Documente Academic

Documente Profesional

Documente Cultură

Series 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-A

Încărcat de

Trie IrsadTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Series 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-A

Încărcat de

Trie IrsadDrepturi de autor:

Formate disponibile

Bulletin A-36-A

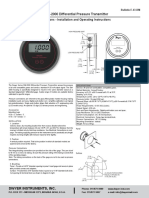

Series 2-5000 Minihelic II ®

Differential Pressure Gage

Specifications: Installation & Operating Instructions

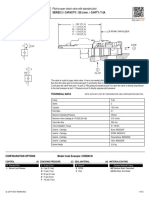

LOW PRESSURE PORT

7/16 (11.11) HOLE IN

PANEL FOR SURFACE MOUNT

(2) 5/32 HOLES

2-19/32 IN PANEL FOR SURFACE

(65.88) 3-1/16 MOUNT

(77.79) 1 (25.40)

HIGH PRESSURE PORT

7/16 (11.11) HOLE IN

1-7/16 (36.51) 2.330 (59.18) PANEL FOR SURFACE MOUNT

SURFACE MOUNT

23/64 (9.13) 2-3/8 HOLES

(60.33)

SPECIFICATIONS

Service: Air and compatible gases.

Wetted Materials: Consult factory.

Housing: Glass filled nylon; polycarbonate lens.

Accuracy: ±5% of full scale at 70°F (21.1°C).

Pressure Limits: 30 psig (2.067 bar) continuous

to either pressure connection.

Temperature Limits: 20 to 120°F (-6.67 to

48.9°C).

Size: 2-1/16˝ (52.39 mm) diameter dial face.

Mounting Orientation: Diaphragm in vertical

® position. Consult factory for other position orien-

Series 2-5000 Minihelic II Differential tations.

Pressure Gages have clean design, small size,

low cost and sufficient accuracy for all but the most Process Connections: Barbed, for 3/16˝ I.D.

demanding applications. With housing molded from tubing (standard); 1/8˝ male NPT (optional).

mineral- and glass-filled nylon and a lens molded Weight: 6 oz (170.1g).

from polycarbonate, this gage will withstand rough

use and exposure, as well as high total pressure up

to 30 psig [2.067 bar]. Over-pressure is accommo- CAUTION: FOR USE ONLY WITH AIR OR

dated by a blow-out membrane molded in con-

junction with the diaphragm. COMPATIBLE GASES.

INSTALLATION

1. Select a location free from excessive vibration

and where ambient temperature will be between 20

to 120°F (-6.7 to 49°C). Sensing lines may be any

length necessary without affecting accuracy.

However, long runs of tubing will dampen readings

slightly and cause a minor increase in response

time. If pulsing pressure or vibration cause exces-

sive pointer oscillation, please contact factory for

ways to provide additional damping.

2. This gage is calibrated and zeroed in the vertical

position at the factory. If the gage is used in any

other position, it must be re-zeroed each time the

position is changed. Gages with ranges under 5˝

w.c.(1.24 kPa), or the equivalent, should be used

only in the vertical position unless special calibration Figure A

was specified when ordering.

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057

e-mail: info@dwyer-inst.com

Bulletin A-36-A

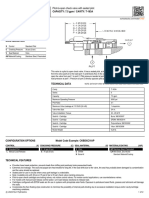

#4 MOUNTING #4 MOUNTING

SCREW SCREW

MOUNTING

LUG

3/16 (4.78) MAX

#6 MOUNTING PANEL THICKNESS

SCREW

PANEL MOUNTED SURFACE MOUNTED

PANEL MOUNTED INSTALLATION

6. To measure positive pressure, connect

3. To surface-mount the gage in a 3/16 (4.78 tubing to port marked “HI” and vent “LO” port

mm) max panel thickness, drill two 5/32˝ (3.97 to atmosphere. For negative pressure (vacu-

mm) holes on a horizontal line, 2.330˝ (59.18 um), connect to port marked “LO” and vent

mm) apart for mounting screws. Next, drill two “HI” port to atmosphere. For differential pres-

7/16˝ (11.11 mm) holes 1.000˝ (25.4 mm) apart sure, connect higher pressure to port marked

on a vertical line for pressure connections. “HI” and lower to “LO” port. If gage is sup-

Secure the gage with two #4 mounting screws. plied with 1/8˝ NPT connections, be careful

Be careful not to block the slotted hole near the not to over-tighten fittings to avoid damage to

right-hand mounting hole, this provides a path the gage.

for pressure relief in the event of over-pressur-

ization. CALIBRATION CHECK

Select a second gage or manometer of

4. To panel-mount the gage, cut a 2-5/8˝ (66.68 known accuracy and in an appropriate range.

mm) diameter hole. Install mounting lugs to the Use short lengths of rubber or vinyl tubing to

back of the gage with two #4 mounting screws, connect the high-pressure side of the gage

thread two #6 mounting screws through mount- and the test gage to two legs of a tee. Very

ing lugs and tighten. slowly, apply pressure through the third leg.

Allow enough time for pressure to equalize

5. Before installation, the Minihelic® II Differential throughout the system and for fluid to drain. if

Pressure Gage may need to be zeroed before a manometer is being used. Compare read-

placing into operation. If zeroing is required, you ings. If the gage being tested exceeds rated

must first remove the locking clip located near accuracy, it should be returned to the factory

the bottom face of the gage (refer to Fig A). Use for recalibration.

a small blade screwdriver or the allen wrench

supplied with the Minihelic® II Differential MAINTENANCE

Pressure Gage to remove the clip. The clip is No lubrication or periodic servicing is

attached with a hinge design so it will not get required. Keep case exterior and cover clean.

lost after removal. After removing the clip, firmly Occasionally, disconnect pressure lines to

hold the case with one hand and rotate the front vent both sides of the gage to atmosphere

cover in the counterclockwise direction with the and re-zero per installation paragraph 5.

palm of the other hand. The Minihelic® II

Differential Pressure Gage utilizes a bayonet Upon final installation of the Series 2-5000

locking design. The cover will rotate approxi- Minihelic® II Differential Pressure Gage, no

mately 9 degrees then stop and can be routine maintenance is required. A periodic

removed. Caution: When removing the cover check of the system calibration is recom-

be careful to slowly pull the cover straight off the mended. The Series 2-5000 is not field ser-

gage housing. Damage can occur to the scale if viceable and should be returned if repair is

the cover is pulled off on an angle. If difficult to needed (field repair should not be attempted

loosen cover, place a small sheet of rubber and may void warranty). Be sure to include a

between the cover and the palm of the hand. brief description of the problem plus any rele-

The zero adjust screw is located below the vant application notes. Contact customer

scale at the “zero” label near the base of the service to receive a return goods authoriza-

pointer. Use the hex allen wrench supplied and tion number before shipping.

adjust until the pointer is on zero. This must be

done with both pressure connections vented to

atmosphere and the gage oriented in the final

mounting position. Replace cover.

©Copyright 2006 Dwyer Instruments, Inc Printed in U.S.A. 12/06 FR# 14-440434-10 Rev.3

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057

e-mail: info@dwyer-inst.com

S-ar putea să vă placă și

- Ficha Tecnica Mod 2-5002Document2 paginiFicha Tecnica Mod 2-5002Nestor Augusto Duran SanchezÎncă nu există evaluări

- Dwyer-1910-1-Product OverviewDocument1 paginăDwyer-1910-1-Product OverviewRusty AllenÎncă nu există evaluări

- Transmisor Presion Diferencial dm-2007-lcdDocument2 paginiTransmisor Presion Diferencial dm-2007-lcdhanshr87Încă nu există evaluări

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyDocument1 paginăDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyMike Alex Herrera DominguezÎncă nu există evaluări

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 paginiSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezÎncă nu există evaluări

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyDocument1 paginăDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyNic DziemianÎncă nu există evaluări

- Series 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 paginiSeries 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionseeeÎncă nu există evaluări

- Magnetrol TD2-8D00-032 + Tma-A210-007Document1 paginăMagnetrol TD2-8D00-032 + Tma-A210-007BRUNOÎncă nu există evaluări

- Tyco Mlaznica TY BDocument8 paginiTyco Mlaznica TY BMilos StojanovicÎncă nu există evaluări

- Compact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%Document1 paginăCompact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%ANGEL FLORESÎncă nu există evaluări

- Uni-Directional and Bi-Directional Ranges: PX2300 SeriesDocument1 paginăUni-Directional and Bi-Directional Ranges: PX2300 SeriesASIM RIAZÎncă nu există evaluări

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 paginiModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaÎncă nu există evaluări

- Versa Stick Pilot Stainless CatalogDocument4 paginiVersa Stick Pilot Stainless CatalogJuan Pablo LoperaÎncă nu există evaluări

- 5 Amot 1672 Product DocumentDocument7 pagini5 Amot 1672 Product DocumentThéodore NlendÎncă nu există evaluări

- Industrial Transmitter For Dew Point Measurement: AutocalibrationDocument4 paginiIndustrial Transmitter For Dew Point Measurement: AutocalibrationАлекс ОколотенкоÎncă nu există evaluări

- Fisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEDocument14 paginiFisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEfiguev2208Încă nu există evaluări

- CXHAXAN - Full - en - Metric - Letter BorbetDocument2 paginiCXHAXAN - Full - en - Metric - Letter BorbetRonaldÎncă nu există evaluări

- Manuals Os2 Release Relay Instruction Manual Fisher en en 5903250Document16 paginiManuals Os2 Release Relay Instruction Manual Fisher en en 5903250fisheriano2049Încă nu există evaluări

- Jet Range PRVDocument4 paginiJet Range PRVneiljonesÎncă nu există evaluări

- Explosion-Proof Differential Pressure SwitchDocument1 paginăExplosion-Proof Differential Pressure SwitchTadau EnergyÎncă nu există evaluări

- 83-132550-000 Sa1 Ba - 55-107Document53 pagini83-132550-000 Sa1 Ba - 55-107thiagoh179Încă nu există evaluări

- Carrier - CC 6400 - Manual de InstalaçaoDocument4 paginiCarrier - CC 6400 - Manual de InstalaçaoAdelson nojosa da silva SilvaÎncă nu există evaluări

- Model Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADocument2 paginiModel Flow Divider Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AErasmo LimaÎncă nu există evaluări

- P - 616KD Manual TransmiterDocument2 paginiP - 616KD Manual TransmiterFR PERAÎncă nu există evaluări

- Sensor de Presion Serie DM-2000Document1 paginăSensor de Presion Serie DM-2000Giancarlo Reategui GuerraÎncă nu există evaluări

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 paginiSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoÎncă nu există evaluări

- Wandfluh Pre ControlDocument3 paginiWandfluh Pre Controlfrancis_15inÎncă nu există evaluări

- CKEB Full en Metric LetterDocument2 paginiCKEB Full en Metric LetterRafalÎncă nu există evaluări

- Series TY-FRB - 2.8, 4.2, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard CoverageDocument14 paginiSeries TY-FRB - 2.8, 4.2, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coveragemy.work.ksabÎncă nu există evaluări

- TY3231Document10 paginiTY3231anon-952920100% (2)

- 603A - Transmisor de Presion DiferencialDocument3 pagini603A - Transmisor de Presion Diferencialugui81Încă nu există evaluări

- Magnehelic Gauge CalibrationDocument7 paginiMagnehelic Gauge CalibrationgrajukankayyaÎncă nu există evaluări

- Rociador TycoDocument4 paginiRociador TycoGabriel TapiaÎncă nu există evaluări

- Calibrated Differential Switch: Series Cdpd1H, Cdpd2H, Vcdpd1H, Vcdpd2HDocument2 paginiCalibrated Differential Switch: Series Cdpd1H, Cdpd2H, Vcdpd1H, Vcdpd2HEliecer DiazÎncă nu există evaluări

- RGFA Full en Metric LetterDocument4 paginiRGFA Full en Metric LetteressamÎncă nu există evaluări

- Dau Sprinklers TYCO - TY315Document4 paginiDau Sprinklers TYCO - TY315hungÎncă nu există evaluări

- Relief Valve 5k 6-015-1Document2 paginiRelief Valve 5k 6-015-1francis_15inÎncă nu există evaluări

- TycoDocument10 paginiTycoTahseenÎncă nu există evaluări

- 876-32 Model SDA Direct-Dial Pilot.Document11 pagini876-32 Model SDA Direct-Dial Pilot.Naveed AliÎncă nu există evaluări

- Aquatec 8800 High Flow Booster Pump Spec PDFDocument2 paginiAquatec 8800 High Flow Booster Pump Spec PDFMandiriÎncă nu există evaluări

- Data Shett FP Valiant MachineDocument47 paginiData Shett FP Valiant MachineRICARDOÎncă nu există evaluări

- Rociador Ty LDocument8 paginiRociador Ty LOscar Fernandez SanchezÎncă nu există evaluări

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocument8 paginiSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageLucila BordenaveÎncă nu există evaluări

- 6-Pressure Safety ValveDocument1 pagină6-Pressure Safety ValveFari NazariÎncă nu există evaluări

- TFP620 05 2014Document8 paginiTFP620 05 2014Furkan KadıÎncă nu există evaluări

- Rociador Ty FRBDocument10 paginiRociador Ty FRBOscar Fernandez SanchezÎncă nu există evaluări

- CKBDXCV ApDocument2 paginiCKBDXCV ApŁukasz OlszewskiÎncă nu există evaluări

- A0.01 General NotesDocument1 paginăA0.01 General NotesAblaze AllÎncă nu există evaluări

- Extended Coverage Sidewall SprinklersDocument8 paginiExtended Coverage Sidewall SprinklersRamesh arumugamÎncă nu există evaluări

- Type R122H First-Stage RegulatorDocument2 paginiType R122H First-Stage RegulatorJVMÎncă nu există evaluări

- Industrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputDocument3 paginiIndustrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputAsif BhatiÎncă nu există evaluări

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 paginăGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirÎncă nu există evaluări

- Dual-Action Explosion-Proof Pressure SwitchDocument1 paginăDual-Action Explosion-Proof Pressure Switchjose amadeo martinez ramirezÎncă nu există evaluări

- GeneralDocument1 paginăGeneralamirÎncă nu există evaluări

- File 5Document1 paginăFile 5VENKATACHALAM SUBBARAJÎncă nu există evaluări

- Sun Hydraulics NFCC-KCNDocument2 paginiSun Hydraulics NFCC-KCNJustinÎncă nu există evaluări

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142De la EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Încă nu există evaluări

- Estimation and Costing by M Chakraborty PDFDocument4 paginiEstimation and Costing by M Chakraborty PDFAakash Kamthane0% (3)

- Vestron VideoDocument3 paginiVestron VideoMIDNITECAMPZÎncă nu există evaluări

- Cii Sohrabji Godrej Green Business Center - SUSTAINABLE ARCHITECTUREDocument23 paginiCii Sohrabji Godrej Green Business Center - SUSTAINABLE ARCHITECTUREBryson Solomon50% (2)

- New Microsoft Office Power Point PresentationDocument21 paginiNew Microsoft Office Power Point PresentationSai DhanushÎncă nu există evaluări

- 'I' Series Incubators With A Natural Air Circulation: CharacteristicsDocument4 pagini'I' Series Incubators With A Natural Air Circulation: CharacteristicstitouÎncă nu există evaluări

- Oracle Secure BackupDocument294 paginiOracle Secure BackupCarlos ValderramaÎncă nu există evaluări

- A330-200 CommunicationsDocument42 paginiA330-200 CommunicationsTarik BenzinebÎncă nu există evaluări

- Euro Guard BrochureDocument28 paginiEuro Guard BrochureNazia SodawalaÎncă nu există evaluări

- Voltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFDocument58 paginiVoltage - V - Salna-T-662-16-Order - and - Reasons OCR PDFHoward KnopfÎncă nu există evaluări

- 5 CombiflameDocument8 pagini5 CombiflamenitantharaniÎncă nu există evaluări

- Article 17 Ijaet Volii Issue IV Oct Dec 2011Document10 paginiArticle 17 Ijaet Volii Issue IV Oct Dec 2011Mustapha Maiz Hadj AhmedÎncă nu există evaluări

- Performance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsDocument4 paginiPerformance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsFredrick IshengomaÎncă nu există evaluări

- Synthesis and Characterization of Alumina Zirconia Composite Material Doped With SilicaDocument7 paginiSynthesis and Characterization of Alumina Zirconia Composite Material Doped With SilicaAdvanced Research PublicationsÎncă nu există evaluări

- JKM410 430N 54HL4 (V) F3 enDocument2 paginiJKM410 430N 54HL4 (V) F3 enAmer CajdricÎncă nu există evaluări

- Experiment No.7 Study of Disc Pelletizer: ObjectivesDocument4 paginiExperiment No.7 Study of Disc Pelletizer: ObjectivesPrafulla Subhash SarodeÎncă nu există evaluări

- Ao-90265ba Pci CardDocument46 paginiAo-90265ba Pci CardFrancisco Javier PérezÎncă nu există evaluări

- V1 001 PDFDocument20 paginiV1 001 PDFG100% (2)

- View/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordDocument2 paginiView/Update Profile Apply For STC: Upload Sponsorship STC Applied Download Certificate Change PasswordlakshmilavanyaÎncă nu există evaluări

- Generic Roadmap For The Counties of Kenya V1.1Document33 paginiGeneric Roadmap For The Counties of Kenya V1.1ICT AUTHORITYÎncă nu există evaluări

- Kristian Tlangau - November, 2016 PDFDocument52 paginiKristian Tlangau - November, 2016 PDFMizoram Presbyterian Church SynodÎncă nu există evaluări

- Dacell Dn-10w, Dn-15w, Dn-20w SpecDocument1 paginăDacell Dn-10w, Dn-15w, Dn-20w SpecmegacobÎncă nu există evaluări

- The Impact of Internet Use For StudentsDocument8 paginiThe Impact of Internet Use For StudentsCharlesÎncă nu există evaluări

- HTTP Download - Yamaha.com API Asset File Language En&site Au - YamahaDocument5 paginiHTTP Download - Yamaha.com API Asset File Language En&site Au - Yamahaericwc123456Încă nu există evaluări

- Guide To Linux+ (2 Edition) ISBN 0-619-21621-2 End of Chapter Solutions Chapter 4 SolutionsDocument8 paginiGuide To Linux+ (2 Edition) ISBN 0-619-21621-2 End of Chapter Solutions Chapter 4 SolutionsNorhasimaSulaimanÎncă nu există evaluări

- Research Proposal RubricsDocument1 paginăResearch Proposal RubricsRonnie Dalgo0% (1)

- 2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Document4 pagini2016-10-03 NYCHA Maximo Siebel Status Closed (Audit Trail)Progress QueensÎncă nu există evaluări

- Bill of Materials SampleDocument31 paginiBill of Materials SampleOcsi YeahÎncă nu există evaluări

- Compressor Service ProcedureDocument22 paginiCompressor Service ProcedureFriget Rusianto100% (2)

- GautierDocument164 paginiGautierDimitar NedkovÎncă nu există evaluări

- Microsoft ISA Server 2006 - Certificate Troubleshooting - Part IIDocument7 paginiMicrosoft ISA Server 2006 - Certificate Troubleshooting - Part IIKhodor AkoumÎncă nu există evaluări