Documente Academic

Documente Profesional

Documente Cultură

Movement Joints

Încărcat de

Yaseen YousafDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Movement Joints

Încărcat de

Yaseen YousafDrepturi de autor:

Formate disponibile

MOVEMENT JOINTS

1. Definition

2. Types of movement joints

3. Placement of joints

1) Definition

Movement joints are used in brick masonry to allow for movement and to avoid

cracking

Movements in a building are due to change in the volume of building material volume

changes due to change in temp

Movement joints must be properly designed for load bearing & non load bearing

components.

TYPES OF MOVEMENT JOINTS

Movement joints are of following types

1. Expansion joints

2. Control joints(contraction joints)

3. Building expansion (isolation) joints

4. Construction joint (cold joints)

EXPANSION JOINTS

Expansion joints are provided to accommodate movement. And its prevent crackling due to

1. Changes in temperature

2. Moisture expansion

3. Elastic deformation due to loads

4. Creep

Expansion joints may be horizontal or vertical

2) CONTROL JOINTS

These joints are provided to create a plane of weakness. With rain forcemeat.

Due to volume changes resulting from shrinkage and creep.

A vertical opening is provided formed of inelastic martial

3) BULDING EXPANSION (ISOLATION) JOINTS

These joints are provided its separate a portion of a building from the rest of building stress developed

due to loading in that section will not effect the re sot the building

4) CONSTRUCTION JOINT (COLD JOINT)

It is mainly used in concrete construction where construction work is required to stop these joint are

provided.

PLACEMENT OF JOINTS

3-1) EXPANSIAN JOINTS

Typical detail of an expansion joint is given in fig (1)

Sealants are used on exterior side.

And foam pad, neoprene pad or lopper water stop is used from inside

Sealant must confirm ASTM C 920

may sealants are available in market but elastomeric sealants are the best :they are highly

elastic & have high resistance to weather

They are of three types

1) urethanes

2) Silicones

3) Polysulfide

Backer road is used behind the sealant it’s maintain constant depth 6mm (1⁄4˝) depth is

minimum with up to half the depth of joint.

Specify OF expansion JOINT

Specific expansion joints is decided by consider the amount of

1. expected wall movement

2. joint material compressibility

3. external factors

If

mu = movement of wall (unrestrained) inches

Ke= coefficient of moisture expiation in/in

Kf = coefficient of free expiation in/in

Kt = coefficient of thermal expiation in/in /t

ΔT = change in temp of (BW)

L = length of wall (in)

Ke = 0.0005 in/in (for day masonry)

Kf = 0.0002 in/in applicable below 14oF (-10 oC)

Lt = 0.000004 in/in/oF

Mu = (Ke+Kf+Kt+ΔΤ )L –(1)

If Se= Specify b/w joints in

Wi = width of expansion joint (in)

Ej = extensibility of expansion joint material (%)

Wi vary from 3/8˝ (10mm) to 1/2˝ (13mm)

Ej = 25% to 50%

ΔΤ vary from 50% (10 oC) to 160 oF (71 oC)

Se = Wjej

( Ke+Kf+kt+ ΔΤ) 100

NUMERICAL

For a brick wall heavy following detail design an expansion joint

1. color light red [

2. joint width wi = 3/8˝ (10mm)

3. extensibility of scaled ej = 50%

4. dry condition for wall are expected (i.e. Kf = o )

Solution

Se = (0.375 (50)

[0.0005+0.000004(100)]

Se = 208 in or 17-4 (5.3m)

So max spacing = (5 3m) or 5.5m

Generally in wall with out openings (30) is the max spacing for exp joints

Openings like doors windows reduce the spacing

PLACES FOR EXPANSION JOINTS

A) VERTICLE

CORNER

OFFSET & SET ACLS

JUNCTIONS

PARAPETS

B) HORIZONTAL

L1 + L2 < Se

( L1 + L2 ) ≤ 10ft

CONTROL JOINT OR CONTRACTION JOINTS

They are of following types

1) Complete construction joint

2) Partial construction joint

3) Dump joint

Along width along length of slab

Water storage tank joints

CONSTRUCTION JOINT

SLABS COLUMMS

PERSTRESSED CONCRETE

1) DEFN

2) BASIC PRINICIPLE

3) TYPES OF TENBARS

4) TYPE OF PRESTRESSING

5) CASTING & PRESTRESSING

I. DEFN

It is applied it’s that type of concrete members in which concrete is

subjected its compressive stresses before external leadings include

tensile stress in bars.

111. TENDONS

Tendons are 1/4˝ diameter wires

Tendons are used in prestesses member whom may be

I. High strength steel wires ( ¼˝ - ½˝ )

II. High strength alloy steel bars (1/2˝ – 1- 1/8˝)

In pretensioned member 7 wire strand is used

In pest tens members 7,19,3 or even more wise strand is used

2. BASIC PRINCIPLE

Tensile force is applied to tensile reinforcement before the application of loads

TYPES OF PRESTRESSING

I. Prestrensiong

II. Post tensioning

In per tensioning tendon is stressed & concrete is poured in the mould.

Concrete embed with the tendon and after Harding the tendon applied force an

the or member

In post tension the member is castled with ducts for tendons the at the end

tendons are stressed using jacks.

CASTING & PRESTRESSING

FISED HEED ,CASTING BED MOKALE HEAL WITH CONE ANCBORY-FIG---

Long line process of casting is commonly use for member of same section

Draped position of cables can be achieved by anchors

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Appendix A Cost Equations and Curves For The CAPCOST ProgramDocument24 paginiAppendix A Cost Equations and Curves For The CAPCOST ProgramAlelucy551280% (5)

- Wedling ModelingDocument32 paginiWedling ModelingManish KumarÎncă nu există evaluări

- Plate Heat Exchanger Gaskets WEBSITEDocument2 paginiPlate Heat Exchanger Gaskets WEBSITESHAKEEL ISMAIL LAMBAYÎncă nu există evaluări

- Schedule of Rate - JKR - MalaysiaDocument29 paginiSchedule of Rate - JKR - MalaysiaĄlmost Ąwhisper86% (7)

- Almasah Alamin Project - Post-Tensioned Method StatmentDocument16 paginiAlmasah Alamin Project - Post-Tensioned Method StatmentMohamed AdelÎncă nu există evaluări

- Part Numbers / Dimensions: Seal RingsDocument1 paginăPart Numbers / Dimensions: Seal RingsWong Chung MengÎncă nu există evaluări

- Requirements For Welding InspectionDocument43 paginiRequirements For Welding Inspectionhitm357Încă nu există evaluări

- Christopher Beaver The Autism File. Autism Friendly Environments 20101Document4 paginiChristopher Beaver The Autism File. Autism Friendly Environments 20101Sayontani Chatterjee100% (1)

- Safety Inspection ChecklistDocument3 paginiSafety Inspection ChecklistBobby IM Sibarani100% (4)

- Natural Bend Radius Cal Rev. C PDFDocument3 paginiNatural Bend Radius Cal Rev. C PDFhamid sobirin100% (2)

- CE 48-Timber Design SyllabusDocument3 paginiCE 48-Timber Design Syllabuspicefeati75% (4)

- Ene-440 Environmental Engineering: Engr. Gul-E-HinaDocument40 paginiEne-440 Environmental Engineering: Engr. Gul-E-HinaYaseen YousafÎncă nu există evaluări

- Ene-440 Environmental Engineering: Engr. Gul-E-HinaDocument32 paginiEne-440 Environmental Engineering: Engr. Gul-E-HinaYaseen YousafÎncă nu există evaluări

- Lec 12-Coagulation & FlocculationDocument29 paginiLec 12-Coagulation & FlocculationYaseen YousafÎncă nu există evaluări

- Soil Works For Road ConstructionDocument40 paginiSoil Works For Road ConstructionYaseen YousafÎncă nu există evaluări

- Lec 7-Design of Sewage SystemDocument68 paginiLec 7-Design of Sewage SystemYaseen Yousaf100% (1)

- Pavements (Introduction)Document46 paginiPavements (Introduction)Yaseen YousafÎncă nu există evaluări

- Assignment No. 1 (Pavement Engineering)Document1 paginăAssignment No. 1 (Pavement Engineering)Yaseen YousafÎncă nu există evaluări

- Design of 2/way Slabs: Design Od Structures, 8th Semester, B.Sc. Civil Engineering 2020Document7 paginiDesign of 2/way Slabs: Design Od Structures, 8th Semester, B.Sc. Civil Engineering 2020Yaseen YousafÎncă nu există evaluări

- Earthen Channel Design - HabibDocument101 paginiEarthen Channel Design - HabibYaseen YousafÎncă nu există evaluări

- Typical Slab Details 2020Document4 paginiTypical Slab Details 2020Yaseen YousafÎncă nu există evaluări

- International Frameworks of Action For Disaster Risk Reduction (DRR)Document10 paginiInternational Frameworks of Action For Disaster Risk Reduction (DRR)Yaseen YousafÎncă nu există evaluări

- Oliju CMVDocument5 paginiOliju CMVRaniaÎncă nu există evaluări

- Ph070213 (Vis733) Si ReportDocument16 paginiPh070213 (Vis733) Si Reporthenjie mirasolÎncă nu există evaluări

- Time Schedule RIIMDocument4 paginiTime Schedule RIIMBayu KurniawanÎncă nu există evaluări

- Proceedings of Spie: High-Field Electrostriction of Elastomeric Polymer Dielectrics For ActuationDocument14 paginiProceedings of Spie: High-Field Electrostriction of Elastomeric Polymer Dielectrics For ActuationrajainrushÎncă nu există evaluări

- Marplex - Injection Moulding of ThermoplasticsDocument24 paginiMarplex - Injection Moulding of ThermoplasticsStarchyLittleOleMeÎncă nu există evaluări

- Carrier - Company ProfileDocument1 paginăCarrier - Company Profiledeboline mitraÎncă nu există evaluări

- CH 05Document11 paginiCH 05chaitanyachegg100% (2)

- Code of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingDocument1 paginăCode of Practice For Installation and Maintenance of Power Cables Up To and Including 33 KV RatingtceterexÎncă nu există evaluări

- Synthetic Lubricating FluidDocument1 paginăSynthetic Lubricating Fluidghani ibnuÎncă nu există evaluări

- Pipe Dimensions Chart Rev Jan 2012Document1 paginăPipe Dimensions Chart Rev Jan 2012Thomas CalvinÎncă nu există evaluări

- Final Report Mauricio Schmidt MunizDocument20 paginiFinal Report Mauricio Schmidt MunizIgnaas JimidarÎncă nu există evaluări

- Oberflächenbehandlungsangaben: PG Norm/StandardDocument11 paginiOberflächenbehandlungsangaben: PG Norm/Standardsafat parÎncă nu există evaluări

- Klingerit 1000 PDFDocument2 paginiKlingerit 1000 PDFindrapatiwÎncă nu există evaluări

- RCC Details of First Floor SlabDocument1 paginăRCC Details of First Floor SlabS V ENTERPRISESÎncă nu există evaluări

- Hammerpoint Home Repair Estimator: ExteriorDocument12 paginiHammerpoint Home Repair Estimator: ExteriorpauuxÎncă nu există evaluări

- Tack Coat Guidelines: State of California Department of Transportation Division of Construction April 2009Document38 paginiTack Coat Guidelines: State of California Department of Transportation Division of Construction April 2009Nuno AntonioÎncă nu există evaluări

- Tensile Test UTMDocument4 paginiTensile Test UTMAman BansalÎncă nu există evaluări

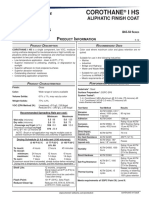

- Protective & Marine Coatings: Corothane IHSDocument4 paginiProtective & Marine Coatings: Corothane IHSImam SitumeangÎncă nu există evaluări

- Iso 9974-2 - Metric - Stud Ends With Elastomeric Sealing (Type E)Document14 paginiIso 9974-2 - Metric - Stud Ends With Elastomeric Sealing (Type E)Gowtham KbÎncă nu există evaluări