Documente Academic

Documente Profesional

Documente Cultură

THQ Temperaturecontrollers Manual Rev B e

Încărcat de

Bernardo RatiaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

THQ Temperaturecontrollers Manual Rev B e

Încărcat de

Bernardo RatiaDrepturi de autor:

Formate disponibile

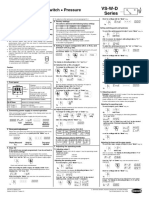

STANDARD CONFIGURATION VIEWING AND SETTING OF THE 1st SET POINT (QS-ES PROCESS VALUE)

st 1st level SET SET VALUE

1 configuration level

Exit from every

Settings: 1st point.=0 °C; 2nd point.=10 °C. To view the set point in the single display version, depress the SET key. To point of the program PROG (PROG depressed for more than 2 seconds)

Autotuning: ATOF = not active. modify the set point act directly on the UP/DOWN keys, the new value is

nd

1st point action: automatic Pidd max. action. updated automatically when the indication UPDT appears or the SET key is 2 level A L 2 1 2nd point code - (value follows).

pressed. By keeping the UP and DOWN keys depressed, the value will 2nd point setting value in °C/°F.

PID values: P=20 °C; I=120 sec.; D=30 sec. ALxx: -999 … +999 relative to 1st point.

1/16 DIN MICROPROCESSOR TEMPERATURE CONTROLLER Cycle time: 20 s. relay vers.;12 s. transistor vers. change at first slowly and then quickly. During the setting operations, the 1 0 FPxx: independent over full scale.

Adt function: Adt0 = not active. regulation continues with the last stored value. The setting is locked if the (see note A)

QS/QD SERIES 2st point action.: AL21 = alarm minimum action. option LOC1 is selected and the LED LOCK is lit up. PROG

- sw release 2.00 - Sensor: tc-J = thermocouple type J. VIEWING AND SETTING OF THE 2nd SET POINT

Scale and unity: -50 ... +760 °C, without digital filter. nd rd

2 and 3 configuration levels (see the diagram on the right) A t O F AtOf: autotuning not active.

INSTRUCTION MANUAL Correction: 0,0 °C. nd rd

To enter the 2 and 3 configuration levels, keep the PROG key depressed AtOn: autotuning active.

LFA function: LFA0 = not active. for more than 2 seconds. To change the values or the selections, use the E n d 2

CONTROL PANEL LOCK level: LOC3 = levels 1 and 2 free, level 3 locked. End of the second configuration level.

UP/DOWN keys. To confirm and continue the configuration, depress the

PROG key; to confirm and exit, depress the SET key. At the end of each level PROG (PROG depressed for less than 2 seconds)

CONNECTIONS [End2] or [End3], you can repeat it depressing the PROG key for less than 2

1st point output PROG (PROG depressed for more than 2 seconds)

ON LED

process value seconds or you can change the level depressing the PROG key for more than

display TRANSITOR OUTPUT RELAY OUTPUT 2 seconds. During the program scrolling the regulation continues, but it stops Pidd: 1st point PID max. action.

3rd level Pidr: 1st point PID min. action.

when a modification occurs. The setting exits automatically if no key is P i d d

active LOCK set value OnFd: 1st point on/off max. action.

function LED MAIN OUT POWER MAIN OUT POWER

display

SUPPLY 250 Vac 5A max

depressed within 30 seconds. OnFr:1st point on/off min. action.

SUPPLY

RESISTIVE LOAD

Load

decreasing PROGRAMMING NOTES PROG H 1. 0 H: on/off hysteresis

programming DOWN key

PROG key ± 0.1 … ± 99.9 °C/°F

A) in case of second point with dead zone, the indication [2 LO] will appear followed by

increasing PROG

UP key + - the lower limit value, then [2 HI] followed by the higher limit value; the autotuning

setting SET P 2 0 P: proportional band 1 … 999 °C/°F.

key 12 VDC 20 mA selection will appear only in case of PID control action.

B) in case of relay 1st point output, a minimum cycle time of 20 seconds [t 20] is

process value PROG

display recommended.

C) adaptative function to improve the response to frequent or fast variations of the

ALARM OUT ALARM OUT i 1 2 0

250 Vac 3A max 250 Vac 3A max load, i.e. start and stop process. i: integrative time 0 … 960 sec.

deviation 2nd point output RESISTIVE LOAD

LED bar ON LED

RESISTIVE LOAD D) settings not included in the sensor scale or in the setting limits, are automatically

corrected with the nearest threshold limit value. PROG

active autotuning

blinking LED E) in case of Fahrenheit degrees selection, please cover the °C symbol on the front

Power supply input: d 3 0

panel with the label °F which is supplied with the controller. d: derivative time 0 … 240 sec.

avoid to supply the temperature controller with loaded lines and avoid

electronic block

installing near electric motors or other sources of electrical disturbance. PROG

extraction trigger CODE alarm CODE fixed point 2ND POINT CONTROL ACTION

Resistance thermometer input:

AL20 FP20 OUTPUT BLOCKED WITH RELAY OFF

ensure all conductors used to attach the resistance thermometer are alike t 1 2

AL21 FP21 MINIMUM ACTION t: cycle time 1 … 120 sec.

TECHNICAL DATA and with a resistance less than 4 ohm/each; when using 2 wire resistance

AL22 FP22 MAXIMUM ACTION (see note B)

thermometer link terminals 2 and 3. AL23 FP23 DEAD ZONE ON PROG

Power supply: version 12 … 24 Vdc/Vac ± 10%, 50/60 Hz; Thermocouple input: AL24 FP24 DEAD ZONE OFF

or version 80 … 240 Vac ± 10%, 50/60 Hz. connect the sensor using the correct compensated extension cable for the AL25 FP25 MINIMUM ACTION WITH STAND-BY A d t 0

Adt0:Adaptative function not active.

Adt1: Adaptative function active.

Power consumption: 5VA max. utilized thermocouple. AL26 FP26 MAXIMUM ACTION WITH STAND-BY (see note C)

Sensor input: thermocouples type J, K, E, T, R, S, L; with Relay output: AL27 FP27 DEAD ZONE ON WITH STAND-BY PROG

reference junction compensation; RTD Pt100 /0 in case of connected inductive loads, the maximum current permitted through AL28 FP28 DEAD ZONE OFF WITH STAND-BY

°C according to standard DIN43760; with 2 or 3 the contacts decreases in relation to the power factor. ALxx/FPxx: 2nd point control

In this area the relay contact is closed. A L 2 1 action.(see Table 1 on the left)

wires connection. Transistor output: In this area the relay contact is closed when the alarm set-point or fixed point

Measurement precision *: RTD ± 0.3% fs, TC ± 0.4% fs, ±1 digit; when the output is high, LED ON1 lights, the terminals 7 (+) and 8 (-) have a is passed for the second time. PROG

(tc-R, tc-S ± 1% fs from 0 to 200°C) rating of 12 Vdc 20 mA, protected and suitable to drive a Solid State Relay

(SSR), recommended in case of high currents or frequent switching. Table 1

temperature drift 0.01% fs/°C of Tamb. tc-x/rt-x: input sensor.

t c J

1st point control action: automatic direct or reverse, ON/OFF or PID with (see Table 2 on the left and note D)

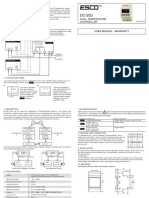

autotuning. DIMENSIONS AND INSTALLATION CODE SENSOR °C SCALE °F SCALE

PROG

1st point output: relay version SPDT 250 Vac, 5 A on resistive rt l RTD Pt100 ohm/0°C int. -150 ... 450 -200 ... 850 U°Cn: Celsius degrees, without digital filtering.

load; or transistor version with 12 Vdc ± 20%, 20 118 rt d RTD Pt100 ohm/0°C dec. -99.9 ... 450.0 -99.9 ... 850.0 U°Cd: Celsius degrees, with digital filtering.

tc S TC Pt10%Rh-Pt, type S 0 ... 1700 30 ... 3000 U C n U°Fn: Fahrenheit degrees, without digital filtering.

mA protected against short circuit.

tc r TC Pt13%Rh-Pt, type R 0 ... 1700 30 ... 3000 U°Fd: Fahrenheit degrees, with digital filtering.

2nd point control action: ON/OFF with hysteresis ± 0.2 °C, direct or 7.8 100.2 10 48 (see note E)

PROG

reverse, dead zone on or off, stand-by option; as tc t TC Cu-CuNi, type T 100 ... 400 -150 ... 750

alarm or fixed point. tc E TC NiCr-CuNi, type E 0 ... 600 0 ... 1100

tc C TC NiCr-NiAl, type K -100 ... 1250 -150 ... 2300 L S P

2nd point output: relay SPST 250 Vac, 3 A on resistive load. QS SERIES

Lower set point code - value follows.

Refresh time: input, output and indications every 500 ms. tc J TC Fe-Cuni, type J -50 ... 760 -50 ... 1400

tc L TC Fe-Cuni, type L -50 ... 760 -50 ... 1400 - 5 0

Data retention: non volatile memory type EEPROM. 1st point setting lower limit.

48

Insulation resistance: 20 M min. with 500 Vdc. °C Table 2 (see note D)

PROG

Operating temperature: -10 … +55 °C. -10 -5 0 +5 +10

Storage temperature: -20 … +65 °C.

ERROR AND MESSAGGES H S P

Humidity: 35 … 85% rH non condensing.

Vibration resistance: 0.35 mm amplitude, 10…55 Hz frequency for Higher set point code - value follows.

mm UnFL Underflow, indication below the sensor range. Short circuit of the sensor

every axis (EN60068-2-6) 7 6 0

RTD PT100. 1st point setting higher limit.

Shock resistance: 18 ms (30 G) for every axis (EN60068-2-27) (see note D)

Housing: ABS Panel cut-out: 45.5x45.5 mm. OvFL Overflow, indication over the sensor range. Breaking of the sensor TC or PROG

RTD PT100 or interruption of the connection.

Mechanical protection: IP50 front panel, IP20 case, IP00 contacts Panel thickness (suggested): 1 … 4 mm.

Connection leads: screw terminals for cabled up to 2,5 mm². 8888 Au...-test, if the message remains fixed the controller must be repaired. 0. 0

Dimensions: 1/16 DIN; 48 x 48 x 118 mm. Insert the controller in the panel cut out and mount the fastening spring from Correction -99.9 … 99.9 °C/°F.

Weight: 175 g. the back pushing it to the panel until the dog clutch locks; to remove the FAIL General failure; the controller must be repaired. PROG

fastening spring, unlock the dog clutch using a screwdriver.

* Radiated, radio-frequency electromagnetic field (see ENV 50140), or conducted LFA0: loop fault alert not active.

L F A 0 LFA1: LFA indication active.

disturbances induced by radio-frequency fields (see ENV 50141), can be the cause of LFA1 LFA: DETECTION OF FAULTS IN THE REGULATION LOOP

Loop Fault Alert: with the 1st point output 100% ON state the measured LFA2: LFA indication active with 1st point OFF in

process value variations in any case not higher than ± 2 % fs. case of loop fault detection.

temperature is not changed according ... the control action within the PROG

LFA2 s...red integral time; a fault in the regulation loop is possible: wrong

configuration, lack of power or breaking of the heater or the cooler,

thermocouple in short circuit or with reversed polarity, etc. ... reset the LFA function, L O C 3 FREE: levels 1, 2, 3 free.

DECLARATION OF CONFORMITY WARRANTY

please modify the configuration or the set-point, or switch off and then on again the LOC3: levels 1 and 2 free, level 3 locked.

DATALOGIC AUTOMATION warrants its products to be free from defects.

We DATALOGIC AUTOMATION declare under our sole responsibility that these products DATALOGIC AUTOMATION will repair or replace, free of charge, any product found to be defective temperature controller. LOC2: level 1 free, levels 2 and 3 locked.

PROG

are conform to the 2004/108/CE Directives and successive amendments. during the warranty period of 36 months from the manufacturing date. LOC1: levels 1, 2, 3 locked.

The function LFA is not active in the following cases: with output lower than 100% ON,

This warranty does not cover damage or liability deriving from the improper application of with integral time at zero, during the au...tuning, in manual position.

DATALOGIC AUTOMATION products. E n d 3 End of the third configuration level.

DATALOGIC AUTOMATION NOTE: In case of OvFL, UnFL, 8888, FAIL, LFA2, the first point output is turned off.

Via Lavino 265 - 40050 Monte S.Pietro - Bologna – Italy PROG (PROG depressed for less than 2 seconds)

Tel: +39 051 6765611 - Fax: +39 051 6759324

www.automation.datalogic.com e-mail:info.automation@datalogic.com PROG (PROG depressed for more than 2 seconds)

DATALOGIC AUTOMATION cares for the environment: 100% recycled paper.

DATALOGIC AUTOMATION reserves the right to make modifications and improvements without prior notification.

826000942 Rev. B

S-ar putea să vă placă și

- Microelectronic Systems N2 Checkbook: The Checkbook SeriesDe la EverandMicroelectronic Systems N2 Checkbook: The Checkbook SeriesÎncă nu există evaluări

- The 2points Temperaturecontrollers Manual Rev B EngDocument1 paginăThe 2points Temperaturecontrollers Manual Rev B EngyulfreÎncă nu există evaluări

- UsermanualREKA3 3Document8 paginiUsermanualREKA3 3David Lemos Sanchez100% (1)

- Operating Instructions: Terminal Connections: SpecificationsDocument2 paginiOperating Instructions: Terminal Connections: Specificationsgillang1Încă nu există evaluări

- Digital Temperatyre ControllerDocument4 paginiDigital Temperatyre ControllerMohd SanaullahÎncă nu există evaluări

- Cooling Heating: 6. General Description. 6.1. Adjustment - 3. Outputs Carrying CapacityDocument1 paginăCooling Heating: 6. General Description. 6.1. Adjustment - 3. Outputs Carrying CapacityCARLOSÎncă nu există evaluări

- Temperature Controller Catalog - EngDocument9 paginiTemperature Controller Catalog - EngJuan Gervacio OrtegaÎncă nu există evaluări

- Mc-2 Series Operation Manual: Maxthermo - Gitta Group CorpDocument24 paginiMc-2 Series Operation Manual: Maxthermo - Gitta Group CorpRobin CruzÎncă nu există evaluări

- RKC CD 101 PDFDocument9 paginiRKC CD 101 PDFFIRMANSYAHÎncă nu există evaluări

- Mypin: Resistance Controller User ManualDocument1 paginăMypin: Resistance Controller User ManualMarcos Luiz AlvesÎncă nu există evaluări

- Operating Manual: Technical Specification Technical SpecificationDocument4 paginiOperating Manual: Technical Specification Technical SpecificationKaran Solanki100% (1)

- FTC100D Panel Interface AT052610Document8 paginiFTC100D Panel Interface AT052610Azahra Bintang DyahÎncă nu există evaluări

- Eliwell EWPC905ManualDocument3 paginiEliwell EWPC905ManualvitapabloÎncă nu există evaluări

- ACF624 680and625manualsDocument2 paginiACF624 680and625manualsGreg OneofakindÎncă nu există evaluări

- TE-W Manual PDFDocument4 paginiTE-W Manual PDFSebastian AmoresÎncă nu există evaluări

- DeltaOhm 9785T Ve 9765T Online PHDocument4 paginiDeltaOhm 9785T Ve 9765T Online PHEnisÎncă nu există evaluări

- ST 710 KHJV 03Document13 paginiST 710 KHJV 03Saad rechamÎncă nu există evaluări

- 20151210201922RC-112E User Manual220v10Document2 pagini20151210201922RC-112E User Manual220v10Anonymous ZLmk6mPPnÎncă nu există evaluări

- Sestos D1S-VR-220 Digital Temperature ControllerDocument3 paginiSestos D1S-VR-220 Digital Temperature ControllermicaÎncă nu există evaluări

- 23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enDocument16 pagini23.5 Eliwell Bedieing Ontdooithermostaat Id985-E-lx enjosepadilla1987Încă nu există evaluări

- Instruction Manual L&TDocument16 paginiInstruction Manual L&TVijay67% (3)

- Termostato Digital - SMP55Document88 paginiTermostato Digital - SMP55Julio Cesar T ProcopioÎncă nu există evaluări

- Contador de PulsosDocument2 paginiContador de PulsosOmar P. Chamana InfanzónÎncă nu există evaluări

- Operating Instructions: SZ-7556-P-DDocument5 paginiOperating Instructions: SZ-7556-P-Djaganks100% (1)

- Operating Manual: Model: TC - 19 - J, K (96 X 96 MM) Connection DiagramDocument2 paginiOperating Manual: Model: TC - 19 - J, K (96 X 96 MM) Connection DiagramAnuj KumarÎncă nu există evaluări

- Honeywell DC1000 Manual PDFDocument28 paginiHoneywell DC1000 Manual PDFdhinesh kumaravelÎncă nu există evaluări

- AKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXDocument2 paginiAKO-14012 AKO-14023, AKO-14123,: 1411H210 Thermometers and Thermostats With 1 Probe and 1 Relay: AKO-140XX, AKO-141XXmartinÎncă nu există evaluări

- KT1210W Temperature Controller Operating Manual::increase ValueDocument1 paginăKT1210W Temperature Controller Operating Manual::increase Valueleonardo vivasÎncă nu există evaluări

- LCD Digital DC Fan Coil Thermostat - Installation InstructionDocument2 paginiLCD Digital DC Fan Coil Thermostat - Installation Instructionhitosnap40% (5)

- Digital Relay E1200 PDFDocument5 paginiDigital Relay E1200 PDFMisdehRasmanÎncă nu există evaluări

- XT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputDocument4 paginiXT110C - XT111C - XT110D - XT111D: Single Stage Digital Controller With Multi Probe InputJennifer Eszter SárközyÎncă nu există evaluări

- DPS 2 SeriesDocument2 paginiDPS 2 SeriesMarco Antonio ReyesÎncă nu există evaluări

- TK 6200Document12 paginiTK 6200Angel RosasÎncă nu există evaluări

- XMTG818 (T) Temperaturecontrollerwithtimer 14315713197 PDFDocument6 paginiXMTG818 (T) Temperaturecontrollerwithtimer 14315713197 PDFyesdanÎncă nu există evaluări

- Manual Contador RC102CDocument2 paginiManual Contador RC102Cdavid del pradoÎncă nu există evaluări

- XMT - 308 Series Intellgence Digital Temperature Control Instrument Insruction ManualDocument4 paginiXMT - 308 Series Intellgence Digital Temperature Control Instrument Insruction ManualAchmad SukmawijayaÎncă nu există evaluări

- Nabertherm Controller R7Document3 paginiNabertherm Controller R7Diógenes Honorato PivaÎncă nu există evaluări

- Vdocuments - MX Horno Secado Dhg9140a LuzerenDocument8 paginiVdocuments - MX Horno Secado Dhg9140a LuzerenAdrian Desiderio Mendoza BaureÎncă nu există evaluări

- Axe 4 Digital (One-Alarm) & 6 Digital Totalizer Counter (72X72Mm)Document2 paginiAxe 4 Digital (One-Alarm) & 6 Digital Totalizer Counter (72X72Mm)Waqar AliÎncă nu există evaluări

- Toyota U760E Codigos y CircuitosDocument207 paginiToyota U760E Codigos y CircuitosLuis Oswaldo Roa PerezÎncă nu există evaluări

- Counter Meter PDFDocument4 paginiCounter Meter PDFM saleemÎncă nu există evaluări

- EST120 2 IN 1 Grain Temperature and Level Monitoring TransmitterDocument3 paginiEST120 2 IN 1 Grain Temperature and Level Monitoring TransmitterAdito JunandaÎncă nu există evaluări

- Graphic-Display Description and Operation: Short User ManualDocument7 paginiGraphic-Display Description and Operation: Short User ManualSmart Boyz SaranÎncă nu există evaluări

- DT-9910 01 v02 07 14Document3 paginiDT-9910 01 v02 07 14CristianSerbanoiuÎncă nu există evaluări

- SMR2012 DCN5 User ManualsDocument9 paginiSMR2012 DCN5 User ManualsMZÎncă nu există evaluări

- TM-42 Manual (ENG) 20050707-97Document8 paginiTM-42 Manual (ENG) 20050707-97Michael Karantzias83% (6)

- Manual Vacuostato Vs W DDocument3 paginiManual Vacuostato Vs W DHigor MoraesÎncă nu există evaluări

- Operating Instructions SINGLE SBC - ControllerDocument12 paginiOperating Instructions SINGLE SBC - ControllerASCI MaintenanceÎncă nu există evaluări

- Multispan TC-19Document4 paginiMultispan TC-19Karan SolankiÎncă nu există evaluări

- NX232A Earth-Fault Relay User's Guide: 1. DescriptionDocument4 paginiNX232A Earth-Fault Relay User's Guide: 1. DescriptiondienlangchuÎncă nu există evaluări

- DSL 600manualDocument2 paginiDSL 600manualMonica CurpasÎncă nu există evaluări

- NX1000A Rev M0 Apr 19 MergedDocument2 paginiNX1000A Rev M0 Apr 19 MergedAldi MaryansyahÎncă nu există evaluări

- TB Series User Manual PDFDocument31 paginiTB Series User Manual PDFEl MacheteÎncă nu există evaluări

- Schneider XBTZG9775 PLC Control Cable To Mitsubishi FX Series MINI DIN 8-PIN RS232 MALE To RS232 DB9 FEMALE Black Length 1.8MDocument15 paginiSchneider XBTZG9775 PLC Control Cable To Mitsubishi FX Series MINI DIN 8-PIN RS232 MALE To RS232 DB9 FEMALE Black Length 1.8MSyed Hassan TariqÎncă nu există evaluări

- Preset Up/Down Counter General SpecificationsDocument6 paginiPreset Up/Down Counter General SpecificationsMira BkhÎncă nu există evaluări

- HP11 Manual 4.0Document1 paginăHP11 Manual 4.0Mauricio Plaza SalinasÎncă nu există evaluări

- DC20DDocument4 paginiDC20DWaqar AhmedÎncă nu există evaluări

- h3ct 5uDocument2 paginih3ct 5uSampath KumarÎncă nu există evaluări

- Uputstvo XMT 608Document6 paginiUputstvo XMT 608drina_pdÎncă nu există evaluări

- BAT54 / BAT54A / BAT54C / BAT54S: Schottky DiodesDocument6 paginiBAT54 / BAT54A / BAT54C / BAT54S: Schottky DiodesJoseph YumulÎncă nu există evaluări

- Celda de Carga SBS-4keDocument2 paginiCelda de Carga SBS-4keBernardo RatiaÎncă nu există evaluări

- Código Fuente CapacimetroDocument1 paginăCódigo Fuente CapacimetroBernardo RatiaÎncă nu există evaluări

- Trabajos BobinadosDocument18 paginiTrabajos BobinadosBernardo RatiaÎncă nu există evaluări

- OZ813Document8 paginiOZ813Bernardo RatiaÎncă nu există evaluări

- Silicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Document1 paginăSilicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Bernardo RatiaÎncă nu există evaluări

- MM2001Prog: Programmation In-Situ: Parallel Port: LPT1 (Default) or LPT2Document2 paginiMM2001Prog: Programmation In-Situ: Parallel Port: LPT1 (Default) or LPT2Bernardo RatiaÎncă nu există evaluări

- Manual ISO SPEEDDocument16 paginiManual ISO SPEEDBernardo RatiaÎncă nu există evaluări

- lf353 NDocument17 paginilf353 NBayu AditiaÎncă nu există evaluări

- 1386fa PDFDocument8 pagini1386fa PDFBernardo RatiaÎncă nu există evaluări

- R5F21255SNFP Renesas PDFDocument525 paginiR5F21255SNFP Renesas PDFBernardo RatiaÎncă nu există evaluări

- Toshs13553 1Document18 paginiToshs13553 1josue herreraÎncă nu există evaluări

- Zapi FC2086 Codes PDFDocument8 paginiZapi FC2086 Codes PDFGabriel BravoÎncă nu există evaluări

- (14-21"color TV Basic Schematic Diagram) : CRT BoardDocument1 pagină(14-21"color TV Basic Schematic Diagram) : CRT BoardAndrei Blas Azaña100% (1)

- Irfr9110, Irfu9110, Sihfr9110, Sihfu9110: Vishay SiliconixDocument11 paginiIrfr9110, Irfu9110, Sihfr9110, Sihfu9110: Vishay SiliconixBernardo RatiaÎncă nu există evaluări

- 02EH02 Regulador DirectvDocument6 pagini02EH02 Regulador DirectvBernardo RatiaÎncă nu există evaluări

- Hydrodynamic Design and Analysis of A Swirling Flow GeneratorDocument16 paginiHydrodynamic Design and Analysis of A Swirling Flow Generatorrone2000Încă nu există evaluări

- Answer of Numerical AssignmentsDocument5 paginiAnswer of Numerical AssignmentsKiran GayakwadÎncă nu există evaluări

- Standards For AC MotorsDocument37 paginiStandards For AC MotorsPandaGendut100% (1)

- Jest 2014 PhysicsDocument7 paginiJest 2014 PhysicsKritiraj KalitaÎncă nu există evaluări

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0160 D, RA 0202 D, RA 0250 D, RA 0302 DDocument32 paginiInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0160 D, RA 0202 D, RA 0250 D, RA 0302 DYunisÎncă nu există evaluări

- MC-306 enDocument2 paginiMC-306 enminhhieuhanam93Încă nu există evaluări

- DLL MATH-2 Week6 Q4Document8 paginiDLL MATH-2 Week6 Q4Magie Lyn MendozaÎncă nu există evaluări

- CE-EMC Test ReportDocument97 paginiCE-EMC Test ReportDuy ChuÎncă nu există evaluări

- Tiger Pro HC JKM515-535M-72HL4-BDVP-A2.1Document2 paginiTiger Pro HC JKM515-535M-72HL4-BDVP-A2.1Parth DaxiniÎncă nu există evaluări

- Pressure MeasurementDocument19 paginiPressure Measurementdevarshikumar vaidya100% (1)

- Chapter 4Document34 paginiChapter 4Ahmad TahirÎncă nu există evaluări

- Stat ComDocument13 paginiStat ComSanthi Manoj VaddiÎncă nu există evaluări

- HRSG - NDE Procedure For Pressure Part (China & Korea)Document502 paginiHRSG - NDE Procedure For Pressure Part (China & Korea)Sreekumar SÎncă nu există evaluări

- MATH 3rd Grading Summative Test 3Document3 paginiMATH 3rd Grading Summative Test 3Aubrey Gay Sarabosquez100% (2)

- Zener Diode Problem Solving TechniquesDocument6 paginiZener Diode Problem Solving TechniquesRaghul R100% (1)

- EIE321 Module 2Document65 paginiEIE321 Module 2Opeyemi OrugunÎncă nu există evaluări

- Q.Bank Air NavDocument14 paginiQ.Bank Air Navsakshee gojreÎncă nu există evaluări

- Dynamics of Rigid BodiesDocument9 paginiDynamics of Rigid BodiesJifford Rois HernanÎncă nu există evaluări

- Comprehensive Fluid Mechanics ComprehensiveDocument336 paginiComprehensive Fluid Mechanics ComprehensiveOsmr Ramos100% (1)

- Applied Physics by M KumarDocument43 paginiApplied Physics by M KumarheloverÎncă nu există evaluări

- General Physics 1: Grade 11 - Quarter 1 - Week 3 Kinematics: Motion in 1-Dimension and 2 DimensionsDocument12 paginiGeneral Physics 1: Grade 11 - Quarter 1 - Week 3 Kinematics: Motion in 1-Dimension and 2 DimensionsKim CortezÎncă nu există evaluări

- Immaculate Conception Archdiocesan Schools Inc. (Icas Inc.)Document3 paginiImmaculate Conception Archdiocesan Schools Inc. (Icas Inc.)rhaiza rasdiÎncă nu există evaluări

- Ebook LCD Best OneDocument125 paginiEbook LCD Best Oneananad addictÎncă nu există evaluări

- Datasheet PWM PDFDocument38 paginiDatasheet PWM PDFEdnaelson SilvaÎncă nu există evaluări

- Datasheet Diodo ChottkyDocument6 paginiDatasheet Diodo ChottkyMAIG ElectricosÎncă nu există evaluări

- Read and Measure Temperature COTDocument57 paginiRead and Measure Temperature COTCyril Lyn Natividad Credo91% (11)

- Centrifugal Pumps: P.K.Nagarajan SR - Lecturer School of Mechanical and Building Sciences VIT UniversityDocument30 paginiCentrifugal Pumps: P.K.Nagarajan SR - Lecturer School of Mechanical and Building Sciences VIT UniversityVikas Kumar100% (1)

- Motor Drive Technical Primer0919 3Document180 paginiMotor Drive Technical Primer0919 3Kepler TiburcioÎncă nu există evaluări

- TA SCAC (R410A 50,60Hz) CSA Colombia IDU CO MFL67986333 20220215Document82 paginiTA SCAC (R410A 50,60Hz) CSA Colombia IDU CO MFL67986333 20220215Oscar Alfonso Piña PertuzÎncă nu există evaluări