Documente Academic

Documente Profesional

Documente Cultură

Perform Brazing-Silver Soldering PDF

Încărcat de

tereveTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Perform Brazing-Silver Soldering PDF

Încărcat de

tereveDrepturi de autor:

Formate disponibile

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

LEARNER’S GUIDE

PERFORM BRAZING AND/OR SILVER SOLDERING

Published by

HEART TRUST/NATIONAL TRAINING AGENCY

Produced by

Learning Management Services Department

Gordon Town Road

Kingston 7

Jamaica W.I.

This material is protected by copyright. Copying this material or any part of it by any means,

including digital or in any form is prohibited unless prior written permission is obtained from

the HEART Trust/NTA.

*** 2003***

Version 1 LRDU – AUG. 03

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

TABLE OF CONTENTS

PAGE

Introduction ................................................................................................................................. 1

Welcome ................................................................................................................... 1

This Competency Unit.................................................................................................... 1

Before You Start ............................................................................................................. 2

Planning Your Learning Programme ............................................................................. 2

Self-Assessment Checklist ............................................................................................. 3

How To Use This Learner’s Guide ................................................................................ 4

Using the Computer and other Resources...................................................................... 6

Method of Assessment.................................................................................................... 6

Element 1: Prepare Materials and Equipment .................................................................. 7

Self-Assessment Checklist ........................................................................................... 21

Element 2: Braze and/or Silver Solder ................................................................................ 22

Self-Assessment Checklist ........................................................................................... 27

Element 3: Inspect Joints ...................................................................................................... 28

Self-Assessment Checklist ........................................................................................... 31

Version 1 LRDU – AUG. 03

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

LG-MEMFAB0051A:

PERFORM BRAZING AND/OR SILVER

SOLDERING

INTRODUCTION

Welcome

Welcome to the Learner’s Guide for Unit of Competency “Perform Brazing and/or Silver

Soldering”. This is just one of a number of Learner’s Guides produced for the Skills stream of the

Metal Engineering and Maintenance Industry, and it is designed to guide you, the learner, through a

series of learning processes and activities that will enable you to achieve the specified learning

outcomes for the competency unit.

The content of this guide was developed from the Competency Standard MEMFAB0051A, which

is one of the basic building blocks for the National Vocational Qualification of Jamaica (NVQ-J)

certification within the industry. Please refer to your Learner’s Handbook for a thorough

explanation of standards and competencies, and how these relate to the NVQ-J certification.

You are also advised to consult the Competency Standard and assessment instrument for a better

understanding of what is required to master the competency.

This Competency Unit

“Perform Brazing and/or Silver Soldering” addresses the knowledge and skills requirements for

effective performance of brazing and/or silver soldering. There are three main areas or elements:

Element 1: Prepare Materials and Equipment

Element 2: Braze and/or Silver Solder

Element 3: Inspect Joints

As you go through each element, you will find critical information relating to each one. You are

advised to study them carefully so that you will be able to develop the necessary knowledge,

skills and attitudes for performing brazing and/or silver soldering.

Version 1 LRDU – AUG. 03 1

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Before you start

Before you start this Learner’s Guide, you need to:

a. Obtain a Learner’s Logbook. You will use it to record evidence of your new skills/competence.

As you demonstrate your new skills, record your activities and have your learning facilitator

sign off on them. This will allow you to provide evidence of your competence when you are

being assessed against the competency standard.

b. Ensure that you have access to the facilities and equipment necessary for learning.

c. Ensure that your learning resources are available.

d. Ensure that you are wearing suitable clothing, that tools and equipment are safe, and that the

correct safety equipment is used.

e. Plan your learning programme (see below)

f. Understand how to use this Learner’s Guide (see below)

Planning your learning programme

The self-assessment checklist on the following page will assist you in planning your training

programme and it will help you to think about the knowledge and skills needed to demonstrate

competency in this unit. As you go through the checklist you will be able to find out what

elements you have already mastered and which ones you will need to pay more attention to as

you go through the learning process.

To complete the self-assessment checklist, simply read the statements and tick the ‘Yes’ or ‘No’

box. You should do this exercise now.

Version 1 LRDU – AUG. 03 2

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Self-Assessment Checklist

Perform Brazing and/or Silver Soldering

Element 1 Prepare Materials and Equipment Yes No

1. I can determine job requirements from specifications

and/or instructions ( ) ( )

2. I can prepare materials correctly using appropriate tools

and techniques ( ) ( )

3. I can assemble/align materials correctly to meet specifications

as required ( ) ( )

4. I can identify distortion prevention measures and take

appropriate action as required ( ) ( )

5. I can assemble and set up heating equipment safely and

correctly in accordance with standard operating procedures ( ) ( )

6. I can select and prepare correct and appropriate consumables ( ) ( )

7. I can undertake and verify test run as required ( ) ( )

Element 2 Braze and/or Silver Solder Yes No

1. I can select, correct and follow appropriate process to meet

specifications ( ) ( )

2. I can preheat materials as required ( ) ( )

3. I can apply consumables using correct and appropriate techniques ( ) ( )

4. I can apply jointing material correctly and in appropriate

quantities to meet job/specifications ( ) ( )

5. I can correct temperatures using appropriate techniques ( ) ( )

Version 1 LRDU – AUG. 03 3

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Element 3 Inspect Joints Yes No

1. I can remove excess jointing materials using correct and

appropriate techniques ( ) ( )

2. I can undertake inspection of joints using standard operating

procedures and meeting specifications ( ) ( )

3. I can report/record inspection results using standard operating

procedures as required ( ) ( )

How did you do?

If you ticked all or most of the ‘Yes’ boxes then you might not need to go through the entire guide.

Ask your learning facilitator to assist you in determining the most appropriate action you should

take.

If you ticked a few of the ‘Yes’ boxes or none at all then you should work through all of the guide,

even though some of the material may be familiar to you.

Plan your learning based on your answers. Be sure to involve your learning facilitator in the

planning process.

How to use this Learner’s Guide

This Learner’s Guide is designed to assist you in working and learning at your own pace.

We suggest that you:

• Go through the sections/elements as they are presented (starting at Section 1)

• Check your progress at each checkpoint to ensure that you have understood the material

• Observe the icons and special graphics used throughout this guide to remind you of what you

have to do and to enhance your learning. The icons and their meanings are as follows:

Version 1 LRDU – AUG. 03 4

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Complete Assessment Exercise

This exercise requires you to think about the knowledge and skills

that you have or will develop in this competency unit.

Definition Box

Words/phrases are defined or explained in this box. The

words/phrases being explained are in bold print.

Checkpoint

This denotes a brain teaser and is used to check your

understanding of the materials presented. No answers are

provided for the questions asked.

Activity

This denotes something for you to do either alone or with

the assistance of your trainer/supervisor.

Reference

Points you to the reference materials and other support

documents or resources used in compiling the unit content.

• Ask your learning facilitator for help if you have any problems with the interpretation of the

contents, the procedures, or the availability of resources.

• Complete each activity as you come to it. If the activity requires you perform an actual task,

be sure to tell your learning facilitator when you get to that activity so that he/she can make

any arrangements, if necessary.

• Get your learning facilitator to sign and date the Learner Logbook when you have completed an

activity.

• Complete the self-assessment checklist at the end of each section or element.

When you have worked through all elements of the guide, and when you can tick every ‘Yes’ box,

you are ready for assessment and should ask your learning facilitator to assist you in making the

arrangements to have your performance assessed.

Version 1 LRDU – AUG. 03 5

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Using the Computer and Other Resources

Where your activities refer you to the library, computer and Internet resources, ask your learning

facilitator to assist you with locating these resources. If you are getting your training in an

institution, there may be a library and a computer laboratory. If this is not the case, visit the local

library and find out what resources are available.

If you are new to the computer and the Internet, someone should be able to show you how to use

these resources.

Please note that in many of your activities you have been referred to information on the Internet.

This is because the Internet has a vast amount of information that can help you in acquiring the

particular competencies. We would like to advise you, however, that we cannot guarantee that all

the sites will be available when you need them. If this happens, ask your learning facilitator to

assist you with locating other sites that have the information you require.

Method of Assessment

Competency will be assessed while you are actually performing the tasks related to this

competency, this may be in a real workplace or a simulated situation that accurately relates to the

work situation. You are advised to consult the associated competency standard and assessment

instrument for further details relating to the assessment strategies.

You may now start your learning. Have fun while you work!

Version 1 LRDU – AUG. 03 6

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ELEMENT 1: PREPARE MATERIALS AND EQUIPMENT

LEARNING OUTCOMES

As you go through this element it will provide you with the knowledge, skills and attitudes required

to prepare materials and equipment. Your learning facilitator is there to assist you with the various

activities so on completion you should be able to:

1. Determine job requirements from work sheet specification.

2. Prepare material correctly by using appropriate tools and applying appropriate techniques.

3. Correctly assemble or align job to meet specifications based on work sheet.

4. Put all the necessary measures in place to prevent or minimize distortion.

5. Assemble and set up oxyacetylene welding equipment to complete operation.

6. Select the correct brazing rod or solder and flux to complete the job.

7. Test run the operation to ensure all steps and procedures are followed.

DETERMINE JOB REQUIREMENTS FROM WORK SHEET SPECIFICATION

As you go through this topic, you will understand that the processes of brazing and soldering are

representative of the family of metallurgical bonds.

Brazing

A metallurgical joining method using filler metal, which

melts over 425˚C and relies on wetting as well as diffusion

for the bond strength.

Soldering

A metallurgical joining method using filler metal (the solder)

with a melting point below 315˚C and relies on wetting for

the bond formation

You generally plan work from drawings or specifications or use your knowledge of fluxes and base

metals to analyze parts. You then select and set up soldering and brazing equipment and examine

joints, to ensure that they meet standards or specifications. Sometimes you may have more limited

duties or may perform routine jobs that already have been planned and laid out and do not require

extensive knowledge of soldering and brazing techniques.

Refer to: Welding, Soldering and Brazing Workers www.bls.gov/oco/ocos226.htm

Version 1 LRDU – AUG. 03 7

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Below you will see an example of a work sheet specification showing the plan and end view of mild

steel plates 1.6 mm x 38 mm x 152 mm.

38 mm

1.6mm

152mm

Material: Mild steel plate

Project: Silver solder/braze a butt joint

You should ensure that the material is correctly prepared according to specification sheet. This can

be done by:

• cutting material using hand hacksaw according to specifications

• prepare edges properly by using file or grinding machine

• using try square to check for squareness

• checking measurements to ensure they are correct

ACTIVITY

Determine job requirements from a worksheet specification

assigned to you by your learning facilitator and discuss

Solder Joint Design

The job sheet specification must be designed to bring out the major advantages of a solder joint.

In the design process you will discover that the material selection is an important aspect of the

preparation process. From the job sheet you will determine the type of base metals, the flux and

the solder alloys. There are six design qualities that you should take into consideration. They

are:

• Electrical conductivity

• Mechanical durability

• Heat dissipation

• Ease of manufacturing

• Simplicity of repair

• Visual inspectability

Version 1 LRDU – AUG. 03 8

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ACTIVITY

Discuss these six design qualities with your learning facilitator

Base Metals - The table below shows the different types of metals and their soldering capabilities:

Different types of metals and their soldering capabilities

Number Metal Solderability

1 Magnesium 2

2 Beryllium 3

3 Aluminium 2

4 Zinc 1

5 Chromium 3

6 Iron 1

7 Cadmium 1

8 Indium 1

9 Cobalt 3

10 Nickel 1

11 Tin 1

12 Lead 1

13 Hydrogen

14 Stainless Steel 2

15 Antimony 1

16 Bismuth 1

17 Silicon 3

18 Copper 1

19 Steel 1

20 Silver 1

21 Palladium 1

22 Gold 1

1 = Solders under normal conditions, 2 = Solders under special conditions,

3 = Not normally soldered

Version 1 LRDU – AUG. 03 9

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

CHECKPOINT

Which one of these metals would you choose for your soldering

activity?

Flux – You must be aware that flux has two functions:

• to influence the equilibrium between the surface of the metal and the tension that exists in

the direction of the spreading solder.

• to provide surfaces that are tarnish free and to keep the surface in a clean state.

Flux

This means, “flow” in Latin. It helps in the rate and the

degree of completion of the solder joint.

There are a number of factors you should consider in the selection and use of flux:

• Time – when selecting a flux you should consider one that affect the solder quickly,

maximizing the number of joints that can be soldered per unit of time.

• Temperature – match the temperature characteristics of the flux to the assembly so that the

materials will not break down under a high temperature.

• Corrosion – this must be controlled or else the joint will weaken and eventually fail.

• Safety – the flux should give off harmless fumes during soldering.

Here are examples of fluxing materials divided into two types: inorganic and organic. Organic is

subdivided into non-rosin base and rosin base (a type of flux ingredient), which we will be looking

at:

Organic: Non – rosin base

Version 1 LRDU – AUG. 03 10

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Non- Typical fluxes Vehicle UseTemperature Tarnish Corrosiveness Post -

rosin stability removal solder

base cleaning

methods

Amines Urea, Water, Structural, Fair Good Moderate Hot water

and ethylenediamine, and electrical rinse,

amides mono and organic organic

triethanolamine solvents solvents

Resins Synthetic and Alcohols, Electrical Fair Good Slight Water and

(type natural resins organic saponifiers

SA) solvents, or

glycols terpenes;

alcohol;

organic

solvents

Organic: rosin base

Rosin Typical Vehicle Use Temperature Tarnish Corrosiveness Post-solder

base fluxes stability removal cleaning

methods

Rosin, Rosin or Alcohols, Structural, Fair Very Moderate Water base

Super resin organic electrical good detergents;

activated with solvents isopropanol;

strong organic

activators solvents

No- Rosin or Alcohols, Electrical Poor Good None Only rosins

clean resin organic can be

rosin activators solvents cleaned

Version 1 LRDU – AUG. 03 11

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

PREPARE MATERIAL CORRECTLY BY USING APPROPRIATE TOOLS AND APPLYING

APPROPRIATE TECHNIQUES

As you prepare your material, there are certain steps that you should consider:

• ensure that material is properly squared up and is free from burrs by using files and try

square

• be sure the material you are soldering is completely clean. Dirt, grease or any foreign matter

limits the holding power of solder. Clean any flat surfaces, which are to be soldered with

steel wool, a file, emery cloth, etc. It's important to take time to clean the surface thoroughly

• any material to be soldered should be scraped, sanded or treated with a soldering flux before

you apply the solder

• materials should be of the correct measurement

• use the necessary soldering/brazing flux to clean metal thoroughly

remember different fluxes are recommended for different silver solders, and you should

always use the one that matches the grade you are using

File any corrosion from the top of the soldering iron or gun

There are many types of soldering pencils, guns and irons that are adequate for use. There are

soldering tips that can be used with your propane torch. There is even a small refillable butane gas-

powered soldering tool.

Before soldering with any pencil, gun or iron, be sure the tip is thoroughly cleaned. Use a light or

medium file to remove any corrosion that is built up on the tip of the soldering point. The tip of a

soldering tool should be clean at all times.

The shape of the tip on the soldering iron or gun is important. The modified chisel tip as illustrated

is ideal for most soldering jobs.

Version 1 LRDU – AUG. 03 12

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Refer to: Learning Basic Soldering:

www.nrha.org/orgill/How-To/electric/soldering/solder.htm

ACTIVITY

Prepare materials for soldering under the direction of your learning

facilitator

CORRECTLY ASSEMBLE OR ALIGN JOB TO MEET SPECIFICATION BASED ON WORK

SHEET

Soldering

There are three basic types of solder joints that you should know: sweat, which is surface to surface

(joining two flat sheets of metal, one on top of the other); strip, or edge to surface (joining a bezel to

its base); and butt, or edge to edge (joining two sheets abutting, or side by side, as in marriage of

metals or as in two wires end to end).

This simple fact dictates where the solder is placed and how the heat is applied in any solder joint.

Disregarding this principle causes more frustration and disasters than anything else except a poor fit.

Sweat-solder joint, surface-to-surface

Version 1 LRDU – AUG. 03 13

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Strip solder joint. Edge-to-edge surface

Butt solder joint. Edge-to-edge surface

• Plates should be properly squared up and free from burrs.

• Plates must be aligned according to work sheet specifications.

Brazing

Brazing is usually used to join both similar and dissimilar metals. These include:

• Steel

• Wrought and Cast Iron

• Brass

• Bronze

• Copper Alloy

• Aluminum

• Silver

The following processes are usually followed by brazing:

• Cleaning

• Filing

• Joint Preparation (for brazing, the base materials must be very clean and the joint must be

perfectly fit with each other. Thus, more time has to be spent on joint preparation.)

Version 1 LRDU – AUG. 03 14

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Below is a joint properly aligned.

Lap joint

Brazing process in progress

A strong brazing bond illustrated that is a result of proper preparation

Version 1 LRDU – AUG. 03 15

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ACTIVITY

Prepare materials for brazing or soldering as directed by your

learning facilitator and ensure to have your progress monitored

PREVENT OR MINIMIZE DISTORTION

A major concern for you, when joining, is the susceptibility to cracking and deformation. Cracks

can occur in various regions of the joint with different orientations, such as centerline cracks,

transverse cracks, and micro cracks in the underlying weld metal or adjacent heat-affected zone

(HAZ). These cracks are primarily due, to low-melting liquid phases, which allow boundaries to

separate under the thermal and shrinkage stresses during weld solidification and cooling. Types of

distortion are listed below:

• Longitudinal shrinkage

• Transverse shrinkage

• Angular distortion

• Bowing

• Buckling

• Twisting

You should ensure that distortion is prevented by:

• using a sequence of welding known as wandering that provides for making welds at

different points of the braze or solder.

• tacking welding both ends prior to completing the weld.

• supporting work piece during the soldering/brazing process.

• pre-setting parts so that welding distortion will achieve overall alignment and dimensional

control with the minimum of residual stress.

• pre-bending edges to counteract distortion and achieve alignment and dimensional control

with minimum residual stress.

ACTIVITY

Discuss with your learning facilitator the distortion prevention

methods and research other means

Refer to: Website on welding: www.weldingengineer.com/Stainless%20Steel.htm

Version 1 LRDU – AUG. 03 16

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ASSEMBLE AND SET UP OXY-ACETYLENE WELDING EQUIPMENT TO COMPLETE

OPERATION

Assembling and setting up your oxy-acetylene equipment is important for a successful operation.

The oxy-acetylene welding equipment should include:

• acetylene cylinder

• oxygen cylinder

• means of securing the cylinders in an upright position.

• acetylene and oxygen regulators and gauges

• acetylene and oxygen hoses

• welding torch

• spark lighter

• safety equipment.

Refer to: William A. Bowditch and Kevin E. Bowditch, (1997), Welding Technology

Fundamentals, The Goodyear/Willcox Company Incorporation Page 36.

Before you use the welding equipment you should:

• check to see if the cylinders are in good condition.

• fasten cylinders to hand truck to prevent them from falling.

• blow out the cylinder opening by opening the valve slightly to blow away any dirt particles

that might be there before attaching regulator to cylinder.

• inspect sealing surfaces and fittings. Avoid using worn or damage parts.

• attach regulator to cylinder. Be sure that the regulator nut fits the cylinder valve fittings

properly.

• connect hoses to regulators. Hoses should not be twisted, one around the other.

• allow high-pressure oxygen or acetylene to pass through the respective hoses, connect hoses

to torch before connecting the torch to hoses

• check for leaks. Use soapy solution on outside joints where leaks is suspected; bubbles will

indicate if any leak exists.

Oxy-acetylene equipment

Version 1 LRDU – AUG. 03 17

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ACTIVITY

With the help of your learning facilitator, assemble and set up

an oxy-acetylene welding equipment

SELECTING THE CORRECT BRAZING ROD/SOLDER AND FLUX TO COMPLETE JOB

Brazing makes use of a solder, often called spelter, which is an alloy of copper and zinc in strip,

wire or granulated form.

The brazing rod is of a special alloy that makes it possible to braze lightweight stainless steel, brass,

copper, bronze, as well as precious metals such as gold and silver.

Brazing Rods

When silver soldering you have to make use of a solder, which is an alloy of copper, zinc and

silver. An example of a silver solder is Stay Brite. This is a versatile non-toxic and low cost silver

solder of great strength for working at low temperatures. It has excellent affinity for all ferrous

and nonferrous alloys. It has more than five times the strength of ordinary tin-lead solders. It can

be used for all metals except aluminum. Stay Brite solder is a composition of 96% tin and 4%

silver and will melt at 430°C. The finished joint will be silver in color.

Version 1 LRDU – AUG. 03 18

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

Solder Wire

A flux designed for external use and compatible with all of the silver solder rods offered.

Brazing flux Solder flux

ACTIVITY

Ask your learning facilitator to assist you in making the

correct selection of brazing and soldering rods and flux

Version 1 LRDU – AUG. 03 19

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

TEST RUNNING THE OPERATION TO ENSURE ALL STEPS AND PROCEDURES ARE

FOLLOWED

When you are running a test, the following is to be taken into consideration:

• emery or file is used to make sure work is clean before starting

• the joint is reasonably tight

• the right flux is used

• work is packed round with firebrick to conserve heat

• the correct amount of solder is used (and size of rod) for the job

• the correct heat for solder being used must be obtained

• avoid prolonged heating. This causes scale to work into the joint

• concentrate the heat on the larger mass of the metal so that both parts of the joint are brought

together

• solder/brazing rod is dipped into flux before applying

• apply the solder at the correct time and place

• control the flow of the solder

• inspect job and make any necessary adjustment

ACTIVITY

Conduct a test run with the supervision of your learning

facilitator on prepared materials and discuss your results

CHECKPOINT

Why is it necessary to clean the joint thoroughly before

soldering?

Version 1 LRDU – AUG. 03 20

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ARE YOU READY TO PROVE YOUR COMPETENCY?

Now that you have completed this element see if you have fully grasped all the components by

doing the following self-assessment:

Checklist 1 Yes No

1. I can identify job requirements from specification sheet ( ) ( )

2. I know how to prepare material correctly by using appropriate

tools and techniques ( ) ( )

3. I know how to correctly assemble or align job to meet specifications

based on work sheet ( ) ( )

4. I understand how to put all the necessary measures in place to

prevent or minimize distortion ( ) ( )

5. I know how to assemble and set up oxy-acetylene welding

equipment ( ) ( )

6. I know how to select the correct brazing rod or solder and flux

to complete the job ( ) ( )

7. I know how to test run the operation to ensure all steps and

procedures are followed ( ) ( )

Checklist 2 Yes No

1. Job requirements from specification sheet are identified ( ) ( )

2. Material is prepared correctly using appropriate tools and

techniques ( ) ( )

3. Job is correctly assembled or aligned to meet specifications ( ) ( )

4. All necessary measures are in place to prevent or minimize

distortion ( ) ( )

5. Oxy–acetylene welding equipment are assembled and set up

appropriately ( ) ( )

6. Correct brazing rod or soldering and flux are selected ( ) ( )

7. Test run on operation was done according to procedures ( ) ( )

Version 1 LRDU – AUG. 03 21

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ELEMENT 2 BRAZE AND/OR SILVER SOLDER

LEARNING OUTCOME

As you go through this element it will provide you with the knowledge, skills and attitudes to braze

and/or silver solder. Your learning facilitator is there to assist you with the various activities, so on

completion you should be able to:

1. Select process appropriate to meet specifications

2. Preheat material as required

3. Use appropriate techniques while using consumables

4. Apply joint material correctly and in appropriate quantities to meet job specifications

5. Use correct temperature and appropriate techniques during operation

SELECT PROCESS APPROPRIATE TO MEET SPECIFICATIONS

Your selection is dependent upon:

• type of job

• desired outcome

• type of material being used

Brazing should be used for joints that are relatively strong and/or and are able to withstand

reasonable heat. Silver solder is mostly useful for brass.

Soldering is commonly used for electrical connection or mechanical joints, but brazing

is only used for mechanical joints due to the high temperatures involved.

ACTIVITY

Discuss with your learning facilitator your selection of a

joining process for the specifications that are required for

mechanical joint

Version 1 LRDU – AUG. 03 22

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

PREHEAT MATERIAL AS REQUIRED

Preheating is often necessary to control or reduce the rate of expansion or contraction in a structure

during welding. This is done by preheating the entire structure before welding and maintaining the

heat during welding. When preheating be sure that you move the torch in a circular or constant

motion. Overheating should be avoided as this weakens the final joint, and is recognized by black

areas of burnt flux.

ACTIVITY

Conduct the preheating of a material for brazing or soldering

under the supervision of your learning facilitator

Use appropriate techniques while using consumables

Forehand welding technique

In this method the welding rod precedes the torch. You should hold the torch at an

approximately 30-degree angle from the vertical, in the direction of the weld. The flame is

pointed in the direction of welding and directed between the rod and the molten puddle. This

method is satisfactory for welding sheets and light plates in all positions.

Backhand welding technique

In this method, the torch precedes the welding rod. You should hold the torch at an angle

approximately 30-degrees from the vertical, away from the direction of welding, with the flame

directed at the molten puddle. The welding rod is between the flame and the molten puddle.

This position requires less transverse motion than is used in forehand welding.

Backhand welding is used principally for welding heavy sections because it permits the use of

narrower V's at the joint

Version 1 LRDU – AUG. 03 23

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

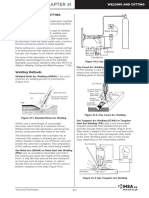

Four Types of Weld Positions

Types of joints

ACTIVITY

Ask your learning facilitator to demonstrate the backhand and the

forehand methods to you, after that, try to emulate his/her example,

and then allow your work to be assessed.

Version 1 LRDU – AUG. 03 24

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

APPLY JOINT MATERIAL CORRECTLY AND IN APPROPRIATE QUANTITIES TO MEET

JOB SPECIFICATIONS

Surfaces of the metals worked on for joining, should be brought to just above the melting point

of the filler rod, when the flux boils and melts into the joint. The filler rod tapped with flux

should now be touched on to the joint at the hottest part until it begins to melt and flow into the

joint. On no account should you melt the rod and allow it to drop off on the joint. The joint

should now be progressively heated and braze/silver soldered.

Welding is always done in the flat position whenever possible. The puddle is much easier to

control, and the welder can work longer periods without tiring. Quite often it is necessary to

weld in the overhead, vertical, or horizontal position in equipment repair. The flat position is

used when the material is to be laid flat or almost flat and welded on the topside. The welding

torch is pointed downward toward the work. This weld may be made by either the forehand or

backhand technique.

The overhead position is used when the material is to be welded on the underside, with the torch

pointed upward toward the work. In welding overhead, you can keep the puddle from sagging if

you do not permit it to get too large or assume the form of a large drop. The rod is used to

control the molten puddle. You should not permit the volume of flame to exceed that required to

obtain a good fusion of the base metal with the filler rod. Less heat is required in an overhead

weld because the heat naturally rises.

You should use the horizontal position when the line of the weld runs horizontal across a piece

of work, and the torch is directed at the material in a horizontal or near horizontal position. The

weld is made from right to left across the plate (for the right-hand welder). The flame is inclined

upward at an angle of 45° to 65°, and the weld is made with a normal forehand technique.

Adding the rod to the top of the puddle will prevent the molten metal from sagging to the lower

edge of the bead (the weld puddle). If the puddle is to have the greatest possible cohesion, it

should not be allowed to get too hot.

In a vertical weld, the pressure exerted by the torch flame must be relied upon to a great extent to

support the puddle. It is important that you keep the puddle from becoming too hot, and to

prevent the hot metal from running out of the puddle onto the finished weld. It may be necessary

for you to remove the flame from the puddle for an instant to prevent overheating, and then

return it to the puddle.

Vertical welds are started at the bottom, and the puddle is carried upward with a forehand

motion. The tip should be inclined from 45° to 60°, the exact angle depending upon the desired

balance between correct penetration and control of the puddle. A continual forward and

backward movement should be used. The rod is added from the top and in front of the flame

with a normal forehand technique.

Version 1 LRDU – AUG. 03 25

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

CHECKPOINT

What is the importance of using a flux during soldering

operation?

What is the usual position in which welding is done? Why?

ACTIVITY

Discuss with your learning facilitator the application of the

correct quantity of joint material before trying to apply method to

successfully carry out a vertical weld

USE CORRECT TEMPERATURE AND APPROPRIATE TECHNIQUES DURING

OPERATION

The flame that you use should be neutral except when the parent or filler metal contains an

appreciable amount of zinc, in which case the flame should be sufficiently oxidizing to prevent the

zinc fuming off.

ACTIVITY

Apply method of using the correct temperature and technique on

a job specified by your learning facilitator and allow it to be

assessed.

Version 1 LRDU – AUG. 03 26

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ARE YOU READY TO PROVE YOUR COMPETENCY?

Now that you have completed this element see if you have fully grasped all the components by

doing the following self-assessment.

Checklist 1 Yes No

1. I know how to select appropriate processes to meet specifications ( ) ( )

2. I know how to preheat a material as required ( ) ( )

3. I understand how to use appropriate techniques while using

consumables ( ) ( )

4. I know how to apply joint material correctly and in appropriate

quantities to meet job specifications ( ) ( )

5. I know how to use correct and appropriate techniques during

operation ( ) ( )

Checklist 2 Yes No

1. Appropriate process is selected to meet specifications ( ) ( )

2. Material is preheated as required ( ) ( )

3. Appropriate techniques are used while using consumables ( ) ( )

4. Joint material is applied correctly and in appropriate quantities ( ) ( )

5. Correct and appropriate techniques are used during operation ( ) ( )

Version 1 LRDU – AUG. 03 27

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ELEMENT 3: INSPECT JOINTS

LEARNING OUTCOME

As you go through this element it will provide you with the knowledge, skills and attitudes to

inspect joints. Your learning facilitator is there to assist you with the various activities, so on

completion you should be able to:

1. Remove excess jointing materials by using appropriate techniques

2. Inspect joints by using standard operating procedures

3. Record and report inspection results

REMOVE EXCESS JOINTING MATERIALS BY USING APPROPRIATE TECHNIQUES

You can remove excess materials by:

• Grinding

• Gouging

Gouging is generally a process used for removing of weld defects. To start gouging preheat work

piece to bright red using standard blow torch with special nozzle, then remove excess material.

CHECKPOINT

What is gouging?

ACTIVITY

Discuss with your learning facilitator other methods to

remove excess materials. Do the necessary research

on the others and include grinding

Version 1 LRDU – AUG. 03 28

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

INSPECT JOINTS BY USING STANDARD OPERATING PROCEDURES

A weld defect is an imperfection in the weld, which may eventually lead to failure of the soldered

joint under service conditions for which it is designed. You will perform visual inspection for

general appearance. Inspection should include:

• meeting the standard of dimensions required from drawing

• nature of penetration

• signs indicating a lack of fusion

• proper filling of joint and where possible attaining complete penetration

ACTIVITY

Inspect a job identified by your learning facilitator using the

points discussed. Record your assessment and have them

evaluated.

Refer to: For other types of inspection check pages 744 – 746 of the book Welding

Principles and Practices (1981), by Raymond Sacks, Glencoe/MacGraw-

Hill

RECORD AND REPORT INSPECTION RESULTS

Inspections are used to locate flaws and defects of the weld. Inspection results could include:

• verification of consistency of dimension of weld deposit

• uniformity of surface

• smoothness of joints

• evenly spaced ripples

• penetration

• freedom from surface imperfections.

Version 1 LRDU – AUG. 03 29

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ACTIVITY

Make a practice weld, then carry out and record inspection results.

Have your learning facilitator verify them

Refer to: Welding Principles and Practices Pages 112, 128 & 740, Sacks, Raymond

(1981), Glencoe/MacGraw-Hill

Version 1 LRDU – AUG. 03 30

LG-MEMFAB0051A PERFORM BRAZING AND/OR SILVER SOLDERING

ARE YOU READY TO PROVE YOUR COMPETENCY?

Now that you have completed this element see if you have fully grasped all the components by

doing the following self-assessment.

Checklist 1 Yes No

1. I can explain how to remove excess jointing materials by using

appropriate techniques ( ) ( )

2. I understand how to inspect joints by using standard operating

procedures ( ) ( )

3. I know how to record and report inspection results. ( ) ( )

Checklist 2 Yes No

1. Excess jointing materials are removed using appropriate techniques ( ) ( )

2. Joints are inspected using standard operating procedures ( ) ( )

3. Inspection results are recorded and reported ( ) ( )

Version 1 LRDU – AUG. 03 31

S-ar putea să vă placă și

- Perform Brazing-Silver SolderingDocument33 paginiPerform Brazing-Silver Solderingtereve50% (2)

- Carry Out Mechanical Cutting Operations - (Basic)Document33 paginiCarry Out Mechanical Cutting Operations - (Basic)tereve100% (2)

- Chapter 1 Introduction To Mechanical WorkshopDocument10 paginiChapter 1 Introduction To Mechanical WorkshopDipayan DasÎncă nu există evaluări

- Brazing: Brazing Is A Joining Process Whereby A NonDocument23 paginiBrazing: Brazing Is A Joining Process Whereby A Nonshayan sohailÎncă nu există evaluări

- Fabrication & Welding - Basic PrinciplesDocument49 paginiFabrication & Welding - Basic Principlesjayapandis83100% (1)

- MEM05010C Apply Fabrication, Forming and Shaping Techniques - Learner GuideDocument22 paginiMEM05010C Apply Fabrication, Forming and Shaping Techniques - Learner Guidequestionbank.com.au100% (1)

- SheetMetal Bend Allowance GuideDocument3 paginiSheetMetal Bend Allowance GuidesunilbholÎncă nu există evaluări

- Sheet Metal Forming WorkshopDocument7 paginiSheet Metal Forming WorkshopIbrahim Khaled0% (1)

- The Basics of Applying Bend FunctionsDocument18 paginiThe Basics of Applying Bend Functionssssf-dobojÎncă nu există evaluări

- Fundamentals of Engineering Workshop Practice - Materials & Processes (2011, E-Version) Edited by O. E. OkoraforDocument549 paginiFundamentals of Engineering Workshop Practice - Materials & Processes (2011, E-Version) Edited by O. E. OkoraforUdochukwu Mark100% (26)

- Alignment Tests On Milling Machine (Metrology)Document6 paginiAlignment Tests On Milling Machine (Metrology)Saikrishna Nagumalli67% (3)

- Sem1WorkShop PDFDocument8 paginiSem1WorkShop PDFGuddu RajputÎncă nu există evaluări

- Welding Positions - 4 Main Types - Weld GuruDocument19 paginiWelding Positions - 4 Main Types - Weld GuruFarid Ahmed Khwaja100% (1)

- Gear and Gear TrainDocument21 paginiGear and Gear Trainm_er100Încă nu există evaluări

- Wood Lathe PDFDocument6 paginiWood Lathe PDFZIYAUDDIN SEIKHÎncă nu există evaluări

- Soldering, Brazing, Braze Welding, Wearfacing: TopicsDocument42 paginiSoldering, Brazing, Braze Welding, Wearfacing: Topicsyared BeleteÎncă nu există evaluări

- Engineering Workshop Manual Fitting ToolsDocument14 paginiEngineering Workshop Manual Fitting ToolsWilliams A.Subanth Assistant ProfessorÎncă nu există evaluări

- Distorsion Corrective TechniquesDocument4 paginiDistorsion Corrective TechniquesMathew RodriguezÎncă nu există evaluări

- Welding Workshop ManualDocument28 paginiWelding Workshop ManualMADHAV GUPTA 10814-07Încă nu există evaluări

- Welding Joints GuideDocument5 paginiWelding Joints GuideSurendra ChoudharyÎncă nu există evaluări

- Procedure Development For Brazing Inconel 718 Honeycomb Sandwich StructuresDocument8 paginiProcedure Development For Brazing Inconel 718 Honeycomb Sandwich StructuresAchmad Arifudin HidayatullohÎncă nu există evaluări

- EscortsDocument2 paginiEscortspratikÎncă nu există evaluări

- SMAW Guide Shielded Metal Arc WeldingDocument44 paginiSMAW Guide Shielded Metal Arc WeldingAndrew TanÎncă nu există evaluări

- Fundamentals of Joining ProcessesDocument21 paginiFundamentals of Joining ProcessesNosta Silva100% (1)

- Sheet Metal StructuresDocument40 paginiSheet Metal StructuresVandane ReyesÎncă nu există evaluări

- Ch#20 SHEET METAL WORKINGDocument119 paginiCh#20 SHEET METAL WORKINGMustaqeem Sajid Khan100% (1)

- Welding, Brazing & Soldering PDFDocument9 paginiWelding, Brazing & Soldering PDFSuryakant PrabhuÎncă nu există evaluări

- Welding WorkshopDocument43 paginiWelding WorkshopJasmeet KaurÎncă nu există evaluări

- Cluster 4 InformationDocument32 paginiCluster 4 InformationLenny HenninghamÎncă nu există evaluări

- Electric WeldingDocument28 paginiElectric WeldingmayankÎncă nu există evaluări

- Welding 8 - Brazing SolderingDocument19 paginiWelding 8 - Brazing SolderingasitacharyaÎncă nu există evaluări

- Die and Punch Design PresentationDocument24 paginiDie and Punch Design PresentationMebit100% (1)

- Gas Welding PDFDocument42 paginiGas Welding PDFManickamEllampoorananÎncă nu există evaluări

- TVL - SM 11 - w7Document3 paginiTVL - SM 11 - w7CrisTopher L CablaidaÎncă nu există evaluări

- Unit 10 Properties and Applications of Engineering MaterialsDocument12 paginiUnit 10 Properties and Applications of Engineering MaterialsRavishanker Baliga0% (1)

- Gas Tungsten Arc Welding ProcessDocument9 paginiGas Tungsten Arc Welding ProcessJacques Sau100% (1)

- HMT Mandrel Bending 101Document80 paginiHMT Mandrel Bending 101zaiofracassadoÎncă nu există evaluări

- Title High Vacuum Technology A PracticalDocument774 paginiTitle High Vacuum Technology A Practicalcachojr100% (2)

- Welding MetallurgyDocument17 paginiWelding Metallurgydanish moinÎncă nu există evaluări

- ARC WELDING FAULTS: CAUSES AND SOLUTIONSDocument7 paginiARC WELDING FAULTS: CAUSES AND SOLUTIONSleijuliaÎncă nu există evaluări

- Assignment Questions: Unit I Subjective QuestionsDocument2 paginiAssignment Questions: Unit I Subjective QuestionsKalai ArasanÎncă nu există evaluări

- WeldingDocument64 paginiWeldingLiyana100% (1)

- MD Design ConsiderationDocument18 paginiMD Design ConsiderationjhpatelÎncă nu există evaluări

- MEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner GuideDocument8 paginiMEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner Guidequestionbank.com.au50% (2)

- Fabrication ProcessDocument5 paginiFabrication ProcessSeafuri Khairunnisa UntadiÎncă nu există evaluări

- TIG Welding Amp ChartsDocument3 paginiTIG Welding Amp ChartsHikmet ParakÎncă nu există evaluări

- Vacuum Brazing: Dawei Induction Heating Machine Co., LTDDocument9 paginiVacuum Brazing: Dawei Induction Heating Machine Co., LTDsajitha p sÎncă nu există evaluări

- Knowledge Base: Joint DesignDocument7 paginiKnowledge Base: Joint Designdm1680Încă nu există evaluări

- Bench FittingDocument161 paginiBench FittingMichael Castro Abudu100% (2)

- MEM05051A Select Welding Processes - Learner GuideDocument13 paginiMEM05051A Select Welding Processes - Learner Guidequestionbank.com.au100% (1)

- Brazing and SolderingDocument18 paginiBrazing and SolderingbendutsÎncă nu există evaluări

- Easy flux-free brazing of copperDocument2 paginiEasy flux-free brazing of copperKarin Aca OviÎncă nu există evaluări

- Sheet Metal FabricationDocument28 paginiSheet Metal Fabricationsamurai7_770% (2)

- Nes 329 Heat ExchangerDocument32 paginiNes 329 Heat ExchangerSharad Kokate100% (1)

- Safety in Welding, Cutting and Allied Processes, © CSADocument14 paginiSafety in Welding, Cutting and Allied Processes, © CSAkakaÎncă nu există evaluări

- Perform Housekeeping DutiesDocument33 paginiPerform Housekeeping DutiestereveÎncă nu există evaluări

- Maintain Equipments and ConsumablesDocument24 paginiMaintain Equipments and ConsumablesCarl Longmore100% (2)

- Mark Off OutDocument38 paginiMark Off OuttereveÎncă nu există evaluări

- Operate A BarDocument46 paginiOperate A BarKenard100% (15)

- 14 Operate Peripherals DevicesDocument27 pagini14 Operate Peripherals DevicesDeon LatchmanÎncă nu există evaluări

- Suzuki Vitara XL7 Timing Chain ReplacementDocument9 paginiSuzuki Vitara XL7 Timing Chain ReplacementtereveÎncă nu există evaluări

- Training Manual For Election Day Workers-Revised 2015 PDFDocument65 paginiTraining Manual For Election Day Workers-Revised 2015 PDFtereveÎncă nu există evaluări

- 320102b Oxy FuelDocument64 pagini320102b Oxy FueltereveÎncă nu există evaluări

- Advanced Welding Using Oxyacetylene PDFDocument45 paginiAdvanced Welding Using Oxyacetylene PDFtereveÎncă nu există evaluări

- Coating Types and SystemsDocument11 paginiCoating Types and Systemstereve100% (1)

- M2 - U2 - Introduction To Oxy-Acetylene WeldingDocument26 paginiM2 - U2 - Introduction To Oxy-Acetylene WeldingAravind Phoenix100% (2)

- Undertake A Routine TaskDocument16 paginiUndertake A Routine Tasktereve100% (2)

- Mill ScaleDocument7 paginiMill ScaletereveÎncă nu există evaluări

- Blast CleaningDocument8 paginiBlast CleaningtereveÎncă nu există evaluări

- Perform Housekeeping DutiesDocument33 paginiPerform Housekeeping DutiestereveÎncă nu există evaluări

- OAW SafetyDocument19 paginiOAW SafetytereveÎncă nu există evaluări

- Mark Off OutDocument38 paginiMark Off OuttereveÎncă nu există evaluări

- Graduated Measuring DevicesDocument21 paginiGraduated Measuring DevicestereveÎncă nu există evaluări

- OH&SDocument25 paginiOH&Stereve100% (2)

- Light Metal Fabrication Level 1Document149 paginiLight Metal Fabrication Level 1tereveÎncă nu există evaluări

- Perform Housekeeping DutiesDocument33 paginiPerform Housekeeping DutiestereveÎncă nu există evaluări

- Learner Guide: Heart Trust/National Training AgencyDocument28 paginiLearner Guide: Heart Trust/National Training AgencytereveÎncă nu există evaluări

- Carry Out Mechanical Cutting Operations - (Basic) PDFDocument33 paginiCarry Out Mechanical Cutting Operations - (Basic) PDFtereve100% (2)

- Positive Approaches to Discipline at School and HomeDocument2 paginiPositive Approaches to Discipline at School and HometereveÎncă nu există evaluări

- (OAW) - Fuel Gas WeldingDocument39 pagini(OAW) - Fuel Gas WeldingtereveÎncă nu există evaluări

- Engineering DrawingDocument30 paginiEngineering DrawingDeepak MmechÎncă nu există evaluări

- Learner'S Guide: Heart Trust/National Training AgencyDocument21 paginiLearner'S Guide: Heart Trust/National Training AgencytereveÎncă nu există evaluări

- Technical Drawing Unit PlanDocument46 paginiTechnical Drawing Unit PlantereveÎncă nu există evaluări

- Product Design Analysis - HandoutDocument2 paginiProduct Design Analysis - HandouttereveÎncă nu există evaluări

- Secondary Teacher Get Started Guide - FINAL - 25sept2014 PDFDocument19 paginiSecondary Teacher Get Started Guide - FINAL - 25sept2014 PDFtereveÎncă nu există evaluări

- VMBS 2017-2018 FEE GUIDE - Members - 1 August 2017 - Post June 16 RevDocument5 paginiVMBS 2017-2018 FEE GUIDE - Members - 1 August 2017 - Post June 16 RevtereveÎncă nu există evaluări

- Firearms ActDocument57 paginiFirearms ActtereveÎncă nu există evaluări

- Mark Scheme (Results) Summer 2015: GCE Chemistry (6CH01/01) The Core Principles of ChemistryDocument21 paginiMark Scheme (Results) Summer 2015: GCE Chemistry (6CH01/01) The Core Principles of ChemistryAmeenIbrahimÎncă nu există evaluări

- BDA30603 Tutorial 4Document7 paginiBDA30603 Tutorial 4Firdaus JannahÎncă nu există evaluări

- Chemical Injection SkidDocument6 paginiChemical Injection SkidRaheel SultanÎncă nu există evaluări

- Biochem Proteins ReviewerDocument4 paginiBiochem Proteins ReviewerStefany JoyÎncă nu există evaluări

- Klbersynth - UH1 - 6-460Document6 paginiKlbersynth - UH1 - 6-460Chiranjeevi VijayaraghavanÎncă nu există evaluări

- 2 MS ElectrochemistryDocument7 pagini2 MS ElectrochemistrysachinÎncă nu există evaluări

- RP 08 - Dehydrogenase Activity in ChloroplastsDocument4 paginiRP 08 - Dehydrogenase Activity in ChloroplastsAlfred SangÎncă nu există evaluări

- Msds Icr 122 LSFDocument12 paginiMsds Icr 122 LSFWisnu AbaraiÎncă nu există evaluări

- Densification and Microstructure of Si3N4-TiN Ceramic CompositesDocument5 paginiDensification and Microstructure of Si3N4-TiN Ceramic CompositesThiago Do Santos FerreiraÎncă nu există evaluări

- Ganoderma laccase optimizationDocument9 paginiGanoderma laccase optimizationRajeshKumarÎncă nu există evaluări

- Quiz 1Document2 paginiQuiz 1Carolyn Campita100% (1)

- (Re) Coating of Pylons With ZINGAENDocument5 pagini(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateÎncă nu există evaluări

- Summary KH2134 Fluid MechanicsDocument4 paginiSummary KH2134 Fluid MechanicsAzman SamerÎncă nu există evaluări

- Safety Assessment of Methyl Glucose Polyethers and Esters As Used in CosmeticsDocument29 paginiSafety Assessment of Methyl Glucose Polyethers and Esters As Used in CosmeticsCesar Miguel JuniorÎncă nu există evaluări

- Installation Details IguzziniDocument133 paginiInstallation Details IguzziniimtiazÎncă nu există evaluări

- Hazop StudyDocument7 paginiHazop StudyAnderson JoeÎncă nu există evaluări

- Sika 521Document3 paginiSika 521Natasha KamalÎncă nu există evaluări

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDocument5 paginiMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrÎncă nu există evaluări

- 맥머리유기화학8판Document1.177 pagini맥머리유기화학8판이경식Încă nu există evaluări

- Maintaining Boiler Water Quality (35 charactersDocument3 paginiMaintaining Boiler Water Quality (35 characterskcp1986Încă nu există evaluări

- Manufacturing and Metal Working Process ClassificationDocument5 paginiManufacturing and Metal Working Process ClassificationPeeka Prabhakara RaoÎncă nu există evaluări

- Water Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolDocument11 paginiWater Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolLeonard PolancoÎncă nu există evaluări

- Chem Unit 5 Transition Metals AnswersDocument13 paginiChem Unit 5 Transition Metals Answersareyouthere9250% (2)

- Macronutrient Project FinalDocument6 paginiMacronutrient Project Finalapi-259363834Încă nu există evaluări

- The Periodic Table of ElementsDocument39 paginiThe Periodic Table of ElementsSamKris Guerrero Malasaga100% (1)

- TB3 Water Quality Analysis Emergency SituationsDocument8 paginiTB3 Water Quality Analysis Emergency Situationsনিস্তব্ধতার প্রহরেÎncă nu există evaluări

- 12.elastic ConstantsDocument18 pagini12.elastic ConstantsaderancÎncă nu există evaluări

- BCH 2202 Chemical Thermodynamics ModuleDocument84 paginiBCH 2202 Chemical Thermodynamics Modulefrancis100% (5)

- Gas Dynamics-Rayleigh FlowDocument26 paginiGas Dynamics-Rayleigh FlowRahul100% (4)

- Dhuime Et Al. 2012 - ScienceDocument4 paginiDhuime Et Al. 2012 - ScienceLady Johana Buritica CortesÎncă nu există evaluări