Documente Academic

Documente Profesional

Documente Cultură

BDM Example 3 - 20190101

Încărcat de

Marco GomesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BDM Example 3 - 20190101

Încărcat de

Marco GomesDrepturi de autor:

Formate disponibile

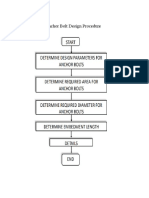

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 1

Design Example 3

APPENDIX A

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED)

METHOD B

GENERAL INFORMATION

Per CDOT Bridge Design Manual (BDM) Section 14.5.8, steel reinforced bearing pads shall be designed using

Method B. This example follows AASHTO LRFD 7th Edition Section 14.7.5.

This example assumes a steel superstructure that can displace under the effects of temperature and assumes a rectangular

bearing shown below in Figures 1 and 2. Externally bonded plates are not used. The structure is assumed to move freely in the

longitudinal direction only for the range of temperatures conforming to AASHTO 3.12.2.1 Procedure A.

MATERIAL AND SECTION PROPERTIES

Bearing Dimensions

Bearing Width W= 20.00 in AASHTO 14.7.5.1

Bearing Length L= 15.00 in AASHTO 14.7.5.1

Bearing Pad Layers

Exterior Elastomeric Thickness hre = 0.125 in OK < 70% hri AASHTO 14.7.5.1

Interior Elastomeric Thickness hri = 0.500 in

Steel Plate Thickness hs = 0.125 in

No. of Steel Shim Plates nshims = 10

No. of Interior Elastomer Layers n= 9 AASHTO 14.7.5.3.3

Total Elastomer Thickness hrt = 4.750 in

Total Bearing Height t= 6.00 in OK 2" minimum height per BDM 14.5.8

Bearing Material Properties

Elastomer Grade Grade = 3 (Zone C) BDM 14.5.8, & AASHTO Table &

Figure 14.7.5.2-1

Shear Modulus

Design drawings shall specify the shear modulus of the elastomer at 73°. With an acceptance variation of ± 15% of the

specified value, the shear modulus used in design will vary. The shear modulus shall be taken as the least favorable value

within the range to cause the more conservative outcome in the specific analysis being considered

(AASHTO 14.7.5.2). The plan shear modulus below assumes a Durometer Hardness of 60.

Gplan= 0.150 ksi AASHTO T14.7.6.2-1

Gmax= 0.173 ksi

Gmin= 0.128 ksi

Check = 0.08 ksi < G < 0.175 ksi OK AASHTO 14.7.5.2

Creep Deflection Factor 𝛼𝛼𝛼𝛼𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 0.35 AASHTO T14.7.6.2-1

Steel Shim Properties

Yield Strength of Steel Fy = 36.00 ksi AASHTO T6.4.1-1

Allowable Fatigue Threshold ΔFTH = 24.00 ksi AASHTO T6.6.1.2.3-1

CDOT Bridge Design Manual January 2018

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 2

FIGURE 1 - TYPE I - STEEL REINFORCED BEARING DETAIL - PLAN

FIGURE 2 - TYPE I - STEEL REINFORCED BEARING DETAIL - SECTION

BEARING LOADS

Loads acting on the bearing are dead and live load girder reactions at the service limit state. Per AASHTO 14.4.1, dynamic load

allowance is excluded from the live load influence. Loads are per bearing.

Service I Limit State Loads

DL = 115.00 kip

LL= 85.00 kip

CDOT Bridge Design Manual January 2018

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 3

BEARING ROTATIONS

Rotations include effects of girder camber. For all rotation values, positive indicates a downward rotation while negative

indicates an upward rotation. Note this example does not account for profile grade differences between supports.

Service I Limit State Rotations

Dead Load Rotations 𝜃𝜃𝜃𝜃𝑑𝑑𝑑𝑑 = -0.002 rad

Live Load Rotations 𝜃𝜃𝜃𝜃𝐸𝐸𝐸𝐸 = 0.001 rad

Include a construction tolerance of 0.005 radians to account for uncertainties in bearing fabrication and bearing seat

construction. Per BDM 14.5.4, the flatness tolerance for bearing seat uncertainties is accounted for in the construction tolerance.

Construction Tolerance 𝜃𝜃𝜃𝜃𝑐𝑐𝑐𝑐 = 0.005 rad AASHTO 14.4.2.1

HORIZONTAL MOVEMENT

Shear deformations include movements from temperature, creep and shrinkage, prestressing effects, and miscellaneous

movement from loads such as live and wind loads from service load combinations per AASHTO C14.4.1. Assume the bearings

are not adjusted after construction; therefore, the 65 percent reduction in thermal movement range per

AASHTO 14.7.5.3.2 is not included per BDM 14.5.3.

Uniform Temperature Movement Range:

Maximum temperature Tmax = 120 ͦ F AASHTO T3.12.2.1-1

Minimum temperature Tmin = -30 ͦ F AASHTO T3.12.2.1-1

Coeff. of thermal expansion α= 6.5E-06 in/in/ ͦ F AASHTO 6.4.1

Expansion length 𝐿𝐿𝐿𝐿 = 80.00 ft = 960.00 in

Service I Load Factor, TU 𝛾𝛾𝛾𝛾𝑇𝑇𝑇𝑇𝑇𝑇𝑇𝑇 = 1.20 AASHTO T3.4.1-1

AASHTO Reduction Factor 𝛼𝛼𝛼𝛼𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴 = 1.00 BDM 14.5.3

∆ 𝑇𝑇𝑇𝑇 = 𝛼𝛼𝛼𝛼𝐿𝐿𝐿𝐿 𝑇𝑇𝑇𝑇𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 − 𝑇𝑇𝑇𝑇𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 = 6.5E-6*960.00*[120-(-30)] = 0.94 in AASHTO 3.12.2.3-1

Creep, Shrinkage, Elastic Shortening, Live Load, and Miscellaneous Movements:

Creep movement ΔCR = 0.00 in

Shrinkage movement ΔSH = 0.00 in

Elastic shortening ΔEL = 0.00 in

Live load movement ΔLL = 0.04 in

Miscellaneous movement ΔMISC = 0.50 in

∆𝑜𝑜𝑜𝑜 = Maximum horizontal displacement of the superstructure

∆𝑠𝑠𝑠𝑠 = Maximum shear deformation of the bearing modified to account for substructure stiffness

Assuming the substructure is stiff enough to prevent movement:

∆𝑜𝑜𝑜𝑜 = ∆𝑠𝑠𝑠𝑠 = � 𝛼𝛼𝛼𝛼𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴 𝛾𝛾𝛾𝛾𝑇𝑇𝑇𝑇𝑇𝑇𝑇𝑇 ∆ 𝑇𝑇𝑇𝑇 + ∆𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 + ∆𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 + ∆𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 + ∆𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 + ∆𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝑀𝐴𝐴𝐴𝐴𝐴𝐴𝐴𝐴 = AASHTO 14.7.5.3.2 & BDM

14.5.3

1.00*1.20*0.94+0.00+0.00+0.00+0.04+0.50 = 1.66 in

SOLUTION

Shape Factor

Rectangular, steel reinforced bearing shape factor without holes:

𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿

𝑆𝑆𝑆𝑆𝑖𝑖𝑖𝑖 = = (15.00*20.00) / [2*0.500*(15.00+20.00)] = 8.57 AASHTO 14.5.7.1-1

2ℎ𝑟𝑟𝑟𝑟𝑖𝑖𝑖𝑖(𝐿𝐿𝐿𝐿 + 𝐿𝐿𝐿𝐿)

CDOT Bridge Design Manual January 2018

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 4

Computed Compressive Stresses

𝐷𝐷𝐷𝐷𝐿𝐿𝐿𝐿 + 𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠 = = (115.00+85.00) / (15.00*20.00) = 0.67 ksi

𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠 = average compressive stress due to total load from applicable service load combinations

𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿

𝜎𝜎𝜎𝜎𝐸𝐸𝐸𝐸 = = 85.00 / (15.00*20.00) = 0.28 ksi

𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿

𝜎𝜎𝜎𝜎𝐸𝐸𝐸𝐸 = average compressive stress due to live load at the service limit state (cyclic load)

𝐷𝐷𝐷𝐷𝐿𝐿𝐿𝐿

𝜎𝜎𝜎𝜎𝑑𝑑𝑑𝑑 = = 115.00 / (15.00*20.00) = 0.38 ksi

𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿

𝜎𝜎𝜎𝜎𝑑𝑑𝑑𝑑 = average compressive stress due to dead load at the service limit state (static load)

Compressive Deflections AASHTO 14.7.5.3.6

Live Load Compressive Deflection

Minimizing deflection from instantaneous live loads is recommended when bridge joints are present. For jointless bridges, these

criteria may be omitted.

𝛿𝛿𝛿𝛿𝐸𝐸𝐸𝐸 ≤ 0.125" AASHTO C14.7.5.3.6

𝛿𝛿𝛿𝛿𝐸𝐸𝐸𝐸 = ∑ 𝜀𝜀𝜀𝜀𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝜀𝜀𝜀𝜀𝐸𝐸𝐸𝐸 ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟 AASHTO 14.7.5.3.6-1

𝜀𝜀𝜀𝜀𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 = instantaneous live load compressive strain in elastomeric pad

𝜎𝜎𝜎𝜎𝐸𝐸𝐸𝐸 AASHTO C14.7.5.3.6-1

𝜀𝜀𝜀𝜀𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 = = 0.28 / (4.8*0.13*8.57^2) = 0.006

4.8𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 2

𝛿𝛿𝛿𝛿𝐸𝐸𝐸𝐸 = 𝜀𝜀𝜀𝜀𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟 = 0.006*4.750 = 0.030 in

Check 𝛿𝛿𝛿𝛿𝐸𝐸𝐸𝐸 ≤ 0.125" 0.030 in < 0.125 in OK

Dead Load Compressive Deflection

AASHTO Method B does not have limitations on initial or long term dead load deflections. The following calculation is for

demonstration only. Engineering judgment shall be used in evaluating appropriate allowable deflections in the bearing.

Initial dead load deflection:

𝛿𝛿𝛿𝛿𝑑𝑑𝑑𝑑 = ∑ 𝜀𝜀𝜀𝜀𝑑𝑑𝑑𝑑𝑚𝑚𝑚𝑚 ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = AASHTO 14.7.5.3.6-2

𝜀𝜀𝜀𝜀𝑑𝑑𝑑𝑑𝑚𝑚𝑚𝑚 = initial dead load compressive strain in i th layer of elastomeric pad

𝜎𝜎𝜎𝜎𝑑𝑑𝑑𝑑 AASHTO C14.7.5.3.6-1

𝜀𝜀𝜀𝜀𝑑𝑑𝑑𝑑𝑚𝑚𝑚𝑚 = = 0.38 / (4.8*0.13*8.57^2) = 0.009

4.8𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 2

𝛿𝛿𝛿𝛿𝑑𝑑𝑑𝑑 = 𝜀𝜀𝜀𝜀𝑑𝑑𝑑𝑑𝑚𝑚𝑚𝑚 ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟 = 0.009*4.750 = 0.040 in.

Long term dead load deflection: AASHTO 14.7.5.3.6-3

𝛿𝛿𝛿𝛿𝑙𝑙𝑙𝑙𝑟𝑟𝑟𝑟 = 𝛿𝛿𝛿𝛿𝑑𝑑𝑑𝑑 + 𝛼𝛼𝛼𝛼𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝛿𝛿𝛿𝛿𝑑𝑑𝑑𝑑 = 0.040+0.35*0.040 = 0.055 in. AASHTO T14.7.6.2-1

CDOT Bridge Design Manual January 2018

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 5

Shear Deformations

Total elastomer thickness = hrt

ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟 ≥ 2∆𝑠𝑠𝑠𝑠 = 2*1.66 = 3.33 in AASHTO 14.7.5.3.2-1

Check ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟 = 4.75 in > 3.33 in OK

Combined Compression, Rotation, and Shear AASHTO 14.7.5.3.3

For demonstration purposes, only rotation about the transverse direction is verified. The Designer shall evaluate the bearing

about both the longitudinal and transverse axis as appropriate, especially in cases where the structure contains a significant

skew (AASHTO C14.7.5.3.3). Cyclic loading shall consist of loads induced by traffic with all other loads considered static

(AASHTO 14.7.5.3.3).

𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 1.75(𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 + 𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 + 𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 ) ≤ 5.0 AASHTO 14.7.5.3.3-1

and

𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 ≤ 3.0 AASHTO 14.7.5.3.3-2

Axial Load Shear Strain

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟

Axial strain from static loads: 𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = 𝐷𝐷𝐷𝐷𝑚𝑚𝑚𝑚 AASHTO 14.7.5.3.3-3

𝐺𝐺𝐺𝐺𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

Axial strain from cyclic loads: 𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝐷𝐷𝐷𝐷𝑚𝑚𝑚𝑚 AASHTO 14.7.5.3.3-3

𝐺𝐺𝐺𝐺𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚

where:

Da = 1.40 AASHTO 14.7.5.3.3-4

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = 𝜎𝜎𝜎𝜎𝑑𝑑𝑑𝑑 = Compressive stress due to total static load at service limit state

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝜎𝜎𝜎𝜎𝐸𝐸𝐸𝐸 = Compressive stress due to cyclic load at service limit state

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 1.40*0.38

𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = 𝐷𝐷𝐷𝐷𝑚𝑚𝑚𝑚 = = 0.491

𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 0.13*8.57

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 1.40*0.28

𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝐷𝐷𝐷𝐷𝑚𝑚𝑚𝑚 = = 0.363

𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 0.13*8.57

Rotational Shear Strain

2

𝐿𝐿𝐿𝐿 𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟

Rotational strain from static loads: 𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = 𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐 AASHTO 14.7.5.3.3-6

ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑛𝑛𝑛𝑛

2

𝐿𝐿𝐿𝐿 𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

Rotational strain from cyclic loads: 𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐 AASHTO 14.7.5.3.3-6

ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑛𝑛𝑛𝑛

where

Dr = 0.50 AASHTO 14.7.5.3.3-7

𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = 𝜃𝜃𝜃𝜃𝑑𝑑𝑑𝑑 + 𝜃𝜃𝜃𝜃𝑐𝑐𝑐𝑐 = Maximum static service limit state design rotation

𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝜃𝜃𝜃𝜃𝐸𝐸𝐸𝐸 = Maximum cyclic service limit state design rotation

2

𝐿𝐿𝐿𝐿 𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟

𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = 𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐 = 0.50 ( 15.00 / 0.500 ) ^2 *(-0.002+0.005) / 9 = 0.150

ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑛𝑛𝑛𝑛

2

𝐿𝐿𝐿𝐿 𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐 = 0.50 ( 15.00 / 0.500 ) ^2 *(0.001) / 9 = 0.050

ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑛𝑛𝑛𝑛

CDOT Bridge Design Manual January 2018

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 6

Shear Deformation Shear Strain

∆𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟

Shear strain from static loads: 𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = AASHTO 14.7.5.3.3-10

ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟

∆𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

Shear strain from cyclic loads: 𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = AASHTO 14.7.5.3.3-10

ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟

where

∆𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = ∆𝑠𝑠𝑠𝑠 − ∆𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 = 1.663 in

∆𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = ∆𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 = 0.040 in

∆𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟

𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = = 1.663 / 4.750 = 0.350

ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟

∆𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = = 0.040 / 4.750 = 0.008

ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟

Combined Shear Strains Checks

𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 1.75(𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 + 𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 + 𝛾𝛾𝛾𝛾𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 ) ≤ 5.0

= 0.491+0.150+0+ 1.75(0.363+0.050+0.008) = 1.73 < 5.00 OK

𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 ≤ 3.0 𝛾𝛾𝛾𝛾𝑚𝑚𝑚𝑚,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 = 0.491 < 3.00 OK

Stability AASHTO 14.7.5.3.4

If the following is satisfied, no further investigation of stability is required:

AASHTO 14.5.3.4-1

2𝐴𝐴𝐴𝐴 ≤ 𝐵𝐵𝐵𝐵

where

ℎ

1.92 𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟 1.92*(4.750 / 15.00) = 0.38 AASHTO 14.7.5.3.4-2

𝐴𝐴𝐴𝐴 = =

2.0𝐿𝐿𝐿𝐿 SQRT [ 1 + (2*15.00) / 20.00]

1+

𝐿𝐿𝐿𝐿

2.67 2.67 = 0.21 AASHTO 14.7.5.3.4-3

𝐵𝐵𝐵𝐵 = =

𝐿𝐿𝐿𝐿 (8.57+2.0) * [1+15.00 / (4.0*20.00)]

(𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 + 2.0)(1 + 4.0𝐿𝐿𝐿𝐿 )

Note that if L is greater than W, stability shall be L= 15.00 in

investigated by interchanging L and W. W= 20.00 in

Check 2𝐴𝐴𝐴𝐴 = 2*0.38 = 0.77 > 0.21 =B FAILS

If the above criteria for stability are not satisfied, the following equations shall be investigated:

CDOT Bridge Design Manual January 2018

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 7

For a bridge deck that is free to translate horizontally:

For demonstration only. Designer shall determine movement capability of bridge on a case by case basis.

𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 0.13*8.57 AASHTO 14.7.5.3.4-4

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠 ≤ = = 1.96 ksi

2𝐴𝐴𝐴𝐴 − 𝐵𝐵𝐵𝐵 2*0.38 -0.21

Check 𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠 = 0.67 ksi < 1.96 ksi OK Bearing is Stable

For a bridge deck that is fixed against horizontal translation:

For demonstration only. Designer shall determine movement capability of bridge on a case by case basis.

𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 0.13*8.57 AASHTO 14.7.5.3.4-5

𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠 ≤ = = 6.36 ksi

𝐴𝐴𝐴𝐴 − 𝐵𝐵𝐵𝐵 0.38 -0.21

Check 𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠 = 0.67 ksi < 6.36 ksi OK Bearing is Stable

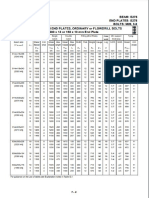

Reinforcement AASHTO 14.7.5.3.5

Note that holes are not present in the bearing. The allowable thickness does not need to be increased per

AASHTO 14.7.5.3.5

The minimum thickness of steel reinforcement shall satisfy the following:

ℎ𝑠𝑠𝑠𝑠 ≥ .0625𝑖𝑖𝑖𝑖𝑛𝑛𝑛𝑛

and

(Service Limit State)

3ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝜎𝜎𝜎𝜎𝑠𝑠𝑠𝑠 3*0.500*0.67 = 0.028 in AASHTO 14.7.5.3.5-1

ℎ𝑠𝑠𝑠𝑠 ≥ =

𝐹𝐹𝐹𝐹𝑐𝑐𝑐𝑐 36

and

(Fatigue Limit State)

2ℎ𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝜎𝜎𝜎𝜎𝐸𝐸𝐸𝐸 2*0.500*0.28 = 0.012 in AASHTO 14.7.5.3.5-2

ℎ𝑠𝑠𝑠𝑠 ≥ =

∆𝐹𝐹𝐹𝐹𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴 24.00

Check

ℎ𝑠𝑠𝑠𝑠 = 0.125 in > 0.0625 in OK

0.125 in > 0.028 in OK

0.125 in > 0.012 in OK

CDOT Bridge Design Manual January 2018

EXAMPLE 3 - TYPE I BEARING (STEEL REINFORCED) METHOD B 8

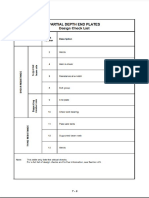

Bearing Anchorage AASHTO 14.7.5.4

For bearings without externally bonded plates, a restraint system is required to secure the bearing against horizontal movement

if:

𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠 3𝜀𝜀𝜀𝜀𝑚𝑚𝑚𝑚 AASHTO 14.7.5.4-1

≥

𝑛𝑛𝑛𝑛 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚

where

𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠 = total of static and cyclic service limit state design rotation. Cyclic component is multiplied by 1.75

𝜀𝜀𝜀𝜀𝑚𝑚𝑚𝑚 = total of static and cyclic average axial strain. Cyclic component is multiplied by 1.75

𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠 = 𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 1.75𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠,𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝜃𝜃𝜃𝜃𝑑𝑑𝑑𝑑 + 𝜃𝜃𝜃𝜃𝑐𝑐𝑐𝑐 + 1.75𝜃𝜃𝜃𝜃𝐸𝐸𝐸𝐸 =

= -0.002+0.005+1.75*0.001= 0.005 rad

𝜀𝜀𝜀𝜀𝑚𝑚𝑚𝑚 = 𝜀𝜀𝜀𝜀𝑠𝑠𝑠𝑠𝑟𝑟𝑟𝑟 + 1.75𝜀𝜀𝜀𝜀𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝜀𝜀𝜀𝜀𝑑𝑑𝑑𝑑 + 1.75𝜀𝜀𝜀𝜀𝐸𝐸𝐸𝐸 = 0.009+ 1.75*0.006= 0.020

Check

𝜃𝜃𝜃𝜃𝑠𝑠𝑠𝑠 3𝜀𝜀𝜀𝜀𝑚𝑚𝑚𝑚 0.005 3*0.020 Restraint

≥ = = 0.001 < = 0.007 FAILS

𝑛𝑛𝑛𝑛 𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚 9 8.57 Required

If the Engineer elects to use externally bonded plates, limitations on hydrostatic pressure per AASHTO 14.7.5.3.3-11 shall be

satisfied.

Anchorage (Bearing Pad Slip) AASHTO 14.8.3

The bearing pad must be secured against horizontal movement if the shear force sustained by the deformed pad exceeds the

minimum vertical force due to permanent loads modified for the concrete friction. Gmax is used since the pad is stiffer at colder

temperatures and will produce larger shear forces. Note this example considers longitudinal deformations only; wind, braking,

and seismic loads shall also be considered as appropriate, in the direction of consideration.

𝐻𝐻𝐻𝐻𝑏𝑏𝑏𝑏 = 𝜇𝜇𝜇𝜇𝑃𝑃𝑃𝑃𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 AASHTO 14.6.3.1-1

and

∆𝑠𝑠𝑠𝑠

𝐻𝐻𝐻𝐻𝑏𝑏𝑏𝑏 = 𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝐴𝐴𝐴𝐴 AASHTO 14.6.3.1-2

ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟

Combining equations:

𝜇𝜇𝜇𝜇𝑃𝑃𝑃𝑃𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟

∆𝑠𝑠𝑠𝑠,𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑎𝑎𝑎𝑎 = = 0.20*115.00*4.75 / (0.17*300.00) = 2.11 in

𝐺𝐺𝐺𝐺𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 𝐴𝐴𝐴𝐴

where

𝜇𝜇𝜇𝜇 = 0.20 Coefficient of friction AASHTO C14.8.3.1

𝑃𝑃𝑃𝑃𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 = DL = 115.00 kip

𝐴𝐴𝐴𝐴 = 𝐿𝐿𝐿𝐿𝐿𝐿𝐿𝐿 = 300.00 in2

ℎ𝑐𝑐𝑐𝑐𝑟𝑟𝑟𝑟 = 4.75 in

Check

∆𝑠𝑠𝑠𝑠,𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑎𝑎𝑎𝑎 = 2.11 in > ∆𝑠𝑠𝑠𝑠 = 1.66 in OK

In cases where Δs exceeds Δs,allow, anchor bolts shall be sized and designed in accordance with those Articles specified in

AASHTO 14.8.3

CDOT Bridge Design Manual January 2018

S-ar putea să vă placă și

- Design Example - Method B - AASHTODocument8 paginiDesign Example - Method B - AASHTOMateo RamirezÎncă nu există evaluări

- Appendix A Example 2 - Type I Bearing (Steel Reinforced) Method ADocument6 paginiAppendix A Example 2 - Type I Bearing (Steel Reinforced) Method AJose ManzanarezÎncă nu există evaluări

- Design Example 1: Example 1 - Elastomeric Leveling Pad Method A 1Document3 paginiDesign Example 1: Example 1 - Elastomeric Leveling Pad Method A 1koreshÎncă nu există evaluări

- 7 1 A11yDocument3 pagini7 1 A11yLartit LIANTHAVYVANHÎncă nu există evaluări

- Example 1 - Elastomeric Bearing Pad Design (Method A) 2021Document9 paginiExample 1 - Elastomeric Bearing Pad Design (Method A) 2021Shailendra SinghÎncă nu există evaluări

- Towerwind Analysis - Anchoragebolt - Base PlateDocument14 paginiTowerwind Analysis - Anchoragebolt - Base PlateJoy lauriaÎncă nu există evaluări

- 1 Beam Fails Ub305x165x54Document4 pagini1 Beam Fails Ub305x165x54Elencheliyan PandeeyanÎncă nu există evaluări

- BDM Example 6 - 20180101Document23 paginiBDM Example 6 - 20180101mustafurade1Încă nu există evaluări

- Elastomeric BearingDocument5 paginiElastomeric Bearingjrjdengineers100% (1)

- Aashto LRFD Railway FlyoverDocument54 paginiAashto LRFD Railway FlyoverShaileshRastogiÎncă nu există evaluări

- RH 47742Document3 paginiRH 47742Zakee MohamedÎncă nu există evaluări

- Send Us An Email: Elastomeric Bridge Bearing DesignDocument2 paginiSend Us An Email: Elastomeric Bridge Bearing DesignVerenice CentenoÎncă nu există evaluări

- Shell & Dish End CalculationDocument46 paginiShell & Dish End CalculationparveshÎncă nu există evaluări

- Input Echo, Leg & Lug Item 1, Description: GuideDocument4 paginiInput Echo, Leg & Lug Item 1, Description: GuideSiri SiriÎncă nu există evaluări

- Conceptual Design of Plem StructureDocument13 paginiConceptual Design of Plem StructureFandy SipataÎncă nu există evaluări

- Flange Input Data Values Description: FLGDocument4 paginiFlange Input Data Values Description: FLGAnonymous AyDvqgÎncă nu există evaluări

- Spreader Bar Calc REF.Document34 paginiSpreader Bar Calc REF.Gokul AmarnathÎncă nu există evaluări

- Wind Calculation SheetDocument32 paginiWind Calculation SheetaauppalÎncă nu există evaluări

- Calculations BracketDocument62 paginiCalculations BracketRoshan HegdeÎncă nu există evaluări

- FACADE MODELING Structural AnalysisDocument39 paginiFACADE MODELING Structural AnalysisGodino Christian100% (3)

- Bearing Design - Steel ReinforcementDocument10 paginiBearing Design - Steel ReinforcementRajesh SarswaÎncă nu există evaluări

- REPORT (3) - MergedDocument29 paginiREPORT (3) - MergedMoustafaÎncă nu există evaluări

- Steel Vessels Under 90 Meters (295 Feet) in Length 2017: Rules For Building and ClassingDocument9 paginiSteel Vessels Under 90 Meters (295 Feet) in Length 2017: Rules For Building and Classingamr_tarek_26Încă nu există evaluări

- Spreadsheet For Design of Bridge BearingsDocument8 paginiSpreadsheet For Design of Bridge BearingsAli Akbar100% (1)

- Significance of Transformed Section Properties in Analysis For Required Prestressing - Jl-02-November-December-7 PDFDocument4 paginiSignificance of Transformed Section Properties in Analysis For Required Prestressing - Jl-02-November-December-7 PDFNguyen Quoc VuÎncă nu există evaluări

- Structural Analysis SST 42 IBS NEW DESIGN 2019 (1 TENANT)Document35 paginiStructural Analysis SST 42 IBS NEW DESIGN 2019 (1 TENANT)Hendra AnantaÎncă nu există evaluări

- Bearing Design MethodDocument38 paginiBearing Design MethodTeguh FahrezaÎncă nu există evaluări

- Bearing Design Method BDocument38 paginiBearing Design Method BTeguh FahrezaÎncă nu există evaluări

- Moment CapacityDocument9 paginiMoment CapacitycmlwtsÎncă nu există evaluări

- TALAT Lecture 2711: Design of A Helicopter DeckDocument11 paginiTALAT Lecture 2711: Design of A Helicopter DeckCORE MaterialsÎncă nu există evaluări

- Pan To Dynamics 110721Document65 paginiPan To Dynamics 110721Prof. TRDÎncă nu există evaluări

- Bearing DesignDocument24 paginiBearing DesignPrabhakaran KarunanithiÎncă nu există evaluări

- Worked Example ADocument10 paginiWorked Example AsoareculÎncă nu există evaluări

- Britisch Code ManualDocument35 paginiBritisch Code ManualVengatesh Hari100% (1)

- Base Ring Analysis PDFDocument9 paginiBase Ring Analysis PDFHomer SilvaÎncă nu există evaluări

- Lifting CalcDocument12 paginiLifting Calcwisnu_bayusaktiÎncă nu există evaluări

- Examples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013Document15 paginiExamples E4.16.1/E4.6.1 and E4.6.2 BPVC VIII-1: ASME PTB-4-2013ordenador90Încă nu există evaluări

- Preliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesDocument4 paginiPreliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesIoana Codrea OrtelecanÎncă nu există evaluări

- 10in Titanium Flange-235psi - Ring Gasket PDFDocument5 pagini10in Titanium Flange-235psi - Ring Gasket PDFmo444444Încă nu există evaluări

- ADS Project (1 To 3)Document43 paginiADS Project (1 To 3)damanÎncă nu există evaluări

- Proračun 4.brzinaDocument11 paginiProračun 4.brzinaJurmanÎncă nu există evaluări

- Pcfk-Channel - Flange Strength CalculationDocument7 paginiPcfk-Channel - Flange Strength CalculationjirrsamaÎncă nu există evaluări

- Vsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeDocument5 paginiVsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeSri RamprasathÎncă nu există evaluări

- Calc PierHeadDocument22 paginiCalc PierHeaddinal031Încă nu există evaluări

- UC100x100x17 Design CalculationDocument4 paginiUC100x100x17 Design CalculationWin ThanÎncă nu există evaluări

- Bracing - Angles - Single RowDocument2 paginiBracing - Angles - Single RowSakthivel VÎncă nu există evaluări

- One Way SlabDocument23 paginiOne Way SlabmeerahÎncă nu există evaluări

- Elastomeric Bearing Design ExampleDocument14 paginiElastomeric Bearing Design ExampleTan Nguyen Cong100% (2)

- Simply Supported Reinforced Concrete Beam Analysis and DesignDocument31 paginiSimply Supported Reinforced Concrete Beam Analysis and DesignAdil ShugayÎncă nu există evaluări

- Design of Steel Plate - R0 - 20.04.21Document1 paginăDesign of Steel Plate - R0 - 20.04.21Srishti Project ConsultantsÎncă nu există evaluări

- GRP Pipe Analysis - Write Up - 1Document8 paginiGRP Pipe Analysis - Write Up - 1Marie SaundersÎncă nu există evaluări

- Bearing DesignDocument16 paginiBearing DesignOmar NajmÎncă nu există evaluări

- PT Design - BS vs. ACIDocument3 paginiPT Design - BS vs. ACIShamim Ahsan ZuberyÎncă nu există evaluări

- Stainless Steel (SUS304 T x38W) Bellow: Siam Steel Works Co., LTDDocument10 paginiStainless Steel (SUS304 T x38W) Bellow: Siam Steel Works Co., LTDสราวุฒิ เอี๊ยบเจริญÎncă nu există evaluări

- Binder1 PDFDocument26 paginiBinder1 PDFTejas DesaiÎncă nu există evaluări

- CVX7640 32Document14 paginiCVX7640 32malingauomÎncă nu există evaluări

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysDe la EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysÎncă nu există evaluări

- T 12Document1 paginăT 12Marco GomesÎncă nu există evaluări

- Bolted Beam To Column Connections-Design Step 2.1Document1 paginăBolted Beam To Column Connections-Design Step 2.1Marco GomesÎncă nu există evaluări

- T 14Document1 paginăT 14Marco GomesÎncă nu există evaluări

- T 15Document1 paginăT 15Marco GomesÎncă nu există evaluări

- T 13Document1 paginăT 13Marco GomesÎncă nu există evaluări

- Bolted Beam To Column Connections-Design Step 1A.2Document1 paginăBolted Beam To Column Connections-Design Step 1A.2Marco GomesÎncă nu există evaluări

- T 10Document1 paginăT 10Marco GomesÎncă nu există evaluări

- T 7Document1 paginăT 7Marco GomesÎncă nu există evaluări

- T 3Document1 paginăT 3Marco GomesÎncă nu există evaluări

- T 8Document1 paginăT 8Marco GomesÎncă nu există evaluări

- T 4Document1 paginăT 4Marco GomesÎncă nu există evaluări

- Bolted Joint Design - The Difference Between Tension, Shear and Bending JointsDocument2 paginiBolted Joint Design - The Difference Between Tension, Shear and Bending JointsMarco GomesÎncă nu există evaluări

- T 6Document1 paginăT 6Marco GomesÎncă nu există evaluări

- T 5Document1 paginăT 5Marco GomesÎncă nu există evaluări

- (PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Document173 pagini(PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Gregory SimmonÎncă nu există evaluări

- T 11Document1 paginăT 11Marco GomesÎncă nu există evaluări

- T 9Document1 paginăT 9Marco GomesÎncă nu există evaluări

- Base Plates and Anchor Rods - Steel Design AISCDocument3 paginiBase Plates and Anchor Rods - Steel Design AISCpenneng0% (2)

- T 2Document1 paginăT 2Marco GomesÎncă nu există evaluări

- AD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionDocument3 paginiAD 288 Discontinuous Columns in Simple Construction Beam-Column ConnectionMarco GomesÎncă nu există evaluări

- Distribution of Forces in Weld GroupsDocument10 paginiDistribution of Forces in Weld GroupsMarco GomesÎncă nu există evaluări

- Unnamed 1Document7 paginiUnnamed 1Marco GomesÎncă nu există evaluări

- Design of End-Plate Connections With Elastomeric Intermediate LayerDocument11 paginiDesign of End-Plate Connections With Elastomeric Intermediate LayerMarco GomesÎncă nu există evaluări

- STAAD - Plate ElementDocument21 paginiSTAAD - Plate Elementkanakanay100% (5)

- Asus P4C800 e Deluxe MotherboardDocument47 paginiAsus P4C800 e Deluxe MotherboardMarco GomesÎncă nu există evaluări

- Metwashflat PDFDocument4 paginiMetwashflat PDFHermanÎncă nu există evaluări

- Behavior of Steel Shear Fin PlateDocument1 paginăBehavior of Steel Shear Fin PlateMarco GomesÎncă nu există evaluări

- Heat Treatment of SteelDocument3 paginiHeat Treatment of SteelpramodÎncă nu există evaluări

- Design of Ohe StructureDocument10 paginiDesign of Ohe StructureAnubhav Hem Kumar JainÎncă nu există evaluări

- Cracking Furnace Tube Metallurgy Part 1 ADocument21 paginiCracking Furnace Tube Metallurgy Part 1 AKaren Romero100% (1)

- Permanent Deformation Model Using Creep in AbaqusDocument326 paginiPermanent Deformation Model Using Creep in AbaqusChristopher Gaines100% (1)

- Stresses in Soil Mass Problem 1: Foundation Engineering 1Document3 paginiStresses in Soil Mass Problem 1: Foundation Engineering 1Kristin ArgosinoÎncă nu există evaluări

- Damage-Plastic Model For Concrete Failure: Peter Grassl, Milan Jira SekDocument31 paginiDamage-Plastic Model For Concrete Failure: Peter Grassl, Milan Jira SekTahir KhanÎncă nu există evaluări

- Bearing Kelompok 1Document23 paginiBearing Kelompok 1Muhammad Rafli Ichwan NoorÎncă nu există evaluări

- Mepdg 2004 PDFDocument219 paginiMepdg 2004 PDFSri RamyaÎncă nu există evaluări

- Solution SetDocument4 paginiSolution SetPrimawati RahmaniyahÎncă nu există evaluări

- ACI Deflection MOD MotiurDocument5 paginiACI Deflection MOD Motiurbasum matÎncă nu există evaluări

- ABAQUS TutorialDocument10 paginiABAQUS Tutorialpetrus_lioe84Încă nu există evaluări

- Seismic Retrofit of RC Circular Columns Using Prefabricated Composite Jacketing by Van Xiao, Member, ASCE, and Rui MaDocument8 paginiSeismic Retrofit of RC Circular Columns Using Prefabricated Composite Jacketing by Van Xiao, Member, ASCE, and Rui MaMarimuthu KaliyamoorthyÎncă nu există evaluări

- Chemistry MCQsDocument9 paginiChemistry MCQsSajid KhanÎncă nu există evaluări

- Direction of Thermodynamic ProcessesDocument26 paginiDirection of Thermodynamic ProcessesJohn MagalongÎncă nu există evaluări

- Material Name C MN Si CR Mo Ni N CB Cu NB: Filler Metal 1 Chemical CompositionDocument5 paginiMaterial Name C MN Si CR Mo Ni N CB Cu NB: Filler Metal 1 Chemical CompositionGerard van BrakelÎncă nu există evaluări

- Valence Electrons For ElementsDocument31 paginiValence Electrons For ElementsVinluan, Kaye Andrei P.Încă nu există evaluări

- Lecture#3 Kinematic AnalysisDocument8 paginiLecture#3 Kinematic AnalysisRenuga Subramaniam100% (1)

- Introduction To Shape Memory Alloys-SpringerDocument31 paginiIntroduction To Shape Memory Alloys-SpringerYah IratoÎncă nu există evaluări

- Fatigue Life of A Mining Dump Truck...Document9 paginiFatigue Life of A Mining Dump Truck...Esteban FaundezÎncă nu există evaluări

- Temporary Footing For Rectangular TankDocument1 paginăTemporary Footing For Rectangular TanksonofalexanderÎncă nu există evaluări

- Ce-424 Structure-V R.C.C DesignDocument38 paginiCe-424 Structure-V R.C.C Designstudio VIIÎncă nu există evaluări

- Prestressed Concrete Piling Design - InputDocument2 paginiPrestressed Concrete Piling Design - InputShirlin CharlesÎncă nu există evaluări

- 1a Boundary Wall Design CalculationDocument9 pagini1a Boundary Wall Design Calculationsanju middya67% (3)

- Failure in MaterialDocument22 paginiFailure in Materialnur afifahÎncă nu există evaluări

- Stress Concentration at NotchesDocument510 paginiStress Concentration at NotchesRodrigo MarinÎncă nu există evaluări

- Convection and Radiation Heat TransferDocument14 paginiConvection and Radiation Heat TransferSalman ShalwaniÎncă nu există evaluări

- 1mechanics of Deformable Bodies I PDFDocument4 pagini1mechanics of Deformable Bodies I PDFChristian Galope33% (3)

- Failure Analysis of Martensitic Stainless Steel Bridge Roller BearingsDocument14 paginiFailure Analysis of Martensitic Stainless Steel Bridge Roller BearingsWylliam Diel WagnerÎncă nu există evaluări

- Hardeness TestDocument6 paginiHardeness TestDilshan MiurangaÎncă nu există evaluări

- Electrode SsDocument29 paginiElectrode SsEbrahim Abdelhady ElmekaweyÎncă nu există evaluări