Documente Academic

Documente Profesional

Documente Cultură

Lecture21 PDF

Încărcat de

Vignesh Waran0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări22 paginiTitlu original

lecture21.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări22 paginiLecture21 PDF

Încărcat de

Vignesh WaranDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 22

Engineering H191 - Drafting / CAD

Fits and Tolerances

Lecture 20

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 1

Engineering H191 - Drafting / CAD

Tolerancing – Control of Variability

• Goals

– Understand the description and control of

variability through tolerancing.

– Use standard tables for tolerancing and

control of fit

• Reference (BTG)

– P. 312-317 – Dimensioning for Interchangeable

Parts

– P. 349-354 – Standard Tables for Fits

– P. 358-369 – Geometric Tolerancing

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 2

Engineering H191 - Drafting / CAD

Definition of Tolerance

• Tolerance is the total amount a dimension may

vary. It is the difference between the maximum

and minimum limits.

• There is no such thing as an "exact size".

• Tolerance is key to interchangeable parts.

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 3

Engineering H191 - Drafting / CAD

Ways to Express Tolerance

• Direct limits or as tolerance limits applied to a

dimension

• Geometric tolerances

• Notes referring to specific conditions

• A general tolerance note in title block

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 4

Engineering H191 - Drafting / CAD

Direct Limits and Tolerance Values

Can be:

Limits: Upper limit – 3.53

Lower limit – 3.49

Unilateral – vary in only one

direction +.04

0

3.49

0 -.0X

+.0X - 0

Bilateral – vary larger or smaller

(may or may not be+.03

same amount)

-.01

3.50

Autumn Quarter +.05 -.01, +.10 -.20

Gateway Engineering Education Coalition +/- 0.05

Lect 20 P. 5

Engineering H191 - Drafting / CAD

Geometric Tolerance System

• Geometric dimensioning

and tolerancing (GDT) is a Feature Control Frame

method of defining parts

Concentricity Symbol

based on how they

function, using standard

ANSI symbols.

• (More about this in a

couple of weeks.)

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 6

Engineering H191 - Drafting / CAD

Notes and Title Block

ALL DECIMAL

DIMENSIONS THAT

ARE THREE PLACE

ACCUARCY (.XXX)

TO BE HELD TO

+/-.005"

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 7

Engineering H191 - Drafting / CAD

Important Terms – Single Part

• Nominal Size – a general size, usually expressed

as a common fraction (1/2”)

• Basic Size – theoretical size used as starting

point (.500”)

• Actual Size – measured size (.501”)

• Limits – maximum and minimum sizes shown by

tolerances

• Tolerance – total allowable variance in

dimensions (upper limit – lower limit)

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 8

Engineering H191 - Drafting / CAD

Important Terms – Multiple Parts

• Allowance – the minimum clearance or maximum

interference between parts

• Fit – degree of tightness between two parts

– Clearance Fit – tolerance of mating parts

always leave a space

– Interference Fit – tolerance of mating parts

always interfere

– Transition Fit – sometimes interfere,

sometimes clear

• Tolerance – total allowable variance in

dimensions (upper limit – lower limit)

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 9

Engineering H191 - Drafting / CAD

Fitting Two Parts

Tolerance of B Tolerance: Clearance

or Interference

Part B

Tolerance of A

Part A

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 10

Engineering H191 - Drafting / CAD

Shaft and Hole Fits

Clearance Interference

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 11

Engineering H191 - Drafting / CAD

Shaft and Hole Fits

Transition

CLEARANCE

FIT

+ .003

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 12

Engineering H191 - Drafting / CAD

Standard Precision Fits: English Units

• Running and sliding fits (RC)

• Clearance locational fits (LC)

• Transition locational fits (LT)

• Interference locational fits (LN)

• Force and shrink fits (FN)

See Tables in the Appendix (pp. A11-A23)

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 13

Engineering H191 - Drafting / CAD

Basic Hole System or Hole Basis

• Definition of the "Basic Hole System":

– The "minimum size" of the hole is equal to the

"basic size" of the fit

• Example: If the nominal size of a fit is 1/2", then

the minimum size of the hole in the system will be

0.500"

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 14

Engineering H191 - Drafting / CAD

Fit Calculations

• Clearance = Hole – Shaft

• Cmax = Hmax – Smin

• Cmin = Hmin – Smax

Both Cmax and Cmin >0 – Clearance fit

Both Cmax and Cmin <0 – Interference fit

Cmax > 0, Cmin < 0 – Transition fit

• Allowance = Hmin - Smax (i.e., Cmin)

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 15

Engineering H191 - Drafting / CAD

Fit Calculations

• System Tolerance = Cmax - Cmin (Sometimes

called Clearance Tolerance)

• Also, System Tolerance = Σ Ti

• So, System Tolerance, or Ts , can be written as:

Ts = Cmax - Cmin = Σ Ti

• Thus, you always have a check value

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 16

Engineering H191 - Drafting / CAD

Example

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 17

Engineering H191 - Drafting / CAD

Metric Limits and Fits

• Based on Standard Basic Sizes – ISO Standard,

see the Appendix material (Appendices 8 - 12)

• Note that in the Metric system:

Nominal Size = Basic Size

• Example: If the nominal size is 8, then the basic

size is 8

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 18

Engineering H191 - Drafting / CAD

Metric Preferred Hole Basis System of Fits

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 19

Engineering H191 - Drafting / CAD

Metric Tolerance Homework

– Example TOL-1B

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 20

Engineering H191 - Drafting / CAD

Good Review Material

• BTG Chapter 7

– Dimensions and Tolerances

– Pages 290-335

• BTG Chapter 8

– Dimensions For Production

– Pages 340-375

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 21

Engineering H191 - Drafting / CAD

Assignments

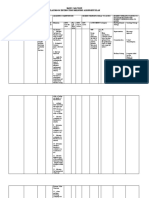

• Dwg 39 – G27 – Tolerances – Single Fits

– Calculate the missing values for each

situation.

– Use the tables for preferred limits and fits for

cylindrical parts.

• Dwg 40 – TOL–1A – Metric Tolerances

– Using the given nominal sizes and fit

specifications, calculate remaining values.

Autumn Quarter Gateway Engineering Education Coalition Lect 20 P. 22

S-ar putea să vă placă și

- Fits and Tolerances: Engineering H191 - Drafting / CADDocument22 paginiFits and Tolerances: Engineering H191 - Drafting / CADVignesh WaranÎncă nu există evaluări

- Fits and TolerancesDocument26 paginiFits and TolerancesPrithviraj Daga100% (3)

- MEM201 L6-Tolerance RCDocument31 paginiMEM201 L6-Tolerance RCKaliya PerumalÎncă nu există evaluări

- 0192 Design Optimization of Eot Crane BridgeDocument9 pagini0192 Design Optimization of Eot Crane BridgeJignesh Tala100% (1)

- MEM201 L6-Tolerance RCDocument82 paginiMEM201 L6-Tolerance RCNizar Pratama PutraÎncă nu există evaluări

- IT in ConstructionDocument25 paginiIT in ConstructionKhan Mahmudul HasanÎncă nu există evaluări

- BECM 4203 - Lecture 5Document25 paginiBECM 4203 - Lecture 5Okapia TingÎncă nu există evaluări

- Advances in Engineering Software: Gürol Yıldırım, Vijay P. SinghDocument8 paginiAdvances in Engineering Software: Gürol Yıldırım, Vijay P. SinghMartin VenichÎncă nu există evaluări

- Part 1-5 - PowerpointsDocument160 paginiPart 1-5 - PowerpointsChrispin BarnigoÎncă nu există evaluări

- Geometric Attributes of Manufactured PartsDocument17 paginiGeometric Attributes of Manufactured PartsDeejay ShivÎncă nu există evaluări

- Dr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process FeedbackDocument38 paginiDr. Greg Hetland - Profile Tolerancing Proof of Compliance - Vs - Process FeedbackpdmnbraoÎncă nu există evaluări

- Construction Stages and Column Shortening Analysis in Tall Buildings PDFDocument49 paginiConstruction Stages and Column Shortening Analysis in Tall Buildings PDFPhu NguyenÎncă nu există evaluări

- 02-Construction Stages and Column Shortening Analysis in Tall BuildingsDocument49 pagini02-Construction Stages and Column Shortening Analysis in Tall BuildingsMaad Ahmed Al-Maroof100% (3)

- Featools Intro Webinar Scripted For IntergraphDocument58 paginiFeatools Intro Webinar Scripted For IntergraphJimmy Alexander Avila100% (1)

- Novel Heat Exchanger Design Using Approximation Assisted OptimizationDocument35 paginiNovel Heat Exchanger Design Using Approximation Assisted Optimizationvinicius schwabÎncă nu există evaluări

- Chap 2 DesignDocument49 paginiChap 2 DesignFareedMohmed100% (1)

- 20201019-Advanced Computer Aided ModellingDocument38 pagini20201019-Advanced Computer Aided ModellingNaveena mÎncă nu există evaluări

- Basic FeaDocument84 paginiBasic FeaSiddharth SridharÎncă nu există evaluări

- Check List For Piping LayoutsDocument5 paginiCheck List For Piping LayoutsThiruThirunavukkarasu100% (3)

- Geo CleaningDocument34 paginiGeo CleaningNanaÎncă nu există evaluări

- Lecture 04A - Design Isometrics and Intro To AutoCADDocument44 paginiLecture 04A - Design Isometrics and Intro To AutoCADTimothy MwirigiÎncă nu există evaluări

- 2 International Conference On Engineering Optimization: Boualem Tliouine, Ferhat FedghoucheDocument8 pagini2 International Conference On Engineering Optimization: Boualem Tliouine, Ferhat FedghoucheReemALMousawiÎncă nu există evaluări

- Geometrical Dimensioning and TolerenceDocument61 paginiGeometrical Dimensioning and TolerenceAd Man GeTigÎncă nu există evaluări

- Beam FLexureDocument4 paginiBeam FLexureNikitaBhattaraiAcharyaÎncă nu există evaluări

- Position Tolerance Run-Out Datum Reference ConcentricDocument1 paginăPosition Tolerance Run-Out Datum Reference ConcentricjcetmechanicalÎncă nu există evaluări

- CW SheetDocument1 paginăCW Sheetcarlosfranx9Încă nu există evaluări

- DCE C18 5th Sem SyllabusDocument156 paginiDCE C18 5th Sem SyllabusRAJ CIVIL TECHÎncă nu există evaluări

- Introduction To Column Shortening Analysis - Case Study of Lotte TowerDocument71 paginiIntroduction To Column Shortening Analysis - Case Study of Lotte TowerAlden CayagaÎncă nu există evaluări

- M.Tech. Integrated ProgrammesDocument25 paginiM.Tech. Integrated ProgrammesNandhu PrasadÎncă nu există evaluări

- GD&TDocument31 paginiGD&TgopojiÎncă nu există evaluări

- Experiment No 10 - Exercises in Preparation of Detailed Production DrawingsDocument29 paginiExperiment No 10 - Exercises in Preparation of Detailed Production DrawingsS S PatilÎncă nu există evaluări

- Motors LabDocument23 paginiMotors LabMohamed ElgeziryÎncă nu există evaluări

- CivilFEM BridgesDocument81 paginiCivilFEM BridgesHooman GhasemiÎncă nu există evaluări

- Graphics - 4: Fits: Engineering Sciences 51 Fall 2005Document9 paginiGraphics - 4: Fits: Engineering Sciences 51 Fall 2005Kiên Trung NguyễnÎncă nu există evaluări

- Structural Analysis and Design: STAAD - Pro Concrete Design (FAQ)Document7 paginiStructural Analysis and Design: STAAD - Pro Concrete Design (FAQ)turbobrikÎncă nu există evaluări

- ENGR-22 Lec-19 Sp07 GDT Tolerancing-1Document45 paginiENGR-22 Lec-19 Sp07 GDT Tolerancing-1familyumaÎncă nu există evaluări

- Rapid Redesign of Metal Load-Bearing Aircraft Brackets in PlasticDocument16 paginiRapid Redesign of Metal Load-Bearing Aircraft Brackets in PlasticSabanSaulicÎncă nu există evaluări

- Geometric Dimensioning 1Document36 paginiGeometric Dimensioning 1mohanÎncă nu există evaluări

- Fasteners and Welding: Engineering H191 - Drafting / CADDocument24 paginiFasteners and Welding: Engineering H191 - Drafting / CADcfcshakerÎncă nu există evaluări

- Stack Up With GD&TDocument2 paginiStack Up With GD&TBadarinath KnÎncă nu există evaluări

- Asphalt Pavement Design-The Design Guide L - Khazanovich PDFDocument44 paginiAsphalt Pavement Design-The Design Guide L - Khazanovich PDFYasruddin MtÎncă nu există evaluări

- Construction and Building Materials: Reza MasoudniaDocument18 paginiConstruction and Building Materials: Reza MasoudniaMazenMowafyÎncă nu există evaluări

- WLC1 Q1Document7 paginiWLC1 Q1SeyahatÎncă nu există evaluări

- INDOT Practice Pointers 1-14-15Document4 paginiINDOT Practice Pointers 1-14-15Mike2322Încă nu există evaluări

- Analysis and Design of Bridge Using STAAD ProDocument156 paginiAnalysis and Design of Bridge Using STAAD Prorctorresh100% (2)

- Pareto Approach in Multi-Objective Optimal DesignDocument9 paginiPareto Approach in Multi-Objective Optimal DesignRonalÎncă nu există evaluări

- Beam Torsion Al Section PropertiesDocument26 paginiBeam Torsion Al Section PropertiesWilliam Gomez ZabaletaÎncă nu există evaluări

- Multidisciplinary Optimization Methods For Preliminary DesignDocument26 paginiMultidisciplinary Optimization Methods For Preliminary DesignMuhanad SolimanÎncă nu există evaluări

- Basic Structural Design ConceptsDocument21 paginiBasic Structural Design Conceptscuterose95Încă nu există evaluări

- Mechanical Technology for Higher Engineering TechniciansDe la EverandMechanical Technology for Higher Engineering TechniciansÎncă nu există evaluări

- MOS Integrated Circuit DesignDe la EverandMOS Integrated Circuit DesignE. WolfendaleÎncă nu există evaluări

- Reflow Soldering: Apparatus and Heat Transfer ProcessesDe la EverandReflow Soldering: Apparatus and Heat Transfer ProcessesÎncă nu există evaluări

- Design Guidelines for Surface Mount TechnologyDe la EverandDesign Guidelines for Surface Mount TechnologyEvaluare: 5 din 5 stele5/5 (1)

- Toc Pmt1944-Eng Snl2019Document8 paginiToc Pmt1944-Eng Snl2019Vignesh WaranÎncă nu există evaluări

- Revit Mep NotesDocument23 paginiRevit Mep NotesVignesh WaranÎncă nu există evaluări

- Job Seeker Details PDFDocument1 paginăJob Seeker Details PDFVignesh WaranÎncă nu există evaluări

- Postdoctoralfellow GuidelinesDocument6 paginiPostdoctoralfellow GuidelinesVignesh WaranÎncă nu există evaluări

- Productivityandom 170320112253 PDFDocument20 paginiProductivityandom 170320112253 PDFVignesh WaranÎncă nu există evaluări

- Revit Family PlanningDocument1 paginăRevit Family PlanningVignesh WaranÎncă nu există evaluări

- EnDuraSim Rigid ElementsDocument6 paginiEnDuraSim Rigid ElementsVignesh WaranÎncă nu există evaluări

- C16 NX11 PDFDocument82 paginiC16 NX11 PDFVignesh WaranÎncă nu există evaluări

- Knowledge and DiplomacyDocument121 paginiKnowledge and DiplomacyVignesh WaranÎncă nu există evaluări

- Airplane Stability and Control Notes GATE Aerospace EngineeringDocument31 paginiAirplane Stability and Control Notes GATE Aerospace Engineeringabrarn179208100% (4)

- Ca 77Document11 paginiCa 77பிரபாகரன் ஆறுமுகம்Încă nu există evaluări

- Indian National Movement Practice Questions and AnswersDocument25 paginiIndian National Movement Practice Questions and AnswersBasheer AhmedÎncă nu există evaluări

- White Paper: Rendering in 3DS Max 2017Document5 paginiWhite Paper: Rendering in 3DS Max 2017Vignesh WaranÎncă nu există evaluări

- 01 - Chapter 2 HyperWorks Desktop - 13Document20 pagini01 - Chapter 2 HyperWorks Desktop - 13Vignesh WaranÎncă nu există evaluări

- nx8 Adv Sim Process PDFDocument422 pagininx8 Adv Sim Process PDFVignesh WaranÎncă nu există evaluări

- Chapter Two 2.1 Cyclic/Fatigue Loading of Structural MembersDocument28 paginiChapter Two 2.1 Cyclic/Fatigue Loading of Structural MembersVignesh WaranÎncă nu există evaluări

- Resume: Name: P. Alexander Mail: Mobile: 9003343851Document2 paginiResume: Name: P. Alexander Mail: Mobile: 9003343851Vignesh WaranÎncă nu există evaluări

- SP16-Design Aid For RC To IS456-1978Document252 paginiSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- Workbench Ansys PDFDocument124 paginiWorkbench Ansys PDFlymacsausarangÎncă nu există evaluări

- Rotating Shaft PDFDocument19 paginiRotating Shaft PDFVignesh WaranÎncă nu există evaluări

- FEA Vs EMADocument9 paginiFEA Vs EMAMithun JohnÎncă nu există evaluări

- Datums GDTDocument47 paginiDatums GDTAmitava DattaÎncă nu există evaluări

- Is 800:2007Document150 paginiIs 800:2007crajtry100% (2)

- Stress TransformationDocument7 paginiStress TransformationVignesh WaranÎncă nu există evaluări

- Form DesignDocument1 paginăForm DesignVignesh WaranÎncă nu există evaluări

- Structural GlossaryDocument11 paginiStructural GlossaryVignesh WaranÎncă nu există evaluări

- What Are The Types of Beams - QuoraDocument23 paginiWhat Are The Types of Beams - QuoraVignesh WaranÎncă nu există evaluări

- NX Training Work BookDocument102 paginiNX Training Work BookMATHI KRISHNAN90% (10)

- A Method of Estimating Plane Vulnerability Based On Damage of Survivors" by Abraham Wald (CRC)Document101 paginiA Method of Estimating Plane Vulnerability Based On Damage of Survivors" by Abraham Wald (CRC)Michele GiulianiÎncă nu există evaluări

- Basic Calculus Classroom Instruction Delivery Alignment PlanDocument7 paginiBasic Calculus Classroom Instruction Delivery Alignment PlanIsrael Morta Garzon75% (4)

- Corporate Governance and Its Contribution To Risk and Crisis Management in Small CompaniesDocument476 paginiCorporate Governance and Its Contribution To Risk and Crisis Management in Small CompaniesAniÎncă nu există evaluări

- Chap08 PDFDocument59 paginiChap08 PDFjijojohnson41Încă nu există evaluări

- Examples of LimitsDocument13 paginiExamples of LimitsBelen Guaigua ZuritaÎncă nu există evaluări

- Dimitri Bertsekas - Nonlinear Programming (Google Books Preview) (2016, Athena Scientific) - Libgen - LiDocument64 paginiDimitri Bertsekas - Nonlinear Programming (Google Books Preview) (2016, Athena Scientific) - Libgen - Lijzhang4Încă nu există evaluări

- Chapter 11: DATA ANALYSIS: FREQUENCY DISTRIBUTION, HYPOTHESIS TESTING, AND CROSS TABULATIONDocument40 paginiChapter 11: DATA ANALYSIS: FREQUENCY DISTRIBUTION, HYPOTHESIS TESTING, AND CROSS TABULATIONAungKoMinÎncă nu există evaluări

- Descriptive Statistics Using SASDocument10 paginiDescriptive Statistics Using SASsxurdcÎncă nu există evaluări

- Using The Min-Max Method To Solve Multiobjective Optimization Problems With Genetic AlgorithmsDocument2 paginiUsing The Min-Max Method To Solve Multiobjective Optimization Problems With Genetic AlgorithmsNguyen VinhÎncă nu există evaluări

- Chapter 20a (Simpson S Rule) - Min PDFDocument12 paginiChapter 20a (Simpson S Rule) - Min PDFImranÎncă nu există evaluări

- M53 Lec2.3 Higher Order Derivatives Implicit Differentiation Linear ApproximationDocument251 paginiM53 Lec2.3 Higher Order Derivatives Implicit Differentiation Linear ApproximationKhen Mehko OjedaÎncă nu există evaluări

- M328 Lec2 2015Document26 paginiM328 Lec2 2015mode4723Încă nu există evaluări

- Review Set 5B: 154 Logarithms (Chapter 5)Document1 paginăReview Set 5B: 154 Logarithms (Chapter 5)Ahmed NallaÎncă nu există evaluări

- Repeatability and Reproducibility StudyDocument4 paginiRepeatability and Reproducibility Studysivaseeni100% (1)

- HPLC - FingerprintDocument8 paginiHPLC - FingerprintMukul SuryawanshiÎncă nu există evaluări

- Module 6 - Analysing Qualitative DataDocument17 paginiModule 6 - Analysing Qualitative DataMinh KhuêÎncă nu există evaluări

- Mathematics Extention 2 2015 HSC Exam Marking GuidelinesDocument38 paginiMathematics Extention 2 2015 HSC Exam Marking GuidelinesMÎncă nu există evaluări

- Lectures On The Differential Geometry of Curves and Surfaces (2005) - BlagaDocument237 paginiLectures On The Differential Geometry of Curves and Surfaces (2005) - Blagacesarantoine100% (1)

- Functional Analysis Oral Exam Study Notes-Func - NotesDocument70 paginiFunctional Analysis Oral Exam Study Notes-Func - NotesshoroukÎncă nu există evaluări

- SOPDocument2 paginiSOPAbidemi AdewaleÎncă nu există evaluări

- Algunas Derivadas TrigonométricasDocument4 paginiAlgunas Derivadas TrigonométricasRaul Humberto Mora VillamizarÎncă nu există evaluări

- Chapter - 6 Interpolation Functions For General Element FormulationDocument25 paginiChapter - 6 Interpolation Functions For General Element FormulationWaleed TayyabÎncă nu există evaluări

- Thesis Proposal Cesar Marolla Harvard UniversityDocument30 paginiThesis Proposal Cesar Marolla Harvard UniversityCesar MarollaÎncă nu există evaluări

- Optimization of Chemical ProcessesDocument2 paginiOptimization of Chemical ProcessesAmol RastogiÎncă nu există evaluări

- EXP8 Frequencyresponse StudentsDocument4 paginiEXP8 Frequencyresponse StudentslucasÎncă nu există evaluări

- (Andrzej Lasota, Michael C. Mackey) Chaos, Fractal PDFDocument490 pagini(Andrzej Lasota, Michael C. Mackey) Chaos, Fractal PDFAngel Leon Geronimo100% (1)

- Appendix Dirac Delta FunctionDocument15 paginiAppendix Dirac Delta Functionexicial87Încă nu există evaluări

- Analytical Paragraph WritingDocument34 paginiAnalytical Paragraph WritingDHARSHAN BOOPALANÎncă nu există evaluări

- Things To Remember - Principal Component AnalysisDocument2 paginiThings To Remember - Principal Component AnalysisUmaprasadÎncă nu există evaluări

- Assignment 02 AE675Document3 paginiAssignment 02 AE675yvnarayanaÎncă nu există evaluări