Documente Academic

Documente Profesional

Documente Cultură

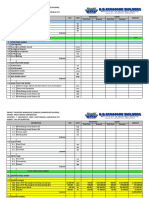

Vacuum de - Watered Flooring Method Statement: Activities

Încărcat de

வினோத் குமார்Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Vacuum de - Watered Flooring Method Statement: Activities

Încărcat de

வினோத் குமார்Drepturi de autor:

Formate disponibile

VACUUM DE - WATERED FLOORING

METHOD STATEMENT

ACTIVITIES

The floor front will be cleaned and levels will be recorded. Final sub base leveling

Flooring level marking will be fixed on the prepared leve base surface as per approved floor layout

growing.

Antitermite BIFLEX TC apply in 1:49 ratio as per specification

HDPE sheet laying in floor area as per specification

The M25 concrete will be poured inside the panel. Concrete mixes per specification

Double beam screed vibrator will be placed over the two rail (floor frame) of the panel for

Self-movement vibration. Where in the vibration will transfer through the both frames of the panel

to ensure the proper vibration, precise strike off and conslidation to the full depth of concrete which

will achieve the nearest flatness of the floor.

Tailor made bottom mat ( sieve mat ) will placed overthe screed operated concrete surface to

Prevent the escape of concrete particles during the vacuum dewatering process

Over the bottom mate, the tailor made size top mate will be placed to create the vacuum zone around

the bottom mat. Where in the periphral area of tpo mat wlll be in contact with the green concrete to

ensure creation of vacuum zone

The fixed one end of suction pipe will be fitted on the top mat the otherendwill be fixed with vacuum

pump. Now the vacuum dewatering process will be started for easy removal of water from the

concrete to ensure the reduction of water cement ratio and optimization of water presence in the

concrete.

The vacuum will be maintained for at least 5 - 10 minutes at vacuum pressure of 2 to 3 kg/cm2

After the vacuum dewatering process power float /discfloatwalk behind type which is fitted

With round plate will be used to remove the surface undulation, prior to finish the concrete

surface.lf crusting occurs the floating operation will be delayed till the concrete carries the

Machine the higher speed floating operations will be carried out

The passes with the floating disc will be made in the junction of two mate in order to avoid

Risk of cracking

The trowel ling operation with walk in power trowel willtake place before the concrete has hardened

enough to carry machine, i.e. the trowel ling blades will not leave any marks on the concrete. This

operation will result in base coat preparation of floor finishing the disc floai has to put in use one two

times or more depends upon the site condition after placement of concrete to ensure the surface is

ready for power trowel operation. Repeated trowel ling with intervals betveen the passes will be

adapted to the setting of the concrete, greatly improves the surface characteristics.

The smoothness of concrete finishing can be achieved by the operation of power trowel one or more

times as directed.

The controljoints will be marked over the flooring as per layout and cutting tool of size 3 mm* 20mm

shall be done within 24 hour of placement of concrete.(Polysulphide sealand)

Now, the flooring is ready for curing.

Water curing will be done for 14days from the date of casting

No Men and Vehicle moments at least four weeks only.

Prepared by Approved by

S-ar putea să vă placă și

- ITEM 100 Latest 2004Document33 paginiITEM 100 Latest 2004Shammir Tabayag MangidaÎncă nu există evaluări

- Shop Drawing of Status SummaryDocument2 paginiShop Drawing of Status SummaryANJellHwanÎncă nu există evaluări

- Pavement MixtureDocument206 paginiPavement MixtureMongi Ben Ouezdou100% (1)

- ABSTRACT ESTIMATE FOR HOUSE IN REDDY COLONYDocument24 paginiABSTRACT ESTIMATE FOR HOUSE IN REDDY COLONYSafa AliÎncă nu există evaluări

- Date ActivityDocument1 paginăDate ActivityMark Roger Huberit IIÎncă nu există evaluări

- QC-Steel Raise FloorDocument1 paginăQC-Steel Raise Floorศิษย์เก่า ทีเจพีÎncă nu există evaluări

- Schedule - Updated9182411975908974007Document4 paginiSchedule - Updated9182411975908974007Alfric AbinsayÎncă nu există evaluări

- Daily report on EBSM upgrading project activitiesDocument1 paginăDaily report on EBSM upgrading project activitiesebsmsartÎncă nu există evaluări

- Stainless Steel PricelistDocument28 paginiStainless Steel Pricelistmanish422Încă nu există evaluări

- MNIT Jaipur Tender for Construction of Academic Lecture TheatresDocument102 paginiMNIT Jaipur Tender for Construction of Academic Lecture Theatresdrjonesg19585102Încă nu există evaluări

- Rev 1Document1 paginăRev 1Wan AzriÎncă nu există evaluări

- RFQ Consumables - Quote RevisedDocument12 paginiRFQ Consumables - Quote RevisedVishal Pratap SinghÎncă nu există evaluări

- CIVIL ESTIMATION FACTORY BUILDINGDocument2 paginiCIVIL ESTIMATION FACTORY BUILDINGTitus PraveenÎncă nu există evaluări

- Miscella Neous Civil Works: SR - Description Unit Rate Quantity AmountDocument7 paginiMiscella Neous Civil Works: SR - Description Unit Rate Quantity AmountSenthilnathan NagarajanÎncă nu există evaluări

- Price List 2017-2018Document50 paginiPrice List 2017-2018Aprilie MihaelaÎncă nu există evaluări

- Rev1 Revised Hording BQ No. 2 M 200.00 338.11 67,622.00: Qtty RateDocument2 paginiRev1 Revised Hording BQ No. 2 M 200.00 338.11 67,622.00: Qtty RatectaciutÎncă nu există evaluări

- Rate Analysis - UniqueDocument3 paginiRate Analysis - UniqueAjay SastryÎncă nu există evaluări

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 paginiLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlÎncă nu există evaluări

- Civil Store Stock ListDocument32 paginiCivil Store Stock ListfranciscoÎncă nu există evaluări

- Price ListDocument11 paginiPrice ListJacy Maricor Reabad100% (1)

- 2x150mw Dmci CWP 001 EarthworksDocument12 pagini2x150mw Dmci CWP 001 EarthworksBenjo FaustoÎncă nu există evaluări

- Strengthening and maintenance of major roads in Zone IDocument15 paginiStrengthening and maintenance of major roads in Zone ISwapnil PalavÎncă nu există evaluări

- AI Quote - Labour Rate AnalysisDocument29 paginiAI Quote - Labour Rate AnalysisKarthi KesanÎncă nu există evaluări

- Rebar ScheduleDocument2 paginiRebar Schedulejoem cuentoÎncă nu există evaluări

- Request For 2nd Time ExtensionDocument3 paginiRequest For 2nd Time ExtensionEngineeri TadiyosÎncă nu există evaluări

- 5.0 Itemized Cost of RevisionDocument9 pagini5.0 Itemized Cost of Revisiondexter guanzon serotÎncă nu există evaluări

- Schedule of RebarsDocument7 paginiSchedule of RebarsJaime Manalili LandinginÎncă nu există evaluări

- Non-Shrink Grout Mix PDFDocument4 paginiNon-Shrink Grout Mix PDFAnonymous AJYdboÎncă nu există evaluări

- Construction Labor RatesDocument12 paginiConstruction Labor RatesJoseph AlcanseÎncă nu există evaluări

- Unit Price List for Construction MaterialsDocument98 paginiUnit Price List for Construction MaterialsYonasÎncă nu există evaluări

- SEAWOODS RESIDENCES MATERIAL REQUIREMENTDocument17 paginiSEAWOODS RESIDENCES MATERIAL REQUIREMENTJohny Lou LuzaÎncă nu există evaluări

- Item # Description QTY Unit I Civil Works A FencingDocument2 paginiItem # Description QTY Unit I Civil Works A FencingNeil San JuanÎncă nu există evaluări

- Sample Renovation Bill of QuantitiesDocument2 paginiSample Renovation Bill of QuantitiesVioMLettyÎncă nu există evaluări

- PRICELISTDocument3 paginiPRICELISTDanilyn LabanÎncă nu există evaluări

- Proposed Warehouse Complex Bill of QuantitiesDocument23 paginiProposed Warehouse Complex Bill of Quantities13 Jose Emanuel LiganÎncă nu există evaluări

- Laboratory Room Works ScheduleDocument1 paginăLaboratory Room Works ScheduleMarieÎncă nu există evaluări

- REPAIR OF DAYCARE CENTER, COMFORT ROOM AND BRGY. HALLDocument18 paginiREPAIR OF DAYCARE CENTER, COMFORT ROOM AND BRGY. HALLRamil S. ArtatesÎncă nu există evaluări

- MOS Infrastructure WorksDocument17 paginiMOS Infrastructure WorksPoruman AnduÎncă nu există evaluări

- MTC For ThermocolDocument2 paginiMTC For ThermocolhariprasadÎncă nu există evaluări

- Teamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689Document6 paginiTeamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689leslieÎncă nu există evaluări

- ME-1 Things To RememberDocument7 paginiME-1 Things To Rememberlebronman58Încă nu există evaluări

- Eaab BomceDocument22 paginiEaab BomceBert EngÎncă nu există evaluări

- Boq 37800Document10 paginiBoq 37800DEEPALIÎncă nu există evaluări

- G+7 Watersupply, Septic AnkDocument633 paginiG+7 Watersupply, Septic AnkSantosh ChowdaryÎncă nu există evaluări

- Unit CostDocument11 paginiUnit CostMarc Gregory Queral OlanioÎncă nu există evaluări

- Generator Transformer & Unit Auxiliary Transformer Installation 070903Document18 paginiGenerator Transformer & Unit Auxiliary Transformer Installation 070903bewid100% (1)

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkDocument6 paginiDate-070209 SR - No. Description Unit Rate A Rcc. WorkAjay SinghÎncă nu există evaluări

- Cement Concrete PavementDocument8 paginiCement Concrete Pavementgtarun22guptaÎncă nu există evaluări

- Dolkha District Building Material RatesDocument80 paginiDolkha District Building Material RatesNiranjan ShresthaÎncă nu există evaluări

- Concrete Fence Project Cost and BOMDocument3 paginiConcrete Fence Project Cost and BOMJun Michael Artates VelascoÎncă nu există evaluări

- Details of Demolition QuantityDocument92 paginiDetails of Demolition QuantityK. Mehedi HasanÎncă nu există evaluări

- Augmentation concreting of barangay road in Iguig, CagayanDocument3 paginiAugmentation concreting of barangay road in Iguig, CagayanJohny VillanuevaÎncă nu există evaluări

- SF - RE500 + G500 Rebar (Sep2015)Document88 paginiSF - RE500 + G500 Rebar (Sep2015)Wesleykit WongÎncă nu există evaluări

- Wooden Floor SpecificationDocument2 paginiWooden Floor SpecificationraviÎncă nu există evaluări

- Schedule of Rates BarisalDocument138 paginiSchedule of Rates Barisal00152100% (3)

- Safe Construction Method StatementDocument7 paginiSafe Construction Method StatementlijosejacobÎncă nu există evaluări

- Garden DSR Civil 2016-17 FinalDocument218 paginiGarden DSR Civil 2016-17 FinalShruti DamgirÎncă nu există evaluări

- BoQ Elevated Tank PDFDocument3 paginiBoQ Elevated Tank PDFسليم البركانيÎncă nu există evaluări

- Floor Area Bill of Quantities Project BreakdownDocument10 paginiFloor Area Bill of Quantities Project BreakdownDan Alfonso de TablanÎncă nu există evaluări

- Vacuum de - Watered Flooring Method Statement: ActivitiesDocument1 paginăVacuum de - Watered Flooring Method Statement: ActivitiesISPRO TVÎncă nu există evaluări

- Accident / Incident Investigation FormDocument3 paginiAccident / Incident Investigation Formவினோத் குமார்Încă nu există evaluări

- Disclosure To Promote The Right To InformationDocument19 paginiDisclosure To Promote The Right To Informationarindam_chowdhu1926Încă nu există evaluări

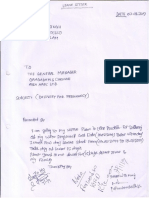

- LEAVE LETTER REQUESTDocument1 paginăLEAVE LETTER REQUESTவினோத் குமார்Încă nu există evaluări

- Ladder Safety ProceduresDocument12 paginiLadder Safety ProceduresjosethompsonÎncă nu există evaluări

- Short Column Lateral TiesDocument36 paginiShort Column Lateral TiesMark Gerald Oreiro100% (2)

- Formwork:: Requirements of A Good Formwork SystemDocument8 paginiFormwork:: Requirements of A Good Formwork SystemJonah ScottÎncă nu există evaluări

- Ready Mix ManualDocument27 paginiReady Mix ManualThomasMaurzÎncă nu există evaluări

- Design of A Plastic Rubber Shredder Machine For Recycling and Management of Waste Ijariie15033 PDFDocument15 paginiDesign of A Plastic Rubber Shredder Machine For Recycling and Management of Waste Ijariie15033 PDFJade DigÎncă nu există evaluări

- Architectural/Mechanical Product Specifications: GirbauDocument4 paginiArchitectural/Mechanical Product Specifications: GirbauLovely BautistaÎncă nu există evaluări

- Locust Bean Pod Waste Improves Clay Brick StrengthDocument16 paginiLocust Bean Pod Waste Improves Clay Brick StrengthJubril Sanusi DanlamiÎncă nu există evaluări

- Astm C478Document8 paginiAstm C478Ferec XalikovÎncă nu există evaluări

- Concrete Durability in Persian Gulf PDFDocument14 paginiConcrete Durability in Persian Gulf PDFMahmood MuftiÎncă nu există evaluări

- INDOT Contractors Feb 2020Document97 paginiINDOT Contractors Feb 2020JP StorkÎncă nu există evaluări

- 300+ (UPDATED) Civil Engineering Interview Questions and AnswersDocument11 pagini300+ (UPDATED) Civil Engineering Interview Questions and AnswersIrfan AwanÎncă nu există evaluări

- Splash Works Water Parks Core Test Report PDFDocument1 paginăSplash Works Water Parks Core Test Report PDFJahid HasanÎncă nu există evaluări

- Tests on Concrete Materials Lab GuideDocument8 paginiTests on Concrete Materials Lab Guidekppy98100% (1)

- Case Studies of Some Concrete Structural FailuresDocument96 paginiCase Studies of Some Concrete Structural FailuresBandilung TzÎncă nu există evaluări

- Lecture 1 - Reinforced Concrete - IntroductionDocument62 paginiLecture 1 - Reinforced Concrete - IntroductionChristopher PaladioÎncă nu există evaluări

- Development On Natural Fibre Based Materials in Malaysia Building Industry: AnDocument6 paginiDevelopment On Natural Fibre Based Materials in Malaysia Building Industry: Angerald077Încă nu există evaluări

- 0116 202006081032 PDFDocument4 pagini0116 202006081032 PDFPatrickÎncă nu există evaluări

- Awash Rive Bridge-Tendaho Project-Feb-2014-1 (Repaired)Document35 paginiAwash Rive Bridge-Tendaho Project-Feb-2014-1 (Repaired)teweldeÎncă nu există evaluări

- Wa0009Document45 paginiWa0009Victor OmotoriogunÎncă nu există evaluări

- Microtunneling enDocument7 paginiMicrotunneling enTauha Aziz ShahÎncă nu există evaluări

- Hammers: H35E, H45E, H55E, H65E H35E, H45E, H55E, H65EDocument8 paginiHammers: H35E, H45E, H55E, H65E H35E, H45E, H55E, H65EAmigo PeruÎncă nu există evaluări

- Experimental Research On The Behaviour of High Frequency Fatigue in ConcreteDocument10 paginiExperimental Research On The Behaviour of High Frequency Fatigue in Concreteming_zhu10Încă nu există evaluări

- LKD as Potential Raw Material in Cement ManufacturingDocument9 paginiLKD as Potential Raw Material in Cement ManufacturingNoraa LindemannÎncă nu există evaluări

- Bridge Design - Sample QuestionsDocument23 paginiBridge Design - Sample QuestionsSena KenaÎncă nu există evaluări

- USACE Pile Foundation Design ManualDocument188 paginiUSACE Pile Foundation Design ManualSiriveri Lakshmi KanthÎncă nu există evaluări

- A Report On Civil Engineering Student's Internship Programme (CESIP) of Building ConstructionDocument29 paginiA Report On Civil Engineering Student's Internship Programme (CESIP) of Building ConstructionShivam DubeyÎncă nu există evaluări

- Bs Megaplast A Ready Mix PlasterDocument1 paginăBs Megaplast A Ready Mix Plasterkavya singhalÎncă nu există evaluări

- Standard Test Methods For Determining The Chemical Resistance of Concrete Products To Acid AttackDocument1 paginăStandard Test Methods For Determining The Chemical Resistance of Concrete Products To Acid AttackSanil JÎncă nu există evaluări

- Experimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesDocument5 paginiExperimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

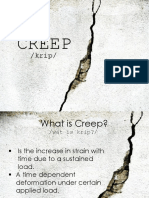

- Understanding Creep and Shrinkage in ConcreteDocument32 paginiUnderstanding Creep and Shrinkage in ConcreteannaÎncă nu există evaluări

- Cross-Laminated Timber (CLT)Document16 paginiCross-Laminated Timber (CLT)Sheen GabaisenÎncă nu există evaluări