Documente Academic

Documente Profesional

Documente Cultură

Chapt14 - On Site Sanitation

Încărcat de

RyeanKRumanoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapt14 - On Site Sanitation

Încărcat de

RyeanKRumanoDrepturi de autor:

Formate disponibile

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng.

, NUST 19/10/2006 14-1

Chapter 14

ON SITE SANITATION

On site sanitation

This is the treatment and disposal of wastewater at the point of production without

conveyance of the wastewater through a sewer reticulation system. However,

some on site systems have facilities to remove the wastewater (off-site disposal)

like the bucket latrines, vaults and sea disposal). The technology is suitable to

small communities and especially in the rural areas where the population density is

low and hence construction of a water-borne sewerage becomes uneconomic.

However the technology should create opportunities for the spread of diseases and

should be culturally acceptable to the community. Other advantages include:

• Minimum construction and operation costs

• Simple to design and construct. The users can design and construct such

facilities on their own

• Affordable and sustainable to many low-income communities

• No need for reliable water supply

• No pumping costs

• No or limited effluents are discharged to water bodies thereby reducing

pollution

Disadvantages

• Not suitable where population densities are high

• There is possibility of groundwater pollution

• The technology may not be acceptable to some communities

• Possible problems of odours with some technologies

• Some technologies require water-borne sewage like septic tanks

Examples of on site technologies are:

• Septic tanks

• aqua privy

• Pit latrines

• Eco-san

• Vacuum systems

• Container systems (bucket and Vaults)

• Sea disposal

• open defection or ground surface disposal

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-2

Open defecation

Excreta are deposited on the ground and is not recommended because of the high

health risks. A small improvement is achieve by digging a very shallow pit before

defecation and then covering the excreta with soil, but although the fly and smell

nuisance may be reduced, there is still risk of transmission of hookworm.

Septic tanks

Rectangular chambers, below ground level which receive waterborne wastewater

(toilet waste and household sullage). The septic tank is separated from the

household and receives water-borne sewage. The wastewater is retained for 1-3

days and during this retention period solids settle to the bottom of the tank and are

digested anaerobically (consolidation and stabilization of sludge). A thick scum is

formed at the surface and this help to maintain anaerobic conditions i.e. growth of

microorganisms in the tank. The treatment in a septic tank is partial and therefore

the effluent stills a health hazard and still needs further treatment before disposal.

The disposal is sometimes discharged to soakaways but no longer recommended

practice. Desludging is necessary approximately in 1-5 years. In general septic

tanks are suitable for individual households.

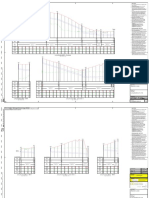

The schematic illustration of the layout of a septic tank system is shown in Fig. 1.0

and the cross-section of the septic tank is illustrated in Fig. 2.

Application

• Septic tanks are slightly expensive compared to pit-latrines

• Suitable to medium or low-density housing areas with large plot sizes

because more space is needed for disposal of effluent.

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-3

Fig.1: Schematic illustration of the layout of a septic tank system

Processes that take place within a septic tank

• Separation of solids dense material settles as the sludge

• Light material float as scum

• In between is liquid liquor which contains material in solution and fine particle

in suspension. The suspended solids may coagulate and settle out as

sludge

• Scum and sludge are partially digested anaerobically by bacteria producing

water, methane and carbon dioxide

• Stabilization of the organic material in the liquor is partially by the anaerobic

bacteria

• Consideration of the sludge occurs due to its weight i.e. there is gravity

thickening and this reduce the water content

3

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-4

Fig. 2: Cross-section of a septic tank

Design aspects (Fig.)

• Two compartments generally preferred to prevent turbulence resulting in less

SS in the effluent. The efficiency of the treatment process is reduced if the

tank contents are disturbed, but some mixing is inevitable because of gas

production and flow of liquid through the tank. The first compartment is twice

the second in length and the liquid depth is about 1-2m and depth of 1.5m is

most preferable. There should be an air space of about 0.5m between the

liquor and the tank roof. Tanks with more than one compartment should

have openings through the dividing walls at liquor level (No. 6 in Fig. ).

• The length to breadth ratio ranges from 2-3 to 1 (2:1 to 3:1)

• Storage of accumulated sludge and scum takes place in 2/3 of the tank

volume

• A gentle flow at inlet is required and the wastewater inlet to be below liquid

level (No.2 in Fig. ). A barrier at the outlet is provided to avoid discharging

sludge or scum (No. 3 in Fig. ), alternatively a Tee pipe or scum board can

be used. A slight slope of the tank makes desludging easier (No. 5 in Fig. )/

• A vent pipe is provided for releasing gases and odours (No.1 in Fig. ).

• Provide access for maintenance and desludging through manholes (No. 4 in

Fig. ).

• It is recommended not to disinfect the tank because this may kill the

microorganisms responsible for the stabilisation of the waste and never

4

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-5

completely empty the tank. This will disrupt the microorganisms system and

maturation time of the microorganisms will be required.

• The septic tank should be located away from wells, streams, embankments,

water table to avoid water pollution.

Fig. Illustration of the design considerations

Some of the guidelines for location of septic tanks are summarised in Table 1.

Table 1: Guidelines on the location of septic tanks

Distance septic tank(m) drain field (m)

Buildings 1.5 3

Property boundaries 1.5 1.5

Wells 30 30

Streams 7.5-60 30-60

Embankments 7.5-60 30-60

Pools 3 7.5

Water pipes 3 3

Paths 1.5 1.5

Large trees 3 3

Water shed area 60 60

Tank volume (1st approach)

Tank volume = V = Q × n × t

Where; Q =wastewater flow, m3/ca.day

5

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-6

n =population

t =retention time, t ≅ 3 days

Tank volume (2nd approach)

V = pq

Where: P =population for each tank

q =average daily volume of wastewater per person, m3/ca.day

Septic tank with full plumbing q=50-120l/ca.day

Septic tank without plumbing q=15-40l/day

Sludge and scum capacity

w = Pnfs

Where: n =number of years between desludging

f =factor relating to rate at which the sludge is digested (Table 2)

s =rate at which sludge accumulate, m3/ca.year

The total volume of the tank is equal to the scum, sludge and liquid volumes:

Total tan k volume = V + w

Or Total tan k volume = 1.5w ; which ever is the greater.

Table 2: Values for f

Interval between >20oC throughout >10oC throughout <10oC during the

desludging the year the year winter months

(years)

1 1.3 1.5 2.5

2 1 1.15 1.5

3 1 1 1.27

4 1 1 1.15

5 1 1 1.06

6 1 1 1

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-7

Table 3: s values

Material used Flush toilet wastes only Domestic sullage and wastes

Water, soft paper 25 40

Leaves, hard paper 40 55

Sand, stone, earth 55 70

Desludging frequency

The tank is empted when it is approximately 1/3 full of sludge:

1

V

t= 3

sludge accumulation × n

The sludge accumulation is in m3/ca.day

Also t can be estimated from:

waste flow waste(m 3 / ca ⋅ day )

t=

(

sludge accumulation m 3 / ca. yr )

Rate of sludge accumulation is temperature related and for Southern Africa a value

of 0.04m3/ca.yr can be used.

Disposal of effluent

The effluent is still a health hazard and still needs further treatment before disposal.

Also, the effluent should not be discharged into sewers because it is anaerobic.

The hydrogen sulphide will be converted to sulphuric acid which will attack the

sewers. The effluent is sometimes discharged to soakaways but it is no longer a

recommended practice. Other options of disposal are:

• soakaways

• small bore sewers

• evapotranspiration beds

• upflow filters

• wastewater stabilisation ponds for large population

• flood irrigation

• Nearest conventional sewer reticulation or wastewater treatment plant (but

note that it is septic and may affect the sewer pipes), small bore sewers.

Soakaways

These are subsurface drainage trenches filled with rocks of 20 to 50mm or even

more. The soil must be course and permeable and the infiltration rate should be

above 10l/day/m2. There should be provision for future replacement of drainfield

due to clogging.

7

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-8

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-9

Fig. 3: Cross-section of a soak-away

Septic tank with upflow filter

The effluent enters at the base, and flows upwards through a layer of coarse

aggregate. The top aggregate is about 3-6mm. Anaerobic bacteria grow on the

surface of the aggregate and oxidise the effluent as it passes through the media.

The head loss in the media is low and about 0.03-0.15m with and a 70% BOD

reduction can be expected. The average filter capacity is about 0.05m3/ca.day and

is backwash by clean water. The filtered effluent is discharged into water bodies,

drain field trenches, and evaporation beds and as flood irrigation. The upflow filters

are illustrated in Figs.

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-10

Effluent

Septic 0.5m

tank Filter

(a)

(b)

Fig. 4: Septic tanks with upflow filters

Evapotranspiration bed

It consists of a top layer of sand and gravel, and a bottom layer of top soil with a fast

growing grass. The effluent is lost due to evapotranspiration from the grass. The

organic fraction is converted to grass and is periodically cut.

10

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-11

Coarse sand

and gravel

0.2-0.5m

1m Top soil with fast

growing grass

Grass

Aquaprivy

An aqua privy is similar to a septic tank but the difference is that it is located

directly below the house (Fig, ), and only water is needed to maintain the water level

in the tank this will control flies and smells. The water level is controlled by

downward projection of a pipe from the bowl to below the water level in the tank.

The amount of wastewater treated is less than in a septic tank.

Fig. : Aqua privy

11

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-12

Fig.: Aqua-privy showing the components

A = squatting plate B =drop pipe C =effluent pipe; D =vent pipe

Design aspects

The tank is designed similar to the septic tank. The average inflow is about 5-

18l/ca. day.

Vacuum systems

The excreta is transported by suction and air pressure but are expensive and are

rarely used.

Container system (bucket)

The excreta is collected in a container which is usually water tight. The contents

are emptied in bigger containers which are transported by carts or vehicles. There

are health risks because the waste is just being removed from point to another,

unless it is transported to a wastewater treatment plant. Also the system is not

popular.

Fig.: Bucket system

Container system (Vault )

A larger water tight container (cesspit) is used and is emptied after a period of time

like a few weeks by buckets, scoops, or more hygienically by vacuum trucks for

12

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-13

disposal. Can also be served by pour flush systems or a squatting hole can be

directly located above the tank.

Sea disposal

The pit latrine discharges directly over the sea or into a river (over hung latrine).

The system can be considered as off-site. This type of disposal has health hazards

since if the water is to be used by the communities.

Fig. Over-hung latrine for sea disposal

PIT LATRINES

A pit is dug and excreta is disposed in the pit. Common types are:

• simple

• pits with sealed lids

• ventilated improved (VIP)

• pour flush

Simple pits

The hole is directly above the squatting hole, which receives the wastes and

decomposition takes place in the pit. They could be single pit, alternate double pit

and multiple pits. There is super structure above the hole. It takes all anal

cleansing material and minimum water requirements. Its disadvantage are:

• odours and flies

• shortage of space for relocation if pit is full

13

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-14

• potential of groundwater pollution

• difficult to construct in rock or boulder laden subsoil

Ventilated improved (VIP)

This pit latrine is similar to the simple pit but has a darkened super structure with a

vent to control flies and odours. The darkness will result in flies being attracted to

the light from top of the vent. The tope of the vent should never be sealed,

otherwise no light will enter and no flies will be caught. It therefore needs a roof and

door which should be closed after use or a spiral wall design which does not needs

a door. If a spiral wall is used then the open end should face the prevailing wind

direction so that air escapes through the vent.

A fly screen is fitted on the top of the vent pipe to prevent flies entering the pit (Fig.

), hence minimal risk to health compared to the simple pit. The ideal mesh wire is of

stainless steel because of the corrosive nature of the gases through the vent and of

size 1.5mm x 1.5mm. Plastic meshes deteriorate due to sunlight but nylon coated

glass fibre is also acceptable. Internal diameter of the vent should be 150mm for

smooth pipe; 225 for a reed and cement mortar; or 225mm square brick. It must

project at least 300mm above the highest point of the roof. Wind blowing across the

top of the vent sucks air out of the pit.

Ideally a smooth concrete slab for ease of cleaning sloping towards the squatting

hole. The squatting should not be larger that 350mm x 180mm with a key hole

shape. Children might fall in if its is big hole and if it is too small it is easily fouled.

Seats can be designed for comfort ability. The slab should raise for about 150mm

to prevent debris entering the pit. The pit should lined for its full length unless the

foundation is stable. In all the soils the top 500mm must be lined to prevent rodents

entering the pit. The bottom part of the pit should be permeable and hence no lining

to allow the waste to infiltrate into the ground. Circular shapes of pits are more

stable than rectangular.

Fig. Ventilated improved pit latrine

14

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-15

Pour flash latrines

It is a pit latrine with a U-trap and water seal to control exit of smells and flies from

the pit. It requires use of water and soft paper for anal cleansing. At least 3 litres of

water must be poured down the pan after use to flush the solids through the trap.

The pit can be may be directly under the pan or offset from it. Double pits can be

used where emptying is feasible.

Fig. : Pour flush pit latrine

Fig. : Combined pan and water seal for direct pour-flush latrine

15

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-16

Fig. : Pan and seal for pour-flush latrine

The decision tree for selection of on-site sanitation is illustrated in Fig.

16

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-17

Fig.: Decision tree for selection of on-site sanitation

17

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-18

MEASUREMENT OF SOIL PERMEABILITY

1. Dig one trail pit about 500mm deep, and clean out the base.

2. In the base of the pit, carefully dig a hole about 300 mm in diameter and

about 300mm. deep.

3. Roughen the sides of the hole.

4. Measure and record the actual size of this hole (Diameter and Depth).

5. Place gravel in the bottom of the hole to a depth of about 50mm.

6. Pour water into the hole, without washing the sides of the hole, until the

water level is just below the base of the trail pit.

7. Over a period of four hours keep topping up the water level to replace the

water that drains away.

8. Check and record the actual diameter of the hole once again. The diameter

may have changed from that measured earlier.

9. Allow the water level to drop until it is about 150mm below the top of the

hole.

10. Lay a straight edge across the top of the hole.

11. Measure the depth from the underside of the straight edge to the water

surface at intervals of 15 minutes over a period of at least one hour and for a

total measured change of level of 30 mm. Record the depths and the times

of measurement.

12. Deepen the trail pit tot a total depth of about 1500mm.

13. Repeat steps 2 to 11 as described above.

14. When the percolation tests have been completed, and the description and

levels of the various soil levels in the trail pit have been recorded, fill in the

trial pit.

Notes.

1. Try not to leave a trail pit open overnight. If this cannot be avoided, provide

safety barriers around the trail pit.

2. Percolation through the base of the hole is ignored; only the perimeter of the

hole is assumed to allow percolation.

18

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-19

Example

Design a septic tank for a family of 12 which has a water consumption of

100l/household per day. The effluent disposal is to be subsurface irrigation in a

drain field. Return flow is 80% of water consumption and allowing 3 day detention

start0up.

Solution

Tank volume:

19

Chapter 14 On site sanitation

cmutsvangwa: Wastewater Engineering, Dept. of Civil & Water Eng., NUST 19/10/2006 14-20

References

1. Mara D., (1976), Sewage Treatment in Hot Climates, John Wiley, UK

2. Mara D., (1997), Design of Waste Stabilisation Ponds in India, Lagoon

Technology, UK

3. Metcalf and Eddy, (1991), Wastewater Engineering, Treatment, Disposal and

Reuse, McGraw Hill, US

20

Chapter 14 On site sanitation

S-ar putea să vă placă și

- Town Planning Circular 70 0f 2004Document5 paginiTown Planning Circular 70 0f 2004RyeanKRumano100% (1)

- MATH8-Relations and Functions Worksheet AnswersDocument15 paginiMATH8-Relations and Functions Worksheet AnswersRhealyn Joy Narciso100% (2)

- Astm C27Document2 paginiAstm C27nee2790Încă nu există evaluări

- Sedimentation PresentationDocument30 paginiSedimentation PresentationShepherd Nhanga100% (3)

- A Minor Project ReportDocument36 paginiA Minor Project ReportPriyanka JainÎncă nu există evaluări

- SSB05 Detailed Design of Trusses 2010-03-22Document131 paginiSSB05 Detailed Design of Trusses 2010-03-22DN GHÎncă nu există evaluări

- Rental Agreement EquipmentDocument1 paginăRental Agreement EquipmentRyeanKRumanoÎncă nu există evaluări

- P3 Past Papers Model AnswersDocument211 paginiP3 Past Papers Model AnswersEyad UsamaÎncă nu există evaluări

- Bill No. 1 - General Items PreliminariesDocument24 paginiBill No. 1 - General Items PreliminariesNorazreen NorAzharÎncă nu există evaluări

- Septic TankDocument55 paginiSeptic TankAslam Laghari100% (1)

- Design of ST With Soak PitDocument26 paginiDesign of ST With Soak PitAmisha Jha100% (1)

- Septic Tank PDFDocument50 paginiSeptic Tank PDFDrShrikant JahagirdarÎncă nu există evaluări

- 3.3.2.1 Sewage Treatment and DisposalDocument7 pagini3.3.2.1 Sewage Treatment and Disposalbrendah kobugabeÎncă nu există evaluări

- Septic Tank 2 DesignDocument38 paginiSeptic Tank 2 DesignPBDC MEPFSÎncă nu există evaluări

- Cec603 32Document15 paginiCec603 32Kingshuk MukherjeeÎncă nu există evaluări

- Ti 5 PDFDocument64 paginiTi 5 PDFkihtrakaÎncă nu există evaluări

- Technical Notes on Drinking Water HygieneDocument4 paginiTechnical Notes on Drinking Water HygienegeminexÎncă nu există evaluări

- WHO EmergencyDocument64 paginiWHO EmergencysandeepanchoudhuryÎncă nu există evaluări

- Wastewater TreatmentDocument49 paginiWastewater TreatmentAshwani Kumar Pati TripathiÎncă nu există evaluări

- LECTURE 11 - Conventional Water Treatment Facility2014Document51 paginiLECTURE 11 - Conventional Water Treatment Facility2014Kaaviyan thirunyanamÎncă nu există evaluări

- Treatment Efficiency of Rapid Sand FiltersDocument16 paginiTreatment Efficiency of Rapid Sand FiltersHari PyakurelÎncă nu există evaluări

- SEPTIC TANKDocument11 paginiSEPTIC TANKelishafailent13Încă nu există evaluări

- M24L40Document7 paginiM24L40Andenet AshagrieÎncă nu există evaluări

- SedimentationDocument6 paginiSedimentationgnino2Încă nu există evaluări

- Septic System Manual3Document23 paginiSeptic System Manual3Sundara LingamÎncă nu există evaluări

- Chapter 3 Dab 30102Document75 paginiChapter 3 Dab 30102Muhammad Fazlan AliffÎncă nu există evaluări

- EE Notes FULLDocument56 paginiEE Notes FULLAnonymous Q4MsQAÎncă nu există evaluări

- Cep ReportDocument29 paginiCep ReportAli AhmadÎncă nu există evaluări

- Septic TankDocument14 paginiSeptic TankAttarwala Abdulqadir Hashim FaridaÎncă nu există evaluări

- Sanitary System: UnplasticizedDocument17 paginiSanitary System: UnplasticizedJeiel ValenciaÎncă nu există evaluări

- Project Report: Small Sewage Treatment PlantDocument58 paginiProject Report: Small Sewage Treatment PlantAnurag Dixit100% (1)

- Design of STPDocument21 paginiDesign of STPMinTzHoÎncă nu există evaluări

- Astewater Reatment Lant DesignDocument2 paginiAstewater Reatment Lant Designas3ateÎncă nu există evaluări

- 1 PB PDFDocument8 pagini1 PB PDFNiwat PhassayawanÎncă nu există evaluări

- Chapter 7:introduction To Sewage Collection and TreatmentDocument16 paginiChapter 7:introduction To Sewage Collection and TreatmentAngel zeeÎncă nu există evaluări

- Environmental Engineering-1 Unit 3Document97 paginiEnvironmental Engineering-1 Unit 3dhanabalÎncă nu există evaluări

- Unit-5 Septic Tank & SoakpitsDocument5 paginiUnit-5 Septic Tank & SoakpitsSree JaniÎncă nu există evaluări

- TreatDocument49 paginiTreatHussen MohammedÎncă nu există evaluări

- Final Design ReportDocument29 paginiFinal Design ReportMikuÎncă nu există evaluări

- Technology Details (Description / Functions) Better Still If Photos, Visuals IncludedDocument12 paginiTechnology Details (Description / Functions) Better Still If Photos, Visuals IncludedShavin ChandÎncă nu există evaluări

- Operation and Maintenance of Urban Sewage System in Puducherry (Cpet 711 Summer Training)Document24 paginiOperation and Maintenance of Urban Sewage System in Puducherry (Cpet 711 Summer Training)md adimÎncă nu există evaluări

- Wastewater DisposalDocument35 paginiWastewater DisposalSibeshKumarSingh25% (4)

- Waste Water Treatment Process & Unit DetailsDocument60 paginiWaste Water Treatment Process & Unit DetailssalmanÎncă nu există evaluări

- 26.12.2018 Overview and Details Regarding Sewerage SchemesDocument51 pagini26.12.2018 Overview and Details Regarding Sewerage SchemesAmandeep Singh100% (1)

- Onsite Sanitation: Architecture GATE SolutionDocument6 paginiOnsite Sanitation: Architecture GATE SolutionPratik ManeÎncă nu există evaluări

- Underground Drainage Systems PDFDocument10 paginiUnderground Drainage Systems PDFNtando Moyo100% (1)

- Lecture Notes Clarification, Filtration, Adsorption (Activated Carbon, and Water Stability CEG8103Document22 paginiLecture Notes Clarification, Filtration, Adsorption (Activated Carbon, and Water Stability CEG8103yusufÎncă nu există evaluări

- Septic tank system basicsDocument64 paginiSeptic tank system basicsRaghu Nayak NayakÎncă nu există evaluări

- Sewage DisposalDocument9 paginiSewage Disposalreagan jumaÎncă nu există evaluări

- BLDGDESIGN Lesson 6 - Plumbing Design (Part 2)Document13 paginiBLDGDESIGN Lesson 6 - Plumbing Design (Part 2)Dough NutÎncă nu există evaluări

- Group 1, A. Environmental Eng.Document8 paginiGroup 1, A. Environmental Eng.Opendi CharlesÎncă nu există evaluări

- Septic TankDocument6 paginiSeptic TankYakdhan YaseenÎncă nu există evaluări

- Wastewatertreatment 130204082216 Phpapp02Document55 paginiWastewatertreatment 130204082216 Phpapp02CakEmUsÎncă nu există evaluări

- WWT6 - Colection and Conveyance of SewageDocument37 paginiWWT6 - Colection and Conveyance of SewageHelder MbidiÎncă nu există evaluări

- Septic Tank and Aqua Privy DesignDocument45 paginiSeptic Tank and Aqua Privy Designryan27165378Încă nu există evaluări

- Environmental Engineering 2Document6 paginiEnvironmental Engineering 2Sajjad HussainÎncă nu există evaluări

- Wastewater Generation & CollectionDocument35 paginiWastewater Generation & Collectionhameedhr1517Încă nu există evaluări

- Design Aspects Drinking Water Treatment.Document32 paginiDesign Aspects Drinking Water Treatment.Milton Alexander Rivera TorresÎncă nu există evaluări

- Liquid Waste Management IiDocument66 paginiLiquid Waste Management Iirodgers omondiÎncă nu există evaluări

- Unit 1 Recent Physico-Chemical Treatments of WastewaterDocument88 paginiUnit 1 Recent Physico-Chemical Treatments of WastewaterBadal NayakÎncă nu există evaluări

- Estimate Seepage Losses in Irrigation Canal SystemDocument4 paginiEstimate Seepage Losses in Irrigation Canal SystemLuis AzulaÎncă nu există evaluări

- Chapt9 Plate SettlersDocument9 paginiChapt9 Plate Settlersdave tafadzwa kuyeri100% (1)

- 255.1-2478 FiltrationDocument40 pagini255.1-2478 FiltrationDOUNIA BELLACHEÎncă nu există evaluări

- Ee2 Module 5Document24 paginiEe2 Module 5mujeebÎncă nu există evaluări

- Sewage Disposal Works: Their Design and ConstructionDe la EverandSewage Disposal Works: Their Design and ConstructionÎncă nu există evaluări

- Dictionary of Hydrology and Water Resources: 2Nd EditionDe la EverandDictionary of Hydrology and Water Resources: 2Nd EditionÎncă nu există evaluări

- Minimum Spiral Reinforcement Requirements and Lateral DisplacementDocument181 paginiMinimum Spiral Reinforcement Requirements and Lateral DisplacementSheraz BashirÎncă nu există evaluări

- Chapt2 - Wastewater Characterisation MUT PDFDocument17 paginiChapt2 - Wastewater Characterisation MUT PDFRyeanKRumanoÎncă nu există evaluări

- Robmeg Catalogue Website PDFDocument44 paginiRobmeg Catalogue Website PDFRyeanKRumanoÎncă nu există evaluări

- Human Sexuality How Do Men and Women DifferDocument4 paginiHuman Sexuality How Do Men and Women DifferRyeanKRumanoÎncă nu există evaluări

- Chapt2 - Wastewater Characterisation PDFDocument17 paginiChapt2 - Wastewater Characterisation PDFRyeanKRumanoÎncă nu există evaluări

- SumatraPDF SettingsDocument2 paginiSumatraPDF SettingsMaxHallÎncă nu există evaluări

- Column Grid B8 LoadsDocument1 paginăColumn Grid B8 LoadsRyeanKRumanoÎncă nu există evaluări

- Road Design Notes Vertical & Horizontal AlignmentDocument41 paginiRoad Design Notes Vertical & Horizontal AlignmentRyeanKRumanoÎncă nu există evaluări

- Beam Inspection Notes ChitambaraDocument1 paginăBeam Inspection Notes ChitambaraRyeanKRumanoÎncă nu există evaluări

- 16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionDocument89 pagini16-Concrete Pavements (Part 2) - Jointing in PCC ConstructionHimanshu SainiÎncă nu există evaluări

- ShearConnectorDesignofSteelBeltTruss To ConcreteMegaColumnConnectionDocument2 paginiShearConnectorDesignofSteelBeltTruss To ConcreteMegaColumnConnectionRyeanKRumanoÎncă nu există evaluări

- Chapt0 - Course Outline and Recommended LiteratureDocument3 paginiChapt0 - Course Outline and Recommended LiteratureRyeanKRumanoÎncă nu există evaluări

- Prokon - GL A8 BASEDocument3 paginiProkon - GL A8 BASERyeanKRumanoÎncă nu există evaluări

- Chapt12 - Control of Nutrients in Activated SludgeDocument8 paginiChapt12 - Control of Nutrients in Activated SludgeRyeanKRumanoÎncă nu există evaluări

- Waste Water Stabilisation PondsDocument24 paginiWaste Water Stabilisation PondsRyeanKRumanoÎncă nu există evaluări

- Quick Start Lessons Network AnalysisDocument158 paginiQuick Start Lessons Network AnalysisSalah Saleh100% (1)

- Wastewater and Excreta Disposal SystemsDocument95 paginiWastewater and Excreta Disposal SystemsRyeanKRumanoÎncă nu există evaluări

- Kod Za Zakljucavanje FolderaDocument1 paginăKod Za Zakljucavanje FolderaМилица ВукићевићÎncă nu există evaluări

- University of Zimbabwe Faculty of Engineering Department of Civil EngineeringDocument19 paginiUniversity of Zimbabwe Faculty of Engineering Department of Civil EngineeringRyeanKRumanoÎncă nu există evaluări

- Chapt3 - BOD Kinetics PDFDocument7 paginiChapt3 - BOD Kinetics PDFRyeanKRumanoÎncă nu există evaluări

- AL HURWWTPDesignCalculationsDocument16 paginiAL HURWWTPDesignCalculationsMedalson RonghangÎncă nu există evaluări

- Enhanced Power Solutions Proposed Sewer and Water Line: Nketa DriveDocument1 paginăEnhanced Power Solutions Proposed Sewer and Water Line: Nketa DriveRyeanKRumanoÎncă nu există evaluări

- Discharge of Conditions - P - 2016 - 00474 Drawing - Drainage - Long SectionsDocument2 paginiDischarge of Conditions - P - 2016 - 00474 Drawing - Drainage - Long SectionsRyeanKRumanoÎncă nu există evaluări

- Type of Structure Concrete Over, MM: Minimum Cover Thickness For Cast-in-Place ConcreteDocument3 paginiType of Structure Concrete Over, MM: Minimum Cover Thickness For Cast-in-Place ConcreteRyeanKRumanoÎncă nu există evaluări

- Nyamupi Invoice 3 SectionDocument1 paginăNyamupi Invoice 3 SectionRyeanKRumanoÎncă nu există evaluări

- Aluminium Sliding Doors Aluminium Windows: Type Width (MM)Document2 paginiAluminium Sliding Doors Aluminium Windows: Type Width (MM)RyeanKRumanoÎncă nu există evaluări

- 44 Sounds Aus EnglishDocument2 pagini44 Sounds Aus EnglishAlfie Arabejo Masong LaperaÎncă nu există evaluări

- CV1000 CV2000 CV3000 Ice Cube Machines SpecsDocument12 paginiCV1000 CV2000 CV3000 Ice Cube Machines SpecsAriel Godoy100% (1)

- Physics SyllabusDocument85 paginiPhysics Syllabusalex demskoyÎncă nu există evaluări

- Nakshatra Exaltation DebilitationDocument3 paginiNakshatra Exaltation DebilitationBhanu Pinnamaneni100% (1)

- Art-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationDocument4 paginiArt-App-Module-12 Soulmaking, Improvisation, Installation, & TranscreationJohn Mark D. RoaÎncă nu există evaluări

- 2.gantry Rotation Safety CheckDocument2 pagini2.gantry Rotation Safety CheckLê Hồ Nguyên ĐăngÎncă nu există evaluări

- Measuring and calculating dimensions for pipes, plates, cylinders and moreDocument100 paginiMeasuring and calculating dimensions for pipes, plates, cylinders and moreGarcia MaybelleÎncă nu există evaluări

- ADDC Construction QuestionairesDocument19 paginiADDC Construction QuestionairesUsman Arif100% (1)

- Datasheet Optris XI 410Document2 paginiDatasheet Optris XI 410davidaldamaÎncă nu există evaluări

- 37th APSDC Scientific PresentationsDocument7 pagini37th APSDC Scientific PresentationsSatyendra KumarÎncă nu există evaluări

- ARES SC4 Service Manual (HP-300UA)Document20 paginiARES SC4 Service Manual (HP-300UA)mike_net8903Încă nu există evaluări

- Products and Services For Consumers: True / False QuestionsDocument65 paginiProducts and Services For Consumers: True / False QuestionsThúy HiềnÎncă nu există evaluări

- Gerovital anti-aging skin care product guideDocument10 paginiGerovital anti-aging skin care product guideכרמן גאורגיהÎncă nu există evaluări

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pagini500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajÎncă nu există evaluări

- DCI-2 Brief Spec-Rev01Document1 paginăDCI-2 Brief Spec-Rev01jack allenÎncă nu există evaluări

- 2nd Quarter Summative Test in MusicDocument2 pagini2nd Quarter Summative Test in MusicIverAlambraÎncă nu există evaluări

- المحاضرة الرابعة المقرر انظمة اتصالات 2Document31 paginiالمحاضرة الرابعة المقرر انظمة اتصالات 2ibrahimÎncă nu există evaluări

- Mahle KFWA MAIN Data SheetDocument4 paginiMahle KFWA MAIN Data SheetRudnikÎncă nu există evaluări

- Is Revalida ExamDocument11 paginiIs Revalida ExamRodriguez, Jhe-ann M.Încă nu există evaluări

- Downstream Processing and Bioseparation - Recovery and Purification of Biological Products PDFDocument313 paginiDownstream Processing and Bioseparation - Recovery and Purification of Biological Products PDFgonbio67% (3)

- Arta Fridei Kahlo A Fost Intotdeauna o ReactieDocument13 paginiArta Fridei Kahlo A Fost Intotdeauna o ReactieAlta DaianÎncă nu există evaluări

- Overlord - Volume 01 - The Undead KingDocument223 paginiOverlord - Volume 01 - The Undead KingPaulo FordheinzÎncă nu există evaluări

- Daftar Harga Airway PT. Surgika 2017Document16 paginiDaftar Harga Airway PT. Surgika 2017Syaofi SofiÎncă nu există evaluări

- Chemistry 12: Provincial ExaminationDocument25 paginiChemistry 12: Provincial ExaminationCát TriệuÎncă nu există evaluări

- Lectura Isaac NewtonDocument2 paginiLectura Isaac NewtonCESAR MAURICIO RODRIGUEZÎncă nu există evaluări

- Pembangkit ListrikDocument2 paginiPembangkit ListrikDede MulyamanÎncă nu există evaluări