Documente Academic

Documente Profesional

Documente Cultură

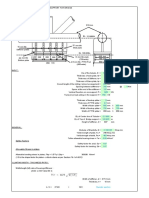

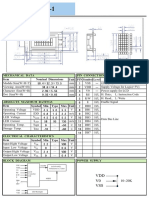

Welding Size Requirement: SR - No. Welding Location Welding Size (K Leg Length of Weld)

Încărcat de

sitam_nitj42020 evaluări0% au considerat acest document util (0 voturi)

17 vizualizări2 paginiThis document outlines welding size requirements for various welding locations on tanks. It provides the minimum leg length (k) of welds for different stiffener and plate thicknesses (T) for box stiffener, vertical plate gusset, HV pocket to rib gusset stiffener, lifting bollards, and tank covers. It also specifies welding sizes for tank walls, rims, stoppers, locating cups, name plates, supports, jacking pads, pipes, flanges, and covers. Notes indicate that welding sizes should be checked before dispatch and that the given k values are minimums.

Descriere originală:

welding

Titlu original

Welding Size Requirement

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document outlines welding size requirements for various welding locations on tanks. It provides the minimum leg length (k) of welds for different stiffener and plate thicknesses (T) for box stiffener, vertical plate gusset, HV pocket to rib gusset stiffener, lifting bollards, and tank covers. It also specifies welding sizes for tank walls, rims, stoppers, locating cups, name plates, supports, jacking pads, pipes, flanges, and covers. Notes indicate that welding sizes should be checked before dispatch and that the given k values are minimums.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

17 vizualizări2 paginiWelding Size Requirement: SR - No. Welding Location Welding Size (K Leg Length of Weld)

Încărcat de

sitam_nitj4202This document outlines welding size requirements for various welding locations on tanks. It provides the minimum leg length (k) of welds for different stiffener and plate thicknesses (T) for box stiffener, vertical plate gusset, HV pocket to rib gusset stiffener, lifting bollards, and tank covers. It also specifies welding sizes for tank walls, rims, stoppers, locating cups, name plates, supports, jacking pads, pipes, flanges, and covers. Notes indicate that welding sizes should be checked before dispatch and that the given k values are minimums.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Welding Size Requirement

Sr.No. Welding location Welding size (k = Leg length of Weld)

T= Thickness of Stiffener

(1.T=4-6mm ,then k=4),

Box stiffener & Vertical plate gusset

1 (2.T=8mm ,then k=6),

to Tank Wall

(3.T=10-16mm ,then k=8),

(4.T=20-32mm ,then k=10)

T= Thickness of Rib Gusset stiffener

(1.T=4-6mm ,then k=4),

2 HV Pocket to Rib Gusset stiffener (2.T=8mm ,then k=6),

(3.T=10-16mm ,then k=8),

(4.T=20-32mm ,then k=10)

1.Pipe to plate(k=15mm)

3 Lifting Bollard (Pipe to Box and Plate)

2.Pipe & box to Latching plate(k=12mm)

1.Flange thickness (10 to 14mm) and Pipe

thickness(2.8 to 3.8mm) K=3mm

2.Flange thickness (18 to 22mm) and Pipe

4 Pipe connector

thickness(4mm) K=4mm

3.Flange thickness (24mm & above) and

Pipe thickness(4.5mm) K=8mm

T= Thickness of tank wall

5 Tank cover to Tank wall (1.T=8mm ,then k=8),

(2.T=10mm ,then k=10)

T= Thickness of tank wall

6 Tank wall at corner (Wet Joint) (1.T=8mm ,then k=8),

(2.T=10mm ,then k=10)

7 Tank Rim to Tank wall 10mm (Inside & Outside)

8 Tank Rim to Stopper(12mmX12mm) 4 mm

9 Locating cup to Bottom plate 10mm outside only

10 Name plate to Tank wall 2mm

11 OLTC DM Box Support with Tank wall 6mm

12 Jacking Pad and with tank wall 12mm

13 Radiator Pipe welding on tank 4mm inside and 5 mm outside

14 BFV Flange to pipe welding 5mm outside & 3mm inside

15 Tank wall & cover to Flange 4mm outside

Notes:

1. Welding Size shall be checked at fabricator end before dispatch the tank.

2. Given value of k (Leg length of Weld) is minimum valve.

3. If in case of doubt, feel free to ask.

S-ar putea să vă placă și

- Design of Overhead Water Tank 29Document28 paginiDesign of Overhead Water Tank 29rashmi bhailaÎncă nu există evaluări

- Limpet CoilDocument2 paginiLimpet CoilPANOLI PROJECTÎncă nu există evaluări

- For Lap Joint For Single Riveted Butt Joint For Double Riveted Butt JointDocument1 paginăFor Lap Joint For Single Riveted Butt Joint For Double Riveted Butt JointManish KashivÎncă nu există evaluări

- Design of Floor Framing SystemDocument37 paginiDesign of Floor Framing SystemBridget Anne BenitezÎncă nu există evaluări

- How To Calculate Length of Limpet CoilDocument2 paginiHow To Calculate Length of Limpet CoilAzhaÎncă nu există evaluări

- Typical Details For Cantilever SlabDocument3 paginiTypical Details For Cantilever SlabshebaÎncă nu există evaluări

- Technical Specification FOR Barge, M.S Pipe & FloatDocument5 paginiTechnical Specification FOR Barge, M.S Pipe & FloatMin Aung Naing TunÎncă nu există evaluări

- Design of Thrust Block: G Q in DegreesDocument56 paginiDesign of Thrust Block: G Q in DegreesChandan VatsÎncă nu există evaluări

- Estimating of Simple RCC StructureDocument19 paginiEstimating of Simple RCC Structurebhatta adminÎncă nu există evaluări

- Integration Course2Document61 paginiIntegration Course2Fiona MiralpesÎncă nu există evaluări

- Bearing Strength of ConcreteDocument5 paginiBearing Strength of ConcreteSatyamÎncă nu există evaluări

- 99 StratergyDocument16 pagini99 StratergyChouhan Akshay SinghÎncă nu există evaluări

- Design of Internal Combustion EngineDocument17 paginiDesign of Internal Combustion EngineAyman EsaÎncă nu există evaluări

- Design of 1.50KL OH Tank 9M Staging PDFDocument21 paginiDesign of 1.50KL OH Tank 9M Staging PDFshivanandarcotÎncă nu există evaluări

- Test Floor Black FinalDocument2 paginiTest Floor Black FinalHAFIZ ARSALAN ALIÎncă nu există evaluări

- Thermal Stress and TorsionDocument17 paginiThermal Stress and TorsionVallestero Siegfred50% (2)

- Water Tank - Is 3370-Sludge TankDocument4 paginiWater Tank - Is 3370-Sludge TankDhayalan PalanisamyÎncă nu există evaluări

- Welded Simple Connection: Based On Block Shear Capacity ofDocument2 paginiWelded Simple Connection: Based On Block Shear Capacity ofMarvin Carl GranadaÎncă nu există evaluări

- Genset Pad 10ftx2ftDocument7 paginiGenset Pad 10ftx2ftAmmad AlizaiÎncă nu există evaluări

- SCT - SN-Steel Formwork Design - WWTP SLABDocument2 paginiSCT - SN-Steel Formwork Design - WWTP SLABshihabÎncă nu există evaluări

- Intz TankDocument47 paginiIntz Tankyashfeen bakhshÎncă nu există evaluări

- Problem SolvingDocument6 paginiProblem SolvingImran NoorÎncă nu există evaluări

- 12 Inch - Page 2Document1 pagină12 Inch - Page 2Juliano André PetryÎncă nu există evaluări

- Beban Mati Merata Berat Sendiri (DL) : Type Balok Letak TulanganDocument16 paginiBeban Mati Merata Berat Sendiri (DL) : Type Balok Letak TulanganAlfian MilitanÎncă nu există evaluări

- Sheet Metal WorkingDocument36 paginiSheet Metal Workingmohdhm100% (1)

- Preliminary Design of Slab Beam and ColumnDocument4 paginiPreliminary Design of Slab Beam and ColumnSandesh GhimireÎncă nu există evaluări

- A Textbook of Machine Design by R.S.khurMI and J.K.guptA (Tortuka)Document1 paginăA Textbook of Machine Design by R.S.khurMI and J.K.guptA (Tortuka)lastjohn100% (1)

- SM2-3 Chap3 Design Welded Joints Tutorial1Document7 paginiSM2-3 Chap3 Design Welded Joints Tutorial1AhmedÎncă nu există evaluări

- Total DataDocument61 paginiTotal DataGANDRETI RAMU (N160267)Încă nu există evaluări

- Weight Estimation of Vessels ADocument16 paginiWeight Estimation of Vessels AAlvin SmithÎncă nu există evaluări

- Mechanical Design of FBRDocument6 paginiMechanical Design of FBRcristianoÎncă nu există evaluări

- Analysis, Design and Estimation of Multi-Storey Building Using Build MasterDocument37 paginiAnalysis, Design and Estimation of Multi-Storey Building Using Build MasternaveenÎncă nu există evaluări

- ستيل ستركشرDocument73 paginiستيل ستركشرAws SamaÎncă nu există evaluări

- CES 40'HC Reefer ContainerDocument6 paginiCES 40'HC Reefer ContainerIdrus Yani Ptk0% (1)

- Pipe Support CALCULATIONDocument2 paginiPipe Support CALCULATIONalvinchuanÎncă nu există evaluări

- Design of Connecting RodDocument8 paginiDesign of Connecting RodDarshan Shinde0% (1)

- Drilling Bits: James A. CraigDocument31 paginiDrilling Bits: James A. CraigPeterMarkÎncă nu există evaluări

- Liffting LugDocument8 paginiLiffting LugQuraisy AmriÎncă nu există evaluări

- Molasses Tank Draft GTP - 12000MT Net-15000 MT GrossDocument14 paginiMolasses Tank Draft GTP - 12000MT Net-15000 MT GrossStressDyn ConsultantsÎncă nu există evaluări

- Bearing DesignDocument5 paginiBearing DesignAnde BhanuÎncă nu există evaluări

- Clean Out Door Bottom Reinf Plate: Add Corrosion AllowanceDocument2 paginiClean Out Door Bottom Reinf Plate: Add Corrosion AllowancesankaranÎncă nu există evaluări

- Design of Concentrated Sulfuric Acid TankDocument12 paginiDesign of Concentrated Sulfuric Acid TankAbdelrhman Uossef100% (1)

- Apron - HB 250 To HB 250Document17 paginiApron - HB 250 To HB 250Hendri HermawanÎncă nu există evaluări

- A. Determine A Radius of Riser: To Calculate Welding Length On TKY Joint Please Follow Below InstructionDocument3 paginiA. Determine A Radius of Riser: To Calculate Welding Length On TKY Joint Please Follow Below InstructionBHARANIÎncă nu există evaluări

- Cad Lab - II ManualDocument44 paginiCad Lab - II ManualmaneiahÎncă nu există evaluări

- Pipe Support CalculationDocument2 paginiPipe Support Calculationthanh100% (1)

- Design of 200m3 TankDocument4 paginiDesign of 200m3 TankMiko AbiÎncă nu există evaluări

- Coupling and Its TypesDocument22 paginiCoupling and Its TypesAnantha BhatÎncă nu există evaluări

- Revised Design of Jetty PilesDocument6 paginiRevised Design of Jetty PilesABHINAY MUVVALA100% (1)

- The Cutting Length of Stirrups in Beam and ColumnDocument12 paginiThe Cutting Length of Stirrups in Beam and ColumnSwostik S SahooÎncă nu există evaluări

- Design of Slab. S1: Between Grid 18 and 19 First Floor: Provide #10 at 150 MM C/C at Bottom Along Short SpanDocument3 paginiDesign of Slab. S1: Between Grid 18 and 19 First Floor: Provide #10 at 150 MM C/C at Bottom Along Short SpanPrashant PatilÎncă nu există evaluări

- Cladding Fixing CalculationDocument26 paginiCladding Fixing Calculationcoolkaisy100% (1)

- Experiment No: 03Document4 paginiExperiment No: 03md.Aktaruzzaman aktarÎncă nu există evaluări

- Circular Water Tank RC Design To IsDocument29 paginiCircular Water Tank RC Design To IsSteve JsobÎncă nu există evaluări

- Maong Besar BridgeDocument24 paginiMaong Besar BridgeWong Chii NguongÎncă nu există evaluări

- Design of Pinned Base ConnectionDocument21 paginiDesign of Pinned Base ConnectionShawkat Ali KhanÎncă nu există evaluări

- Bridge Sliding End and Fixed End-CIFB03Document7 paginiBridge Sliding End and Fixed End-CIFB03Sai SushankÎncă nu există evaluări

- Lec 19Document32 paginiLec 19sitam_nitj4202Încă nu există evaluări

- Lec 20Document29 paginiLec 20sitam_nitj4202Încă nu există evaluări

- Optimization of Power Transformer Design Losses VoDocument30 paginiOptimization of Power Transformer Design Losses VoghersimonÎncă nu există evaluări

- Global Transformer Optimization Method UDocument5 paginiGlobal Transformer Optimization Method Usitam_nitj4202Încă nu există evaluări

- Impact of Accelerated Stresses On PowerDocument15 paginiImpact of Accelerated Stresses On Powersitam_nitj4202Încă nu există evaluări

- Stochastic Noise Removal On Partial DiscDocument6 paginiStochastic Noise Removal On Partial Discsitam_nitj4202Încă nu există evaluări

- Lec 22Document38 paginiLec 22sitam_nitj4202Încă nu există evaluări

- Applied Data Analysis For Process Improvement - A Practical Guide To Six Sigma Black Belt Statistics-Hytinen, - AnnemiekeDocument303 paginiApplied Data Analysis For Process Improvement - A Practical Guide To Six Sigma Black Belt Statistics-Hytinen, - Annemiekekalgm4437Încă nu există evaluări

- C 0Document2 paginiC 0Ravi ValakrishnanÎncă nu există evaluări

- Lec 21Document35 paginiLec 21sitam_nitj4202Încă nu există evaluări

- VSMDocument296 paginiVSMpgrdic100% (4)

- Standard Work IntroductionDocument3 paginiStandard Work Introductionsitam_nitj4202Încă nu există evaluări

- Lean Management BOKDocument68 paginiLean Management BOKsitam_nitj4202Încă nu există evaluări

- Lean Manufacturing ProjectDocument5 paginiLean Manufacturing Projectsitam_nitj4202Încă nu există evaluări

- Managing To LearnDocument132 paginiManaging To LearnJose Ortega88% (26)

- Case Study - Logistics IndustryDocument3 paginiCase Study - Logistics Industrysitam_nitj4202Încă nu există evaluări

- Green BWLT Question PaperDocument5 paginiGreen BWLT Question Papersitam_nitj4202Încă nu există evaluări

- A3 ThinkingDocument17 paginiA3 Thinkingfdsa01100% (5)

- SigmaFlow VSM Reference ManualDocument236 paginiSigmaFlow VSM Reference ManualluisÎncă nu există evaluări

- Standardization: Standard WorkDocument2 paginiStandardization: Standard WorkMenganoÎncă nu există evaluări

- 04 3 Elements WorkbookDocument5 pagini04 3 Elements Workbooksitam_nitj4202Încă nu există evaluări

- Toyota A3 Process Ntro Chapt 1and2Document46 paginiToyota A3 Process Ntro Chapt 1and2Vijayasekar100% (10)

- Prerequisites To Standard Work: A Stable ProcessDocument1 paginăPrerequisites To Standard Work: A Stable Processsitam_nitj4202Încă nu există evaluări

- Standard Work Course: WorkbookDocument4 paginiStandard Work Course: Workbooksitam_nitj4202Încă nu există evaluări

- SW Process Capacity SheetDocument2 paginiSW Process Capacity Sheetsitam_nitj4202Încă nu există evaluări

- 219 PDFDocument13 pagini219 PDFAntónioSimõesBorbaÎncă nu există evaluări

- Toyota A3 Process Ntro Chapt 1and2Document46 paginiToyota A3 Process Ntro Chapt 1and2Vijayasekar100% (10)

- TAKT Time Mixed ModelDocument113 paginiTAKT Time Mixed Modelsitam_nitj4202Încă nu există evaluări

- LEAN ProjectDocument33 paginiLEAN Projectsitam_nitj4202Încă nu există evaluări

- Ejemplo de Instruccion de Trabajo PDFDocument2 paginiEjemplo de Instruccion de Trabajo PDFJose nuñezÎncă nu există evaluări

- Questionnaire Supply ChainDocument4 paginiQuestionnaire Supply ChainKshatriy'as ThigalaÎncă nu există evaluări

- All I Need Is Love by Klaus Kinski 0394549163 PDFDocument5 paginiAll I Need Is Love by Klaus Kinski 0394549163 PDFFernanda ArzaguetÎncă nu există evaluări

- Jurnal: Ekonomi PembangunanDocument14 paginiJurnal: Ekonomi PembangunanAgus MelasÎncă nu există evaluări

- London A Day in The Citypdf 2 PDF FreeDocument18 paginiLondon A Day in The Citypdf 2 PDF FreePuri RodriguezÎncă nu există evaluări

- Tankless Vs TankDocument2 paginiTankless Vs TankClick's PlumbingÎncă nu există evaluări

- Unit 2-Translation Practice MarkDocument3 paginiUnit 2-Translation Practice MarkHương ThảoÎncă nu există evaluări

- B737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysDocument6 paginiB737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysAlex CanizalezÎncă nu există evaluări

- C Urriculum Vitae: Sarvesh Narain SrivastavaDocument4 paginiC Urriculum Vitae: Sarvesh Narain SrivastavanarainsarveshÎncă nu există evaluări

- Segway v1 04 Eng Segway Atv Snarler Manual t3b L7eDocument192 paginiSegway v1 04 Eng Segway Atv Snarler Manual t3b L7eMarouane LASRYÎncă nu există evaluări

- V0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemDocument1 paginăV0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemBasir Ahmad NooriÎncă nu există evaluări

- English Project Basic Listo (Realizado)Document3 paginiEnglish Project Basic Listo (Realizado)Javier ToapantaÎncă nu există evaluări

- AVT 2217 Module 5 Aiport Lighting SystemDocument15 paginiAVT 2217 Module 5 Aiport Lighting SystemJane PazÎncă nu există evaluări

- Very High Frequency Omni-Directional Range: Alejandro Patt CarrionDocument21 paginiVery High Frequency Omni-Directional Range: Alejandro Patt CarrionAlejandro PattÎncă nu există evaluări

- Practical FileDocument108 paginiPractical FileRakesh KumarÎncă nu există evaluări

- Paragraph Completion Material 1Document5 paginiParagraph Completion Material 1d.jyr2xÎncă nu există evaluări

- Haggling As A Socio-Pragmatic Strategy (A Case Study of Idumota Market)Document15 paginiHaggling As A Socio-Pragmatic Strategy (A Case Study of Idumota Market)Oshoja Tolulope OlalekanÎncă nu există evaluări

- Good Parenting 1Document6 paginiGood Parenting 1honey13Încă nu există evaluări

- BD Bactec Mgit 960 Mycobacteria Culture SystemDocument6 paginiBD Bactec Mgit 960 Mycobacteria Culture SystemHuguens DesrosiersÎncă nu există evaluări

- 2 Mathematics For Social Science-1-1Document58 pagini2 Mathematics For Social Science-1-1ሀበሻ EntertainmentÎncă nu există evaluări

- Electrical Service Minimum RequirmentDocument97 paginiElectrical Service Minimum RequirmentachniajosiÎncă nu există evaluări

- Ten Steps To An Amazing INFJ LifeDocument15 paginiTen Steps To An Amazing INFJ LifeG. S.100% (5)

- S1 Mock 2Document13 paginiS1 Mock 2Abdulrahman HatemÎncă nu există evaluări

- Psyc 1100 Research ExperimentDocument10 paginiPsyc 1100 Research Experimentapi-242343747Încă nu există evaluări

- SAP2000 Analysis - Computers and Structures, IncDocument6 paginiSAP2000 Analysis - Computers and Structures, IncshadabghazaliÎncă nu există evaluări

- RWB 60-856 Inst - Op. Mantto.Document52 paginiRWB 60-856 Inst - Op. Mantto.Daniel Dennis Escobar Subirana100% (1)

- Collimation of Binoculars With A LampDocument33 paginiCollimation of Binoculars With A LampchristianÎncă nu există evaluări

- Sec ListDocument288 paginiSec ListTeeranun NakyaiÎncă nu există evaluări

- The Big Table of Quantum AIDocument7 paginiThe Big Table of Quantum AIAbu Mohammad Omar Shehab Uddin AyubÎncă nu există evaluări

- Daily ReportDocument39 paginiDaily ReportLe TuanÎncă nu există evaluări

- Airsprings - TroubleshootingDocument4 paginiAirsprings - TroubleshootingCihan CantaşÎncă nu există evaluări