Documente Academic

Documente Profesional

Documente Cultură

Regulators and Final Control Elements

Încărcat de

jigjigawDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Regulators and Final Control Elements

Încărcat de

jigjigawDrepturi de autor:

Formate disponibile

Regulators and Final Control

Elements

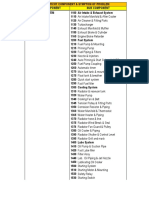

7

7.1 Electric Motors 1377

DAMPERS AND LOUVERS 1362 Motor Drivers 1378

Introduction 1362 Controllers 1378

Damper Designs 1363 Sensors for Feedback 1378

Parallel-Blade Dampers and Louvers 1364 Communication Protocols 1380

Rotating Disc Dampers 1365 Conclusions 1380

Multiple-Disc Dampers 1365 References 1380

Fan Suction Dampers 1366 Bibliography 1381

Variable-Orifice Dampers 1366

Conclusions 1367 7.4

Bibliography 1367 PUMPS AS CONTROL ELEMENTS 1382

Rotodynamic or Centrifugal Pumps 1384

7.2

Radial-Flow 1384

EELECTRIC ENERGY MODULATION 1368

Axial- and Mixed-Flow 1385

Introduction 1368 Peripheral or Regenerative Turbine 1385

On/Off Power Control 1369 Positive-Displacement Pumps 1386

Throttling Power Controllers 1369 Rotary Pumps 1386

Saturable Core Reactors 1369 Gear Pumps 1387

SCR Power Controllers 1370 Reciprocating Pumps 1387

Zero-Voltage-Fired SCR Controllers 1371 Air Pumps and Air Lifts 1388

Controlling Infrared Tungsten Heaters 1372 Condensate Pumps 1388

Common SCR Limitations 1372 Air Lifts 1388

Ignitron Tube 1373 Design of Pumping Systems 1388

Power Amplifier 1374 Head Requirements 1388

References 1374 NPSH Calculation 1389

Bibliography 1374 Specific Speed 1390

Horsepower 1390

7.3 Installation Considerations for Wastewater

LINEAR AND ANGULAR Pumping Stations 1390

POSITIONING OF MACHINERY 1375 Metering Pumps 1391

Open- and Closed-Loop Positioning 1376 Plunger Pumps 1391

Positioning System Components 1376 Diaphragm Pumps 1392

Motors and Actuators 1377 Pneumatic Metering Pumps 1393

1359

© 2006 by Béla Lipták

1360 Regulators and Final Control Elements

Installation Considerations 1393 Stability 1422

NPSH and Pulsation Dampening 1395 Safety 1423

Opposed Centrifugal Pumps 1395 Installation 1423

Bibliography 1396 Bibliography 1423

ISA Specification Form (Table 7.7s) 1425

Instructions for ISA Form S20.51 1425

7.5

REGULATORS—FLOW 1397

7.8

Introduction 1398 REGULATORS—TEMPERATURE 1426

Purge Flow Regulators 1398

Introduction 1427

Flow Regulators for Chromatographs 1399

Variable-Orifice Flow Regulators 1399 Control Quality 1427

HVAC Balancing Flow Regulators 1399 Types of Temperature Regulators 1428

Oil Flow Regulator 1401 Direct- and Pilot-Actuated 1428

Industrial Flow Regulators 1401 Remote or Internal Element 1428

Thermal Mass Flowmeters 1402 Accessories and Special Features 1429

Bibliography 1403 Thermal Systems 1430

Bulbs, Wells, Fittings 1430

Vapor-Filled System 1431

7.6 Liquid-Filled System 1434

REGULATORS—LEVEL 1405 Hot Chamber System 1435

Fusion-Type System (Wax-Filled) 1435

Introduction 1405 The Regulator Valve 1436

Float-Type Level Regulators 1405 Single- and Double-Seated Valves 1436

The Phenomenon of Offset 1406 Three-Way Valves 1436

Span, Dead Band, and Hysteresis 1406 Valve Features 1438

Power Generated by the Float 1406

Conclusions 1438

Specific Gravity and Temperature Effects 1407

Bibliography 1438

Stuffing Boxes 1408

Installation 1408

Conclusions 1409 7.9

Diverter Valves 1409 THERMOSTATS AND HUMIDISTATS 1440

Altitude Valves 1410 Introduction 1441

Bibliography 1411 Accuracy of Thermostats and Humidistats 1441

Conventional 1441

Advanced 1441

7.7 Thermostats 1441

REGULATORS— PRESSURE 1412 ElectroMechanical Designs 1442

Introduction 1413 Electrical/Electronic Design Features 1442

Regulators vs. Control Valves 1414 Microprocessor-Based Units 1443

Control Valves 1414 Control by Phone 1443

Regulator Applications 1414 The Proportional-Only Controller 1443

Gas Industry Applications 1415 Thermostat Action and Spring Range 1445

Liquid Pressure Regulation 1415 Thermostat Design Variations 1445

Gas Station Safety Regulators 1416 Special-Purpose Thermostats 1446

Pressure Surge Relief Valves 1416 Humidistats 1450

Pressure Regulator Designs 1416 Relative Humidity Sensors 1450

Weight-Loaded Regulators 1418 Humidistat Design Features 1452

Spring-Loaded Regulators 1418 Bibliography 1453

Pilot-Operated Regulators 1418

Regulator Characteristics and Sizing 1419

Seating and Sensitivity 1419 7.10

Droop or Offset 1420 VARIABLE-SPEED DRIVES 1454

Noise 1421 Introduction 1455

Cavitation 1422 Transportation Efficiency 1455

Sizing and Rangeability 1422 Characteristics of Variable-Speed Drives 1455

© 2006 by Béla Lipták

Contents of Chapter 7 1361

Electromechanical Drives 1456 Thyristor DC Drives 1464

Mechanical Variable-Speed Drives 1456 Variable-Frequency Drives 1465

Hydraulic Variable-Speed Drives 1458 Comparison of Solid-State Drives 1468

Magnetic Variable-Speed Drives 1459 Efficiency of Solid-State Drives 1469

Variable Voltage 1461 Recent VFD Developments 1469

Pole-Changing AC Motors 1461 Efficiency of Variable-Speed Drives

Solid-State Variable-Speed Drives 1461 and Pumps 1469

Underlying Semiconductor Technology 1461 Evaluation of VSD Efficiencies 1470

Drive Circuit Topologies 1462 Conclusions 1471

Variable-Speed DC Motors 1462 Bibliography 1471

© 2006 by Béla Lipták

7.1 Dampers and Louvers

A. BRODGESELL (1970) B. G. LIPTÁK (1985, 1995, 2005)

Flow sheet symbol

Types of Designs: A. Multiple blade or louver

B. Rotating disc, including multiple disc

C. Radial vanes

D. Iris-type variable orifice

(Note: Some butterfly valves and guillotine-type slide gate valves are similar in

their functions to dampers. They are discussed in Chapter 6.)

Design Pressure: Type A designs can usually handle up to 10 in. H2O (2.5 kPa) shut-off differen-

tials; type D units can handle up to 15 psid (103 kPa)

Materials of Construction: Steel, galvanized steel, aluminum, and fiberglass; stainless steel is used in special

cases

Sizes: Type A dampers are available up to 6 ft × 8 ft (1.8 m × 2.4 m) for HVAC

applications and in even larger sizes for boilers and other industrial applications

Flow Characteristics: See Figure 7.1b

2

Leakage through Each ft At 3 in. H2O (0.75 kPa) shut-off pressure differential: the leakage of standard type

2 2 2

(0.092 m ) of Damper Area: A units is 50 SCFM (250 l/s/m ); special low-leakage type A, 5 SCFM (25 l/s/m );

2

positive-steel type B, 0.5 SCFM (2.5 l/s/m )

Costs: Type A costs range from $100 to $250 per square foot of area ($1000 to $2500

per square meter) as a function of size, features, and accessories

Partial List of Suppliers: Air Clean Damper Co. (www.aircleandamper.com)

Arrow United Industries (www.arrowunited.com)

Babcock & Wilcox Co. (www.babcock.com)

Bachmann Industries (www.bachmannusa.com)

Belimo Air Controls (www.belimo.org)

Damper Design Inc.(www.damperdesign.com)

Flextech Industries (www.flextech-ind.com)

FMC Corp. (www.fmc.com)

Honeywell Sensing and Controls (www.honeywell.com/sensing)

Johnson Controls (www.jci.com)

Louvers & Dampers Inc. (www.louvers-dampers.com)

Miracle Vent Inc. (www.miraclevent.com)

Polymil Products Inc. (www.polymil.com)

Ruskin Air & Sound Control (www.ruskin.com)

Safe-Air/Dowco (www.safeair-dowco.com)

Vent Products Co. (www.ventprod.com)

Young Regulator Co. (www.youngregulator.com)

INTRODUCTION such as heating, ventilation, and air conditioning (HVAC),

while the process control-quality units can handle higher

Dampers and louvers are used to control the flow of gases and pressures, higher temperatures, and corrosive vapors. The

vapors. These streams usually flow in large ducts at relatively process control-quality units also can provide superior leak-

low static pressures. There are both “commercial” and “pro- age and control characteristics.

cess control” quality dampers on the market. Commercial- Dampers are also used to control the flow of solids or to

quality units are used for the less-demanding applications, throttle the capacity of fans and compressors. There is no

1362

© 2006 by Béla Lipták

7.1 Dampers and Louvers 1363

Top 1.0

0.8

0.6

Joint unsupported

by vertical 0.5

edge stop

0.4

Air flow

Joint supported Vertical edge stop 0.3

by vertical

edge stop

0.2

Joint unsupported

Top and bottom by vertical

leaf edges 0.15

edge stop

deflect toward

Damper pressure drop (in. w.g.)

horizontal

io

edge stop under 0.1

rat

pressure 0.09

a

are

0.08

Parallel Bottom

0

0.5

e

0.07

0.7 0

Fre

0.6

damper Opposed blade proportioning

0

0.06

5

(uni-rotational damper

0.7

0.05

0

0.8

louvre) (counter-rotational louvre)

0.04

FIG. 7.1a

The designs of the parallel-blade and opposed-blade dampers, 0.03

which are also referred to as uni-rotational and counter-rotational

louver designs. 0.02

0.015

1.0

0.01

90° louvre

(parallel)

0.8 0.008

Fraction of maximum flow

0.007

0.006

0.6 0.005

0.004

0.4 Butterfly 500 700 1000 1500 3000 5000

(150) (210) (300) (450) (900) (1500)

800 2000 4000

0.2 (240) (600) (1200)

Approach velocity ft/m (m/m)

0 FIG. 7.1c

0 0.2 0.4 0.6 0.8 1.0

Fraction of maximum rotation Pressure drop through wide-open dampers. The free-area ratio of

100 Percent of total

an open damper is the total open area between the blades, divided

A-1

B-2 system drop by the nominal area.

Linear C-5 through the

80 D-8 damper in the

E - 22 wide open

Percent maximum flow

F - 50 position

clear distinction between butterfly valves and butterfly damp-

60

C G - Inherent character- ers or between slide-gate valves and guillotine dampers. The

A B E F G

D istic of an opposed design features of these dampers are quite similar to their

blade damper with

40 equal percentage control valve counterparts, which are discussed in Chapter 6.

linkage at a constant

pressure drop

Dampers in general are large in size, and their operating

20 and shut-off pressures are limited to lower values. The diam-

eters of the largest dampers can exceed 20 ft (6 m).

0

0 20 40 60 80 100

Percent linkage movement

DAMPER DESIGNS

FIG. 7.1b

The flow characteristics of a parallel-blade damper are similar to

those of a conventional butterfly valve (see top part of this figure). Dampers and louvers can be grouped according to their

The flow characteristics of an opposed-blade damper approach equal- shapes into parallel-blade, disc and multiple-disc, radial vane,

percentage characteristics when the total system pressure drop is and variable-orifice designs. Within each design category,

through it and it shifts its characteristics toward quick opening, as there can be subdivisions according to leakage rates, materi-

the damper receives less and less of the total pressure differential. als of construction, actuator designs, or accessories provided.

© 2006 by Béla Lipták

1364 Regulators and Final Control Elements

3−1/2 in.

90 mm

FIG. 7.1d

2 2

Standard commercial damper frame sizes and areas, ft /m . (Courtesy of Ruskin, previously Johnson Controls.)

Parallel-Blade Dampers and Louvers positioned manually, pneumatically, or electrically. In the

uni-rotational louver (parallel damper) design, the vanes

Multiblade dampers consist of two or more rectangular remain parallel at all rotational positions. In a counter-

vanes mounted on shafts that are one above the other, which rotational louver (opposed blade), alternate vanes rotate

are interconnected so they rotate together (Figure 7.1a). in opposite directions. Both designs are illustrated in

The vanes are operated by an external lever, which can be Figure 7.1a.

© 2006 by Béla Lipták

7.1 Dampers and Louvers 1365

Flow guides are sometimes installed between adjacent Sealed, low-leakage damper

vanes in order to improve the effectiveness of throttling. In

4

the top of Figure 7.1b, the blade-angle vs. flow characteristics

(1.00)

of a parallel-blade damper and a butterfly valve are shown.

The sensitivity of this design is very high at mid-flow while

Pressure differential, inches of H2O (kPa)

the last 30° of rotation is relatively ineffective. The flow

3

characteristics of butterfly valves are similar though some- (0.75)

what superior to those of louvers.

The lower portion of Figure 7.1b shows an opposed-blade

damper with equal percentage linkage. As less and less of 2

the total system pressure drop is assigned to the damper, the (0.50)

characteristics of this damper shift toward quick opening.

Figure 7.1c gives the pressure drop across wide-open

dampers. Ideally the wide-open pressure drop should be 1

between 4 and 8% of the pressure difference across the closed (0.25)

damper. If the damper is sized so that closed pressure differ-

ence is between 12 and 25 times the pressure drop, when the

damper is open, its apparent characteristic will be nearly 0

0 1 2 3 4 5 6 7 8

linear (see curves C and D in Figure 7.1b). (0.3) (0.6) (0.9) (1.2) (1.5) (1.8) (2.1) (2.4)

Figure 7.1d provides some dimensional data for standard Leakage, cfm/ft2 [(m3/min)/m2]

commercial damper frames, including their areas. Static across damper, inches of H2O (kPa)

Low-Leakage Designs The parallel-blade damper cannot Standard unsealed damper

provide tight shut-off because of the long length of unsealed 4

(1.00)

seating surfaces. The leakage characteristics of unsealed stan-

dard dampers are given in the lower portion of Figure 7.1e. In 3

low-leakage damper designs, blade seals are installed along the (0.75)

seating surfaces of the blades, resulting in the reduced leakage 2

characteristic shown in the upper portion of Figure 7.1e. (0.50)

There are a number of variations in the blade-edge seal 1

designs. Some of these designs are illustrated in Figure 7.1f. (0.25)

0

Corrosion Resistant Designs For corrosive services, both 0 10 20 30 40 50 60 70 80 90

(3) (6) (9) (12) (15) (18) (21) (24) (27)

the parallel- and the opposed-blade designs are available in

sizes from 12 by 24 in. up to 60 by 120 in. These units are Leakage, cfm/ft2 [(m3/min)/m2]

made of fiberglass-reinforced polymer with 304 stainless steel FIG. 7.1e

hardware. Some design variations are shown in Figure 7.1g. The leakage rates through sealed, low-leakage dampers are shown

in the top, while the leakage rates of unsealed dampers are given

Actuators and Accessories Damper actuators can be man- in the bottom portion of the figure. (Courtesy of Honeywell and

ual, electric, hydraulic, or pneumatic. Standard pneumatic actu- Ruskin, formerly Johnson Controls.)

2

ators vary their effective diaphragm areas from 2 to 24 in. (13

2

to 155 cm ), while their stroke lengths range from 2 to 6 in. (51

Rotating Disc Dampers

to 152 mm). The amount of force they produce ranges from

about 10 to 300 lbf (4.5 to 136 kgf). The standard spring ranges The rotating disc damper designs are very similar to the but-

for dampers include the spans of 3–7, 5–10, and 8–13 PSIG terfly valve designs, which were discussed in detail in

(0.2–0.48, 0.34–0.68, and 0.54–0.88 bars). Electronic actuators Section 6.17. These dampers are usually installed in circular

can be operated by 4 to 20 mA DC analog or by digital signals. ducts and can be operated both manually or automatically. A

For more accurate throttling, the actuators can also be corrosion-resistant version of this design is made of fiberglass-

provided with positioners. If remote indication of damper reinforced plastics materials and is illustrated in Figure 7.1h.

status is desired, limit switches can be installed to detect the

blade angle. These can be pneumatic sensors of nozzle back- Multiple-Disc Dampers

pressure or mechanically actuated position sensors. The

damper position switch can be furnished with an adjustable A unique variation of the butterfly design is the multiple

mounting flange, which allows the unit to be mounted rotating disc damper. In this design several disc elements are

through a duct wall with the trip lever positioned so that it distributed over an area (Figure 7.1i). One advantage of this

is actuated by the damper blade itself. configuration is improved flow control characteristics,

© 2006 by Béla Lipták

1366 Regulators and Final Control Elements

Model ABK6 Model ABF6 Model ABFA

“K” style “F” style “FA” style

Enlarged view of

blade seal

Pressure

effects

seal

High pressure Low pressure

side side

FIG. 7.1f

Low-leakage damper designs tend to increase the efficiency of 45° Adjustable 90° Adjustable Combination

HVAC systems. In this figure, two blade-edge seal designs are stationary &

adjustable

illustrated. (Courtesy of Honeywell and Ruskin, formerly Johnson

Controls.)

FIG. 7.1g

Corrosion-resistant fiberglass-reinforced polymer damper designs

for both adjustable and stationary applications. (Courtesy of

because each disc can have its own unique spring range and Polymil Products Inc.)

failure position.

Another major advantage is the substantial reduction in Variable-Orifice Dampers

leakage compared to the parallel-blade design. At a static pres-

sure of 3 in. H2O (0.75 kPa) the leakage can be estimated as Variable-orifice dampers use the same principle as the iris

0.01% of full damper capacity, which corresponds to about 0.5 diaphragm of a camera. In order to achieve control action,

2 2 2

SCFM (2.5 l/s/m ) leakage per ft (0.092 m ) of damper area. the closure element moves within an annular ring in the

damper body and produces a circular flow orifice of variable

Fan Suction Dampers

On blowers and fans, when throughputs must be controlled,

radial vane dampers can be utilized. The damper consists of

a number of radial vanes arranged to rotate about their radial

axis (Figure 7.1j).

The radial vane dampers do not provide high-quality

control, and their closed position leakage rates are also high.

Their control applications include furnace draft control.

Usually a positioner is furnished with these units, which

provides a linear relationship between the control signal and

the blade pitch angle. In certain packages the positioner is

factory set in the reverse acting mode, meaning that an increas-

ing control air signal will reduce the air flow by decreasing

the blade pitch. In such packages, one has to install a reversing FIG. 7.1h

relay between the positioner and the actuator, if direct action Corrosion-resistant single-disc damper (Courtesy of Polymil Prod-

is desired. ucts Inc.)

© 2006 by Béla Lipták

7.1 Dampers and Louvers 1367

D-2 D-1 D-1 D-1 D-1 D-2

Actuator

D-3 D-3 D-3

D-4 D-4 Wafer

valve

body

Adjustable

Section A-A orifice

A

FIG. 7.1k

FIG. 7.1i Variable-orifice or iris damper. The sleeve can be made of nylon

Multiple-disc dampers provide better sealing and control or of other materials and is provided with a built-in retaining ring

characteristics. at each end. When the upper end is fixed and the lower end is

rotated, this gradually reduces the orifice opening. At 180° of

diameter (Figure 7.1k). The flow characteristics are similar rotation the orifice is completely closed. If the sleeve is first turned

to those of a linear valve. back on itself, partly “inside out,” the effect of rotation is exactly

However, tight shut-off is not possible, and leakage rates the same, but operates in a much more compact form, as a pleated

are comparable to or greater than those of a butterfly valve duplex diaphragm.

of equal size. Maximum pressure differential is limited to

approximately 15 psid (104 kPa). Dual valve units can be

provided with a common discharge port for applications CONCLUSIONS

involving the blending of two streams.

For solids service, the variable-orifice valve can be used Dampers are suitable for control of large flows at low pressures

for throttling, if the valve is installed in a vertical line. In where high control accuracy is not a requirement. Typical

horizontal lines, the shutter mechanism of the valve forms a applications of these units include air conditioning systems

dam, which makes the valve unsuitable for solids service. and furnace draft control. Variable-orifice or iris dampers are

Standard sizes range from 4 to 12 in. (100 to 300 mm). smaller than other dampers, offer better control quality, and

can also be used to control vertical solid flows.

Bibliography

Ball, K. E., “Final Elements, Final Frontier,” InTech, November 1986.

Brown, E. J., “Air Diffusing Equipment,” in ASHRAE Handbook, Equipment

Volume, Chapter 2, 1979.

“Catalog of U.S. & Canadian Valves & Actuators,” Washington, D.C.: Valve

Manufacturers Association of America, 2003.

Dickey, P. S., “A Study of Damper Characteristics,” Reprint No. A-8, Bailey

Meter Co.

Daryanani, S., et al., “Variable Air Volume Systems,” Air Conditioning,

Heating and Ventilating, March 1966.

“Evaluation Finding for Oiles Multiple Viscous Shear Dampers,” Cerf.

Report: Hitec 99-04, American Society of Civil Engineers, 1999.

Lipták, B. G., “Reducing the Operating Costs of Buildings by Use of Com-

FIG. 7.1j

puters,” ASHRAE Transactions, Vol. 83, Part 1, 1977.

Radial vane dampers are used to throttle the flow on the suction Lipták, B. G., “Optimization of Semiconductor Manufacturing Plants,”

side of air fans and blowers. Instruments and Controls Systems, October 1982.

© 2006 by Béla Lipták

S-ar putea să vă placă și

- Delphi Technologies Vehicle Electronics Catalogue 2017-18 PDFDocument1.460 paginiDelphi Technologies Vehicle Electronics Catalogue 2017-18 PDFGuidoÎncă nu există evaluări

- 2005 Dodge Dakota Transmision 42RLEDocument346 pagini2005 Dodge Dakota Transmision 42RLEGerardo Tamayo Rosas50% (2)

- DR0741 SCH5000CL Parts Manual S N 1K PDFDocument416 paginiDR0741 SCH5000CL Parts Manual S N 1K PDFNova Kurniawan100% (2)

- Transducer Handbook: User's Directory of Electrical TransducersDe la EverandTransducer Handbook: User's Directory of Electrical TransducersÎncă nu există evaluări

- 4239 OEM Engines and Accessories (Saran) : Parts CatalogDocument473 pagini4239 OEM Engines and Accessories (Saran) : Parts CatalogRichard BurbanoÎncă nu există evaluări

- 134-XS 134 S HandBook EDocument110 pagini134-XS 134 S HandBook Emustafa saad50% (2)

- SMCS Codes For Expanded MiningDocument24 paginiSMCS Codes For Expanded MiningJean Claude EidÎncă nu există evaluări

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsDe la Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsEvaluare: 1 din 5 stele1/5 (1)

- PS0601 Commissioning GuidelinesDocument25 paginiPS0601 Commissioning GuidelinesAadarsh Reddy50% (4)

- Suzuki Xl7 Grand Vitara XL 7 Jc636 2007 2009 en Es Info PDFDocument68 paginiSuzuki Xl7 Grand Vitara XL 7 Jc636 2007 2009 en Es Info PDFFaisal Mohammad HassaniÎncă nu există evaluări

- 6.6 Capacity Testing: Standard Formatted For Publication in This Handbook by A. Bálint, 2005)Document4 pagini6.6 Capacity Testing: Standard Formatted For Publication in This Handbook by A. Bálint, 2005)jigjigawÎncă nu există evaluări

- ISO Standards IssuedDocument1 paginăISO Standards IssuedBond BeeBee67% (3)

- Rinnai Tankless Service Manual 100000098 Rev BDocument112 paginiRinnai Tankless Service Manual 100000098 Rev BJonn TaylorÎncă nu există evaluări

- Centrifugal Fans - FlaktwoodsDocument45 paginiCentrifugal Fans - Flaktwoodsnagagop930100% (2)

- Psychrometry Part-2Document11 paginiPsychrometry Part-2Tushar Sharma100% (1)

- Air DryersDocument99 paginiAir Dryersapi-384214360% (5)

- Manual On DIY Hot Water SystemDocument104 paginiManual On DIY Hot Water SystemMeor Amri100% (7)

- API Data SheetsDocument7 paginiAPI Data SheetsalfruizpÎncă nu există evaluări

- Instrument AirDocument11 paginiInstrument AirShariq Ali100% (1)

- 5544 E Refrigeration and Air-Conditioning TechnologyDocument70 pagini5544 E Refrigeration and Air-Conditioning TechnologyOsman KoçakÎncă nu există evaluări

- Bomba Hidraulica Mixer A4VTG090 (SINOTRUCK) PDFDocument20 paginiBomba Hidraulica Mixer A4VTG090 (SINOTRUCK) PDFHector Dongo Arrayan100% (1)

- Airframe HandbookDocument604 paginiAirframe HandbookSantosh BasnetÎncă nu există evaluări

- Transformer Oil Pumps-Operation Installation & Maintenance PDFDocument16 paginiTransformer Oil Pumps-Operation Installation & Maintenance PDFCT Barokah0% (1)

- Nutrafin Aquatic News NR 4 USADocument16 paginiNutrafin Aquatic News NR 4 USAcornerstone2Încă nu există evaluări

- Hidraulic CA-511Document13 paginiHidraulic CA-511Adrian Alonso Bustos GonzalezÎncă nu există evaluări

- Operation and Installation Manual: Prds - Prs - DSH SystemsDocument125 paginiOperation and Installation Manual: Prds - Prs - DSH Systemskikokiko Karim100% (2)

- Apm30 User Guide - (v200r303 - 03)Document181 paginiApm30 User Guide - (v200r303 - 03)Lubo PicturesMakerÎncă nu există evaluări

- BS5440 Quick GuideDocument4 paginiBS5440 Quick Guidenyj martin100% (2)

- Heating Value Measurement of Natural GasDocument8 paginiHeating Value Measurement of Natural GasCarlos Manuel ParionaÎncă nu există evaluări

- Page 1846 PDFDocument1 paginăPage 1846 PDFYeimsÎncă nu există evaluări

- Index Terms Links: Next PageDocument1 paginăIndex Terms Links: Next PageYeimsÎncă nu există evaluări

- Engine (Engine Cooling) : Section 1DDocument9 paginiEngine (Engine Cooling) : Section 1DJuan Alfonso Romero HaroÎncă nu există evaluări

- DTC - Códigos de Avería Mitsubishi (Motores Gasolina y Diesel) - PDFDocument42 paginiDTC - Códigos de Avería Mitsubishi (Motores Gasolina y Diesel) - PDFJose Aguero PomachaguaÎncă nu există evaluări

- T6 XXXDocument21 paginiT6 XXXJózsef JuhászÎncă nu există evaluări

- Armario Snack Concept 1400 DespieceDocument5 paginiArmario Snack Concept 1400 DespiecePedroÎncă nu există evaluări

- Danais 150 ActuadoresDocument28 paginiDanais 150 Actuadoresedark2009Încă nu există evaluări

- G - M Code ListDocument3 paginiG - M Code ListmwasicÎncă nu există evaluări

- AC RTP Nutrunner - US - FINALDocument3 paginiAC RTP Nutrunner - US - FINALManish MohananÎncă nu există evaluări

- Chapter 14 - Pneumatic Control: Service ManualDocument16 paginiChapter 14 - Pneumatic Control: Service ManualAugusto OliveiraÎncă nu există evaluări

- AccuStream 13903 AccuValve Configuration SheetDocument1 paginăAccuStream 13903 AccuValve Configuration SheetAdelaÎncă nu există evaluări

- Manual Banco de Pruebas Motor pt6 2-11-6Document1 paginăManual Banco de Pruebas Motor pt6 2-11-6Jaime Ivan Gonzalez RinconÎncă nu există evaluări

- Fluid I - Lec 11 - ProductionDocument8 paginiFluid I - Lec 11 - Productionamr mohamedÎncă nu există evaluări

- Siyahi Dok.Document2 paginiSiyahi Dok.Namig BabazadehÎncă nu există evaluări

- NISSANDocument1 paginăNISSANJohnny GarciaÎncă nu există evaluări

- Service Manual For Electrical/Electronic: P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028 Utility EquipmentDocument116 paginiService Manual For Electrical/Electronic: P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028 Utility EquipmentMario Garcia100% (1)

- Hierarchy Trouble Code For TSRDocument10 paginiHierarchy Trouble Code For TSRAsri YanÎncă nu există evaluări

- Ifs4000 - AquafluxDocument18 paginiIfs4000 - Aquafluxavikbhai100% (1)

- Operating Manual: RobinairDocument21 paginiOperating Manual: RobinairGeorge Anderzon Victoriano RengifoÎncă nu există evaluări

- Variable Displacement Pump A4VSO: RE 92 050/09.97 1/40 Replaces: 03.97 and 11.95Document40 paginiVariable Displacement Pump A4VSO: RE 92 050/09.97 1/40 Replaces: 03.97 and 11.95nguyễn văn dũngÎncă nu există evaluări

- 394M - Parr - 4540 High Pressure Reactor Inst PDFDocument32 pagini394M - Parr - 4540 High Pressure Reactor Inst PDFlorenzoÎncă nu există evaluări

- Datasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFDocument6 paginiDatasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFshahrol effendy rodziÎncă nu există evaluări

- RTP Nutrunner: Slim, Light, Powerful - Heavy Duty Bolting Has Never Been This Easy!Document8 paginiRTP Nutrunner: Slim, Light, Powerful - Heavy Duty Bolting Has Never Been This Easy!Rizal Agus FiantoÎncă nu există evaluări

- Aptta - Bo 2020 - 003Document30 paginiAptta - Bo 2020 - 003mhgnoseuaÎncă nu există evaluări

- Designed For Use With ILP, IHP Automatic Suppression Unit: Pressure SwitchesDocument2 paginiDesigned For Use With ILP, IHP Automatic Suppression Unit: Pressure SwitchesJohan Villarreal100% (1)

- 1 Fluid Power Devices CircuitsDocument20 pagini1 Fluid Power Devices CircuitshamidouÎncă nu există evaluări

- Manual AWHP UdemodulDocument186 paginiManual AWHP Udemodulscribdbugmenot1919Încă nu există evaluări

- EASA B1 Aircraft Technician Model 130ST Trainer Courseware Card SetsDocument1 paginăEASA B1 Aircraft Technician Model 130ST Trainer Courseware Card SetsAli AbushhiwaÎncă nu există evaluări

- Galaxy D 150 GX GX 415v 50hz enDocument1 paginăGalaxy D 150 GX GX 415v 50hz enBassem MouelhiÎncă nu există evaluări

- Control and Optimization of Unit Operations: 8.1 Aeration and Do Controls 1484Document34 paginiControl and Optimization of Unit Operations: 8.1 Aeration and Do Controls 1484jigjigawÎncă nu există evaluări

- PUHZ-RP35-140 Service Manual (OC334A) PDFDocument138 paginiPUHZ-RP35-140 Service Manual (OC334A) PDFjose antonio MelladoÎncă nu există evaluări

- RE04R01ADocument217 paginiRE04R01As9h6zrywf4Încă nu există evaluări

- WD401Document4 paginiWD401alikuncoro1005Încă nu există evaluări

- CRS390 Packing ListDocument4 paginiCRS390 Packing ListPool Quispe AlcántaraÎncă nu există evaluări

- E415e-1 Bolting Tools en-GBDocument152 paginiE415e-1 Bolting Tools en-GBCristian PardauÎncă nu există evaluări

- Inlet Pressure Regulators: Type A4A-DN, A4AK-DN, A4AE-DN, A4Ar-DnDocument8 paginiInlet Pressure Regulators: Type A4A-DN, A4AK-DN, A4AE-DN, A4Ar-Dn13667514Încă nu există evaluări

- 02 1design CasingDocument37 pagini02 1design CasingSreekanthMylavarapuÎncă nu există evaluări

- SM 7Document317 paginiSM 7ferÎncă nu există evaluări

- LiquifloCatalog 2009 EngineeringDocument67 paginiLiquifloCatalog 2009 Engineeringleo cejaÎncă nu există evaluări

- Hydro EN 12845 Fireset DatabookDocument36 paginiHydro EN 12845 Fireset DatabookfebousÎncă nu există evaluări

- Low Voltage FrequencyDocument40 paginiLow Voltage Frequencyaltax734Încă nu există evaluări

- JAGUAR Fault Codes 0438Document1 paginăJAGUAR Fault Codes 0438sysdlsÎncă nu există evaluări

- Merni Instrumenti PDFDocument108 paginiMerni Instrumenti PDFMareHCÎncă nu există evaluări

- Mercedes-Benz Fault Code List For Control Unit of Engine Control (MR)Document3 paginiMercedes-Benz Fault Code List For Control Unit of Engine Control (MR)Александр СахновÎncă nu există evaluări

- Control and Optimization of Unit Operations: 8.1 Aeration and Do Controls 1484Document34 paginiControl and Optimization of Unit Operations: 8.1 Aeration and Do Controls 1484jigjigawÎncă nu există evaluări

- Regulators and Final Control ElementsDocument9 paginiRegulators and Final Control ElementsjigjigawÎncă nu există evaluări

- 6.23 Valve Types: Sliding Gate Valves: C. S. Beard B. G. LiptákDocument5 pagini6.23 Valve Types: Sliding Gate Valves: C. S. Beard B. G. Liptáksalic2013Încă nu există evaluări

- 1081ch6 8Document4 pagini1081ch6 8jigjigawÎncă nu există evaluări

- 6.18 Valve Types: Digital Valves: D. R. A. Jones B. G. LiptákDocument6 pagini6.18 Valve Types: Digital Valves: D. R. A. Jones B. G. LiptákjigjigawÎncă nu există evaluări

- 6.22 Valve Types: Saunders Diaphragm Valves: C. E. Gaylor B. G. LiptákDocument5 pagini6.22 Valve Types: Saunders Diaphragm Valves: C. E. Gaylor B. G. LiptákjigjigawÎncă nu există evaluări

- 6.5 Diseño Avanzado de Steam PackingDocument6 pagini6.5 Diseño Avanzado de Steam Packingpca97Încă nu există evaluări

- 2.24 Real-Time Performance Assessment: J. P. GerryDocument7 pagini2.24 Real-Time Performance Assessment: J. P. GerryjigjigawÎncă nu există evaluări

- 2.25 Relative Gain Calculations: B. D. Campbell, P. G. Friedmann F. G. ShinskeyDocument5 pagini2.25 Relative Gain Calculations: B. D. Campbell, P. G. Friedmann F. G. ShinskeyjigjigawÎncă nu există evaluări

- 2.26 Robustness: A Guide For Sensitivity and Stability: J. P. GerryDocument3 pagini2.26 Robustness: A Guide For Sensitivity and Stability: J. P. GerryjigjigawÎncă nu există evaluări

- 2.36 Tuning Level Control Loops: H. L. WadeDocument10 pagini2.36 Tuning Level Control Loops: H. L. WadejigjigawÎncă nu există evaluări

- 2.20 Optimizing Control: F. G. Shinskey C. G. Laspe B. G. Lipták M. RuelDocument10 pagini2.20 Optimizing Control: F. G. Shinskey C. G. Laspe B. G. Lipták M. RueljigjigawÎncă nu există evaluări

- 2.23 Ratio Control: F. G. Shinskey B. G. Lipták J. E. Jamison, A. RohrDocument6 pagini2.23 Ratio Control: F. G. Shinskey B. G. Lipták J. E. Jamison, A. RohrjigjigawÎncă nu există evaluări

- 1.4 Electronic vs. Pneumatic Instruments: H. L. Feldman R. K. Kaminski B. G. LiptákDocument5 pagini1.4 Electronic vs. Pneumatic Instruments: H. L. Feldman R. K. Kaminski B. G. LiptákjigjigawÎncă nu există evaluări

- 1081app A 9Document7 pagini1081app A 9jigjigawÎncă nu există evaluări

- 1.7 Speech Synthesis and Voice Recognition: D. H. F. Liu B. G. LiptákDocument7 pagini1.7 Speech Synthesis and Voice Recognition: D. H. F. Liu B. G. LiptákjigjigawÎncă nu există evaluări

- 1081ch2 12 PDFDocument4 pagini1081ch2 12 PDFCristopher EntenaÎncă nu există evaluări

- 1081ch2 1Document25 pagini1081ch2 1jigjigawÎncă nu există evaluări

- 1081app A 10Document3 pagini1081app A 10jigjigawÎncă nu există evaluări

- Composition of Metallic and Other MaterialsDocument3 paginiComposition of Metallic and Other MaterialsGaurav MishraÎncă nu există evaluări

- A.6 Friction Loss in Pipes: B. G. LiptákDocument4 paginiA.6 Friction Loss in Pipes: B. G. LiptákjigjigawÎncă nu există evaluări

- A.5 Steam and Water Tables: B. G. LiptákDocument8 paginiA.5 Steam and Water Tables: B. G. LiptákjigjigawÎncă nu există evaluări

- Control and Optimization of Unit Operations: 8.1 Aeration and Do Controls 1484Document34 paginiControl and Optimization of Unit Operations: 8.1 Aeration and Do Controls 1484jigjigawÎncă nu există evaluări

- 6.22 Valve Types: Saunders Diaphragm Valves: C. E. Gaylor B. G. LiptákDocument5 pagini6.22 Valve Types: Saunders Diaphragm Valves: C. E. Gaylor B. G. LiptákjigjigawÎncă nu există evaluări

- Chemical Resistance of MaterialsDocument9 paginiChemical Resistance of MaterialsGaurav MishraÎncă nu există evaluări

- 6.23 Valve Types: Sliding Gate Valves: C. S. Beard B. G. LiptákDocument5 pagini6.23 Valve Types: Sliding Gate Valves: C. S. Beard B. G. Liptáksalic2013Încă nu există evaluări

- 6.18 Valve Types: Digital Valves: D. R. A. Jones B. G. LiptákDocument6 pagini6.18 Valve Types: Digital Valves: D. R. A. Jones B. G. LiptákjigjigawÎncă nu există evaluări

- 1081ch6 8Document4 pagini1081ch6 8jigjigawÎncă nu există evaluări

- Climavair Vai 2025 ManualDocument26 paginiClimavair Vai 2025 ManualRobredoroÎncă nu există evaluări

- Honeywell ThermostatDocument24 paginiHoneywell Thermostatasdfasdf88Încă nu există evaluări

- VRV-3W Service ManualDocument302 paginiVRV-3W Service ManualMarceloÎncă nu există evaluări

- Advance Payment of Materials - Percentage BreakdownDocument4 paginiAdvance Payment of Materials - Percentage BreakdownRohitÎncă nu există evaluări

- NL Master Specification Guide For Public Funded Buildings: Revised 2010/09/02Document7 paginiNL Master Specification Guide For Public Funded Buildings: Revised 2010/09/02bertoyÎncă nu există evaluări

- 50TD Continuous Physical Refining Equipment ListDocument4 pagini50TD Continuous Physical Refining Equipment ListWanda OilpressÎncă nu există evaluări

- Keeping Motor Windings Dry: Facilities Instructions, Standards, and TechniquesDocument10 paginiKeeping Motor Windings Dry: Facilities Instructions, Standards, and TechniquesAns MehmoodÎncă nu există evaluări

- Tide Load 10 V 1Document48 paginiTide Load 10 V 145saulÎncă nu există evaluări

- 2017 York VRF Gen II Brochure - 053017 - DigitalDocument8 pagini2017 York VRF Gen II Brochure - 053017 - DigitalDaniel VelasquezÎncă nu există evaluări

- Firstenburg Detailed Case Study PDFDocument10 paginiFirstenburg Detailed Case Study PDFArunimaHarshan0% (1)

- Water Steam PathDocument14 paginiWater Steam PathJenal TampubolonÎncă nu există evaluări

- AQIS Methyl Bromide Fumigation Standard v1.5Document62 paginiAQIS Methyl Bromide Fumigation Standard v1.5Isa AltunÎncă nu există evaluări

- Longman Press Test Your Professional English - Hotel and Catering 2Document40 paginiLongman Press Test Your Professional English - Hotel and Catering 2Soraya QuirinoÎncă nu există evaluări

- User Manual For Greenstar I Junior Manufactured From Aug 09Document20 paginiUser Manual For Greenstar I Junior Manufactured From Aug 09Ady HughesÎncă nu există evaluări

- New Microsoft Word DocumentDocument25 paginiNew Microsoft Word DocumentRathin KukrejaÎncă nu există evaluări