Documente Academic

Documente Profesional

Documente Cultură

Civil Work Specification Part 38

Încărcat de

AM MADrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Civil Work Specification Part 38

Încărcat de

AM MADrepturi de autor:

Formate disponibile

tends to follow an easy course through the wood and in this case it is essential that the knife be firmly

guided along the glue line.

The bond should just pass the requirement, it is judged by the relative amount of wood fibre left on the

core veneer, and the area prised off. The grading is assessed chiefly on the appearance of the break.

The force needed to effect separation is also an accompanying requirement.

The bond is ‘excellent’, when it is difficult to find the glue line and impossible to keep the tool within it

for more than 6 mm without cutting adjacent wood. On prising upwards, the veneer usually breaks off

over a width slightly greater than that of the tool.

The bond is ‘poor’ when knife meets little opposition in the glue line and the prise results in the easy

removal of almost all the veneers from one side of the test piece. The separated veneers are usually

almost free from adherent fibre.

(iii) Reporting of test results : The results shall be reported as ‘pass standard’ ‘excellent’ or ‘poor’.

F-3. GLUE ADHESION TEST

Four square sections, 150 x 150 mm shall be cut from the corners of the door. These four corner

sections as cut from the door shall be immersed in boiling water for 4 hours, then dried at 27 ± 2°C and

relative humidity of 65 ± 5 per cent for 24 hours. At the end of the drying period, the samples shall be

examined for delamination. In the case of the glue lines in the plywood, all the four exposed edges of the

plywood on both faces of a specimen shall be examined for delamination.

A specimen shall be considered to have passed the test if no delamination has occured in the glue

lines in the plywood and if no single delamination more than 50 mm in length and more than 3 mm in

depth has occured in the assembly glue lines between the plywood faces and the stile and rail.

Delamination at the corner shall be measured continuously around the corner. Delamination at a knot,

knot hole, a pitch pocket and worm hole or other permissible wood defects shall not be considered in

assessing the sample. A door shall be deemed to have passed this test if three of the four specimens

tested pass the test.

359 SUB HEAD 9.0 : WOOD WORK AND P.V.C. WORK

APPENDIX G

TEST FOR MORTICE LOCKS

(Clause 9.15.13)

The finally assembled lock shall withstand the test given as below :

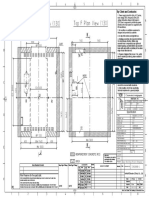

The locking bolt shall be first locked in the forward position. A load of 40 kg. shall be applied without

shock in the direction perpendicular to securing face as well as on both the locking faces of protruding

bolt in turn. Then the load shall be applied by means of a fixed steel board 3 mm thick by rounded edge

held in such a position that the centre line is approximately 3 mm from the fore end. A typical

arrangement for the purpose of this test is shown in Fig. below :

Beam 75 cm Fixed Bearer

Long Approx

Lock Fixed Block

Steel Bar 75 cm

Long Approx.

Movable Weight 40 kg

Base

Fig. : Strength Test for Locking Bolt

When the spindle with handle is inserted into hole in the follower and turned, the latch bolt shall draw

smoothly into the lock body and shall be within one millimetre from the face of the fore end.

When the latch bolt is pressed in to the lock body by pressure, the action shall be smooth and when

fully pressed the latch bolt shall not project more than one millimetre from the face of the fore end.

When a key is inserted in key hole from one side of the lock and turned to withdraw the locking bolt

the action shall be smooth and without impediment. When the direction of turn is reversed to lock the

locking bolt then also the action shall be smooth and without impediment. In the locked position the

locking bolt shall project 12 mm from the face of the fore end, although one millimetre free movement is

permissible. In the withdrawn position the locking bolt shall not project more than one millimetre from the

face of the fore end. The locking bolt shall be worked by turning key in both the direction 6000 times. At

the end of the test, the lock shall continue to work smoothly.

The test shall be repeated with the key inserted from the other side of the lock.

Note : The clearance for levers while in the operating condition shall not exceed 0.25 mm.

When the key is turned to lock the locking bolt at the same time applying a reasonable pressure by

finger on it, after completion of the key rotation the locking bolt shall be positively locked in the forward

position. This test shall be repeated with the key inserted from the other side of the lock.

CPWD SPECIFICATIONS 2009 360

APPENDIX H

SCHEDULE OF FITTING FOR DOORS AND WINDOWS

(Clause 9.6.8)

Sl. Name of Fittings Double Single Single Single Single Single Fan Desi- Length Remarks

No leaf leaf door leaf door leaf leaf leaf light/ gna- in mm

. doors shutters shutters wire wardrobe/ window clear tion of

shutters external inter guaze cup- shutters storey no. of wood

panelled panelled commu- door board panelled window wood screws

or or glazed nicating shu- shutters or shutters screw IS

glazed panelled tters glazed 6760

or glazed

1 2 3 4 5 6 7 8 9 10 11 12

1. Butt Hinges 100 6 3 3 3 - - - 9 40

mm

2 Butt Hinges 75 mm - - - - - 2 2 8 20

3 Butt Hinges 50 mm - - - - 1 1 - 6 20 For fixing

wooden

cleat

4 Piano Hinges - - - - - - - 6 20

5 Tower Bolt 250 mm 3 2 3 2 - 1 - 10 30

6 Tower Bolt 150 mm - - - - - 1 - 8 30

7 Tower Bolt 100 mm - - - - - - - 6 30

8 Sliding door Bolt 1 - - - - - - 9 35

300 mm

9 Sliding door Bolt - 1 - - - - - 9 35

250 mm

10 Floor door stopper 2 1 1 - 1 - - 9 30

11 Door handle with 2 2 2 1 - - - 6 25

plate 100 mm

12 Window handle with - - - - - 1 - 6 20

plate 75 mm

13 Casement stay 300 - - - - - 1 - 6 30

mm

14 Helical door spring - - - 1 - - - 6 30

(Superior quality)

15 Cupboard - - - 1 1 - - 6 20

/Wardrobe Lock

16 Fanlight Catch - - - - - - 1 8 30

Notes :

A : Door Shutters

1. Door of room adjoining the verandah, corridor, lobby or hall, shall be considered as external door.

2. Where the height of the door leaf exceeds 2.15 metres above the floor level, one extra hinge shall be provided for every additional height

of 0.50 metre, or part thereof and the length of top bolts shall be increased by the height of the leaf above 2.15 metres from floor level.

3. Single leaf door shutters of more than 0.80 m in width shall be provided with one extra hinge.

4. Fan light shutters of more than 0.80 metre width shall be provided with one extra hinge and extra quadrant stay.

5. In double leaf shutters of doors, two door bolts shall be fixed to the first shutter and one to the closing shutter at the top.

6. In case of single leaf inter communicating, panelled, glazed or panelled door shutter for bath and w.c. one tower bolts will be replaced by a

bathroom latch.

7. For shutter exceeding 40 mm thickness, heavy type M.S. butt hinges of 125 x 90 x 4 mm shall be used.

8. In case of external door shutters, instead of sliding door ball mortice lock can be provided where specified.

9. Cupboard and wardrobe shutters will have ball catches where specified.

10. Finger plates shall be provided in case of bath and wc shutters in office buildings.

B : Window Shutters

11. In case of windows with double shutters, two tower bolts shall be fixed to the closing shutters and one tower bolt to the first shutter at the

top.

12. In case of window shutters, hooks and eyes may be provided in lieu of casement stays where specified.

13. Where the height of window shutter exceeds 1.20 metres one extra hinge shall be provided and length of top bolts shall be increased by

height of the leaf above 2.15 metres from the floor level.

14. Window shutter with steel frames shall be provided with six hinges in case of double leaf shutters and three hinges in case of single leaf

shutters, irrespective of height and width of shutters.

C : Fanlight and Clerestory Window or Ventilator

15. Centrally hung and bottom hung CS windows and fan lights, will be provided with chain and hook bamboo pole with hook for opening

ventilators shall be provided for each residence or for set of 4 rooms in case of office building.

16. Centrally hung clerestory windows or fan lights will have fan light pivots in lieu of hinges.

361 SUB HEAD 9.0 : WOOD WORK AND P.V.C. WORK

APPENDIX I

METHOD OF TEST FOR EDGE STRAIGHTNESS AND SQUARENESS

OF PLYWOOD

(Clause No. 9.2.8.3)

I.1 PROCEDURE FOR EDGE STRAIGHTNESS

I.1.1 The straightness of the edge and ends of plywood shall be verified against a straight edge not less

than the full length of the plywood. If the edge on the end of the plywood is convex, it shall be held

against the straight edge in such a way as to give approximately equal gap at each end. The largest

gap between the straight edge and the edge shall be measured to the nearest millimeter and recorded.

I.2 PROCEDURE FOR SQUARENESS

I.2.1 The squareness of plywood shall be checked with a 1200 mm x 1200 mm square by applying one

arm of the square to the plywood. The maximum width of the gap shall be recorded.

APPENDIX J

METHOD FOR TEST FOR EDGE STRAIGHTNESS AND SQUARENESS OF

COIR VENEER BOARD

(Clause 9.2.10.6)

J-1 PROCEDURE FOR EDGE STRAIGHTNESS

J-1.1 The straightness of the edges and ends of coir veneer board shall be verified against a

straightedge not less than the full length of the coir veneer board. If the edge on the end of coir veneer

board is convex, it shall be held against the straight edge in such a way as to give approximately equal

gap at each end. The largest gap between the straightness and the edge shall be measured to the

nearest millimeter and recorded.

J-2 PROCEDURE FOR SQUARENESS

J-2.1 The squareness of coir veneer board shall be checked with a 1200 mm x 1200 mm square, by

applying one arm of the square to the coir veneer board. The maximum width of the gap shall be

recorded.

CPWD SPECIFICATIONS 2009 362

APPENDIX K

METHOD OF TEST FOR COIR VENEER BOARD FOR DETERMINATION OF

GLUE SHEAR STRENGTH

(Clause 9.2.10.8 )

K-1 OBJECT

K-1.1 This test is intended to estimate the tenacity with which the bonding material holds the coir

veneer board together.

K-2 TEST SPECIMEN

K-2.1 Six test specimens shall be cut from the coir veneer board from three locations separated by the

greatest possible distance from each other.

K-2.2 The test specimens shall be prepared as shown in Fig. 1 below.

K-2.3 The test pieces for 3 ply coir veneer board shall be prepared by gluing an additional 3 ply coir

veneer board as shown in Fig. 1A below. The test pieces for 5 ply shall be prepared as shown in Fig. 1B

below. The test pieces for 7 ply coir veneer board shall be prepared as shown in Fig. 1C below.

The specimen is glued with room temperature setting epoxy resin and clamped/tied overnight.

Note - This method of preparation of specimen will avoid the failure on notches.

K-2.4 Before test, the specimen shall be conditioned to constant mass at relative humidity of 65 ± 5 per

cent and at a temperature of 270o C ± 20oC.

K-3 PROCEDURE

K-3.1 Each test specimen shall be gripped symmetrically at two ends in the jaws of a suitable testing

machine, and shall be pulled apart. The distance between the notches on the test specimen and the

ends of the gripping jaws of the testing, machine shall be between 10 mm and 20 mm. The pull should

be, as far as possible, in the centre line of the central veneer. The grain of the centre ply shall be

perpendicular to the direction of application of load. The width of each specimen and distance between

the notches shall be measured to nearest 0.025 cm. to determine the shear area.

K-3.2 During the test, the load shall be applied to the test specimens as uniformly as possible, and so

adjusted as to have the traverse of the movable head of 1 mm/min.

K-3.3 The maximum load at the time of complete failure of each specimen shall be recorded. Record

shall be made regarding the type of failure whether in ply or in glue by visual examination of the area

under shear. In case of ply failure, the percentage ply failure shall also be recorded.

K-4 REPORT

K-4.1 Shear strength of the specimens determined in accordance with K-3 shall be straight averaged.

K-4.2 All details shall be recorded under the following sub-heads.

(a) Name of the manufacturer/source from whom the coir veneer board is procured

(b) Type and grade of coir veneer board

(c) Adhesive used

(d) End use of coir veneer board

(e) Specimen No. /Ref.

(f) Area of cross-section of bonding surface under shear

(g) Maximum load and

(h) Percentage failure of glue/ply contd......

363 SUB HEAD 9.0 : WOOD WORK AND P.V.C. WORK

APPENDIX K (Contd.)

25 ± 0.3

150

3 53 3

Veneer

Coir

25 ± 0.3 25 ± 0.3 Reinforcement

1A : 3-ply Test Specimen

25 ± 0.3

150

3 53 3 3

Coir Veneer

25 ± 0.3 25 ± 0.3

1B : 5-ply Test Specimen

25 ± 0.3

150

3 53 3

Coir Veneer

25 ± 0.3 25 ± 0.3

1C : 7-ply Test Specimen

Drawing not to scale

All dimensions are in mm

Fig. 1 : Test Specimen for Glue Adhesion Test

CPWD SPECIFICATIONS 2009 364

JOINTS IN TIMBER

Sub Head : Wood Work and PVC Work

Clause : 9.0

A. TONGUE & GROOVE JOINT B. MITRED JOINT

C. DOVETAIL JOINT D. MORTISE & TENON JOINT

Drawing not to Scale

Fig. 9.1 : Joints in Timber

365 SUB HEAD 9.0 : WOOD WORK AND P.V.C. WORK

TERMINOLOGY TIMBER DOOR, WINDOW &

VENTILATOR COMPONENTS

Sub Head : Wood Work and PVC Work

Clause : 9.6

A

Width of Opening

Head of Frame

Top Rail DETAILS AT A

Hold Fast

Glazed Panel 8 to 10 mm

Door Frame

Stile T/3

Meeting Stile T/3

T/3

45°

Lock Rail SPLAYED TYPE

REBATE

Wooden

Panel

Bottom Rail 8 to 10 mm

Finished T/2

Floor Level

Metal Pin T/2

Structural Floor Level

GLAZED AND PANELLED DOOR SQUARE TYPE

REBATE

Head of Frame

Glass Panel

Transome

Hold Fast

Glass Panel

Stile

Bottom Rail

TOP HUNG CENTRE HUNG BOTTOM HUNG

VENTILATOR VENTILATOR VENTILATOR

WINDOWS AND VENTILATORS

Drawing not to Scale

All dimensions are in mm

Fig. 9.2 : Terminology Timber Door, Window & Ventilator Components

CPWD SPECIFICATIONS 2009 366

WOODEN FLUSH DOORS SHUTTERS

Sub Head : Wood Work and PVC Work

Clause : 9.7

TOP RAIL

Lipping Where

Provided

Stile

Cross Band

Face Veneer

BLOCK BOARD & PARTICLE PARTICLE BOARD

BOARD CORE CORE

Battens

Equally Battens

Distributed

Voids Intermediate Rail

Equally Distributed

Voids

CELLULAR CORE BLOCK BOARD CORE HOLLOW CORE

Drawing not to Scale

Fig. 9.3 : Wooden Flush Doors Shutters

367 SUB HEAD 9.0 : WOOD WORK AND P.V.C. WORK

HOLD FAST

Sub Head : Wood Work and PVC Work

Clause : 9.13

40

20

100 100

Door Frame Hold Fast

200

10 11 mm Hole

50

15

Nut & Bolt

Wooden Plug 10 mm dia

5 C.C. Block

Enlarged Section of Bolt

50

Drawing not to Scale

All dimensions are in mm

Fig. 9.4 : Hold Fast

CPWD SPECIFICATIONS 2009 368

S-ar putea să vă placă și

- Notice Potence 901A FRDocument18 paginiNotice Potence 901A FRMohamed Seghir BenzemraneÎncă nu există evaluări

- Stegbar Installation - Aluminium Sliding Door PDFDocument8 paginiStegbar Installation - Aluminium Sliding Door PDFAussiePortablesÎncă nu există evaluări

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument21 paginiVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesEliel AbadÎncă nu există evaluări

- Builders' Metalwork: Ci/Sfb 21.9 Xt6Document32 paginiBuilders' Metalwork: Ci/Sfb 21.9 Xt6JC TsuiÎncă nu există evaluări

- Chain Link Fencing Guide: Specs, Installation & MoreDocument3 paginiChain Link Fencing Guide: Specs, Installation & MorevanmurthyÎncă nu există evaluări

- QC Casing Installation GuideDocument27 paginiQC Casing Installation GuideHuemac ContrerasÎncă nu există evaluări

- Rodded Installation Maintenance WebDocument2 paginiRodded Installation Maintenance WebMihaela SanpetreanÎncă nu există evaluări

- G Aging InfoDocument32 paginiG Aging InfoAsghar AliÎncă nu există evaluări

- Research Report On Single Plate Shear Connections: North Carolina State UniversityDocument51 paginiResearch Report On Single Plate Shear Connections: North Carolina State UniversityHarshaVeeragandhamÎncă nu există evaluări

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument20 paginiVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilÎncă nu există evaluări

- Charging Ox Parts ListDocument6 paginiCharging Ox Parts Listondise.publiÎncă nu există evaluări

- Simpson Wedge AnchorDocument20 paginiSimpson Wedge AnchorTim CooperÎncă nu există evaluări

- Flowserve Seal - ISC2 - Install - LTRDocument8 paginiFlowserve Seal - ISC2 - Install - LTRjame11inÎncă nu există evaluări

- 6-4. Abestos RoofingDocument8 pagini6-4. Abestos RoofingNAKSET GAMINGÎncă nu există evaluări

- FLOOR DETAILSDocument29 paginiFLOOR DETAILSmeetvinayak2007Încă nu există evaluări

- Curtain Wall Fabrication Manual 1 2Document69 paginiCurtain Wall Fabrication Manual 1 2Suruthi Dasan67% (3)

- Rear Sway Bar Installation InstructionsDocument4 paginiRear Sway Bar Installation InstructionsRaduÎncă nu există evaluări

- Maintenance of Enhanced Drawgear - CMI9901Document7 paginiMaintenance of Enhanced Drawgear - CMI9901Dwijamani SinghaÎncă nu există evaluări

- The Seismic Design and Performance of Reinforced Concrete Beam-Column Knee JointsDocument8 paginiThe Seismic Design and Performance of Reinforced Concrete Beam-Column Knee JointsMarimuthu KaliyamoorthyÎncă nu există evaluări

- FRP Installation GuideDocument8 paginiFRP Installation GuideDouglas HillÎncă nu există evaluări

- WR Rflex Instructions Chamber-EN-20090709Document2 paginiWR Rflex Instructions Chamber-EN-20090709Noorul Mufas MnÎncă nu există evaluări

- AADSS1205923Document8 paginiAADSS1205923RennieÎncă nu există evaluări

- Builders MetalworkDocument32 paginiBuilders MetalworkGeorge ChristodoulidisÎncă nu există evaluări

- Sheet pile capping systems guideDocument54 paginiSheet pile capping systems guideGabriel AmorimÎncă nu există evaluări

- FAS Data SheetDocument2 paginiFAS Data SheetYusÎncă nu există evaluări

- ST Louis Screw & Bolt Binder CatalogDocument52 paginiST Louis Screw & Bolt Binder Catalogmailmuncher2000Încă nu există evaluări

- Inclinometer QC Casing Installation GuideDocument29 paginiInclinometer QC Casing Installation Guideapi-3706095Încă nu există evaluări

- Serrated Safety Washers: Light Duty and Medium DutyDocument1 paginăSerrated Safety Washers: Light Duty and Medium DutyJEORJEÎncă nu există evaluări

- Maintain Rail Coach Draw GearDocument8 paginiMaintain Rail Coach Draw Gearanunay kumarÎncă nu există evaluări

- Instalaçao Cap de RastilhoDocument16 paginiInstalaçao Cap de RastilhosurtaoÎncă nu există evaluări

- Assembly Instructions For Bondstrand Fiberglass FlangesDocument8 paginiAssembly Instructions For Bondstrand Fiberglass FlangesHoang CongÎncă nu există evaluări

- J-76-1 IKS Wellhead Installation and Operation ManualDocument72 paginiJ-76-1 IKS Wellhead Installation and Operation Manualmam100% (1)

- 3M Cable Termination Installation InstructionDocument8 pagini3M Cable Termination Installation Instructionnixsol75Încă nu există evaluări

- Sheet Pile Capping Manual-DawsonDocument54 paginiSheet Pile Capping Manual-DawsonSankar CdmÎncă nu există evaluări

- General Conversion Instructions For 3 X 4 In. (75 X 00 MM) Orbital SandersDocument2 paginiGeneral Conversion Instructions For 3 X 4 In. (75 X 00 MM) Orbital Sandersherysyam1980Încă nu există evaluări

- EXPAMET - Builders - MetalworkDocument32 paginiEXPAMET - Builders - MetalworkMatthew AshworthÎncă nu există evaluări

- Victaulic Flexible Hose Connecting To Regular Reliable SprinklerDocument27 paginiVictaulic Flexible Hose Connecting To Regular Reliable SprinklerOwais AhmedÎncă nu există evaluări

- Multi-Stage Cementing Collar: Specification GuideDocument2 paginiMulti-Stage Cementing Collar: Specification GuideOdesya SatyaÎncă nu există evaluări

- Megaprofil - Profile GalvanizateDocument43 paginiMegaprofil - Profile GalvanizateSebastian PopÎncă nu există evaluări

- Sears Catalog 1966Document16 paginiSears Catalog 1966Kevin Haworth100% (3)

- QC Casing Installation Guide PDFDocument36 paginiQC Casing Installation Guide PDFAnonymous PibYPghÎncă nu există evaluări

- Sprinkflex Product SubmittalDocument6 paginiSprinkflex Product SubmittalAhmed NabilÎncă nu există evaluări

- Carpenter's Metalwork Guide to Joist Hangers and Roof AnchorsDocument5 paginiCarpenter's Metalwork Guide to Joist Hangers and Roof AnchorsJFAFPÎncă nu există evaluări

- Stealthpivot XL v2 Quickstart GuideDocument8 paginiStealthpivot XL v2 Quickstart GuideSegun AwoyinkaÎncă nu există evaluări

- 750 Double Interlock Preaction System, Type D, 2 To 8 InchesDocument30 pagini750 Double Interlock Preaction System, Type D, 2 To 8 InchesAhmad SalahÎncă nu există evaluări

- Victaulic Flexible Hose Connecting To Dry Barrel SprinklerDocument27 paginiVictaulic Flexible Hose Connecting To Dry Barrel SprinklerOwais AhmedÎncă nu există evaluări

- Fis190 en A5Document8 paginiFis190 en A5andhucaosÎncă nu există evaluări

- Ficha Tecnica Mezclador Pressure Balance Ref 04447000 - HansgroheDocument3 paginiFicha Tecnica Mezclador Pressure Balance Ref 04447000 - HansgroheALEJANDRO CANIZALESÎncă nu există evaluări

- 2178CL-S Series F/O Splice Case: InstructionDocument13 pagini2178CL-S Series F/O Splice Case: InstructionHữu Khánh NguyễnÎncă nu există evaluări

- Electromagnetic Lock Installation Instruction (Indoor Series)Document2 paginiElectromagnetic Lock Installation Instruction (Indoor Series)Marcin B.Încă nu există evaluări

- Catalog 100 G1 Locksets NM Series1Document10 paginiCatalog 100 G1 Locksets NM Series1Uniquesport flooringÎncă nu există evaluări

- Series YD - YS Instruction ManualDocument16 paginiSeries YD - YS Instruction ManualEnerprec SASÎncă nu există evaluări

- Installation Instructions: BW Seals Q, QB SeriesDocument8 paginiInstallation Instructions: BW Seals Q, QB SeriesJoseGarciaRÎncă nu există evaluări

- I TFC 280 Instruction ManualDocument6 paginiI TFC 280 Instruction Manualsharri_myidtr11Încă nu există evaluări

- Catalog HRC Jaw CouplingsDocument8 paginiCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Catalogo Allied Locke PDFDocument241 paginiCatalogo Allied Locke PDFGuillermo MendezÎncă nu există evaluări

- Connectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeDocument4 paginiConnectors For HELIAX® HJ8-50 Coaxial Cab - 0d - 0a LeAnonymous cDWQYsjd9Încă nu există evaluări

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideDe la EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideÎncă nu există evaluări

- The Gun Digest Book of Tactical Weapons Assembly/DisassemblyDe la EverandThe Gun Digest Book of Tactical Weapons Assembly/DisassemblyÎncă nu există evaluări

- Civil Work Specification Part 40Document10 paginiCivil Work Specification Part 40AM MAÎncă nu există evaluări

- Fixing butt hinges to T-iron framesDocument10 paginiFixing butt hinges to T-iron framesAM MAÎncă nu există evaluări

- Sub Head 9.0: Wood Work and P.V.C. WorkDocument10 paginiSub Head 9.0: Wood Work and P.V.C. WorkAM MAÎncă nu există evaluări

- Civil Work Specification Part 39Document10 paginiCivil Work Specification Part 39AM MAÎncă nu există evaluări

- Civil Work Specification Part 47Document10 paginiCivil Work Specification Part 47AM MAÎncă nu există evaluări

- Civil Work Specification Part 43Document10 paginiCivil Work Specification Part 43AM MAÎncă nu există evaluări

- Civil Work Specification Part 41Document10 paginiCivil Work Specification Part 41AM MAÎncă nu există evaluări

- Civil Work Specification Part 40Document10 paginiCivil Work Specification Part 40AM MAÎncă nu există evaluări

- 10.0 STEEL WORK: Fabrication, Erection and MeasurementDocument10 pagini10.0 STEEL WORK: Fabrication, Erection and MeasurementAM MAÎncă nu există evaluări

- Civil Work Specification Part 45Document10 paginiCivil Work Specification Part 45AM MAÎncă nu există evaluări

- Civil Work Specification Part 44Document10 paginiCivil Work Specification Part 44AM MAÎncă nu există evaluări

- Civil Work Specification Part 53Document10 paginiCivil Work Specification Part 53AM MAÎncă nu există evaluări

- Civil Work Specification Part 48Document10 paginiCivil Work Specification Part 48AM MAÎncă nu există evaluări

- Civil Work Specification Part 49Document10 paginiCivil Work Specification Part 49AM MAÎncă nu există evaluări

- Civil Work Specification Part 50Document10 paginiCivil Work Specification Part 50AM MAÎncă nu există evaluări

- Civil Work Specification Part 51Document10 paginiCivil Work Specification Part 51AM MAÎncă nu există evaluări

- Civil Work Specification Part 54Document10 paginiCivil Work Specification Part 54AM MAÎncă nu există evaluări

- Civil Work Specification Part 52Document10 paginiCivil Work Specification Part 52AM MAÎncă nu există evaluări

- Civil Work Specification Part 55Document4 paginiCivil Work Specification Part 55AM MAÎncă nu există evaluări

- 16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Document16 pagini16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Ahmed Said GhonimyÎncă nu există evaluări

- Bespoke Revolving DoorsDocument6 paginiBespoke Revolving Doorsnaveenarora298040Încă nu există evaluări

- Basic Mechanical Materials and Methods 0606 (PDF Library)Document17 paginiBasic Mechanical Materials and Methods 0606 (PDF Library)nifilimÎncă nu există evaluări

- 6 King Air C90GTi-GTx Pilot Training ManualDocument445 pagini6 King Air C90GTi-GTx Pilot Training ManualMike William100% (2)

- Commercial Building Lift Installation RequirementsDocument4 paginiCommercial Building Lift Installation RequirementsDaveÎncă nu există evaluări

- Vito SpecificationsDocument2 paginiVito SpecificationsSorin Barlatzean100% (1)

- Technical Specifications For SCIF Construction-V1.0 Issued-MDocument150 paginiTechnical Specifications For SCIF Construction-V1.0 Issued-Mpipperic100% (1)

- Installation Instructions Product-Ident: 75168: Doorboards With Soundsystem, BMW 8 Series E31Document10 paginiInstallation Instructions Product-Ident: 75168: Doorboards With Soundsystem, BMW 8 Series E31post8713Încă nu există evaluări

- L1103ADocument4 paginiL1103Ac131508Încă nu există evaluări

- Trailblazer 28288123 PDFDocument300 paginiTrailblazer 28288123 PDFkamote ka0% (1)

- FRDLDocument3 paginiFRDLrameshÎncă nu există evaluări

- Clean Agent Enclosure Design For NFPA 2001 Retrotec Version PDFDocument8 paginiClean Agent Enclosure Design For NFPA 2001 Retrotec Version PDFNa2_tuÎncă nu există evaluări

- Toys at Home-OldsDocument104 paginiToys at Home-OldsAntônio Castro100% (5)

- E-Kabin - O Series - Monoblock Enclosure - ENGDocument12 paginiE-Kabin - O Series - Monoblock Enclosure - ENGCatalina CocoşÎncă nu există evaluări

- Elevonic Manual OtisDocument323 paginiElevonic Manual OtisFelipe Villegas100% (1)

- Easy Lifter RDO ManualDocument24 paginiEasy Lifter RDO ManualMartin SiemsenÎncă nu există evaluări

- Sliding Comparison Table - Shiva - EN.06.24062020Document5 paginiSliding Comparison Table - Shiva - EN.06.24062020kewa abraham desseuÎncă nu există evaluări

- Wood Pellet Pre Delivery ChecklistDocument11 paginiWood Pellet Pre Delivery ChecklistPriska MalvinÎncă nu există evaluări

- Katalog NEWDocument64 paginiKatalog NEWHanif HarunÎncă nu există evaluări

- ES-S StepDocument8 paginiES-S StepOsy ToursÎncă nu există evaluări

- Nammcesa 000008 PDFDocument197 paginiNammcesa 000008 PDFBasel Osama RaafatÎncă nu există evaluări

- SPECS Series 980 Pivot DoorDocument9 paginiSPECS Series 980 Pivot Dooryamanta_rajÎncă nu există evaluări

- Kode Akun Dan Laporan AkutansiDocument44 paginiKode Akun Dan Laporan AkutansiHalimÎncă nu există evaluări

- Encravamento de PortasDocument26 paginiEncravamento de PortasLeonardo Marteleto BerniniÎncă nu există evaluări

- HBN 20 3rded 2005 PDFDocument66 paginiHBN 20 3rded 2005 PDFSundar DAACÎncă nu există evaluări

- FP Metal Enclosed Switchgear BrochureDocument24 paginiFP Metal Enclosed Switchgear BrochureAlex Jr ApuyaÎncă nu există evaluări

- WEBSITE: WWW - Kakadelaser.in: Address: S. No. 30/2, Near Pari / Dran Company, Dhayari, Sinhagad Road, Pune - 411041Document16 paginiWEBSITE: WWW - Kakadelaser.in: Address: S. No. 30/2, Near Pari / Dran Company, Dhayari, Sinhagad Road, Pune - 411041CRaZy BuDdYÎncă nu există evaluări

- ADC Section 4 - Commuter Facilities Design Requirements and Checklist Forms A3Document216 paginiADC Section 4 - Commuter Facilities Design Requirements and Checklist Forms A3Vi HuaÎncă nu există evaluări

- Military Dog Facilities Design GuideDocument31 paginiMilitary Dog Facilities Design GuideCAP History LibraryÎncă nu există evaluări

- 2021 SF Bar Series Catalog AlumuniumDocument18 pagini2021 SF Bar Series Catalog AlumuniumJoe NoeÎncă nu există evaluări