Documente Academic

Documente Profesional

Documente Cultură

Packaging Aspects of Milk PDF

Încărcat de

hema varshiniTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Packaging Aspects of Milk PDF

Încărcat de

hema varshiniDrepturi de autor:

Formate disponibile

PACKAGING ASPECTS OF MILK & MILK BASED PRODUCTS 191

Chapter

11

PACKAGING ASPECTS OF MILK

& MILK BASED PRODUCTS

K R Kumar

Food Packaging Technology Department

Central Food Technological Research Institute

Mysore 570 020 (INDIA)

PLASTICS IN FOOD PACKAGING

192 Chapter 11

PLASTICS IN FOOD PACKAGING

PACKAGING ASPECTS OF MILK & MILK BASED PRODUCTS 193

Chapter 11

PACKAGING ASPECTS OF MILK

& MILK BASED PRODUCTS

INTRODUCTION unhygienic. Also, loose-vending introduces

the possibility of mixing with water and

Traditional milk-based products have also harmful ingredients. Hence, proper

played a significant role in the cultural and packaging assumes greater importance in

nutritional areas of our country. More the distribution of raw and pasteurized milk

often, these products are produced in in hygienic and wholesome form in specified

unorganized small-scale sector. Although volumes leading to consumer convenience

standardization in quality and mechani- and safety.

zation in production are taking place, there

is a great need for the development of Milk, being a complex physico-chemical

appropriate and economical packages. system, consists of a water solution of salts,

lactose, lactalbumin, etc. Proteins are dis-

Packaging is the vital link in the entire

persed in a colloidal form while milk-fat

chain of production, storage, transporta-

solids are present in a partially emulsified

tion, distribution and marketing. Functional

suspension.

packaging of dairy products leads not only

to resource raising and their optimal Milk is susceptible to oxidation of fat

utilization, but also protects the contents (phospholipids in milk) which produces a

against deteriorative changes and waxy odour. This dete-riorative change is

associated hazards. enhanced by heat, acid and metallic ions.

Exposure of milk to natural and artificial

LIQUID MILK (fluorescent) light leads to deterioration in

Liquid milk forms a major item of food quality and loss of vitamins.

in our country especially in rural areas. It Hence, a package intended for milk

forms the major ingredient in beverages, should possess the following protective

tea and coffee and essential part of the diet functions:

either as milk itself or as curd, butter milk,

ghee and savories. i) Protection against contamination due to

dirt and microorganisms.

Surplus milk is marketed by door-to-door

vending and the containers used are often ii) Protection against light and heat.

PLASTICS IN FOOD PACKAGING

194 Chapter 11

iii) Protection against external odours. since the weight of empty bottles and crates

is nearly the same as that of the quantity of

iv) Physical protection to withstand milk distributed. The collection, washing

distribution hazards. and accounting of return bottles is costly

and cumbersome.

Bulk Distribution of Milk In the context of existing bad roads in

The conventional containers for bulk most of the cities and unsystematic handling

packaging and distribution are the operations, the bottle breakage is very high.

aluminium cans with lids, while in recent This leads not only to higher milk losses,

years, bulk vending by machines through but also to added cost of handling. The

operation by token system has become milk losses vary between 1.0 and 1.5%.

popular. This system is now operating

successfully in many cities. Bulk vending Distribution in Non-Returnable

is well suited to Indian consumers since it Containers

allows the purchase of relatively small

quantities of milk, two times a day and use Plastic pouches: Most of the dairies in

of buyers’ own containers avoiding the cost cities of India have introduced packaging

and inconvenience of handling bottles or and distribution of milk through

pouches. The system ensures hygienic, polyethylene pouches. The plastic pouches

good quality milk at a price reflecting low are single-trip packages, very light in

overheads and low packaging costs. weight, and hence distribution costs are less

compared to glass bottles. Losses during

It is claimed that the capital cost of bulk pouch filling are less than bottle filling and

vending system is nearly 20% less than the less floor space is required for packing

bottling system and the operating and section and cold storage.

running cost less than 50%. The milk losses

are claimed to be between 0.50 and 0.65%. Bureau of Indian Standards prescribes

requirements and testing of polyethylene

pouches for the packing of pasteurized

Distribution in Bottles liquid milk in 1 litre and ½ litre capacities in

IS:11805-1986. According to this standard,

This was the most universally accepted

the pouches should be made from virgin

milk distribution system before the advent

polyethylene (LDPE, LLDPE, HDPE or EVA)

of single-serve containers. The bottling

for meeting the food grade requirements.

system is highly capital intensive — not

only the bottle filling and washing machi- Initially, LDPE film was used for milk

nes are costly, but the system requires larger packaging but now LLDPE is the preferred

operational areas, large store space, and fully choice. More recently, octene and butene-

automatic machines are difficult and based LLDPE are used due to the following

expensive to maintain while the manual factors:

systems require a large labour force.

i) Reduction in losses due to leakage.

Transport costs for distribution are high Average losses due to leakage vary from

PLASTICS IN FOOD PACKAGING

PACKAGING ASPECTS OF MILK & MILK BASED PRODUCTS 195

1-5% with LDPE film and 0.6% with Paperboard Cartons

LLDPE film.

The material cost for paper board cartons

ii) Reduction in the area of pouches to is very high so also the capital cost of filling

suitable limits by reducing the length of machines. The overall distribution cost for

pouches. This leads to saving of 3 pasteurized milk in carton is said to be more

pouches/kg and 1 pouch/kg for 0.5 and than 1½ times as compared to the bottles

and for sterilized milk aseptically packed, it

1.0 litre pouches respectively.

is more than twice. Since this precludes the

iii) Enhancement in yield (number of capture of major share of market, however,

pouches per kg) by down-gauging. It it can be used to meet the requirement of

specific market segment.

has been shown that by reducing the

thickness of film by one micron only, 1 Liquid milk is packed in carton systems

kg of film will give 9 half-litre pouches of Tetrapak, Tetrabrik and Purepak (Fig.

and 6 one-litre pouches more. 11.1). The equipment necessary to produce

tetrabrik is expensive to instal, but its

It has been shown that coloured cartons advantages include a PE-lining which is

(Purepack) and pigmented pouch (black) strong and does not leak, and a lower price

with light transmission of less than 1% in per unit of milk in running costs.

the visible spectrum were very effective in

The comparative distribution costs for

preventing light induced changes in milk

milk in bottles, pouches and bulk vending

(350-750 nm) whereas polyethylene jugs

systems are given in Table 11.1.

with 2% titanium dioxide were not very

effective.

The revised BIS Standard (2003) for

polyethylene pouches for packaging liquid

milk - specifications (2nd revision) indicates

that the material shall be made from virgin

polyethylene (LDPE, LLDPE or a blend

thereof) trim meeting the food grade

requirements. Coextruded 50:50 blend of

LDPE of melt flow index (MFI) 0.5 and octene

- LLDPE of MFI of 1.0 is the common film in

vogue.

The specification IS 11805 specifies the

thickness (85 µm for 1 litre and 75 µm for 0.5

litre pouch), yield strength (11.77 MPa and

8.33 MPa for the machine and transverse

directions), elongation, dart impact strength

and slip. It also specifies tests on leakage Fig. 11.1. Tetrapak, Tetrabrik

(drop) and ink adhesion. and Purepak cartons

PLASTICS IN FOOD PACKAGING

196 Chapter 11

Table 11.1. Comparative distribution costs for milk

Distribution cost (paise per litre)

Factor

Bottles Pouches Bulk vending

1. Annual running cost (Energy + Spares +

Storage + Labour + Admn. expenses) 11.9 7.6 5.4

2. Packaging material + Crates 10.5 25.5 -

3. Milk losses 5.0 7.0 2.5

4. Transport & Distribution 11.2 7.5 6.5

5. Retailer commission 10.0 10.0 10.0

6. Interest + depreciation on packing &

distribution equipment 5.4 3.0 4.5

Total cost 54.0 60.6 21.9

Sterilized Milk for traditional milk-based sweets are:

The ultra-high temperature treatment of l Protection against ingress of water

milk sterilization kills all vegetative cells vapour resulting in loss of texture,

hydrolytic rancidity, microbial growth,

and spores with very little effect on flavour

etc.

or loss of nutrients.

l Protection from deleterious reactions due

The milk is then filled in sterile contai-

to oxygen, both chemical, nutritional and

ners (for ex., Tetrabrik cartons) under aseptic microbiological.

conditions. Such cartons made of paper

board/aluminium foil/PE, in the absence l Avoidance of tainting from external

sources leading to development of off-

of ambient air provided best protection

odours.

against loss of ascorbic acid and vitamin B

(riboflavin and folic acid) and maintained l Good resistance towards exudation of

best organoleptic properties when stored oils and fats — grease-resistance.

upto 4 months at ambient temperature l Freedom from metallic and chemical

conditions. In the presence of air, the contaminations.

keeping quality was maintained upto 3 l Conformity to national and international

months. Sterilized milk when packed in specifications and standards.

ordinary plastic containers acquired

In the case of milk-based sweets, as in

unacceptable smell and taste.

the case of all food products, the relationship

TRADITIONAL MILK-BASED between the moisture content and the water

SWEETS activity is the prime factor indicating

chemical, physical and microbial intera-

In general, the requirement of a package ctions.

PLASTICS IN FOOD PACKAGING

PACKAGING ASPECTS OF MILK & MILK BASED PRODUCTS 197

It is not moisture content per se, but the cardamom 0.1% and packed in 75 µm LDPE

water activity which determines the spoilage film pouch had a shelf-life of more than 120

of foodstuffs. Spoilage in milk-based foods days at 30°C and 70% RH condition. The

is mainly due to proteolysis, lipolysis, changes in gulab jamun mix stored in four

oxidative reactions, texture and flavour types of flexible packages are presented in

changes and onset of microbial growth. Table 11.2.

Considerable amount of research work has

been carried out on these aspects in relation Foods with Intermediate Water

to water activity. The possibility of Activity

preservation effect of reduced water activity

in combination with other preservatives is Khoa or Mawa

gaining importance. This is essentially prepared by partial

From the packaging point of view, dehydration of milk under controlled

indigenous milk-based confections can be conditions. It forms an important base for

divided into three categories, those with low the preparation of indigenous milk sweets

water activity, intermediate water activity such as burfi, peda and jamun.

and high water activity and the packaging Studies were carried out on packaging

aspects will be considered on these lines. of khoa (500 g) in 5 types of pouches and

were stored at (a) 37°C, (b) 8°C and (c) -

Foods with Low Water Activity 20°C and analyzed for moisture, acidity,

These are foods having low moisture peroxide value, free fatty acid and also

content and equilibrating to 0.3 to 0.4 water sensory and microbiological qualities.:

activity at normal temperature. These i) Vegetable parchment paper

comprise ready mixes such as gulab jamun,

ii) MS DT cellophane/LDPE

kheer, ice-cream mix, malted milk foods and

mita chocolates. iii) High-density polyethylene

Ready gulab jamun mix consists of wheat iv) Paper/PE/Al.foil/PE

flour, skimmed milk powder, edible oil, ghee v) Paper/PE/0.02 mm. Al-foil/PE

and leavening agents. IS:12220 (1987)

specifies a maximum moisture content of Khoa samples packed in parchment and

8%, minimum fat of 12%, maximum HDPE were found satisfactory up to 5 days

carbohydrate of 60% and absence of at 37°C and good up to 14 days at 8°C. At

coliform and Staphylococcus. Packaging and -20°C condition, storage studies up to 75

marking specifications are that the ready days indicated that gulab jamun made from

gulab jamun mix shall be packed in flexible khoa were of good quality in all the packaging

food grade hermetically sealed pouches or materials.

in other sound moisture-proof containers. Hot filling (80-90°C) of khoa in tinplate

Gulab jamun mix consisting of roller-dried containers provided shelf-life up to 14 days

skim milk powder (4.5%), bleached wheat- at 37°C, while the use of laminates paper/

flour (maida) 25%, semolina 15%, butter fat foil/PE or poly cell provided 10 days storage

15%, baking powder 1.5% and ground life at 37°C and 60 days refrigerated

PLASTICS IN FOOD PACKAGING

198 Chapter 11

Table 11.2. Changes in organoleptic qualities of packed gulab

jamun mix at 30°C

Package Type Storage Penetration Texture Flavour Overall

period value acceptability

Initial - 148 25.6 32.3 91.6

LDPE / LLDPE 60 158 26.0 31.2 90.5

120 178 26.3 29.9 89.3

180 207 26.8 29.1 88.3

240 246 27.3 28.1 87.6

MXXT Cellophane 60 160 26.2 31.5 91.2

120 181 26.9 30.6 90.4

180 207 26.9 30.4 90.1

240 253 27.4 30.1 90.0

Paper / Foil / PE 60 175 26.4 31.7 91.1

120 190 26.9 31.21 90.7

180 220 27.0 30.8 89.9

240 272 27.5 29.6 89.1

MetPET / PE 60 175 26.4 31.6 91.2

120 186 27.0 31.5 91.4

180 218 27.0 29.8 88.5

240 269 27.3 28.3 86.9

condition. Four-ply structure of CPP/ aseptic precautions are taken during

LDPE/Al-foil/PE increased the shelf-life to packaging.

14 days at 30°C and 75 days in the cold

Antioxidants such as BHA and TBHQ

storage. The chemical quality changes in were found not effective as antimicrobial

packed khoa and stored at 4-5°C are shown agents in improving the shelf-life of khoa.

in Table1. 11.3.

Flexible packages can be exposed to Pedha

gamma-radiation for sterilization, prior to Pedha is the heat desiccated milk sweet

filling. Addition of 0.3% potassium sorbate prepared from khoa and sugar to provide

at the last stage of khoa making also improves the granular and hard texture and flavour.

shelf-life by additional 10 days, provided Since it is highly prone to the development

PLASTICS IN FOOD PACKAGING

PACKAGING ASPECTS OF MILK & MILK BASED PRODUCTS 199

Table 11.3. Chemical quality changes in packed khoa (4-5°C)

Packaging Storage Moisture Titrable FFA PV m.eqt/

material period content acidity, (%) kg fat

(days) (%) lactic acid

(%)

- 0 27.2 0.45 0.055 0.1

Paper (50 gsm) 20 27.1 0.49 0.074 0.1

Al.foil (0.02 mm) 40 27.0 0.54 0.089 0.1

LDPE (37 µm) 60 26.7 0.60 0.109 0.1

Paper (40 gsm) 20 27.0 0.51 0.080 0.1

Al.foil (0.015 mm) 40 26.9 0.57 0.099 0.1

LDPE (37 µm) 60 26.6 0.63 0.117 0.1

MST Cellophane 20 27.0 0.52 0.084 0.1

LDPE (37 µm) 40 26.8 0.58 0.105 0.1

60 26.5 0.64 0.123

Tinplate 20 27.1 0.55 0.090 0.1

40 27.0 0.60 0.110 0.1

60 26.9 0.67 0.130 0.1

of microorganisms, addition of preservatives activity of 0.84 at 27°C. Storage studies on

like potassium sorbate, nisin, and sodium/ 100 g pedha packed in 12 x 15 cm pouches

potassium bisulphite have been found made of the following were undertaken:

useful in extending the shelf-life. Two

i) 12 µm PET/9 µm foil/ 37um LDPE

different concentrations (0.02 and 0.05%) of

sorbic acid when added to buffalo milk ii) 12 µm PET/37 µm LDPE and

pedha was found to lower the enhance-ment

iii) 100 µm LLDPE/BA/PA/BA/EAA

of acidity, FFA, PV, proteolysis and inhibit

microbial growth. Pedha containing 0.02% The pouches under three treatments, (i)

sorbic acid extended the shelf-life up to 9 normal or with ambient air, (ii) vacuum

days at 30°C and 37 days at 7°C. At a and (iii) with free-oxygen absorber (FOA-

concentration of 0.05%, it was effective Ageless SS 100) have been stored under

against chemical and microbiological accelerated and normal storage conditions.

deterioration up to 55 days at 7°C. Samples were analyzed for head-space gas

analysis, moisture, titratable acidity and

Pedha, with an initial moisture content changes in taste, aroma, texture and mould

of 14% (as is) or 16.3% (dry wt.) had water growth.

PLASTICS IN FOOD PACKAGING

200 Chapter 11

It was found that aluminium foil based vi) PVDC coated cellophane/PE laminate

laminate provided a shelf-life of nearly 30 vii) Polycell inside + PE outside

days, while the composites based on PET or

PA provided protection up to nearly 22 days, viii) Paper/Al.foil/PE

even under high temperature and RH (38ºC, Burfi having an initial shelf-life of 6-8

90% RH) conditions, when vacuum packed days (due to mould infestation and surface

with respect to visible mould growth. drying), the addition of 0.15% sorbic acid

However, vacuum packaging could not be and humectants like liquid glucose would

recommended due to unacceptable changes. extend the shelf-life to nearly 50 days when

The corresponding shelf-life was more than packed in folding cartons. Product

42 days under the storage conditions when containing sorbic acid and packed with

packed with FOA. Inclusion of oxygen polycell inner and PE outside did not show

absorbent sachet extended the shelf-life mould growth and surface hardening. This

considerably. was acceptable even when stored for 90

days.

Burfi

Burfi packed in vegetable parchment

Milk burfi is the most popular milk-based paper and stored at 36°C had good texture

confection favoured for its taste and and flavour up to 15 days and that at 5ºC

nutritional value. The several varieties of remained acceptable up to 50 days with

burfi are mawa, fruit, chocolates, coconut, some loss of moisture. Burfi packed in

rawa depending on the ingredients used, tinplate container and stored at 5ºC was

but all are based on khoa and sugar. IS:5550- acceptable for more than 150 days.

specification (1970) for burfi has the

requirement of 15% maximum moisture, Chhana Butter-spread

12.5% minimum milk fat, acidity max. of Low-fat 60:40 butter and chhana spread

0.35% and specification for sucrose, lactose with or without addition of 0.1% sodium

and microbiological standards. benzoate and 0.1% potassium sorbate were

An optimum water activity of 0.70 is stored in polystyrene containers at 4°C and

recommended for storage of burfi. At higher 10°C. Storage at 4°C resulted in higher

water activity, it becomes too soft and moisture loss and the shelf-life was 15 days

susceptible to mould growth, while at low at both temperatures for control sample.

water activities, the product loses moisture Sensory evaluation revealed that addition

and the surface becomes dry and hard. of potassium sorbate increased the shelf-

Extensive studies have been carried out on life to 45 days at 10ºC and 60 days at 4°C

storage studies of milk burfi in the following and the use of sodium benzoate up to 60

flexible packaging materials. days at 10°C and 75 days at 9°C storage

temperature.

i) MSAT cellophane

ii) LDPE film Foods with High Water Activity

iii) HDPE film Rasogolla and gulab jamun are the major

iv) MSAT inside + HDPE outside milk sweets of high water activity while

others are paneer, channa, kulfi, sandesh and

v) Glassine/PE laminate curds.

PLASTICS IN FOOD PACKAGING

PACKAGING ASPECTS OF MILK & MILK BASED PRODUCTS 201

Rasogolla

Rasogolla (including canning) is pre-

pared in the following sequence:

Tinplate container of A 2½ size is the

conventional package which provides best-

before indication of 3 months from the date

of packing. Alternatives to this are chrome

steel (tin-free-steel) container with easy-

open-ends. These are claimed to be

economical and provide products with

suitable organoleptic quality.

Fig.11.2. Packages for high water activity

Another package which has good dairy products

potential is the thermoprocessable

(retortable) pouches made of laminates such

OTHER MILK BASED

as PA/CPP, PET/CPP and PET/foil/CPP. PRODUCTS

Also, solid PP containers with EVOH, where Kunda is a desiccated milk product made

see-through possibility exists can be tried by continuous heating of milk or high

for processing and packaging of rasogolla. moisture khoa and specific amount of sugar

which is very popular in the western region.

Sandesh The shelf-life studies on kunda has indicated

light brown product kept well for about 4

The effect of various packages such as

days at ambient temperature compared to

folding cartons, polystyrene and HDPE

about 12 days in case of dark brown kunda.

pouches, tinplate containers and nylon

The spoilage was observed to begin with

based pouches on the shelf life of soft grade

buffalo milk sandesh stored at 30°C/70%

visible mould growth. Vacuumization and

RH and 7°C/90% RH have been studied.

storing at low temperature (5-8°C) were

found to provide shelf-life of 3-4 months.

At both the storage conditions, maximum

chemical, microbiological and organoleptic Ghee

deterioration were found in the sandesh Traditionally, ghee is packed in tinplate

samples packed in paperboard carton, containers which are suitable for long term

followed by PS containers, HDPE pouches storage. Retail distribution in 200 ml to

and PA pouches. 1000 ml in economical and functional

At the high temperature/RH (38-40ºC/ flexible package is gaining acceptance,

90%) condition, the product in cartons and Storage studies in 200 ml units at accelerated

cans became unacceptable on 10th day with and normal (BIS) conditions in the following

respect to flavour, but the extent of materials have been carried out:

deterioration differed. At the low tempe- i) HDPE 85 µm

rature condition, the product remained

acceptable up to 30 days in cartons and 45 ii) Metallized PET/HDPE-LDPE (white

days in tinplate containers. opaque, 12.5 µm)

PLASTICS IN FOOD PACKAGING

202 Chapter 11

canned rasogolla, khoa, chhana, paneer, burfi,

chakka, shrikhand and dahi. Clauses on

packaging are also included in the

specifications.

All plastic materials, lacquers and other

components coming in direct contact with

dairy products have to conform to specific

regulations regarding actual transfer into

Fig. 11.3. Unit packages for Ghee them. Regarding adjuvants in packaging

iii) LLDPE/T/PA/T/EAA, (White materials, only those materials listed and

opaque), 95 µm within the specified limits should be used.

Global migration tests to be conducted

iv) HDPE/LLDPE (yellow), 100 µm depend on the type of product, i.e. aqueous,

v) HDPE/T/PA/T/EAA (yellow), 120 acidic and fatty/oily.

µm In conclusion, it can be said that milk-

based products involve different types of

It was found that with equilibrium

packaging and it is very important that

moisture content of 0.06 to 0.08%, the RH

proper selection of materials and

would be 20 to 32% with critical moisture

constructional features for packages is to be

content of 0.11% corresponding to 56% RH,

made so that the most appropriate new

at 27°C. Agmark and PFA specifications

materials, methods and machinery are

maxima are 0.3% and 0.5%, respectively.

employed. The packages should be

Chemical and sensory analyses of the functional and economical and highlight

packed ghee has indicated that PE alone is the unique characteristics of particular food

not suitable for long storage. Co-extruded products.

films based on polyamide and laminates

based on PET can be preferred as good BIBLIOGRAPHY

economical alternatives for longer shelf-life

Abhay Kumar, Rajorhia GS and Srinivasan,

of more than 120 days at 27°C or normal

MR (1975). Effect of modern packaging

distribution conditions.

materials on the keeping qualities of khoa.

Studies on the keeping quality of ghee in J Food Sci Technol, 12 (4): 172-177.

composite containers (body made of kraft/

Balasubrahmanyam N and Dhar S (1999).

Al-foil/PE) with metal ends have shown

Packaging and storage studies of ghee in

that it provides shelf-life of more than 90

flexible pouches. Indian J Dairy Sci, 52

days even at higher temperature and RH

(2): 82-89.

conditions.

Ghosh BC, Rajohria GS and Dharampal

CONCLUSIONS (1984). Formulation and storage studies

of gulab jamun mix powder. Indian J

Bureau of Indian Standards (BIS) has

Dairy Sci, 37(4): 362-368.

formulated specifications for a number of

indigenous milk-based sweets such as Goyal GK and Srinivasan MR (1989). Effect

PLASTICS IN FOOD PACKAGING

PACKAGING ASPECTS OF MILK & MILK BASED PRODUCTS 203

of packaging on the chemical quality of Ramanna BR, Bhat KK, Mahadeviah B,

khoa during storage. Indian J Dairy Sci, Dwarakanath CT and Potty VH (1983).

42(2): 165-170. Investigation on large scale preparation

and preview of milk burfi, J Food Sci

Indiramma AR, Vijayalakshmi NS and

Technol, 20 (2): 67-71.

Kumar KR (2002). Extension of shelf-life

of pedha by suitable packaging means.

Satish Kulkarni, Ghosh BC, Balasubraman-

Popular Plastics & Pack, 47(5): 57-62.

yam BV and Jaya Rao K (2001). Kunda-

Kumar G and Srinivasan MR (1983). desiccated dairy product of Northern

Influence of packaging materials and Karnataka. Indian Dairyman, 53(11): 65-

storage on the microbiological quality of 67.

chhana. Indian J Dairy Sci, 36(4):427-

429. Sen DC and Rajorhia GS (1990). Suitabi-

lity of some packaging materials for

Kumar KR (1997). Packaging materials packaging sandesh. J Food Sci Technol,

evaluation and research observations 27(3): 156-161.

of dairy product. Packaging Technol,

6(6): 22-24, 68-70. Sharma VP, Zariwala IT and Agarwal SR

Kumar KR and Indiramma AR (1998). (1978). Preservation aspects of khoa in

Assessment of composite container for relation to use of radio-sterilized flexible

packaging ghee. Packaging Technol, packages. J Food Sci Technol, 15(4):158-

8(3):14-16. 160.

Kumar KR and Indiramma AR (2000). Vijayalakshmi NS, Asha MR, Prema

Packaging aspects of dairy products. Vishwanath, Indiramma, AR and

Intelpack, 6(1): 6-10. Kumar KR (2003). Storage characteri-

stics of almond-milk powder mix

Patil GR (2002). Present status of traditional

packaged in flexible and rigid contai-

dairy products, Indian Dairyman, 54(10):

ners. J Food Sci Technol, 40(3): 280-284.

35-46.

PLASTICS IN FOOD PACKAGING

204 Chapter 11

PLASTICS IN FOOD PACKAGING

S-ar putea să vă placă și

- 11-Final - PMD Khoa PDFDocument0 pagini11-Final - PMD Khoa PDFProf C.S.PurushothamanÎncă nu există evaluări

- PackingDocument8 paginiPackingCẩm Tú Phan ThịÎncă nu există evaluări

- 5 Packaging of Milk and Milk ProductsDocument30 pagini5 Packaging of Milk and Milk ProductsMonty KushwahaÎncă nu există evaluări

- Unit 15 Packaging, Storage, Quality Attributes and Common Defects of Dried MilksDocument17 paginiUnit 15 Packaging, Storage, Quality Attributes and Common Defects of Dried MilksRonak RawatÎncă nu există evaluări

- Packaging - Milk: The Reason Behind The Change in Packaging Can Be Read AsDocument19 paginiPackaging - Milk: The Reason Behind The Change in Packaging Can Be Read Ashema varshiniÎncă nu există evaluări

- 9 Packaging - Materials and ProcessDocument6 pagini9 Packaging - Materials and ProcessMonty KushwahaÎncă nu există evaluări

- Lesson 1Document7 paginiLesson 1Tanmay ParekhÎncă nu există evaluări

- Lesson 12. Filling and Packaging of MilkDocument9 paginiLesson 12. Filling and Packaging of Milkdevdixit1915Încă nu există evaluări

- Lesson 2Document9 paginiLesson 2Tanmay ParekhÎncă nu există evaluări

- Milk Proteins For Edible Films and Coatings PDFDocument14 paginiMilk Proteins For Edible Films and Coatings PDFNina Vania PanjaitanÎncă nu există evaluări

- Paper Bottles - Potential To Replace Conventional Packaging For Liquid ProductsDocument27 paginiPaper Bottles - Potential To Replace Conventional Packaging For Liquid ProductsCarinna Saldaña - PierardÎncă nu există evaluări

- Whey Protein Layer Applied On Biodegradable Packaging Film To Improve Barrier Properties While Maintaining BiodegradabilityDocument7 paginiWhey Protein Layer Applied On Biodegradable Packaging Film To Improve Barrier Properties While Maintaining Biodegradabilityfahrullah unhasÎncă nu există evaluări

- Yogurt PRCSGDocument13 paginiYogurt PRCSGGurnoor KaurÎncă nu există evaluări

- Modes of Packaging: B.J.B Junior CollegeDocument15 paginiModes of Packaging: B.J.B Junior CollegeAbhishek MahapatraÎncă nu există evaluări

- Packaging of PaneerDocument13 paginiPackaging of PaneeramohuidromÎncă nu există evaluări

- Presentation On Dairy Industry: Presented byDocument28 paginiPresentation On Dairy Industry: Presented byHamXa CHÎncă nu există evaluări

- Green Polymers - GautamDocument26 paginiGreen Polymers - Gautamgautamahuja100% (1)

- Research 7Document13 paginiResearch 7NohaÎncă nu există evaluări

- Paper No.: 12 Paper Title: Food Packaging Technology Module-19: Packaging of Dairy Products - IIDocument8 paginiPaper No.: 12 Paper Title: Food Packaging Technology Module-19: Packaging of Dairy Products - IIM SÎncă nu există evaluări

- Chem ProjectDocument2 paginiChem Projecttetoradwan1212Încă nu există evaluări

- Packaging, Transport, Storage, and Distribution Nikita SinghDocument23 paginiPackaging, Transport, Storage, and Distribution Nikita SinghNikki SinghÎncă nu există evaluări

- Integration Paper Abou1Document1 paginăIntegration Paper Abou1yna calneaÎncă nu există evaluări

- SFM Assignment (19TE48)Document4 paginiSFM Assignment (19TE48)Rameen SiddiquiÎncă nu există evaluări

- Packaging Requirements of Milk: Nimisha K Third Semester MSC FST KufosDocument31 paginiPackaging Requirements of Milk: Nimisha K Third Semester MSC FST Kufoshema varshiniÎncă nu există evaluări

- Ali H (2018)Document14 paginiAli H (2018)SRIDEVI CHANDRA SÎncă nu există evaluări

- PATENT PAPER Plant Based MilkDocument36 paginiPATENT PAPER Plant Based MilkCARMELA LOLONGÎncă nu există evaluări

- Comercial Sterilization of Milk ProductsDocument5 paginiComercial Sterilization of Milk ProductsAndres MarinÎncă nu există evaluări

- Dairy Waste N ManagementDocument11 paginiDairy Waste N ManagementMudit MisraÎncă nu există evaluări

- Packaging, Storage and Common Defects in Condensed MilksDocument14 paginiPackaging, Storage and Common Defects in Condensed MilksRonak Rawat100% (1)

- Development of EcoDocument9 paginiDevelopment of EcoARJYA ROYÎncă nu există evaluări

- By Products TechnologyDocument234 paginiBy Products TechnologyTara NahÎncă nu există evaluări

- Tetra BrickDocument29 paginiTetra BrickAzeem AbbasÎncă nu există evaluări

- Shubham Rami: Department of Dairy Technology, Parul University, Vadodara Academic Year 2020-21Document7 paginiShubham Rami: Department of Dairy Technology, Parul University, Vadodara Academic Year 2020-21SMITKUMAR PATELÎncă nu există evaluări

- 2020 1-S2.0-S0141813019383813-MainDocument10 pagini2020 1-S2.0-S0141813019383813-MainwrathgodÎncă nu există evaluări

- CH 5 - Lactic Acid FermentationDocument13 paginiCH 5 - Lactic Acid FermentationPrima Fitria HillmanÎncă nu există evaluări

- 22 SnackfoodDocument13 pagini22 SnackfoodMoshmi MazumdarÎncă nu există evaluări

- Quantification of Whole Ultra High Temperature UHT Milk Waste As ADocument8 paginiQuantification of Whole Ultra High Temperature UHT Milk Waste As AAncuţa-IonelaPartinÎncă nu există evaluări

- Bioplastics in Food Packaging PDFDocument13 paginiBioplastics in Food Packaging PDFcesamavÎncă nu există evaluări

- Whey, Waste or ValueDocument5 paginiWhey, Waste or Valuemeyajoh806Încă nu există evaluări

- Plastic Packaging For Milk & Other Food Products - Dr. R S Sodhi - AmulDocument41 paginiPlastic Packaging For Milk & Other Food Products - Dr. R S Sodhi - AmulAsif Iqbal KhanÎncă nu există evaluări

- Packaging, Storage, Common Defects, Shelf Life and PreservationDocument13 paginiPackaging, Storage, Common Defects, Shelf Life and PreservationRonak RawatÎncă nu există evaluări

- Waste Water Disposal and Pollution Control in DairyDocument14 paginiWaste Water Disposal and Pollution Control in Dairy19 CH 056 Vaishali Vivek100% (1)

- Smitkumar Patel: Department of Dairy Technology, Parul University, VadodaraDocument4 paginiSmitkumar Patel: Department of Dairy Technology, Parul University, VadodaraSMITKUMAR PATELÎncă nu există evaluări

- Not To Be Confused WithDocument3 paginiNot To Be Confused Withtsf1903Încă nu există evaluări

- Biodegrdable AssignmentDocument5 paginiBiodegrdable AssignmentSummayya ShafiqueÎncă nu există evaluări

- Processors Look For Sustainable Packages For Dairy Foods, BeveragesDocument3 paginiProcessors Look For Sustainable Packages For Dairy Foods, BeveragesDivya PaidipatiÎncă nu există evaluări

- JurnalDocument23 paginiJurnalfirtaÎncă nu există evaluări

- A Review On Mechanization of Traditional Dairy Products: Gopika Talwar and Sandeeppal Kaur BrarDocument18 paginiA Review On Mechanization of Traditional Dairy Products: Gopika Talwar and Sandeeppal Kaur BrarDipu AhirÎncă nu există evaluări

- Effect of Spray and Freeze Drying On Physico-Chemical, Functional, Moisture Sorption and Morphological Characteristics of Camel Milk PowderDocument10 paginiEffect of Spray and Freeze Drying On Physico-Chemical, Functional, Moisture Sorption and Morphological Characteristics of Camel Milk PowderCsaba AndrásÎncă nu există evaluări

- Proteolytic Development and Volatile Compounds Profile of Domiati Cheese Under Modified Atmosphere PackagingDocument18 paginiProteolytic Development and Volatile Compounds Profile of Domiati Cheese Under Modified Atmosphere PackagingCsaba AndrásÎncă nu există evaluări

- Advances in Research and Development of Bioplastic For Food PackagingDocument49 paginiAdvances in Research and Development of Bioplastic For Food PackagingDCPÎncă nu există evaluări

- Coatings: Cactus Mucilage For Food Packaging ApplicationsDocument19 paginiCoatings: Cactus Mucilage For Food Packaging ApplicationsKatherin Maza GomezÎncă nu există evaluări

- 10 1 1 392 7168Document3 pagini10 1 1 392 7168ashish.walleÎncă nu există evaluări

- SanJoseLiu PDFDocument13 paginiSanJoseLiu PDFghost2011Încă nu există evaluări

- Advancements in Manufacture of Paneer: Darji Kinjal, H. G. Patel and A. J. GokhaleDocument6 paginiAdvancements in Manufacture of Paneer: Darji Kinjal, H. G. Patel and A. J. GokhaleAshokkumar ManickamÎncă nu există evaluări

- STRCH Based ApplicationsDocument10 paginiSTRCH Based ApplicationsdhirenÎncă nu există evaluări

- Unit 14Document27 paginiUnit 14nitishÎncă nu există evaluări

- Pollution Prevention Control in Dairy IndustryDocument7 paginiPollution Prevention Control in Dairy Industryyusuf anwerÎncă nu există evaluări

- Advanced Packaging Technologies for Fruits and VegetablesDe la EverandAdvanced Packaging Technologies for Fruits and VegetablesÎncă nu există evaluări

- Advanced Packaging Technologies For Fruits and Vegetables: For Fruits and VegetablesDe la EverandAdvanced Packaging Technologies For Fruits and Vegetables: For Fruits and VegetablesÎncă nu există evaluări

- Gloves HemaDocument4 paginiGloves Hemahema varshiniÎncă nu există evaluări

- Gloves - HemaDocument13 paginiGloves - Hemahema varshiniÎncă nu există evaluări

- HLP Boards and BriefDocument6 paginiHLP Boards and Briefhema varshiniÎncă nu există evaluări

- What Is A Touring BicycleDocument12 paginiWhat Is A Touring Bicyclehema varshiniÎncă nu există evaluări

- Leather Bicycle AccessoriesDocument25 paginiLeather Bicycle Accessorieshema varshiniÎncă nu există evaluări

- 2019 Consumer Types Webinar - Final - RGDocument44 pagini2019 Consumer Types Webinar - Final - RGhema varshiniÎncă nu există evaluări

- What Is A Touring BicycleDocument12 paginiWhat Is A Touring Bicyclehema varshiniÎncă nu există evaluări

- What Is A Touring BicycleDocument12 paginiWhat Is A Touring Bicyclehema varshiniÎncă nu există evaluări

- Packaging Boards and BriefDocument5 paginiPackaging Boards and Briefhema varshiniÎncă nu există evaluări

- A2 MILK - Packaging ResearchDocument2 paginiA2 MILK - Packaging Researchhema varshiniÎncă nu există evaluări

- DchitraDocument20 paginiDchitrahema varshiniÎncă nu există evaluări

- European BrandDocument6 paginiEuropean Brandhema varshiniÎncă nu există evaluări

- 1Document2 pagini1hema varshiniÎncă nu există evaluări

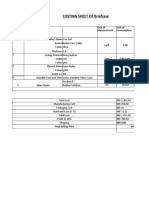

- COSTING SHEET OF Desktop Article: S.No. Details Unit of Measurement Unit of Consumption Leather: NameDocument2 paginiCOSTING SHEET OF Desktop Article: S.No. Details Unit of Measurement Unit of Consumption Leather: Namehema varshiniÎncă nu există evaluări

- Packaging Requirements of Milk: Nimisha K Third Semester MSC FST KufosDocument31 paginiPackaging Requirements of Milk: Nimisha K Third Semester MSC FST Kufoshema varshiniÎncă nu există evaluări

- Product Research - Bicycle: BackgroundDocument5 paginiProduct Research - Bicycle: Backgroundhema varshiniÎncă nu există evaluări

- Costing Sheet of Jewellery Box: S.No. Details Unit of Measurement Unit of Consumption Leather: NameDocument2 paginiCosting Sheet of Jewellery Box: S.No. Details Unit of Measurement Unit of Consumption Leather: Namehema varshiniÎncă nu există evaluări

- Costing Sheet of Photo FrameDocument1 paginăCosting Sheet of Photo Framehema varshiniÎncă nu există evaluări

- Costing Breif CaseDocument2 paginiCosting Breif Casehema varshiniÎncă nu există evaluări

- Costing Sheet of Photo Frame: S.No. Details Unit of Measurement Unit of Consumption Leather: NameDocument2 paginiCosting Sheet of Photo Frame: S.No. Details Unit of Measurement Unit of Consumption Leather: Namehema varshiniÎncă nu există evaluări

- Costing Sheet of BriefcaseDocument1 paginăCosting Sheet of Briefcasehema varshiniÎncă nu există evaluări

- JB HemaDocument2 paginiJB Hemahema varshiniÎncă nu există evaluări

- Leather Bicycle AccessoriesDocument25 paginiLeather Bicycle Accessorieshema varshiniÎncă nu există evaluări

- Leather Bicycle AccessoriesDocument25 paginiLeather Bicycle Accessorieshema varshiniÎncă nu există evaluări

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDocument13 paginiUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanÎncă nu există evaluări

- Preliminary Examination The Contemporary WorldDocument2 paginiPreliminary Examination The Contemporary WorldJane M100% (1)

- Understanding Culture Society, and PoliticsDocument3 paginiUnderstanding Culture Society, and PoliticsVanito SwabeÎncă nu există evaluări

- IFSSO Newsletter Jul-Sep 2010Document2 paginiIFSSO Newsletter Jul-Sep 2010rjotaduranÎncă nu există evaluări

- GSE v. Dow - AppendixDocument192 paginiGSE v. Dow - AppendixEquality Case FilesÎncă nu există evaluări

- Salwico CS4000 Fire Detection System: Consilium Marine ABDocument38 paginiSalwico CS4000 Fire Detection System: Consilium Marine ABJexean SañoÎncă nu există evaluări

- Motion To Dismiss Guidry Trademark Infringement ClaimDocument23 paginiMotion To Dismiss Guidry Trademark Infringement ClaimDaniel BallardÎncă nu există evaluări

- Team 6 - Journal Article - FinalDocument8 paginiTeam 6 - Journal Article - FinalAngela Christine DensingÎncă nu există evaluări

- Beng (Hons) Telecommunications: Cohort: Btel/10B/Ft & Btel/09/FtDocument9 paginiBeng (Hons) Telecommunications: Cohort: Btel/10B/Ft & Btel/09/FtMarcelo BaptistaÎncă nu există evaluări

- Products ListDocument11 paginiProducts ListPorag AhmedÎncă nu există evaluări

- NCP - DMDocument4 paginiNCP - DMMonica Garcia88% (8)

- B.e.eeeDocument76 paginiB.e.eeeGOPINATH.MÎncă nu există evaluări

- Case Study in Architectural Structures: A-7E Avionics System - ADocument36 paginiCase Study in Architectural Structures: A-7E Avionics System - Ajckz8Încă nu există evaluări

- Nuttall Gear CatalogDocument275 paginiNuttall Gear Catalogjose huertasÎncă nu există evaluări

- Preblending of Raw Materia1Document26 paginiPreblending of Raw Materia1Mohammed Abdo100% (1)

- Multibody Dynamics Modeling and System Identification For A Quarter-Car Test Rig With McPherson Strut Suspension PDFDocument122 paginiMultibody Dynamics Modeling and System Identification For A Quarter-Car Test Rig With McPherson Strut Suspension PDFnecromareÎncă nu există evaluări

- A Tall Order - Cooling Dubai's Burj Khalifa: FeatureDocument2 paginiA Tall Order - Cooling Dubai's Burj Khalifa: FeatureMohsin KhanÎncă nu există evaluări

- Crusader Castle Al-Karak Jordan Levant Pagan Fulk, King of Jerusalem MoabDocument3 paginiCrusader Castle Al-Karak Jordan Levant Pagan Fulk, King of Jerusalem MoabErika CalistroÎncă nu există evaluări

- Atoll 1400Document2 paginiAtoll 1400David M. SeoaneÎncă nu există evaluări

- NCDC-2 Physical Health Inventory Form A4Document6 paginiNCDC-2 Physical Health Inventory Form A4knock medinaÎncă nu există evaluări

- 2012 Conference NewsfgfghsfghsfghDocument3 pagini2012 Conference NewsfgfghsfghsfghabdÎncă nu există evaluări

- Science Grade 10 (Exam Prep)Document6 paginiScience Grade 10 (Exam Prep)Venice Solver100% (3)

- Subject: PSCP (15-10-19) : Syllabus ContentDocument4 paginiSubject: PSCP (15-10-19) : Syllabus ContentNikunjBhattÎncă nu există evaluări

- Full Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFDocument42 paginiFull Download Ebook PDF Introductory Econometrics A Modern Approach 7th Edition by Jeffrey PDFtimothy.mees27497% (39)

- EPA Section 608 Type I Open Book ManualDocument148 paginiEPA Section 608 Type I Open Book ManualMehdi AbbasÎncă nu există evaluări

- Teal Motor Co. Vs CFIDocument6 paginiTeal Motor Co. Vs CFIJL A H-DimaculanganÎncă nu există evaluări

- Voice Over Script For Pilot TestingDocument2 paginiVoice Over Script For Pilot TestingRichelle Anne Tecson ApitanÎncă nu există evaluări

- State Farm Claims: PO Box 52250 Phoenix AZ 85072-2250Document2 paginiState Farm Claims: PO Box 52250 Phoenix AZ 85072-2250georgia ann polley-yatesÎncă nu există evaluări

- Aqa Ms Ss1a W QP Jun13Document20 paginiAqa Ms Ss1a W QP Jun13prsara1975Încă nu există evaluări

- Context in TranslationDocument23 paginiContext in TranslationRaluca FloreaÎncă nu există evaluări