Documente Academic

Documente Profesional

Documente Cultură

CM Construction and Features: One Moving Component

Încărcat de

John Jairo SimancaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CM Construction and Features: One Moving Component

Încărcat de

John Jairo SimancaDrepturi de autor:

Formate disponibile

CM Construction and Features

The CM element provides all of the features associated with the

type CB element plus greater heat dissipation characteristics. They

are used in applications where moderate slippage is encountered

which would shorten the operating life of a CB element.

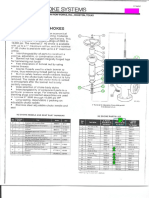

The actuating tube of the CM element is bonded to a steel rim. The

rim has male and female registers which allows the elements to be

easily assembled into dual and triple arrangements. Ventilated

friction shoes are attached to the tube by pins which in turn are

held in position by cotter pins. Rubber lugs on the inside diameter

of the actuating tube fit into recesses in the friction shoe backing

plate providing a positive interface between the shoe and tube.

Elbow Assembly

Element torque capacity is dependent upon the applied pressure and

and rotating speed. Catalog ratings are given at 75 psi (5,2 bar) and Air Connection Tube

zero speed. Tube construction for the CM elements permits a

higher operating pressure than that recommended for CB element.

Maximum recommended pressure is 150 psi (10,3 bar).

Adjustment for pressure and speed is explained under Selection

Procedure.

CM elements are available in 5 sizes which are identified by the

drum diameter in inches on which they constrict and the width in

inches of its friction lining. For instance, size 26CM475 is designed

to constrict on a 26 inch diameter drum and has a friction lining

width of 4.75 inches. The smallest CM element will constrict on a

26 inch (660 mm) diameter drum and the largest on a 48 inch

(1219 mm). Individual elements can be bolted together to form dual

or triple elements having twice or triple the torque capacity of a

single element.

Because the rubber tube is the connecting member between the

driving and driven shafts, the CM design offers the following

features in addition to the constricting features described earlier in

this section.

Rim and Tube

One moving component

Friction Lining

The tube is the only moving component. Shoe Pins

Friction shoe backing plates have air passages through their entire

There are no springs or sliding parts.

length resulting in greater thermal capacity.

Cushioned action Where Used:

The tube transmits the torque through its sidewalls, cushioning

• Marine Propulsion

damaging shock loads thereby protecting drive components. The

rubber tube construction dampens the effects of torsional vibra-

tions. Torque Ratings

Size English SI

Flexible coupling lb•in

@ 75 psi

N•m

@ 5,2 bar

26CM475 120000 13600

The tube flexibility is able to compensate for minor shaft misalign-

30CM500 171000 19300

ment and axial movement.

35CM500 240000 27100

40CM550 336000 38000

Ventilated construction 48CM650 558000 63100

Copyright Eaton Corporation, 1997, All rights reserved. B - 88

CM Elements

Technical Data – Sizes 26 thru 48

lb⋅in

English @ 75 psi rpm psi/rpm2 lb⋅ft2 lb in2 inches in3 in

26CM475 146211 120000 1030 40 E-06 280 160 302 0.30 0.21 120 25.81

30CM500 146212 171000 915 48 E-06 430 190 379 0.33 0.18 210 29.81

35CM500 146207 240000 790 58 E-06 760 250 433 0.33 0.18 250 34.81

40CM550 146208 336000 700 68 E-06 1150 310 540 0.33 0.18 320 39.81

48CM650 146209 558000 605 79 E-06 2020 400 752 0.33 0.18 430 47.75

Ê CS New Worn Î

Part Mr Maximum Centrifugal Wk 2 Weight Friction Air Minimum

Size Number Torque Speed Loss Area Friction Lining Thickness Cavity Drum

Rating Constant J Mass Volume Diameter

New Worn

26CM475 146211 13600 1030 2,8 E-06 11,76 72 2099 8 5 1,97 656

30CM500 146212 19300 915 3,3 E-06 18,06 86 2634 8 5 3,44 757

35CM500 146207 27100 790 4,0 E-06 31,92 113 3009 8 5 4,10 884

40CM550 146208 38000 700 4,7 E-06 48,30 140 3753 8 5 5,25 1011

48CM650 146209 63100 605 5,5 E-06 84,84 181 5226 8 5 7,05 1213

N⋅m

SI @ 5,2 bar rpm bar/rpm2 kg⋅m2 kg cm2 millimeters dm3 mm

Notes:

Ê Dynamic torque shown, static torque approxi- Ì Tolerance +0.005/-0.000 in

mately 25% greater. Torque in each application is (+0,13/-0,00 mm).

dependent upon air pressure and speed.

Í American National Pipe Thread

Ë Tolerance +0.000/-0.006 in

(+0,00/-0,15 mm).

Î Drum contact with worn shoes.

B - 89 Copyright Eaton Corporation, 1997, All rights reserved.

CM Elements

Dimensional Data – Sizes 26 thru 48

D2 Q

.38 (10mm) .19 (5mm) O3

O4 D24 L

H7

W V H2

H6

M1

G M3

lb⋅in

English @ 75 psi

Dimensions in inches

26CM475 146211 120000 6.94 3.38 34.750 33.438 26.19 32.88 12 0.69 31.500 31.125 0.38 3/8-18 15.000 1.00 4.75

30CM500 146212 171000 7.19 3.50 39.375 38.000 30.19 37.50 12 0.81 35.750 35.380 0.50 1/2-14 15.000 1.00 5.00

35CM500 146207 240000 7.69 3.75 45.875 44.375 35.19 43.75 12 0.81 42.000 41.380 0.63 3/4-14 15.000 1.25 5.00

40CM550 146208 336000 8.44 4.13 51.375 49.875 40.19 49.25 12 0.81 47.375 46.755 0.63 3/4-14 15.000 1.38 5.50

48CM650 146209 558000 9.06 4.44 59.500 58.000 48.19 57.25 16 0.81 55.375 54.760 0.63 3/4-14 11.250 1.19 6.50

M

Ê Ë No. Dia. Ë Ì Í

Part r Q

Size Number Torque D2 D24 G H2 H6 H7 L M1 M3 O3 O4

(Deg) V W

Rating

No. Dia.

26CM475 146211 13600 176 86 882,7 849,3 665 835 12 18 800,1 790,6 10 3/8-18 15,000 25 121

30CM500 146212 19300 183 89 1000,1 965,2 767 953 12 21 908,1 898,7 13 1/2-14 15,000 25 127

35CM500 146207 27100 195 95 1165,2 1127,1 894 1111 12 21 1066,8 1051,1 16 3/4-14 15,000 32 127

40CM550 146208 38000 214 105 1304,9 1266,8 1021 1251 12 21 1203,3 1187,6 16 3/4-14 15,000 35 140

48CM650 146209 63100 230 113 1511,3 1473,2 1224 1454 16 21 1406,5 1390,9 16 3/4-14 11,250 30 165

N⋅m

SI @ 5,2 bar

Dimensions in millimeters

Copyright Eaton Corporation, 1997, All rights reserved. B - 90

CM Mounting Components

Drums – Dimensional and Technical Data

D6

L

D31

H10 H9

D46

H1

Notes:

Ê Tolerance +0.000/-0.010 in

(+0,00/-0,25 mm).

Ë Tolerance +0.003/-0.000 in

(+0.08/-0.00 mm).

English Dimensions in inches

26CM475 0.75 26 10 0.81 5.25 3.25 16.130 14.750 5.25 4.19 21.630 20.250

30CM500 0.75 30 10 0.88 5.50 3.75 20.130 18.750 5.50 3.88 25.630 24.250

35CM500 1.00 35 10 1.00 6.50 4.25 23.505 21.875 6.69 4.25 30.005 28.375

40CM550 1.25 40 10 1.06 6.50 4.00 26.255 24.375 6.50 3.50 33.755 31.875

48CM650 1.25 48 12 1.06 7.00 3.06 37.760 35.875 7.00 4.50 42.010 40.000

Ê No. Dia. D6 D46 H9 Ê H10Ë D6 D46 H9 Ê H10 Ë

Size D31 H1 L Forward Drive Drum Reverse Drive Drum

No. Dia. D6 D46 H9 Ê H10Ë D6 D46 H9 Ê H10 Ë

26CM475 19 660 10 21 133 83 409,7 374,7 133 106 549,4 514,4

30CM500 19 762 10 22 140 95 511,3 476,3 140 99 651,0 616,0

35CM500 25 889 10 25 165 108 597,0 555,6 170 108 762,1 720,7

40CM550 32 1016 10 27 165 102 666,9 619,1 165 89 857,4 809,6

48CM650 32 1219 12 27 178 78 959,1 911,2 178 114 1067,1 1016,0

SI Dimensions in millimeters

Forward Drive Drum Reverse Drive Drum

English SI English SI

Size Part Size Part

Number Weight Wk2 Mass J Number Weight Wk2 Mass J

lb lb⋅ft2 kg kg⋅m2 lb lb⋅ft2 kg kg⋅m2

26CM475 512239 190 170 86 7,14 26CM475 512240 145 150 66 6,30

30CM500 512349 210 280 95 11,76 30CM500 512350 175 250 79 10,50

35CM500 512241 310 570 140 23,94 35CM500 512242 245 490 111 20,58

40CM550 512243 460 990 208 41,58 40CM550 512244 350 830 159 34,86

48CM650 512245 590 1970 267 82,74 48CM650 512246 500 1750 227 73,50

B - 91 Copyright Eaton Corporation, 1997, All rights reserved.

S-ar putea să vă placă și

- Me 463-Machine Design 2: Instructor: Engr. Danielle D. Cabana, MengDocument27 paginiMe 463-Machine Design 2: Instructor: Engr. Danielle D. Cabana, MengChristian Breth BurgosÎncă nu există evaluări

- Embragues de Freno Eaton Airflex - Uncoiler R4 (8CB250-142096JB) PDFDocument40 paginiEmbragues de Freno Eaton Airflex - Uncoiler R4 (8CB250-142096JB) PDFCesarFTAÎncă nu există evaluări

- VAM SFC 0511 SPDocument8 paginiVAM SFC 0511 SP11tkt11Încă nu există evaluări

- Effective Control: Spring BuffersDocument3 paginiEffective Control: Spring Buffersakın ersözÎncă nu există evaluări

- Freyssibar enDocument12 paginiFreyssibar enDario MarcoraÎncă nu există evaluări

- Catalogue Linear Motion SolutionsDocument16 paginiCatalogue Linear Motion SolutionsofanÎncă nu există evaluări

- Acoplamientos TSK PDFDocument4 paginiAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesÎncă nu există evaluări

- LIS Dharampur Baroti 3Document2 paginiLIS Dharampur Baroti 3Rishav ChaudharyÎncă nu există evaluări

- New Products Mets 2019Document38 paginiNew Products Mets 2019Sh LzÎncă nu există evaluări

- Drive System Bearings: June 1, 2018Document24 paginiDrive System Bearings: June 1, 2018Anonymous YggO6T6GzÎncă nu există evaluări

- Oteva 75 SC, Oteva 75 SC PlusDocument5 paginiOteva 75 SC, Oteva 75 SC PlusGonzaloÎncă nu există evaluări

- Hydraulic Bolt Tensioners EnerpacDocument2 paginiHydraulic Bolt Tensioners EnerpacGurdeep Sungh AroraÎncă nu există evaluări

- IR 7100 Datasheet PDFDocument4 paginiIR 7100 Datasheet PDFAnonymous TXOkcdyÎncă nu există evaluări

- Wykrawarka Ramienna Atom G999-BroszuraDocument4 paginiWykrawarka Ramienna Atom G999-BroszuraSeba O.Încă nu există evaluări

- Improved Switch Expansion Joints Prevent Rail FracturesDocument44 paginiImproved Switch Expansion Joints Prevent Rail FracturesVatsal VatsaÎncă nu există evaluări

- Mckissick Overhaul Balls Mckissick Overhaul BallsDocument1 paginăMckissick Overhaul Balls Mckissick Overhaul BallsKonstantinos SynodinosÎncă nu există evaluări

- LIS Dharampur Churu Tubewell Submersible2Document2 paginiLIS Dharampur Churu Tubewell Submersible2Rishav ChaudharyÎncă nu există evaluări

- Drive ControlDocument3 paginiDrive Controljorge rodriguezÎncă nu există evaluări

- LIS Dharampur Baroti 2Document2 paginiLIS Dharampur Baroti 2Rishav ChaudharyÎncă nu există evaluări

- LIS Dharampur SeohDocument2 paginiLIS Dharampur SeohRishav ChaudharyÎncă nu există evaluări

- Kinex. Special Bearings For Water PumpsDocument40 paginiKinex. Special Bearings For Water Pumpsa04205100% (1)

- TSeries CouplingDocument6 paginiTSeries Couplingcarlos sotoÎncă nu există evaluări

- T Series CouplingsDocument4 paginiT Series CouplingsiradocajÎncă nu există evaluări

- 81 Yanfung Instalation CostingDocument1 pagină81 Yanfung Instalation CostingPradip ManeÎncă nu există evaluări

- LIS Gopalpur Raserh SubmersibleDocument2 paginiLIS Gopalpur Raserh SubmersibleRishav ChaudharyÎncă nu există evaluări

- SSR M37-45 BrochureDocument2 paginiSSR M37-45 BrochurejiangshencaoÎncă nu există evaluări

- PS1909 SpfeDocument2 paginiPS1909 SpfeCelular Oil Control 05Încă nu există evaluări

- Disclaimer: The Information On This Page Has Not Been Checked by An Independent Person. Use This Information at Your Own RiskDocument11 paginiDisclaimer: The Information On This Page Has Not Been Checked by An Independent Person. Use This Information at Your Own RiskRavi SubramanianÎncă nu există evaluări

- LIS Dharampur Baroti1Document2 paginiLIS Dharampur Baroti1Rishav ChaudharyÎncă nu există evaluări

- Achieving Precision in Belt Driven MachineryDocument38 paginiAchieving Precision in Belt Driven MachineryCham BauerÎncă nu există evaluări

- DF150 175 SetupDocument16 paginiDF150 175 SetupElvin HernándezÎncă nu există evaluări

- LIS Gopalpur Seer Khad Mataur TandaDocument2 paginiLIS Gopalpur Seer Khad Mataur TandaRishav ChaudharyÎncă nu există evaluări

- ADPL718 Catalog Page 25 - Yellow B AckDocument1 paginăADPL718 Catalog Page 25 - Yellow B AckSugeng DarmintoÎncă nu există evaluări

- D ConcreteDocument48 paginiD ConcreteHumam SaifulÎncă nu există evaluări

- Steel Girder Comparison and Sensitivity AnalysisDocument6 paginiSteel Girder Comparison and Sensitivity AnalysisvinoraamÎncă nu există evaluări

- Cable Reel With Automated Layering - Mahdi DesignsDocument1 paginăCable Reel With Automated Layering - Mahdi DesignsMatthews Andrea MachilaÎncă nu există evaluări

- LIS Gopalpur Seer Khad Bhambla SubmersibleDocument2 paginiLIS Gopalpur Seer Khad Bhambla SubmersibleRishav ChaudharyÎncă nu există evaluări

- LIS Gopalpur RaserhDocument2 paginiLIS Gopalpur RaserhRishav ChaudharyÎncă nu există evaluări

- TSKDocument4 paginiTSKar174_569868987Încă nu există evaluări

- Elecon Cable Relling Drum Catalogue PDFDocument11 paginiElecon Cable Relling Drum Catalogue PDFKasyap RajÎncă nu există evaluări

- BLO Data Sheet 2015 1Document2 paginiBLO Data Sheet 2015 1mramos4191Încă nu există evaluări

- BLO Bearing Housing Upgrade for Improved ReliabilityDocument2 paginiBLO Bearing Housing Upgrade for Improved Reliabilitymramos4191Încă nu există evaluări

- AG Aluminium Filter Housing DatasheetDocument4 paginiAG Aluminium Filter Housing DatasheetMiroslavÎncă nu există evaluări

- TSCS 0033Document8 paginiTSCS 0033Ranjan ShankarÎncă nu există evaluări

- Gnosis 2.0 DesignSynopsisDocument17 paginiGnosis 2.0 DesignSynopsisHimanshu vishwakarmaÎncă nu există evaluări

- Strainer E-X43HDocument2 paginiStrainer E-X43HRobert BorsanÎncă nu există evaluări

- Vp-En SOGITECH PDFDocument8 paginiVp-En SOGITECH PDFSgk ManikandanÎncă nu există evaluări

- Global Leader in Hydraulic BreakersDocument8 paginiGlobal Leader in Hydraulic BreakersHidayatÎncă nu există evaluări

- Hydraulic Drifter: Innovative DesignDocument2 paginiHydraulic Drifter: Innovative DesignEsty50% (2)

- Metal Membrane Coupling L Series: Product Description Design FeaturesDocument8 paginiMetal Membrane Coupling L Series: Product Description Design FeaturesAl jabr Al khwarizmiÎncă nu există evaluări

- Eterna CW: Kirloskar Brothers LimitedDocument2 paginiEterna CW: Kirloskar Brothers Limitedudiptya_papai2007Încă nu există evaluări

- Tube Products of India gears up with growthDocument12 paginiTube Products of India gears up with growthMohamed HarisÎncă nu există evaluări

- Wastemaster Gcev: In-Channel Vertical Screw ScreenDocument4 paginiWastemaster Gcev: In-Channel Vertical Screw ScreenGustavo San MartinÎncă nu există evaluări

- IFS Stancor SEW50 DatasheetDocument2 paginiIFS Stancor SEW50 DatasheetMaruRojaÎncă nu există evaluări

- Differences Between 130 Differences Between 130 - 3 and 130 3 and 130 - 5 5Document39 paginiDifferences Between 130 Differences Between 130 - 3 and 130 3 and 130 - 5 5Firman andika100% (1)

- LIS Dharampur Brang 2Document2 paginiLIS Dharampur Brang 2Rishav ChaudharyÎncă nu există evaluări

- VSL SlabDocument12 paginiVSL SlabhazemÎncă nu există evaluări

- Fibra Optica-Ducto Armado LSZH GYXTWDocument1 paginăFibra Optica-Ducto Armado LSZH GYXTWJuan Espinosa RomeroÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Completion Equipment: One Company Unlimited SolutionsDocument4 paginiCompletion Equipment: One Company Unlimited SolutionsJohn Jairo SimancaÎncă nu există evaluări

- Catalogo Power ChokeDocument4 paginiCatalogo Power ChokeJohn Jairo SimancaÎncă nu există evaluări

- Manual XQ 140 en Ingles PDFDocument61 paginiManual XQ 140 en Ingles PDFJohn Jairo SimancaÎncă nu există evaluări

- MTU12V2000DS800 800kW Standby PDFDocument4 paginiMTU12V2000DS800 800kW Standby PDFJohn Jairo SimancaÎncă nu există evaluări

- T3 Annulars BOP Operators Manual 7022 PDFDocument28 paginiT3 Annulars BOP Operators Manual 7022 PDFJohn Jairo Simanca100% (2)

- Pump Performance Chart (General Pumps)Document27 paginiPump Performance Chart (General Pumps)John Jairo SimancaÎncă nu există evaluări

- Especificaciones D 2Document8 paginiEspecificaciones D 2John Jairo SimancaÎncă nu există evaluări

- Slip Type ElevatorDocument15 paginiSlip Type ElevatorJohn Jairo SimancaÎncă nu există evaluări

- Manual XQ 140 en Ingles PDFDocument61 paginiManual XQ 140 en Ingles PDFJohn Jairo SimancaÎncă nu există evaluări

- SS 7154026 18397814 001Document6 paginiSS 7154026 18397814 001Amr Abd ElrahmanÎncă nu există evaluări

- Choke H2Document1 paginăChoke H2John Jairo SimancaÎncă nu există evaluări

- Design of a 5-Ton Bridge CraneDocument104 paginiDesign of a 5-Ton Bridge CraneAndres RestrepoÎncă nu există evaluări

- Rotary Slips PDFDocument118 paginiRotary Slips PDFJohn Jairo Simanca100% (3)

- G-40 Cameron 4 7500 Psi DMDocument2 paginiG-40 Cameron 4 7500 Psi DMJohn Jairo SimancaÎncă nu există evaluări

- Gate Valve CameronDocument13 paginiGate Valve CameronJohn Jairo Simanca100% (1)

- Brochure Trailers HerculesDocument43 paginiBrochure Trailers HerculesJohn Jairo SimancaÎncă nu există evaluări

- King-Pin Walking Foot: Technical SpecificationsDocument1 paginăKing-Pin Walking Foot: Technical SpecificationsJohn Jairo SimancaÎncă nu există evaluări

- Top DrveDocument2 paginiTop DrveJohn Jairo SimancaÎncă nu există evaluări

- DuraDeck 1 Specifications W Detailed Testing ResultsDocument1 paginăDuraDeck 1 Specifications W Detailed Testing ResultsJohn Jairo SimancaÎncă nu există evaluări

- Process Solutions International: MAX2000 AgitatorsDocument4 paginiProcess Solutions International: MAX2000 AgitatorsJohn Jairo Simanca100% (1)

- Process Solutions International: MAX2000 AgitatorsDocument4 paginiProcess Solutions International: MAX2000 AgitatorsJohn Jairo Simanca100% (1)

- Alberta's Engineering Occupations List for ImmigrantsDocument1 paginăAlberta's Engineering Occupations List for ImmigrantsJohn Jairo SimancaÎncă nu există evaluări

- Alberta's Engineering Occupations List for ImmigrantsDocument1 paginăAlberta's Engineering Occupations List for ImmigrantsJohn Jairo SimancaÎncă nu există evaluări

- Four Quadrant Operation: PresentationDocument11 paginiFour Quadrant Operation: PresentationAnkit RohatgiÎncă nu există evaluări

- SAWE Recommended Practice Provides Weight Classification GuidanceDocument117 paginiSAWE Recommended Practice Provides Weight Classification Guidancejohn kasich100% (1)

- 2.5.2.4 Inspection Task Fluidizing Blower and Rotary Vane FeederDocument2 pagini2.5.2.4 Inspection Task Fluidizing Blower and Rotary Vane Feedervikash kumar100% (1)

- Spare Parts List: For Prop. Directional Spool Valves Type PSL, PSV and PSM Size 3Document42 paginiSpare Parts List: For Prop. Directional Spool Valves Type PSL, PSV and PSM Size 3words2zhigang_612545100% (2)

- Spesifikasi: PT Madhani Talatah Nusantar A Training & Res Earch DeptDocument4 paginiSpesifikasi: PT Madhani Talatah Nusantar A Training & Res Earch DeptAgus DaniÎncă nu există evaluări

- CompressorDocument8 paginiCompressorMad MaxÎncă nu există evaluări

- 5E Serija - Brosura PDFDocument8 pagini5E Serija - Brosura PDFbrujula24Încă nu există evaluări

- Albert SGT Screw JackDocument0 paginiAlbert SGT Screw JackDado Maja ArseninÎncă nu există evaluări

- MANUAL PACIFIC E27 - EG27 Rev 01-17 ENGDocument94 paginiMANUAL PACIFIC E27 - EG27 Rev 01-17 ENGArturÎncă nu există evaluări

- P 7177 BGM en A4Document496 paginiP 7177 BGM en A4Anonymous lbHcyX2WlÎncă nu există evaluări

- Aircraft Landing Gear SystemsDocument120 paginiAircraft Landing Gear SystemsJoshua Christopher RamirezÎncă nu există evaluări

- Timing Chain Oil SealDocument2 paginiTiming Chain Oil SealEduardo Segundo Gonzalez MuñozÎncă nu există evaluări

- Mercedes-Benz MBE 900Document6 paginiMercedes-Benz MBE 900Sergey100% (1)

- Refrigerant Receiver-Dryer - Remove and InstallDocument2 paginiRefrigerant Receiver-Dryer - Remove and InstallAnonymous cS9UMvhBqÎncă nu există evaluări

- Actuators & Sensors For Robot: DNT352 Industrial Robotics & AutomationDocument77 paginiActuators & Sensors For Robot: DNT352 Industrial Robotics & AutomationAzim UcinÎncă nu există evaluări

- Control and Protection of Hydro Electric Power PlantDocument181 paginiControl and Protection of Hydro Electric Power PlantMd Abdul Raheman33% (3)

- Demag DF 115p Wheel PaverDocument174 paginiDemag DF 115p Wheel PaverHữu Dũng Nguyễn100% (5)

- Owner's Manual: Outboard MotorDocument85 paginiOwner's Manual: Outboard MotorJasmin PartingtonÎncă nu există evaluări

- SM Tm3989 Knott A4Document1 paginăSM Tm3989 Knott A4Marc GlebÎncă nu există evaluări

- Pcat17694 CouplingsDocument13 paginiPcat17694 CouplingsMykola TitovÎncă nu există evaluări

- Theory of Machine (TOM) CurriculumDocument4 paginiTheory of Machine (TOM) CurriculumRushabh LaddhaÎncă nu există evaluări

- Testing Commissioning of Water Supply Piping System Network PDFDocument3 paginiTesting Commissioning of Water Supply Piping System Network PDFAnil RadheshwarÎncă nu există evaluări

- CMP40 - 50sL (Lot No - 9585)Document284 paginiCMP40 - 50sL (Lot No - 9585)Humberto Augusto de BorbaÎncă nu există evaluări

- Guangzhou Electway Technology Co.,LtdDocument21 paginiGuangzhou Electway Technology Co.,Ltdabdelhamed mahmoudÎncă nu există evaluări

- Alternator (Automotive)Document4 paginiAlternator (Automotive)Cornel BicaÎncă nu există evaluări

- Hilti Te805Document6 paginiHilti Te805weldsaidiÎncă nu există evaluări

- Friction in IC EnginesDocument27 paginiFriction in IC EnginesRobinson Prabu100% (1)

- L 48-60 Operating InstructionsDocument243 paginiL 48-60 Operating InstructionsdugouhaÎncă nu există evaluări

- 140H Cat: GraderDocument22 pagini140H Cat: GraderFacundo VarasÎncă nu există evaluări

- Kenr5131kenr5131-02 PDocument60 paginiKenr5131kenr5131-02 PPaulo CÎncă nu există evaluări