Connect 2 wiring harness plugs

37. Close bonnet

S-ar putea să vă placă și

- Opel Corsa C Coolant Pump ReplacementDocument10 paginiOpel Corsa C Coolant Pump ReplacementAndrásBakosÎncă nu există evaluări

- Timing Cover 190EDocument8 paginiTiming Cover 190ESergio Belmar CrisostoÎncă nu există evaluări

- BMW E46 RearlightDocument4 paginiBMW E46 RearlightLiviu CasuneanuÎncă nu există evaluări

- Yacc Module For Opel Astra G MidDocument17 paginiYacc Module For Opel Astra G MidPrudencio L. Serviano IIIÎncă nu există evaluări

- Alfa Romeo TSpark Timing Belt ReplacementDocument3 paginiAlfa Romeo TSpark Timing Belt ReplacementPier Angelo PalumboÎncă nu există evaluări

- Timing Tool Kit InstructionsDocument4 paginiTiming Tool Kit Instructionsasas100% (1)

- 123 IndexDocument18 pagini123 IndexembokoÎncă nu există evaluări

- Volvo 850 GLT Owners Manual 1993Document176 paginiVolvo 850 GLT Owners Manual 1993jpaulorosado2186Încă nu există evaluări

- Mercedes 04 WDocument6 paginiMercedes 04 WDoszlop DiannaÎncă nu există evaluări

- w169 Mercedes Benz A150 Remove and Install Ignition CoilDocument2 paginiw169 Mercedes Benz A150 Remove and Install Ignition CoilAlex60% (5)

- Infodiag 213Document14 paginiInfodiag 213ArturHeiseÎncă nu există evaluări

- Volvo XC70 - 2006 Late Version - Rear Seat Entertainment System (RSE WIRING DIAGRAMDocument8 paginiVolvo XC70 - 2006 Late Version - Rear Seat Entertainment System (RSE WIRING DIAGRAMsen tilÎncă nu există evaluări

- Fuel Pump Flow RatesDocument6 paginiFuel Pump Flow Rateshenry0% (1)

- Saab CarburettorsDocument86 paginiSaab Carburettorsvanapeer100% (9)

- CatalogDocument45 paginiCatalogAbhinav SharmaÎncă nu există evaluări

- Alfa 156 Front Suspension V 2Document5 paginiAlfa 156 Front Suspension V 2Danny Sabato100% (1)

- Peugeot Citroen Vacuumpomp XUD9Document1 paginăPeugeot Citroen Vacuumpomp XUD9VASEKÎncă nu există evaluări

- Opel Astra H - Simboluri Sigurante ElectriceDocument5 paginiOpel Astra H - Simboluri Sigurante ElectricebunaciuneÎncă nu există evaluări

- Remove The Centre Console Astra GDocument3 paginiRemove The Centre Console Astra GMilosÎncă nu există evaluări

- X5 Navigation RetrofitDocument37 paginiX5 Navigation RetrofitMa100% (1)

- Bosch KE3-Jetronic Mixture AdjustmentDocument5 paginiBosch KE3-Jetronic Mixture Adjustmentasamu10Încă nu există evaluări

- Fiat Grande Punto 293Document17 paginiFiat Grande Punto 293sansam77Încă nu există evaluări

- BMW E23 24 28 OdogearDocument9 paginiBMW E23 24 28 OdogearporkfaceÎncă nu există evaluări

- 1.4 Golf Fluctuating Idle and Poor StartingDocument23 pagini1.4 Golf Fluctuating Idle and Poor StartingEngine Tuning UPÎncă nu există evaluări

- Tolerance Data 2009.1 Tools 1. "999-5452"Document8 paginiTolerance Data 2009.1 Tools 1. "999-5452"volvoosad100% (1)

- Sportautomatic DIY: Upgrading Cars From non-SATDocument16 paginiSportautomatic DIY: Upgrading Cars From non-SATArik YeganyanÎncă nu există evaluări

- 1 PDFDocument17 pagini1 PDFMaxim MackenzyÎncă nu există evaluări

- Seats With Memory RetrofitDocument19 paginiSeats With Memory RetrofitEdi NicolauÎncă nu există evaluări

- 4.0 CDI Virtual EGR SystemsDocument9 pagini4.0 CDI Virtual EGR SystemsExtrat poisÎncă nu există evaluări

- Renault MeganeDocument7 paginiRenault MeganeMickey4mickey100% (2)

- VW T4 - Pump Adjustment2Document3 paginiVW T4 - Pump Adjustment2Samuel Anthony LloydÎncă nu există evaluări

- Manual - Abarth500 EcuDocument16 paginiManual - Abarth500 EcuJdkdkd KddkfkÎncă nu există evaluări

- 1991 VW LT Owners ManualWMDocument141 pagini1991 VW LT Owners ManualWMTom capitao. skipperÎncă nu există evaluări

- New 5 - and 6-Cylinder VW Diesel EnginesDocument28 paginiNew 5 - and 6-Cylinder VW Diesel EnginesErick RodriguesÎncă nu există evaluări

- 87 190E 190e2point6 OMDocument113 pagini87 190E 190e2point6 OMCenk KORKUTURÎncă nu există evaluări

- Golf-March-2006 PDFDocument30 paginiGolf-March-2006 PDFCaroline PuckettÎncă nu există evaluări

- Haltech Support CenterDocument15 paginiHaltech Support Centerkorovnikovdenis8Încă nu există evaluări

- Diesel Information: Vehicle ElectronicsDocument6 paginiDiesel Information: Vehicle ElectronicsAminadavÎncă nu există evaluări

- Scenic Family RenaultDocument20 paginiScenic Family RenaultUZNAPMÎncă nu există evaluări

- Fiat Stilo 1.9 JTD 115 Active Manual 3 Door SpecsDocument3 paginiFiat Stilo 1.9 JTD 115 Active Manual 3 Door SpecsSándor SzarkaÎncă nu există evaluări

- 1.2 3cyl EngineDocument17 pagini1.2 3cyl Engineeurohaus100% (4)

- Aj6 Engineering IgnitionDocument9 paginiAj6 Engineering IgnitionBo BoboÎncă nu există evaluări

- ZP Cat Ebook Oil-Change-Kits-Pc in 2013Document80 paginiZP Cat Ebook Oil-Change-Kits-Pc in 2013Israel TomalaÎncă nu există evaluări

- Crankshaft Position Sensor BMW E39 PDFDocument21 paginiCrankshaft Position Sensor BMW E39 PDFCiufi 1Încă nu există evaluări

- SSP 157 - ABF Engine ManagementDocument13 paginiSSP 157 - ABF Engine ManagementMatt DethÎncă nu există evaluări

- 407 Auxiliary Heating Thermo TopDocument32 pagini407 Auxiliary Heating Thermo ToptarekamininfoÎncă nu există evaluări

- W164 OM642 Diesel Camshaft Position Sensor Replacement DIY AMG - W211Document4 paginiW164 OM642 Diesel Camshaft Position Sensor Replacement DIY AMG - W211gastronomicaÎncă nu există evaluări

- DIY Heated Seats RetrofitDocument27 paginiDIY Heated Seats RetrofitvalymadÎncă nu există evaluări

- W211 Charcoal Filter Replacement PDFDocument1 paginăW211 Charcoal Filter Replacement PDFTiago SantosÎncă nu există evaluări

- Volkswagen TransporterDocument11 paginiVolkswagen TransporterKhaled FatnassiÎncă nu există evaluări

- Webasto Telestart T90 Octavia Installation GuideDocument12 paginiWebasto Telestart T90 Octavia Installation GuidePavel CosminÎncă nu există evaluări

- Rear - Camera MINI OEMDocument18 paginiRear - Camera MINI OEMEdiJonÎncă nu există evaluări

- Alfa 147 Oil PressureDocument15 paginiAlfa 147 Oil PressureStefan SvenssonÎncă nu există evaluări

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesDe la EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesÎncă nu există evaluări

- SM Communication-SystemDocument10 paginiSM Communication-SystemAndrásBakosÎncă nu există evaluări

- SM Body-StructureDocument2 paginiSM Body-StructureAndrásBakosÎncă nu există evaluări

- SM Cruise-ControlDocument14 paginiSM Cruise-ControlAndrásBakosÎncă nu există evaluări

- SM Combination-MeterDocument28 paginiSM Combination-MeterAndrásBakosÎncă nu există evaluări

- SM SunroofDocument24 paginiSM SunroofAndrásBakosÎncă nu există evaluări

- SM - Cruise Control DiagDocument26 paginiSM - Cruise Control DiagAndrásBakosÎncă nu există evaluări

- SM 6Document228 paginiSM 6AndrásBakosÎncă nu există evaluări

- SSP385 6-Speed Automatic Gearbox 09L 0AT 0B6 0BQ 09EDocument96 paginiSSP385 6-Speed Automatic Gearbox 09L 0AT 0B6 0BQ 09EdeklokkieÎncă nu există evaluări

- SSP 284 6 Speed Automatic Gearbox 09E in The Audi A8 '03 2Document52 paginiSSP 284 6 Speed Automatic Gearbox 09E in The Audi A8 '03 2AndrásBakosÎncă nu există evaluări

- PHILIPS CH - TPN15.1E LA PDFDocument150 paginiPHILIPS CH - TPN15.1E LA PDFnego20100% (1)

- VESTEL 17mb62-Service-ManualDocument74 paginiVESTEL 17mb62-Service-Manualzarevg100% (5)

- Part List Mazda 3Document19 paginiPart List Mazda 3Rujisak Muangsong100% (1)

- 39pfl3088h - 12 - Fin - Aen Instalation Instruction PDFDocument2 pagini39pfl3088h - 12 - Fin - Aen Instalation Instruction PDFdansempaiÎncă nu există evaluări

- Delta Adp-90sb BBDocument1 paginăDelta Adp-90sb BBatomo33100% (1)

- Etl Squix4 enDocument16 paginiEtl Squix4 enCesar HdzÎncă nu există evaluări

- Information Sheet 2.1-3docxDocument5 paginiInformation Sheet 2.1-3docxErnesto CabuyadaoÎncă nu există evaluări

- EPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 21-40Document20 paginiEPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 21-40Ion IonutÎncă nu există evaluări

- Service Manual Bell Howell BH1585Document57 paginiService Manual Bell Howell BH1585Luiz GerbaseÎncă nu există evaluări

- Thermofix LasinstructiesDocument174 paginiThermofix LasinstructiesDaniel GarcíaÎncă nu există evaluări

- Filtros RotatoriosDocument2 paginiFiltros RotatoriosManuel Alejandro Gonzalez AguayoÎncă nu există evaluări

- 1 VFB IomDocument22 pagini1 VFB IomshambhoiÎncă nu există evaluări

- Manual p5000 Servicio CatDocument349 paginiManual p5000 Servicio CatSimón100% (1)

- Samsung Washer Wa17l9wDocument65 paginiSamsung Washer Wa17l9wfixioncj100% (2)

- Conveyor Material HandlingDocument79 paginiConveyor Material HandlingmichaelÎncă nu există evaluări

- Belt Conveyor Counter Weight CalculationDocument1 paginăBelt Conveyor Counter Weight Calculationm_verma2180% (5)

- 4 PulleysDocument14 pagini4 PulleysMuhammadTaufikAliRahmanÎncă nu există evaluări

- Unit Operations - George Granger Brown ... (Et Al.) - PDFDocument8 paginiUnit Operations - George Granger Brown ... (Et Al.) - PDFMegatantri Sekar HapsariÎncă nu există evaluări

- GB PelletizingDocument20 paginiGB PelletizingsetavietnamÎncă nu există evaluări

- Optimum: Modification InstructionDocument101 paginiOptimum: Modification Instructiondelbes Aurelien (Delbes tgb13)Încă nu există evaluări

- Sensor Gaurd Installation and Maintenance ManualDocument57 paginiSensor Gaurd Installation and Maintenance ManualCapacitacion TodocatÎncă nu există evaluări

- Unit IDocument3 paginiUnit Imahendra babu mekalaÎncă nu există evaluări

- Best Maintenance Repair PracticesDocument4 paginiBest Maintenance Repair PracticesMahaveer SinghÎncă nu există evaluări

- Powerscreen Chieftain 2100X 2 Deck Technical Specification Rev 8 01 01 2016 PDFDocument11 paginiPowerscreen Chieftain 2100X 2 Deck Technical Specification Rev 8 01 01 2016 PDFS Sathish Kumar100% (1)

- Bobcat 637Document581 paginiBobcat 637Sava IonuTz88% (16)

- BME Unit 8 Power TransmissionDocument8 paginiBME Unit 8 Power Transmissionalysonmicheaala100% (1)

- Falk True Torque Fluid CouplingsDocument32 paginiFalk True Torque Fluid CouplingsJms JayasingheÎncă nu există evaluări

- Kinematics of MachineryDocument20 paginiKinematics of MachineryJustin MercadoÎncă nu există evaluări

- Me6601 QB 4 PDFDocument15 paginiMe6601 QB 4 PDFpremgmech762Încă nu există evaluări

- Development and Application of Geneva Mechanism For Bottle Washing.Document11 paginiDevelopment and Application of Geneva Mechanism For Bottle Washing.AJER JOURNALÎncă nu există evaluări

- Machinist MathsDocument16 paginiMachinist Mathsjaydeep jethavaÎncă nu există evaluări

- How To Fix A Washing Machine: 9 Common Problems: Attempting RepairsDocument6 paginiHow To Fix A Washing Machine: 9 Common Problems: Attempting RepairsLouieGonzalesÎncă nu există evaluări

- Machine Elements in MotionDocument28 paginiMachine Elements in Motionalvaromviegas_191514Încă nu există evaluări

- En 13463-5-2003 Non-Electrical Equipment For Use in Potentially Explosive Atmospheres - Protection by Constructional Safety CDocument32 paginiEn 13463-5-2003 Non-Electrical Equipment For Use in Potentially Explosive Atmospheres - Protection by Constructional Safety Cshreyshah2488Încă nu există evaluări

- D4204T5 EngineDocument52 paginiD4204T5 EngineCristian100% (7)