Documente Academic

Documente Profesional

Documente Cultură

Serie D3 - Cetop 5

Încărcat de

Hugo MenendezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Serie D3 - Cetop 5

Încărcat de

Hugo MenendezDrepturi de autor:

Formate disponibile

Catalog HY14-2500/US Directional Control Valves

Introduction Series D3

Application Features

Series D3 hydraulic directional control valves are high • Easy access mounting bolts.

A performance, direct operated 4-way valves, available • 345 Bar (5000 PSI) pressure rating.

in 2 or 3-position. They are manifold mounted which

conform to NFPA’s D05, CETOP 5, ISO NG10 mount-

• Flows to 40 GPM depending on spool.

ing patterns. These valves were designed for industrial • Choice of four operator styles.

and mobile hydraulic applications which require high • Rugged four land spools.

cycle rates, long life and high efficiency. • Low pressure drop.

Operation • Phosphate finish body.

Series D3 directional control valves consist of a • CSA approved and UL recognized available.

4-chamber style body, and a case hardened sliding • Proportional spool available.

spool. The spool is directly shifted by a variety of op-

erators including: solenoid, lever, cam, or air pilot.

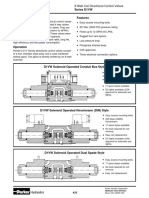

D3W Solenoid Operated Conduit Cavity Style

• Wired in cavity.

• Easy access mounting bolts.

• 22 spool styles available.

• Three electrical connection

options.

• AC and DC lights available.

• CSA approved.

• Available in low-watt DC

version.

D3W Solenoid Operated Hirschmann (DIN) Style

• DIN Style (43650)

Hirschmann.

• 22 spool styles available.

• No tools required for coil

removal.

• Easy coil replacement.

• AC and DC lights available.

• CSA approved.

• Available in low-watt DC

version.

D3.indd, dd

A44 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Introduction Series D3

D3L Lever Operated

A

• Spring return or detent styles available.

• Heavy duty handle design.

• High flow, low pressure drop design.

D3A Air Operated

• Low pilot pressure required –

4.1 Bar (60 PSI) minimum.

• High flow, low pressure drop

design.

D3C Cam Operated

• Choice of 2 cam roller positions

(D3C and D3D).

• Short stroke option.

• High flow, low pressure drop

design.

D3.indd, dd

A45 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Introduction Series D3DW

Application Operation

Series D3DW hydraulic directional control valves are Series D3DW directional control valves consist of a

A high performance, direct operated 4-way valves, avail-

able in 2 or 3-position. They are manifold mounted

5-chamber style body, and a case hardened sliding

spool.

which conform to NFPA’s D05, CETOP 5, ISO NG10

mounting pattern. These valves were designed for

industrial and mobile hydraulic applications which re-

quire high cycle rates, long life and high efficiency.

D3DW Solenoid Operated Hirschmann (DIN) Style

• Easy access mounting bolts.

• No tools required for coil

removal.

• 22 spool styles available.

• Signal lights available.

• CSA approved.

D3.indd, dd

A46 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3

D3 Spool Reference Data

Maximum Flow, LPM (GPM)

350 Bar (5000 PSI)

w/o Malfunction

Maximum Flow, LPM (GPM)

350 Bar (5000 PSI)

w/o Malfunction

A

Model Spool Symbol D3W D3W*F† D3DW Model Spool Symbol D3W D3W*F† D3DW

A B A B

D3*1 P T 150 (40) 78 (20) 130 (33) D3*12 P T 95 (24) 59 (15) 75 (19)

A B A B

D3*2 P T 150 (40) 78 (20) 115 (30) D3*14 P T 50† (13) 59# (15) 70† (18)

A B A B

D3*3 P T 150 (40) 78 (20) 120 (31) D3*15 P T 150 (40) 78 (20) 120 (31)

A B A B

D3*4 P T 150 (40) 59 (15) 130 (33) D3*16 P T 150 (40) 78 (20) 130 (33)

A B A B

D3*5 P T 150 (40) 78 (20) 130 (33) D3*20 P T 150 (40) 78 (20) 130 (33)

A B A B

D3*6 P T 150 (40) 78 (20) 130 (33) D3*21 P T 115 (30) N/A 120 (31)

A B A B

D3*7

P T 50† (13) 59# (15) 70† (18) D3*22 P T 115 (30) N/A 120 (31)

A B A B

D3*8 P T 50‡ (13) 59# (15) 39 (10) D3*26 P T 115 (30) N/A 75 (19)

A B A B

D3*9 P T 39 (10) 59# (15) 75 (19) D3*30 P T 39 (10) 59# (15) 75 (19)

A B A B

D3*10 P T 115 (30) N/A 75 (19) D3*81 P T 115† (30) N/A 130 (33)

A B A B

D3*11 P T 115 (30) 59# (15) 130 (33) D3*82 P T

115† (30) N/A 130 (33)

Center or De-energized position is indicated by P, A, B & T port notation.

† 3000 PSI Max. ‡ 2900 PSI Max. # 1500 PSI Max.

D3A, D3C, D3L Spool Reference Data (Four Chamber Body Only)

Maximum Flow, LPM (GPM) Maximum Flow, LPM (GPM)

350 Bar (5000 PSI) 350 Bar (5000 PSI)

Model Spool Symbol w/o Malfunction Model Spool Symbol w/o Malfunction

A B A B

D3*1 P T 150 (40) D3*20 P T 150 (40)

A B A B

D3*2 P T 150 (40) D3*26 P T 115 (30)

A B A B

D3*4 P T 150 (40) D3*30 P T 39 (10)

A B

A B

D3*8 P T 50 (13) D3*81

P T 115 (30)

A B A B

D3*9 P T 39 (10) D3*82 P T 115 (30)

Center or De-energized position is indicated by A, B, P & T port notation.

D3.indd, dd

A47 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Performance Curves Series D3

D3W-30/32 DC and AC Rectified Shift Limits

A PSI Bar

5000 345

9, 30 10, 21,

22, 26

300

4000

Supply Pressure

250 8 11, 81, 82

12

3000

200

7, 14

150 8, 9, 30

2000

100

1000

50 20D, 26D 1, 2, 3,

30D 4, 5, 6,

15, 16, 20

0

LPM 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

0

GPM 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

Flow

Example:

Determine the maximum allowable flow of a D3W Important Notes for Switching Limit Charts

Series valve (20D) at 150 Bar (2175 PSI) supply 1. For F & M style valves, reduce flow to 70% of that shown.

2. Shift limits charted for equal flow A and B ports. Unequal

pressure. Locate the curve marked “20D”. At 150 Bar A and B port flows may reduce shift limits.

(2175 PSI) supply pressure, the maximum flow is 3. These charts do not show explosion proof performance.

98 LPM (25 GPM). At 345 Bar (5000 PSI), the flow is Consult factory for explosion proof duty.

72 LPM (18.5 GPM). 4. Blocking A and B ports will reduce flow to 70% of that shown.

D3W-30/32 Low Watt DC and AC Rectified Shift Limits

PSI Bar

3000 200

Supply Pressure

150 4

2000

100

1, 2, 3,

1000 7, 8, 9 5, 6,

50 11, 12, 14, 15, 16, 20

30

0

LPM 10 20 30 40 50 60 70

0

GPM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Flow

D3.indd, dd

A48 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Performance Curves Series D3

D3W-30/32 AC Shift Limits

PSI Bar

5000 345

A

1, 3, 4, 5,

15, 16, 11

2

300 20, 30

4000

6

Supply Pressure

250 3, 4, 5,

15, 16, 30 1, 6, 20

3000

200

150 9 12

2000

100 7, 8,

14

1000

50 20D,

30D

0

LPM 10 20 30 40 50 60 70 80 90 100 110 120

0

GPM 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32

Flow

D3W-30/32 Soft Shift Limits (High Watt Coil Only)

Important Notes for Switching Limit Charts

1. For F & M style valves, reduce flow to 70% of that shown.

2. Shift limits charted for equal flow A and B ports. Unequal

A and B port flows may reduce shift limits.

3. These charts do not show explosion proof performance.

Consult factory for explosion proof duty.

4. Blocking A and B ports will reduce flow to 70% of that shown.

D3.indd, dd

A49 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Performance Curves Series D3

D3W-30/32 Soft Shift Response

A

Response Time*

Signal to 95% spool stroke measured at

172 Bar (2500 PSI) and 65 LPM (17 GPM).

Soft Shift

Option Energize De-energize

S3 400 650

S4 320 550

S7 160 370

* For reference only. Response time varies

with flow, pressure and oil viscosity.

D3DW-40/41 Shift Limits

Important Notes for Switching Limit Charts

1. For F & M style valves, reduce flow to 70% of that shown.

2. Shift limits charted for equal flow A and B ports. Unequal

A and B port flows may reduce shift limits.

3. These charts do not show explosion proof performance.

Consult factory for explosion proof duty.

4. Blocking A and B ports will reduce flow to 70% of that shown.

D3.indd, dd

A50 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3

Pressure Drop vs. Flow D3W and D3DW Pressure Drop Reference Chart

The table shown provides Curve Number

flow vs. pressure drop curve

reference for D3 Series valves

Spool Shifted Center Condition

No. P–A P–B B–T A–T (P–T) (B–A) (A–B) (P-A) (P-B) (A-T) (B-T)

A

by spool type. 1 5 5 2 2 — — — — — — —

The chart below demonstrates 2 4 4 1 1 2 3 3 3 3 1 1

graphically the performance 3 5 5 2 3 — — — — — 1 —

characteristics of the D3. The 4 4 4 3 3 — — — — — 1 1

low watt coil and other design 5 6 5 2 2 — — — 2 — — —

features of the standard 6 6 6 2 2 — 4 4 2 2 — —

D3W*****F accommodate a 7 5 4 2 1 3 — — — 3 — 1

maximum flow of 8 8 8 7 7 6 — — — — — —

78 LPM (20 GPM) at 9 5 5 4 4 7 — — — — — —

207 Bar (3000 PSI). 10 5 5 — — — — — — — — —

11 5 5 2 2 — — — — — 10 10

12 5 5 2 2 11 — — 10 10 10 10

14 4 5 1 2 3 — — 3 — 1 —

15 5 5 3 2 — — — — — — 1

16 5 6 2 2 — — — — 2 — —

20 5 5 2 2 — — — — — — —

21 5 4 — 1 — 9 — — — — —

22 4 5 1 — — — 9 — — — —

26 5 5 — — — — — — — — —

30 5 5 2 2 — — — — — — —

Note: Viscosity Correction Factor

For 81 and 82

Viscosity 75 150 200 250 300 350 400

spools, consult

(SSU)

factory.

% of ∆P 93 111 119 126 132 137 141

(Approx.)

Curves were generated using 110 SSU hydraulic oil.

For any other viscosity, pressure drop will change per chart.

Performance Curves

D3.indd, dd

A51 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US

Notes

D3.indd, dd

A52 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3W

General Description

Series D3W directional control valves are

high-performance, 4-chamber, direct operated, wet

armature, solenoid controlled, 3 or 4-way valves. They

B AB A A

are available in 2 or 3-position and conform to NFPA’s

D05, CETOP 5 mounting patterns. PT

Features

• Worldwide, high flow, low pressure drop design.

• Soft shift available.

• 22 spools available including proportional.

• DC surge suppression available to protect electrical

equipment.

• Three electrical connection options.

• AC & DC lights available.

• Easy access mounting bolts.

• Explosion proof availability.

• CSA approved. Specifications

• No tools required for coil removal. Interface NFPA D05, CETOP 5, NG 10

• Rectified coils available for high flow AC applications. Max. Operating P, A, B:

Pressure 345 Bar (5000 PSI) Standard

Response Time (ms) CSA 207 Bar (3000 PSI)

Signal to 95% spool stroke measured at Tank:

172 Bar (2500 PSI) and 75 LPM (20 GPM) 103 Bar (1500 PSI) AC Standard

Solenoid Type m sec 207 Bar (3000 PSI) AC Optional

AC Energize 21 DC/AC Rectified Standard

AC De-energize 35 CSA 103 Bar (1500 PSI)

DC Energize 110 CSA File Number LR060407

DC De-energize 85 Leakage Rates Maximum Allowable:

100 SSU @ 19.6 cc (0.38 Cu. in.) per Minute/

49°C (120°F) Land @ 69 Bar (1000 PSI)*

35 cc (2.19 Cu. in.) per Minute/

Land @ 207 Bar (3000 PSI)*

* #008 and #009 Spools may exceed these rates, consult

factory

D3.indd, dd

A53 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D3W

D 3 W

A Directional

Control Valve

Basic Valve Actuator Spool Style Seal Solenoid

Voltage

NFPA D05 Code Description Code Description

CETOP 5 N Nitrile E# 24/60 - 24/50 VAC

NG 10 V Fluorocarbon Y 120/60 - 110/50 VAC

T 240/60 - 220/50 VAC

Wet armature K 12 VDC

solenoid J 24 VDC

D# 120 VDC

U# 98 VDC

Code Symbol Code Symbol Z# 250 VDC

A B A B

1 14 # High Watt Coil only.

P T P T

A B A B

2 15

P T P T Code Description Symbol

A B A B

Single solenoid, 2 position, b A B

3 16 B* spring offset.

P T P T P to A and B to T in offset position P T

A B A B b A B a

4 20* C Double solenoid, 3 position,

P T P T spring centered. P T

A B A B b A B a

5 21† D† Double solenoid, 2 position, detent

P T P T P T

A B A B Single solenoid, 2 position, b A B

6 22† E spring centered.

P T P T

P to B and A to T when energized. P T

b A B

A B A B Single solenoid, 2 position. Spring offset,

7 26*† F** energized to center position. Spool spacer on A

P T

side. P to A and B to T in spring offset position. P T

P T

a

A B A B Single solenoid, 2 position, A B

*

8 30** H* spring offset.

9** P to B and A to T in offset position. P T

P T P T

A B a

A B A B Single solenoid, 2 position.

10† 81† K Spring centered.

†† P to A and B to T when energized. P T

P T P T

A B a

A B A B

Single solenoid, 2 position, spring offset, energized

11 82† M** to center position. Spool spacer on B side. P to B

†† and A to T in spring offset position. P T

P T P T

* Only spools 20, 26 & 30.

A B

** High Watt Coil.

2

1 † Only spools 20 & 30. This condition varies

P T

with spool code.

* 8, 20 & 26 spools have closed crossover.

** 9 & 30 spools have open crossover.

† Available only with high-watt rectified AC coils

or high-watt DC coils.

†† Spring centered versions C, E, F, K & M only.

Valve schematic symbols are per NFPA/ANSI

standards, providing flow P to A when energizing

solenoid A. Note operators reverse sides for #8

and #9 spools. See installation information for

details.

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D3.indd, dd

A54 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D3W

Solenoid

Connection

Solenoid/Tube

Options

Manual

Override

Options

Electrical Shift

Options Response

and

Approvals Variations Design

Series

NOTE:

A

Indication Not required

Code Description when ordering.

C** Conduit Cavity Code Description

K Conduit Box Omit Standard Valve

J#* Deutsch (DT06-2S) Code Description 3*† CSA US (UL429)

P Hirschmann w/Plug Omit Standard Tube 4* CSA Canada

W* Hirschmann w/o Plug P* Extended Manual * Not available with AC high

E* Explosion Proof Override pressure tube.

* Lights not available. * Not available with soft shift † B, C, H styles only.

** No variations (See “K”). or explosion proof. Y voltage with conduit

# DC voltage only. connection only, must be

rectified.

Options Coil Tube Rating Code Description

AC DC/AC Rectified

Omit Standard Valve

Omit High Watt 103.5 Bar (1500 PSI) 207 Bar (3000 PSI)

S3** Soft Shift, 0.030” Orifice

F*# Low Watt n/a 207 Bar (3000 PSI)

S4** Soft Shift, 0.040” Orifice

H High Watt 207 Bar (3000 PSI) n/a

S7** Soft Shift, 0.070” Orifice

D† Explosion Proof, EEXD ATEX

I7* Monitor Switch Direct

U† Explosion Proof, UL/CSA Op. End Stroke

* Available only with J, K and Y (Rectified), T (Rectified) voltages. I8* Monitor Switch

# Not available with soft shift or with F and M style valves.

* Single solenoid models only. Not

† Explosion proof coils are 60 Hz at standard voltage; dual rating not

CE or CSA approved. Spools 8, 9,

available.

81 & 82 not available.

Valve Weight: ** High watt coil only.

Code Description

Single Solenoid:

Omit No Option

AC 4.3 kg (9.5 lbs.)

DC 5.3 kg (11.6 lbs.) V# Varistor Surge

Suppressor

Double Solenoid:

AC 5.0 kg (11.0 lbs.) Z AC Rectified

DC 7.3 kg (16.0 lbs.) with MOV Surge

Suppressor

Seal Kit:

Nitrile SKD3W # DC voltage only.

Fluorocarbon SKD3WV Code Description

Mounting Bolt Kits Omit Standard Valve

5 Signal Lights

UNC Bolt Kits for use with D3W 6 Manaplug, Brad Harrison Mini

Directional Control Valves & Sandwich Valves

7 Manaplug, Brad Harrison Micro (M12x1)

Number of Sandwich Valves

56 Manaplug (Mini) with Lights

@ 2.00” (50mm) thickness

57 Manaplug (Micro) with Lights (M12x1)

0 1 2 3

1A Manaplug (Mini) Single Sol. 5-Pin

D3W Standard: BK98 BK141 BK142 BK143

1.62” 3.50” 5.50” 7.50” 1B Manaplug (Micro) Single Sol. 5-Pin (M12x1)

Metric: BKM98 BKM141 BKM142 BKM143 1C Manaplug (Mini) Single Sol. 5-Pin w/Lights

40mm 90mm 140mm 190mm 1D Manaplug (Micro) Single Sol. 5-Pin w/Lights (M12x1)

D3W with Standard: BK144 BK61 BK62 BK63 1M Manaplug Opposite Normal

explosion 2.37” 4.25” 6.25” 8.25”

proof coils Metric: BKM144 BKM61 BKM62 BKM63

60mm 110mm 160mm 210mm

NOTE: All bolts are SAE grade 8, 1/4-20 UNC-2A thread, torque to

16 Nm (12 ft-lbs)

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D3.indd, dd

A55 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3W

Solenoid Ratings**

Insulation Class H D3W*****F Solenoid Electrical Characteristics‡

A Allowable Deviation

from rated voltage

DC, AC Rect

AC

-10% to +15%

-5% to +5%

Solenoid Nominal In Rush Holding

Code Volts/Hz Amps Amps Watts

Armature Wet pin type KF 12 VDC — 1.50 18

** DC Solenoids available with optional molded metal oxide varistor JF 24 VDC — 0.75 18

(MOV) for surge suppression.

Leadwire length 6” from coil face. ‡ Based on nominal voltage @ 22°C (72°F)

D3W Solenoid Electrical Characteristics† D3W Rectified AC Solenoid Electrical

Solenoid Nominal In Rush Holding Nominal Characteristics‡

Code Volts/Hz VA VA Watts (Ref) Solenoid Nominal In Rush Holding

Y 120/60 298 95 32 Code Volts/Hz Amps Amps Watts

110/50 294 102 Y 120/60 — .37 36

T 240/60 288 96 32 110/50

220/50 288 101 T 240/60 — .18 36

E 24/60 290 77 32 220/50

24/50 381 110 YF 120/60 — .18 18

K 12 VDC — 3.00† 36 110/50

J 24 VDC — 1.50† 36 TF 240/60 — .09 18

220/50

D 120 VDC — 0.30† 36

‡ Based on nominal voltage @ 22°C (72°F)

U 98 VDC — 0.37† 36

Z 250 VDC — 0.14† 36

† DC holding amps.

Explosion Proof Solenoids

Explosion Proof Solenoid Ratings Electrical Characteristics* ED and EU†

U.L. /CSA (EU) Class I, Div. 1 & 2, Groups C & D Solenoid Nominal In Rush Holding Nominal

Class II, Div 1 & 2, Groups E, F & G Code Volts/Hz VA VA Watts (Ref)

As defined by the N.E.C. Y 120/60 266 82 36

ATEX Complies with ATEX requirements for:

T 240/60 266 82 36

Exd, Group IIB;

EN50014: 1999+ Amds 1 & 2, K 12 VDC — 3.00† 36

EN50018: 200 J 24 VDC — 1.50† 36

D 120 VDC — 0.30† 36

* Dual frequency not available on explosion proof coils.

† DC holding amps.

D3.indd, dd

A56 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3W

Inch equivalents for millimeter dimensions are shown in (**)

Hirschmann, Double AC Solenoid

A

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

Hirschmann, Single AC Solenoid

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

D3.indd, dd

A57 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3W

Inch equivalents for millimeter dimensions are shown in (**)

Conduit Cavity, Double DC Solenoid

A

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

Conduit Cavity, Single DC Solenoid

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

D3.indd, dd

A58 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3W

Inch equivalents for millimeter dimensions are shown in (**)

Conduit Box, Single AC Solenoid

with Variation 6 (Manaplug) & Variation P (Extended Manual Override) A

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

Conduit Box, Double DC Solenoid

with Variation 6 (Manaplug) & Variation P (Extended Manual Override)

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

D3.indd, dd

A59 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3W

Inch equivalents for millimeter dimensions are shown in (**)

Explosion Proof U.L. & CSA, Double Solenoid

A

Note: Mounting bolts included with valve.

Explosion Proof ATEX, Double Solenoid

Bolthole

M20 x 1.5-6H Metric Thread Centerline

Reference

Ground Stud

134.7

(5.31)

103.6 18.9

(4.08) (0.74)

11.6

36.0 (0.46)

(1.42)

18.9 (0.74) Ref.

11.3

23.0 Bolthole 23.0 (0.44)

(0.91) 12.1 Centerline (0.91) 64.9 (2.56)

58.1 (0.47) Reference 75.6 (2.98) 76.7 (3.02)

(2.29) 154.1 207.7

(6.07) (8.18)

Note: Mounting bolts included with valve.

D3.indd, dd

A60 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3W

Inch equivalents for millimeter dimensions are shown in (**)

Hirschmann, Single AC Solenoid

with Variation I7 (Monitor Switch) A

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

Monitor Switch

(Variation I7) End of Stroke

This feature provides for electrical confirmation of

the spool shift. This can be used in safety circuits, to

assure proper sequencing, etc.

Switch Data

Inductive switch requiring +18-42 volt input. Outputs

“A” and “B” are opposite; one at “0” voltage, the

other at input voltage. During switching, “A” and “B”

outputs reverse. Provides 0.4A switching current.

For repetitive switch power-up conditions, please consult

factory.

D3.indd, dd

A61 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Accessories Series D3W

Conduit Box

(connection option K)

A Interface – 152.4 cm (6.0 inch) lead wires, 18 awg.

– Meets NEMA 4 and IP65

Manaplug

(valve variations 6, 56, 1A, 1C)

Interface – Brad Harrison Plug

– 3-Pin for Single Solenoid

– 5-Pin for Double Solenoid

Ground

Wire #1 (Green)

Solenoid (Negative)

Solenoid (Positive)

Wire #3 (Red/Black)

Wire #2 (Red/White)

3-Pin Manaplug (Mini) with Lights

Single Solenoid Valves – Installed Opposite Side of Solenoid

Pins are as seen on valve (male pin connectors)

Hirschmann Plug with Lights (P5) Manaplug - Micro Connector

(valve variations 7, 57, 1B, 1D)

Pin #3

(Ground)

Pin #1

(Negative)

Pin #2

(Positive)

Face View of Plug

Conforms to DIN43650, ISO4400, Form A 3-Pin

Pins are as seen on valve (male pin connectors)

D3.indd, dd

A62 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3DW

General Description

Series D3DW directional control valves are

high performance, 5-chamber, direct operated, wet

armature, solenoid controlled, 3 or 4-way valves. They B AB A A

are available in 2 or 3-position and conform to NFPA’s

D05, CETOP 5 mounting patterns. PT

Features

• 22 spools available including proportional.

• DC surge suppression available to protect electrical

equipment.

• Easy access mounting bolts.

• CSA approved.

• No tools required for coil removal.

• High pressure tank line capability.

• Monitor switch available.

Specifications

Response Time (ms) Interface NFPA D05, CETOP 5, NG 10

Signal to 95% spool stroke measured at Max. Operating P, A, B:

175 Bar (2500 PSI) and 75 LPM (20 GPM) Pressure 345 Bar (5000 PSI) Standard

CSA 207 Bar (3000 PSI)

Solenoid Type Pull-In Drop-Out

DC 110 85 Tank:

207 Bar (3000 PSI) Standard

CSA 103 Bar (1500 PSI)

Maximum Flow See Spool Reference Chart

Leakage Rates Maximum Allowable:

Solenoid Ratings** 100 SSU @ 19.7 cc (1.2 Cu. in.) per Minute/

49°C (120°F) Land @ 69 Bar (1000 PSI)*

Insulation Class H

Allowable Deviation DC only 73.8 cc (4.5 Cu. in.) per Minute/

Land @ 207 Bar (3000 PSI)*

from rated voltage -10% to +15%

Armature Wet pin type Typical:

** DC Solenoids available with optional molded metal oxide varistor

4.9 cc (0.3 Cu. in.) per Minute/

(MOV) for surge suppression. Land @ 69 Bar (1000 PSI)*

26.2 cc (1.6 Cu. in.) per Minute/

Land @ 345 Bar (5000 PSI)

* #008 and #009 Spools may exceed these rates, consult

D3DW Solenoid Electrical Characteristics factory.

Solenoid Nominal In Rush Holding Nominal

Code Volts Amps Amps Watts (Ref)

K 12 VDC — 3.00 36

J 24 VDC — 1.50 36

D 120 VDC — 0.30 36

Y* 120/60 — 0.37 36

110/50

T* 240/60 — 0.18 36

220/50

* AC input rectified to DC

D3.indd, dd

A63 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D3DW

D 3 D W

A Directional

Control Valve

Basic

Valve

Body Actuator Spool Style Seal Solenoid

Voltage

NFPA D05

CETOP 5 Code Description

NG 10 K 12 VDC

J 24 VDC

5-Chamber D 120 VDC

Body

Y* 120/60 AC

110/50

T* 240/60 AC

Wet armature

220/50

solenoid

* Must be rectified.

Code Symbol Code Symbol Code Description

A B A B N Nitrile

1 14 V Fluorocarbon

P T P T

A B A B

2 15

P T P T

A B A B Code Description Symbol

b A B

3 16 Single solenoid, 2 position,

P T P T B* spring offset.

A B A B P to A and B to T in offset position P T

b A B a

4 20*

P T P T

C Double solenoid, 3 position,

A B A B

spring centered. P T

b A B a

5 21

D† Double solenoid, 2 position, detent

P T P T

P T

A B A B

b A B

6 22 Single solenoid, 2 position,

E spring centered.

P T P T

P to B and A to T when energized. P T

A B A B

b A B

7 26* Single solenoid, 2 position. Spring offset,

F energized to center. Position spool spacer on

P T P T

A B

A side. P to A and B to T in spring offset position. P T

A B

A B a

8* 30** Single solenoid, 2 position,

9** H* spring offset.

P T P T

A B A B

P to B and A to T in offset position. P T

A B a

10 81 Single solenoid, 2 position.

K Spring centered.

P T P T

A B A B

P to A and B to T when energized. P T

A B a

11 82 Single solenoid, 2 position, spring offset, energized

P T

M to center position. Spool spacer on B side. P to B

P T

and A to T in spring offset position. P T

A B

12 * Only spools 20, 26 & 30. This condition varies

† Only spools 20 & 30. with spool code.

P T

* 8, 20 & 26 spools have closed crossover.

** 9 & 30 spools have open crossover.

Valve schematic symbols are per NFPA/ANSI

standards, providing flow P to A when energizing

solenoid A. Note operators reverse sides for #8 and

#9 spools. See installation information for details.

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D3.indd, dd

A64 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D3DW

Solenoid

Connector

Manual

Override

Options

Electrical

Options

Shift

Indication

Approvals Variations Design

Series

NOTE:

A

Not required

when ordering.

Code Description

Code Description

Omit Standard Valve

P Hirschmann w/Plug

5 Signal Lights

W* Hirschmann w/o Plug

* Not available with signal lights.

Code Description

Omit Standard Valve

4 CSA Approval

Code Description

Omit Standard Valve

I7* Monitor Switch

* Single solenoid models only.

Not CE or CSA approved.

Not available with spools 8,

9, 81 & 82.

Code Description Code Description

Omit Standard Tube Omit No Option

P Extended Manual Override V# Varistor Surge Suppresor

Z AC Rectified with MOV

# DC Voltage only.

Mounting Bolt Kits

UNC Bolt Kits for use with D3DW

Valve Weight:

Directional Control Valves & Sandwich Valves

Single Solenoid 5.3 kg (11.6 lbs.)

Number of Sandwich Valves

Double Solenoid 7.3 kg (16.0 lbs.)

@ 2.00” (50mm) thickness

Seal Kit:

0 1 2 3

Nitrile SKD3DW

D3DW Standard: BK98 BK141 BK142 BK143 Fluorocarbon SKD3DWV

1.62” 3.50” 5.50” 7.50”

Metric: BKM98 BKM141 BKM142 BKM143

40mm 90mm 140mm 190mm

NOTE: All bolts are SAE grade 8, 1/4-20 UNC-2A thread, torque to

16 Nm (12 ft-lbs).

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D3.indd, dd

A65 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3DW

Inch equivalents for millimeter dimensions are shown in (**)

Hirschmann, Double DC Solenoid

A

106.2

83.0 (4.18)

(3.27) 87.8

(3.46)

36.0

(1.42)

12.0 21.5

(0.47) 23.0 (0.85)

58.9 (0.91) 80.1 76.2

(2.29) (3.16) (3.00)

122.5 177.2

(4.83) (6.98)

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

Hirschmann, Single DC Solenoid

83.0 88.2

(3.27) (3.48)

36.0 See

(1.42) Note

12.0 21.5

23.0 (0.47) (0.85)

40.5 76.2

58.0 (0.91)

(1.60) (3.00)

(2.29) 122.5 87.9

(4.83) (3.46)

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

D3.indd, dd

A66 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3DW

Inch equivalents for millimeter dimensions are shown in (**)

Hirschmann, Single DC Solenoid

with Variation I7 (Monitor Switch) A

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

Monitor Switch

(Variation I7) End of Stroke

This feature provides for electrical confirmation of

the spool shift. This can be used in safety circuits,

to assure proper sequencing, etc.

Switch Data

Inductive switch requiring +18-42 volt input. Out-

puts “A” and “B” are opposite; one at “0” voltage,

the other at input voltage. During switching, “A”

and “B” outputs reverse. Provides 0.4A switching

current.

For repetitive switch power-up conditions, please consult factory.

D3.indd, dd

A67 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3A

General Description

Series D3A directional control valves are high perfor-

A mance, 4-chamber, direct operated, air pilot controlled,

4-way valves. They are available in 2 or 3-position and B AB A

conform to NFPA’s D05/CETOP 5 mounting patterns.

P T

Features

• Low pilot pressure required – 4.1 Bar (60 PSI) minimum.

• High flow, low pressure drop design.

Specifications

Mounting Pattern NFPA D05, CETOP 5, NG 10

Maximum Operating: 345 Bar (5000 PSI)

Pressure Tank Line: 34 Bar (500 PSI)

Maximum Flow See Spool Reference Chart

Pilot Pressure Air Minimum 4.1 Bar (60 PSI)

Air Maximum 6.9 Bar (100 PSI)

Response Time* (ms)

Signal to 95% spool stroke measured at

172 Bar (2500 PSI) and 75 LPM (20 GPM)

Air Operated

Shift Volume. The air pilot chamber requires a volume of Pilot Pressure Pull-In Drop-Out

1.8 cc (.106 in.3) for complete shift from center to end. 60 PSI 23.0 ms 23.0 ms

Pilot Piston. The pilot piston area is 506 mm2 (.785 in.2). 100 PSI 19.0 ms 38.0 ms

Pilot piston stroke is 3.4 mm (.135 in.).

* Chart is for reference only. Response time will vary with pilot line

size, length, air pressure and air valve flow capacity (Cv).

D3.indd, dd

A68 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D3A

D 3 A

Directional

Control Valve

Basic Valve Actuator Spool Style Seal Variations Design

Series

NOTE:

A

Not required

NFPA D05 when ordering.

CETOP 5

NG10 Code Description

Omit Standard

Air 90 1/4 BSPP Pilot Port

Operator

Code Description

N Nitrile

Code Symbol Code Symbol V Fluorocarbon

A B A B

1 20*

P T P T

A B A B Code Description Symbols

2 30† Single operator, two position b A B

P T P T

B # spring offset.

A B A B P to A and B to T in offset position.

P T

4 81 Double operator, b A B a

P T P T C three position,

A B A B spring centered.

P T

8* 82 Double operator, b A B a

P T P T D # two position,

A B detent. P T

9†

Two position, spring centered. b A B

P T E P to B and A to T

* 8 and 20 spools have closed crossover. in shifted position. P T

† 9 and 30 are open crossover. Single operator, two position, A B a

H # spring offset. P to B and A to T

Valve schematic symbols are per NFPA/ANSI standards, providing in offset position. P T

flow P to A when energizing operator A. Note operators reverse

Two position, spring centered. A B a

sides for #8 and #9 spools. See installation information for details.

K P to A and B to T

in shifted position. P T

# B, D & H styles available with 20 and 30 spools only.

Indicates air pilot.

This condition varies

with spool code.

Mounting Bolt Kits

UNC Bolt Kits for use with D3A

Directional Control Valves & Sandwich Valves

Number of Sandwich Valves

@ 2.00” (50mm) thickness

0 1 2 3

D3A Standard: BK98 BK141 BK142 BK143

1.62” 3.50” 5.50” 7.50”

Valve Weight: 4.1 kg (9 lbs.)

Metric: BKM98 BKM141 BKM142 BKM143

40mm 90mm 140mm 190mm Seal Kit:

Nitrile SKD3A

NOTE: All bolts are SAE grade 8, 1/4-20 UNC-2A thread, torque to

Fluorocarbon SKD3AV

16 Nm (12 ft-lbs).

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D3.indd, dd

A69 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Dimensions Series D3A

Inch equivalents for millimeter dimensions are shown in (**)

Air Operated, Double Pilot

A

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

Air Operated, Single Pilot

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

D3.indd, dd

A70 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3C, D3D

General Description

Series D3C and D3D directional control valves are

high performance, 4-chamber, direct operated, cam

controlled, 3 or 4-way valves. They are available in

A

2-position and conform to NFPA’s D05, CETOP 5

mounting patterns.

Features

• Choice of 2 cam roller positions (D3C and D3D).

• Short stroke option.

• High flow, low pressure drop design.

Specifications

Mounting Pattern NFPA D05, CETOP 5, NG 10

Maximum Operating: 345 Bar (5000 PSI)

Pressure Tank Line: 34 Bar (500 PSI)

Maximum Flow See Spool Reference Chart

Force Required 235 N (53 lbs.)

to Shift

Maximum 30°

Cam Angle

Ordering Information

D 3

Directional Basic Valve Actuator Spool Style Seal Variations Design

Control Valve Series

NOTE:

Not required

when ordering.

NFPA D05

CETOP 5

NG10 Code Description Code Description

N Nitrile Omit Standard

V Fluorocarbon B5 Short Stroke

Code Description

C Cam (90° to

mounting surface)

D Cam parallel to

mounting surface Code Description Symbol

Two position, A B

B spring offset operator

Code Symbol at “A” port end. P T

A B

Two position, A B

20* H spring offset operator

P T at “B” port end. P T

A B

Valve schematic symbols are per NFPA/ANSI

30†

standards. See installation information for details.

P T

* 20 spool has closed

crossover.

Valve Weight: 3.6 kg (8 lbs.)

† 30 spool has open

crossover. Seal Kit:

Nitrile SKD3C

Fluorocarbon SKD3CV

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D3.indd, dd

A71 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3C,D3D

Mounting Bolt Kits

A

UNC Bolt Kits for use with D3C & D3D

Directional Control Valves & Sandwich Valves

Number of Sandwich Valves

@ 2.00” (50mm) thickness

0 1 2 3

D3C, D3D Standard: BK98 BK141 BK142 BK143

1.62” 3.50” 5.50” 7.50”

Metric: BKM98 BKM141 BKM142 BKM143

40mm 90mm 140mm 190mm

NOTE: All bolts are SAE grade 8, 1/4-20 UNC-2A thread, torque to

16 Nm (12 ft-lbs)

Dimensions

Inch equivalents for millimeter dimensions are shown in (**)

Cam Operated

Full

Valve Type Pre-Travel Spool Over-Travel

Travel

Standard 1.75 5.75 2.03

Valve (0.07) (0.23) (0.08)

B5 0 4.00 2.03

Short Stroke (0) (0.16) (0.08)

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

D3.indd, dd

A72 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Technical Information Series D3L

General Description

A

Series D3L directional control valves are high perfor-

mance, 4-chamber, direct operated, lever controlled, A B

4-way valves. They are available in 2 or 3-position and

conform to NFPA’s D05, CETOP 5 mounting patterns.

P T

Features

• Spring return or detent styles available.

• High flow, low pressure drop design.

• Heavy duty handle design.

Specifications

Mounting Pattern NFPA D05, CETOP 5, NG 10

Maximum Operating: 345 Bar (5000 PSI)

Pressure Tank Line: 34 Bar (500 PSI)

Maximum Flow See Spool Reference Chart

Force Required

to Shift Lever 173 N (39 lbs.)

Operator

Dimensions

Inch equivalents for millimeter dimensions are shown in (**)

Lever Operated D3L

Note: 30.0mm (1.18") from bottom of bolt hole counterbore to bottom of valve.

D3.indd, dd

A73 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Ordering Information Series D3L

D 3

A Directional

Control Valve

Basic Valve Operator

Type & Location

Spool Style Seal Variations Design

Series

NOTE:

Not required

NFPA D05 when ordering.

CETOP 5

NG10

Code Description

Omit Standard

I7* Monitor Switch

Operator Location (A or B End)

Code Operator Type For Valve Style * Not available on C, D or

B C D E H K N N styles. Not CE or CSA

Code Description approved.

L Lever (Standard) B B B A B B B N Nitrile

LB Lever (Alternate) A A A N/A A N/A A V Fluorocarbon

Code Symbol Code Symbol Code Description Symbol

A B A B

Two position, spring offset. A B

1 20* B* P to A and B to T in offset

P T P T position. P T

A B A B

A B

2 30† C Three position,

P T P T spring centered. P T

A B A B

A B

4 81 D* Two position, detent.

P T P T

P T

A B A B

Two position, spring centered. A B

8* 82 E P to B and A to T

P T P T in shifted position. P T

A B

Two position, spring offset. A B

9† H* P to B and A to T

P T in offset position. P T

* 8 and 20 spools have closed crossover. Two position, spring centered. A B

† 9 and 30 are open crossover. K P to A and B to T

in shifted position. P T

Valve schematic symbols are per NFPA/ANSI A B

standards, providing flow P to A when energizing N Three position, detent.

operator A. Note operators reverse sides for #8 and #9

P T

spools. See installation information for details.

* 20 and 30 spools only.

This condition varies

with spool code.

Mounting Bolt Kits

UNC Bolt Kits for use with D3L

Directional Control Valves & Sandwich Valves

Valve Weight: 3.6 kg (8 lbs.)

Number of Sandwich Valves

Seal Kit:

@ 2.00” (50mm) thickness

Nitrile SKD3L

0 1 2 3 Fluorocarbon SKD3LV

D3L Standard: BK98 BK141 BK142 BK143

1.62” 3.50” 5.50” 7.50”

Metric: BKM98 BKM141 BKM142 BKM143

40mm 90mm 140mm 190mm

NOTE: All bolts are SAE grade 8, 1/4-20 UNC-2A thread, torque to

16 Nm (12 ft-lbs).

Bold: Designates Tier I products and options.

Non-Bold: Designates Tier II products and options. These products will have longer lead times.

D3.indd, dd

A74 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Installation Information Series D3

Fluid Recommendations Flow Path Data

Premium quality hydraulic oil with a viscosity range

between 32-54 cSt (150-250 SSU) at 38°C (100°F) is

recommended. The absolute operation viscosity range

D3*

Operator B Operator A

A

is from 16-220 cSt (80-1000 SSU). Oil should have

maximum anti-wear properties and rust and oxidation

treatments.

*Note: On valves with 008 or 009 spool, A and/or B operators

Fluids and Seals reverse sides. Flow paths remain the same as viewed from top of

valve.

Valves using synthetic, fire-resistant fluids require

special seals. When phosphate ester or its blends are

Double Solenoid. With solenoid “A” energized,

used, fluorocarbon seals are required. Water-

flow path is P→A and B→T. When solenoid “B” is

glycol, water-in-oil emulsions, and petroleum oil may

energized, flow path is P→B and A→T. The center

be used with NITRILE seals.

condition on a spring-centered valve exists when both

Temperature Recommendation coils are de-energized, or during a complete shift, as

Recommended oil temperature: the spool passes through center.

-29°C to +71°C (-20°F to +160°F) Detent and Spring Offset. The center condition exists

on detent and spring offset valves only during spool

Filtration

crossover. To shift and hold a detented spool, only a

For maximum valve and system component life, the momentary energizing of the solenoid is necessary.

system should be protected at a contamination level The minimum duration of the signal is aproximately

not to exceed 125 particles greater than 10 microns 0.13 seconds for both AC and DC voltages. This

per milliliter of fluid. (SAE Class 4 or better, ISO Code position will be held provided the spool center line is in

16/13). a horizontal plane, and no shock or vibration is present

Tank Line Surges to displace the spool.

If several valves are piped with a common tank line, Single Solenoid. Spring offset valves can be ordered

flow surges in the line may cause unexpected spool in six styles: B, E, F, H, K and M. Flow path data for the

shift. Detent style valves are most susceptible to this. various styles are described in the order chart.

Separate tank lines should be used when line surges Lever Operated (on B end)

are expected in an application. Pull lever away from valve P→A; B→T

Recommended Mounting Position Push lever toward valve P→B; A→T

Valve Type Recommended Mounting Position Note: Reverse with a #8 or #9 spool.

Detent (Solenoid) Horizontal

Electrical Failure

Spring Offset Unrestricted

Should electric power fail, spring offset and spring

Spring Centered Unrestricted

centered valves will shift to the spring held position.

Detented valves will stay in the last position held

Silting before power failure. If main flow does not fail or stop

Silting can cause any sliding spool valve to stick simultaneously, machine actuators may continue to

and not spring return, if held shifted under pressure function in an undesirable manner or sequence.

for long periods of time. The valve should be cycled

periodically to prevent sticking. Loss of Pilot Pressure (D3A)

Should a loss of pilot pressure occur, spring offset

Single Pass Operation

and spring centered valves will shift to the spring held

Valve flow ratings are for double pass operation position. Detented valves will remain in the last position

(with equal flow in both paths). When using these held. If main hydraulic flow does not simultaneously

components in single pass applications, flow stop, machine actuators may continue to function in an

capabilities may be reduced. Consult your local Parker undesirable manner or sequence.

representative for details.

Torque Specifications

Torque values recommended for the bolts which mount

the valve to the manifold or subplate are as follows:

1/4-20 thread (M6x1) torque 16.0 Nm (12 ft-lbs).

D3.indd, dd

A75 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

Catalog HY14-2500/US Directional Control Valves

Installation Information Series D3

Mounting Pattern — NFPA, D05, CETOP 5, NG 10

Inch equivalents for millimeter dimensions are shown in (**)

A 91.2

(3.62)

-B-

54.0

(2.13)

50.8

(2.00)

37.3

(1.47)

27.0

(1.06) 16.7

(0.66)

21.4 6.4 3.2

(0.84) (0.25) (0.13)

O 11.2 (0.441) max.

-A-

P.A.B. & T ports

0.56

P (0.022)

L A B

32.5

(1.28)

75.0 46.0

(2.95) (1.81) A B

¼ – 20 UNC – 2B (M6 x 1) th'd

x 9.7 (0.38) min. th'd depth

T T 4 places

0.28

(0.011) S A B

D3.indd, dd

A76 Parker Hannifin Corporation

Hydraulic Valve Division

Elyria, Ohio, USA

S-ar putea să vă placă și

- Pressure Control EquipmentDocument173 paginiPressure Control EquipmentParvezTanwari TanwariÎncă nu există evaluări

- Rotary SectionDocument36 paginiRotary SectionGustavo HurtadoÎncă nu există evaluări

- Hydra Rig HR 6100 Coiled Tubing Injector Data Sheet PDFDocument2 paginiHydra Rig HR 6100 Coiled Tubing Injector Data Sheet PDFoswaldo58100% (1)

- Parker Valvula D1VW PDFDocument37 paginiParker Valvula D1VW PDFChagas OliveiraÎncă nu există evaluări

- Trade Skills Assessment GuideDocument25 paginiTrade Skills Assessment GuideRandz Lampa0% (1)

- Mobile Cylinder Div.: Dump Product & Quick Reference GuideDocument56 paginiMobile Cylinder Div.: Dump Product & Quick Reference GuideMario JayaÎncă nu există evaluări

- Ricoh 2090Document832 paginiRicoh 2090cosmin176100% (1)

- DYNATORQUE CAMERON Gear and AccesoriesDocument12 paginiDYNATORQUE CAMERON Gear and Accesoriesemperor_vamsi100% (1)

- Datasheet Universal Rectifier 50v30ampDocument2 paginiDatasheet Universal Rectifier 50v30ampRonald Rosales Lopez100% (1)

- SVPumps LowaraDocument64 paginiSVPumps LowaraIsakov IgorÎncă nu există evaluări

- Serie ULAC+ULOC+ULDC+ULHCDocument32 paginiSerie ULAC+ULOC+ULDC+ULHCHugo MenendezÎncă nu există evaluări

- Parker Valvula Direcional D3W PDFDocument20 paginiParker Valvula Direcional D3W PDFChagas OliveiraÎncă nu există evaluări

- Válvula Direcional - Série D3W - Série 91Document19 paginiVálvula Direcional - Série D3W - Série 91Fabricio LucioÎncă nu există evaluări

- Serie D1 - Cetop 3Document39 paginiSerie D1 - Cetop 3Hugo MenendezÎncă nu există evaluări

- 2502 A 002Document10 pagini2502 A 002Mohamed ElmakkyÎncă nu există evaluări

- 4174-3300 WWW - Hmchydraul I: Di Stri Bui Dor e Revendedor Autori ZadoDocument38 pagini4174-3300 WWW - Hmchydraul I: Di Stri Bui Dor e Revendedor Autori ZadoEduardo BritoÎncă nu există evaluări

- Industrial 2023 4 Page FlyerDocument4 paginiIndustrial 2023 4 Page FlyerMel NormanÎncă nu există evaluări

- SH 60 TD enDocument98 paginiSH 60 TD enCésar David Pedroza DíazÎncă nu există evaluări

- Gate ValvesDocument20 paginiGate ValvesaliÎncă nu există evaluări

- Rectangular Whirlpool or Bath: Model No. Description Approx - WTDocument2 paginiRectangular Whirlpool or Bath: Model No. Description Approx - WTmichael7315Încă nu există evaluări

- Serie D41 - Cetop 7Document22 paginiSerie D41 - Cetop 7Hugo MenendezÎncă nu există evaluări

- Barton 316c 318c DP Indicator SwitchDocument16 paginiBarton 316c 318c DP Indicator SwitchGeorge T. RogersÎncă nu există evaluări

- Caterpillar 3516C Genset Specification Sheets (PDF, ENG, 1 MB) PDFDocument6 paginiCaterpillar 3516C Genset Specification Sheets (PDF, ENG, 1 MB) PDFChakrouneÎncă nu există evaluări

- Parker Quick Coupling Products 60 Series 2012Document5 paginiParker Quick Coupling Products 60 Series 2012dlanorxÎncă nu există evaluări

- Standby 1 2 0 0 e K W 1 5 0 0 K V A 50 HZ 1500 RPM 400 VoltsDocument6 paginiStandby 1 2 0 0 e K W 1 5 0 0 K V A 50 HZ 1500 RPM 400 VoltsRainier AyapÎncă nu există evaluări

- Parker - Conectores RapidosDocument6 paginiParker - Conectores RapidosJimyTeránAgudeloÎncă nu există evaluări

- AccessoriesDocument4 paginiAccessoriesNetaxion CelularÎncă nu există evaluări

- Doxa B10i - EngDocument12 paginiDoxa B10i - EngAymen BabourÎncă nu există evaluări

- Serie - BA Honeywell Sensing Micro Switch BZ Basic Product Sheet 004955 6 ENDocument20 paginiSerie - BA Honeywell Sensing Micro Switch BZ Basic Product Sheet 004955 6 ENpandahiuÎncă nu există evaluări

- Specification Sheets PDFDocument6 paginiSpecification Sheets PDFVu TongÎncă nu există evaluări

- Wilo 252754Document13 paginiWilo 252754Elshad AslanliÎncă nu există evaluări

- Honeywell Sensing Micro Switch Gla Product Sheet 002408 1 enDocument24 paginiHoneywell Sensing Micro Switch Gla Product Sheet 002408 1 enion popescuÎncă nu există evaluări

- Evaporadores - Arctigo IsDocument2 paginiEvaporadores - Arctigo IsedamiandcrÎncă nu există evaluări

- Scotch Yoke Design: Eha / Ehas High Pressure Electro-Hydraulic ActuatorsDocument24 paginiScotch Yoke Design: Eha / Ehas High Pressure Electro-Hydraulic ActuatorsfabioÎncă nu există evaluări

- Acttech Act Pavpo T Act Eatubv TDocument1 paginăActtech Act Pavpo T Act Eatubv TSony CÎncă nu există evaluări

- Fused and Non-Fused Disconnect Switches: Technical DataDocument62 paginiFused and Non-Fused Disconnect Switches: Technical DataGUSTAVO MENDOZAÎncă nu există evaluări

- 1000 KW Diesel Gen SetDocument6 pagini1000 KW Diesel Gen SetMidhun MathewÎncă nu există evaluări

- Serie D101 - Cetop 10Document23 paginiSerie D101 - Cetop 10Hugo MenendezÎncă nu există evaluări

- BilgeLSw DSDocument4 paginiBilgeLSw DSargaÎncă nu există evaluări

- SPECTRACOOL™ Narrow Indoor/Outdoor: Air ConditionersDocument18 paginiSPECTRACOOL™ Narrow Indoor/Outdoor: Air ConditionersSayuti SidikÎncă nu există evaluări

- RM7AG102Document2 paginiRM7AG102Lucas FigueiredoÎncă nu există evaluări

- Axial Fans Hua and Vla FansDocument30 paginiAxial Fans Hua and Vla FansSangeeth PillaiÎncă nu există evaluări

- F117 Pressure Fuelling Nozzle for Heavy Duty ServiceDocument2 paginiF117 Pressure Fuelling Nozzle for Heavy Duty ServiceAmoy AliciaÎncă nu există evaluări

- BLS-7 Level SwitchDocument4 paginiBLS-7 Level SwitchargaÎncă nu există evaluări

- Modutrol M62Document28 paginiModutrol M62Sergio MandelliÎncă nu există evaluări

- ActuatorDocument8 paginiActuatorMuhammed Ali PisuwalaÎncă nu există evaluări

- Low Flow CCDocument44 paginiLow Flow CCAhsan HaseebÎncă nu există evaluări

- BFV Tech DocDocument120 paginiBFV Tech DocLuis MozoÎncă nu există evaluări

- BFV TechDocument120 paginiBFV Techeder_peruchÎncă nu există evaluări

- Viraaj TechnoCrats Guide Marine Valves, Actuators & Control SystemsDocument10 paginiViraaj TechnoCrats Guide Marine Valves, Actuators & Control SystemsRahulÎncă nu există evaluări

- LUMINARIADocument4 paginiLUMINARIAEduardo García OrtegaÎncă nu există evaluări

- PmledDocument4 paginiPmledEDOG1486Încă nu există evaluări

- Electro-Hydraulic Linear and Rotary Actuator SpecsDocument6 paginiElectro-Hydraulic Linear and Rotary Actuator SpecsGoutham KSÎncă nu există evaluări

- Serie D61 - Cetop 8Document23 paginiSerie D61 - Cetop 8Hugo MenendezÎncă nu există evaluări

- 1279 Data SheetDocument2 pagini1279 Data SheetJuan SÎncă nu există evaluări

- Prospekt SV OrigDocument64 paginiProspekt SV OrigJose Gregorio MarchanÎncă nu există evaluări

- WMS TechnologiesDocument4 paginiWMS Technologiesketan parmarÎncă nu există evaluări

- CEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZDocument48 paginiCEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZValbertÎncă nu există evaluări

- Lowara PumpDocument68 paginiLowara Pumpa safaieÎncă nu există evaluări

- Packaged Climate Changer™: Air Handler Product CatalogDocument120 paginiPackaged Climate Changer™: Air Handler Product CatalogDaniel Joshua FestinÎncă nu există evaluări

- Submirssible PumpDocument13 paginiSubmirssible PumpNP METALPROTECTIONÎncă nu există evaluări

- Bomba de Paletas 04-04 - T7-T67-T6C-uk-728-33Document1 paginăBomba de Paletas 04-04 - T7-T67-T6C-uk-728-33Hugo MenendezÎncă nu există evaluări

- Serie D101 - Cetop 10Document23 paginiSerie D101 - Cetop 10Hugo MenendezÎncă nu există evaluări

- Astm A161Document2 paginiAstm A161TeoTyJayÎncă nu există evaluări

- README JumboDocument1 paginăREADME JumboHugo MenendezÎncă nu există evaluări

- Serie D31 - Cetop 5Document35 paginiSerie D31 - Cetop 5Hugo MenendezÎncă nu există evaluări

- Serie D61 - Cetop 8Document23 paginiSerie D61 - Cetop 8Hugo MenendezÎncă nu există evaluări

- Belt 1 PDFDocument31 paginiBelt 1 PDFHugo MenendezÎncă nu există evaluări

- Transom Return R2SP PDFDocument1 paginăTransom Return R2SP PDFHugo MenendezÎncă nu există evaluări

- Serie D81 - Cetop 8Document27 paginiSerie D81 - Cetop 8Hugo MenendezÎncă nu există evaluări

- Serie D41 - Cetop 7Document22 paginiSerie D41 - Cetop 7Hugo MenendezÎncă nu există evaluări

- Serie 3L CILINDROS PDFDocument92 paginiSerie 3L CILINDROS PDFHugo MenendezÎncă nu există evaluări

- Serie D111VW - Cetop 10Document12 paginiSerie D111VW - Cetop 10Hugo MenendezÎncă nu există evaluări

- Serie Mma CilindrosDocument20 paginiSerie Mma CilindrosHugo MenendezÎncă nu există evaluări

- Cilindros HidráulicosDocument30 paginiCilindros HidráulicosHugo MenendezÎncă nu există evaluări

- Cilindros CatálogoDocument24 paginiCilindros CatálogoHugo MenendezÎncă nu există evaluări

- OB121Document1 paginăOB121Hugo MenendezÎncă nu există evaluări

- PGP030 031 SeriesDocument28 paginiPGP030 031 SeriesWesame ShnodaÎncă nu există evaluări

- RTJ Dimension ASME B16.5/B16.47Document1 paginăRTJ Dimension ASME B16.5/B16.47parayilomer0% (1)

- Joy Global SolutionsDocument18 paginiJoy Global Solutionsjvr001100% (1)

- Structural Analysis of Beams Using Moment Distribution MethodDocument15 paginiStructural Analysis of Beams Using Moment Distribution MethodneetuÎncă nu există evaluări

- TSB 1106 - MFY Starter Solenoid - ChangeDocument1 paginăTSB 1106 - MFY Starter Solenoid - ChangeChrisMÎncă nu există evaluări

- A Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?Document6 paginiA Rope of Mass 0.65 KG Is Stretched Between Two Supports 30 M Apart. If The Tension in The Rope Is 120 N, How Long Will It Take A Pulse To Travel From One Support To The Other?peyying12Încă nu există evaluări

- Wrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaDocument5 paginiWrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaEdison EspinalÎncă nu există evaluări

- Theory of Metal Cutting-Module 1Document116 paginiTheory of Metal Cutting-Module 1rejeesh_rajendranÎncă nu există evaluări

- Freezing pipes-FPSDocument2 paginiFreezing pipes-FPSBinu SulochananÎncă nu există evaluări

- Instructions For Installation, Operating and Maintenance InstructionDocument30 paginiInstructions For Installation, Operating and Maintenance InstructionmilacronÎncă nu există evaluări

- American English File Starter Ichecker - File 3Document3 paginiAmerican English File Starter Ichecker - File 3Daniel AugustoÎncă nu există evaluări

- Contactor Cap Lc1dDocument4 paginiContactor Cap Lc1dAlfiansyah Dharma Setia DjaketraÎncă nu există evaluări

- Abbreviations Plumbing Symbols: Fort Worth DistrictDocument21 paginiAbbreviations Plumbing Symbols: Fort Worth DistrictDenzel NgÎncă nu există evaluări

- Emergency CallDocument6 paginiEmergency CallNugrohoÎncă nu există evaluări

- Development and Evaluation - KocabaDocument263 paginiDevelopment and Evaluation - KocabaWRLSÎncă nu există evaluări

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDocument28 paginiBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasÎncă nu există evaluări

- SN 761672 ADocument19 paginiSN 761672 ANhất TríÎncă nu există evaluări

- Implementing A Maintenance Strategic Plan Using TPM MethodologyDocument13 paginiImplementing A Maintenance Strategic Plan Using TPM MethodologyJeyson Lendro ParedesÎncă nu există evaluări

- Aerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityDocument4 paginiAerial Robotics Lecture 1B - 5 Agility and ManoeuvrabilityIain McCulloch100% (1)

- Peanut Brittle LabDocument2 paginiPeanut Brittle LabMary Bacon HillebrandÎncă nu există evaluări

- Stop Motion Pre Production - Negotiated BriefDocument10 paginiStop Motion Pre Production - Negotiated Briefp4nd3m0n1c100% (1)

- Mechanical Power Transmission ReviewDocument17 paginiMechanical Power Transmission ReviewRoshan TiwariÎncă nu există evaluări

- PalindromeDocument7 paginiPalindromeZy AdrianneÎncă nu există evaluări

- Mycom Nims ProptimaDocument4 paginiMycom Nims ProptimasamnemriÎncă nu există evaluări

- Catalogo DeltaDocument2 paginiCatalogo DeltaHelena ChagasÎncă nu există evaluări

- R5310105-Structural Analysis - IIDocument4 paginiR5310105-Structural Analysis - IIsivabharathamurthyÎncă nu există evaluări

- Manual Huawei Hg655bDocument36 paginiManual Huawei Hg655bAnonymous nJm0Ff8z0sÎncă nu există evaluări

- Calibration of A Pressure GaugeDocument6 paginiCalibration of A Pressure GaugeThapelo100% (2)

- ATS1801 - Interface PC - ImpDocument8 paginiATS1801 - Interface PC - ImpluismantonioÎncă nu există evaluări