Documente Academic

Documente Profesional

Documente Cultură

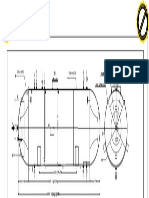

Propane Storage Tank

Încărcat de

MarakanaMaheshDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Propane Storage Tank

Încărcat de

MarakanaMaheshDrepturi de autor:

Formate disponibile

A B C D E F G H I J K

DRAWN

REV DESCRIPTION CHECKED BY APPROVED BY

NOTE:- BY DATE

0 ORIGINAL DRAWING Aniket 02.10.2017 Pooja AAP

1) ALL DIMENSION ARE IN MM UNLESS AND OTHERWISE SPECIFIED.

X C h a n g e Vie X C h a n g e Vie

F- w F- w

PD

PD

er

er

!

!

2) ALL BUTT WELDS SHALL BE BACK CHIPPED TO SOUND METAL & RE-WELD FROM INSIDE.

W

O

O

N

N

y

y

bu

bu

to

to

3) SHELL AND DISHED END SHOULD NOT HAVE NEGATIVE TOLERANCE. NOZZLE SCHEDULE

k

lic

lic

C

C

w

w

m

m

w w

w

o

o

c c REINFORCING PAD

.d o k. .d o k.

1 c u -tr a c c u -tr a c NOZZLE DISCRIPTION QTY. SIZE STD. PIPE SIZE PROJECTION

OD THK

REMARK

WITH

ANSI B-16.5,300# ID -590

M1 MANHOLE 1 600 NB 900 mm 1150mm 18 mm

WNRF,ASTM A- 350 LF-2 THK - 12mm BLIND FLANGE

PNEUMATICALLY TESTED AT 1.5 Kg/cm^2

ANSI B-16.5,300# 50 NB WITH DIP PIPE

N1 LIQUID INLET 1 50 NB 3505 mm

WNRF,ASTM A- 350 LF-2 SCH-80

5) D.P.:- ALL L-SESM,C-SEAM & FILLET FINAL WELD SHALL BE 100% DP TESTED.

ANSI B-16.5,300# 40 NB

N2 VAPOUR INLET 1 40 NB 150 mm

WNRF,ASTM A- 350 LF-2 SCH-80

NAME PLATE 6) WELDING PROCESS :- SMAW ANSI B-16.5,300# 40 NB

N3 VAPOUR OUTLET 1 40 NB 150 mm

WNRF,ASTM A- 350 LF-2 SCH-80

7) ALL BOLT HOLES SHALL STRADDLE TO PRINCIPLE CENTERLINE OF VESSELS. HIGH LEVEL ANSI B-16.5,300# 50 NB

150 mm

N4 1 50 NB

ALARM WNRF,ASTM A- 350 LF-2 SCH-80

SAFETY RELIEF

N5 ANSI B-16.5,300# 50 NB

RADIUS UNLESS OTHERWISE SPECIFIED. A/B VALVE 2 50 NB

WNRF,ASTM A- 350 LF-2 SCH-80

150 mm

ANSI B-16.5,300# 65 NB

8) INNER EDGE OF NOZZLES SHALL BE FLUSH & CORNERS SHALL BE ROUNDED OFF TO MIN. 3 mm N6 SPARE 1 65 NB

WNRF,ASTM A- 350 LF-2 SCH-80

150 mm

TEMPERATURE ANSI B-16.11,6000# 15 NB WITH

N7 1 1/2" BSP 2430 mm

THERMOWELL

C1 W2 C2 C3 C4 C4 W2

C5 9) ALL NOZZLE FLANGE FACES HAVE 125RMS AARH FINISH. GAUGE HC ,ASTM A- 350 LF-2 SCH-80

ANSI B-16.5,300# ID -331 WITH

M2 MANHOLE 1 350 NB 900 mm 650mm 18 mm

WNRF,ASTM A- 350 LF-2 THK - 12mm BLIND FLANGE

10) IS 2062 GR- B IS WELD ABLE QUALITY.

FIXED LEVEL 1 1/4" NPT ANSI B-16.11,6000# - - -

N8 - -

GAUGE FC ,ASTM A- 350 LF-2

W1

2 W1 W1 N9

PRESSURE

GAUGE

1 3/4" NPT ANSI B-16.11,6000#

HC ,ASTM A- 350 LF-2

- - - - -

MAGNETIC LEVEL SPECIAL FLANGE

1 65 NB 59 ID 150 mm

SAFETY VALVE CALCULATION N10 GAUGE ASTM A- 350 LF-2 SPECIAL FLANGE

ANSI B-16.5,300# 25 NB

N11 SPARE 1 25 NB 150 mm

WNRF,ASTM A- 350 LF-2 SCH-80

EXTERNAL SURFACE AREA 1076.11 SQ .FT N12 SPARE 1 25 NB

ANSI B-16.5,300# 25 NB

150 mm

WNRF,ASTM A- 350 LF-2 SCH-80

A DISCHARGE FLOW REQUIRED

SAFETY VALVE QUANTITY

PROVIDED SRV SIZING

4927.97 CFM

2 NOS

50 NB N13 LIQUID OUTLET 1 50 NB

ANSI B-16.5,300#

WNRF,ASTM A- 350 LF-2

50 NB

SCH-80

206 mm 100 mm 18 mm

WITH PIPE

& BEND

MAKE OF S.R.V. Anil Engg. / Chandra & Co.

615 L X 50 W X 12THK.

2 Nos. SUPPORTS 75 L X 150 W X 16THK. (PAD)

59 PAD FOR N13 2 SA 516 GR -70 75 L x 150 W x 12 THK.

58 SUPPORT PIPE FOR N11 2 SA 333 GR -6 80 NB x SCH 40 x 150 L

57 SUPPORT FOR N13 2 SA 516 GR -70 615 L x 50 W x 12 THK.

56 CATHODIC PROTECTION CLEAT 8 SA 516 GR-70 50 L x 75 W x 12 THK.

55 8 SA 516 GR-70 100 L x 100 W x 12 THK.

3 80 NB X SCH- 40 X 150 L

54

PAD FOR CATHODIC PROTECTION CLEAT

1 S S 304 210 W x 180 LG

NAME PLATE

+ 10 mm

53 NAME PLATE BRACKET 1 IS 2062 GR B 210X 180 X 6 THK

52 BEARING PAD 2 SA 516 GR -70 2980 L x 400 W x 18 THK.

+ 50 mm

SIDE VIEW 51

50

EARTHING CLEAT

STIFFENER FOR LUG

2

16

SA 516 GR -70

IS 2062 GR - B

150 L x 75 W x 10 THK.

40 W X 80 H X 10 THK.

LIFTING

LUG

48 LIFTING LUG BASE PLATE 4 SA 516 GR-70 250 W X 150 L X 18 THK

+ 50 mm

FROM A -A 47 LIFTING LUG 4

1

IS 2062 GR - B

SA 516 GR -70

200 H X 200 W X 25 THK

100 OD X 60.3 ID X 18 THK.

46 R.F. PAD FOR N13

45 NOZZLE FLANGE FOR N13 1 SA 350 LF-2 50 NB X 300# X WNRF

N13

44 PIPE FOR N13 1 SA 333 GR-6 50 NB X SCH-80 X 3885 L

43 ELBOW FOR N13 1 SA 420 WPL-6

ELEVATION 42

41

SUPPORT FOR N11 & N12

PIPE FOR N12

4

1

M.S.

SA 333 GR-6

75 X 75 X 5 THK.

25 NB X SCH-80 X 150L

N12

DESIGN DATA 40 NOZZLE FOR N12 1 SA 350 LF-2 25 NB X 300# X WNRF

DESIGN CODE IS 2825 CL - I & SMPV (U) RULES 2016 39 PIPE FOR N11 1 SA 333 GR-6 25 NB X SCH-80 X 150L

N11

38 NOZZLE FOR N11 1 SA 350 LF-2 25 NB X 300# X WNRF

Tf - Thickness of Flange W6 DESIGN PRESSURE 21 Kg/cm2 + Static Head = 21.25 Kg/cm2

37 PIPE FOR N10 1 SA 333 GR-6 59 ID X 150 LONG

N10

W7

1 SA 350 LF-2

DESIGN TEMPERATURE 36 NOZZLE FOR N10 65 NB (SPECIAL FLANGE)

N9

35 COUPLING FOR N9 SA 350 LF-2 3/4" NPT X 6000#

HYDRAULIC TEST PRESSURE 27.63 Kg/cm2 1 SA 350 LF-2

N8

W4 34 COUPLING FOR N8 1/4" NPT(FC) X 6000#

33 MANHOLE NECK 1 SA516 GR-70 659 ID X 900 H X 12 THK.

MAWP 21 Kg/cm2

32 R F PAD FOR M 1 SA516 GR-70 650 OD X 359 ID X 18 THK.

MANHOLE -2

RADIOGRAPHY 100 % STUDS & NUTS 20STUDS SA 320 GR L7 M 27 X 175 LG

31

&NUTS SA 194 GR L7

1 SS304 SPIRALWOUNDED 3.5 THK

30 GASKET FOR M 2

JOINT EFFICIENCY 1 ASBESTOTES FREE

29 COVER FLANGE 1 SA 350 LF-2 350 NB X 300# X BLRF

SERVICE PROPANE 28 MANHOLE FLANGE 1 SA 350 LF-2 350 NB X 300# X WNRF

27 END PLATE FOR N7 1 SA 516 GR-70

CORROSION ALLOWANCE 1.50 mm

N7

26 PIPE FOR N7 1 SA 333 GR-6 20 NB X SCH-80 X 2430L

COUPLING FOR N7 1 SA 350 LF-2 3/4" NPT X 6000#

WATER CAPACITY 58,000 Ltrs. 25

24 PIPE FOR N6 1 SA 333 GR-6 65 NB X SCH-80 X 150L

N6

DENSITY 440 Kg/m3 23 1 SA 350 LF-2 65 NB X 300# X WNRF

NOZZLE FLANGE FOR N6

2"NPT THREAD

N5 A/B

22 PIPE FOR N5 A / B 2 SA 333 GR-6 50 NB X SCH-80 X 150L

FILLING DENSITY 420 Kg/m3 ( 95 % )

21 NOZZLE FLANGE FOR N5 A / B 2 SA 350 LF-2 50 NB X 300# X WNRF

2"NPT HALF HEAT TREATMENT STRESS RELIEVING OF FULL VESSEL

20 PIPE FOR N4 1 SA 333 GR-6 50 NB X SCH-80 X 150L

COUPLING

N4

INSPECTION AGENCY M/S. INDUSTRIAL MANAGEMENT COUNSEL. 19 NOZZLE FLANGE FOR N4 1 SA 350 LF-2 50 NB X 300# X WNRF

VESSEL CLASS CLASS - I 2 M.S. 75 X 75 X 5 THK.

18 SUPPORT FOR N3 A / B

N3

17 PIPE FOR N3 1 SA 333 GR-6 40 NB X SCH-80 X 150L

W7

1 SA 350 LF-2

W7 M8 TAPPED HOLE WITH PLUG 16 NOZZLE FLANGE FOR N3 40 NB X 300# X WNRF

15 SUPPORT FOR N2 A / B 2 M.S. 75 X 75 X 5 THK.

N2

14 PIPE FOR N2 1 SA 333 GR-6 40 NB X SCH-80 X 150L

W3 W3 W3 W3

NOZZLE- N7 - DETAIL (1/2" BSP) 13 NOZZLE FLANGE FOR N2

1

SA 350 LF-2

SA 516 GR-70

40 NB X 300# X WNRF

150 H X 100 W X 12 THK

12 SUPPORT FOR N1

11 PAD FOR N1 1 SA 516 GR-70

N1

PIPE FOR N1 1 SA 333 GR-6 50 NB X SCH-80 X 3505L

10

1 SA 350 LF-2 50 NB X 300# X WNRF

MANHOLE DETAIL - 600 NB (M1) MANHOLE DETAIL - 350 NB(M2) 9

8

NOZZLE FLANGE FOR N1

MANHOLE NECK 1 SA516 GR-70 615 ID X 900 H X 12 THK.

MANHOLE -1

1 1150 OD X 615 ID X 18 THK.

W3 7 R F PAD FOR M SA516 GR-70

7 W5 STUDS & NUTS

24STUDS SA 320 GR L7

M36 X 230 LG

NOZZLE- N13- DETAIL (50 NB) 6

5 GASKET FOR M

&NUTS

1

SA 194 GR L7

SS304 SPIRALWOUNDED 3.5 THK

ASBESTOTES FREE

4 COVER FLANGE 1 SA 350 LF-2 600 NB X 300# X BLRF

3 MANHOLE FLANGE 1 SA 350 LF-2 600 NB X 300# X WNRF

TO BE WELDED AT SITE

CATHODIC PROTECTION LIFTING LUG DETAIL 2 DISHED END 2 SA516 GR-70 ID 2515 X 12 THK.

NAME PLATE DETAIL

NOZZLE- N8 - DETAIL (1/4" NPT) 1 SHELL 1 SA516 GR-70 ID 2515 X 9998 WL / WL X 18 THK.

W7

NOZZLE- N1 - DETAIL (50 NB) CLEAT SR.NO DESCRIPTION QTY MATERIAL SIZE

Tf - Thickness of Flange Tf - Thickness of Flange Tf - Thickness of Flange Tf - Thickness of Flange

BILL OF MATERIAL

SUPPORTS W7 SUPPORTS W7

7

W7

W7

W4

W6 W4

8 W4 W4 8

W4 DE

CATEGORY OF DRG. APPROVAL INFORMATION REFERENCE RECORD CONSTRUCTION

NOZZLE- N11 & N12 PROJECT :

NOZZLE- N9 - DETAIL (3/4" NPT) NOZZLE- N4,N5 A/B- DETAIL (50 NB) NOZZLE- N2 , N3 - DETAIL (40 NB) NOZZLE- N10 - DETAIL (65 NB) NOZZLE- N6 DETAIL (65 NB)

EARTHING CLEAT DETAIL DETAIL - (25 NB) CLIENT :

Ts - SHELL THICKNESS Tn - Nozzle Thickness ( whichever is less. ) ( whichever is less. )

L = Min. 4 Y Ts - SHELL THICKNESS

W1 Ts - SHELL THICKNESS

W2 Z = 1/2 ( Ts - Th ) Th - HEAD THICKNESS W3 Tp - R.F. PAD THICKNESS W4 Tf - Flange Thickness W5 0.7 tc or 6mm

W6 0.7 tc or 6mm

W7 MFG BY: STEELCON TECHNOVISION PVT. LTD.

Tn - Nozzle THICKNESS

B = 0.7 Tp OR 0.7 Ts

B + F = 1.5 Tn or 1.5 Tf T-110, M.I.D.C., BHOSARI, PUNE - 26.

( whichever is less. )

( whichever is less. )

F Should not exceed 16mm DESIGN Aniket

nor less than Tn/2

DRAWN Aniket TITLE : 58,000 LTRS PROPANE MOUNDED STORAGE TANK.

BACK CHIP TO SOUND METAL BACK CHIP TO SOUND METAL

& REWELD FROM INSIDE CHKD Pooja

& REWELD FROM INSIDE

BACK CHIP TO SOUND METAL

BACK CHIP TO SOUND METAL WELDING DETAIL FOR

& REWELD FROM INSIDE WELDING DETAIL FOR HALF COUPLING APPROVED A.A.P.

WELDING DETAIL FOR ALL BUTT WELD JOINT & REWELD FROM INSIDE

WELDING DETAIL FOR PIPE TO FLANGE WELDING DETAIL FOR FULL COUPLING MFG DRG. NO.:- STPL-F-212 REV : 0 DT. 02.10.2017

WELD DETAIL FOR SHELL TO HEAD WELDING DETAIL FOR RF PADS PIPE TO FLANGE

SCALE N.T.S.

I J K

S-ar putea să vă placă și

- PO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDDocument18 paginiPO BOX:41027, Dammam-31521 Kingdom of Saudi Arabia. Petronash Arabia Co. LTDUmair RazaÎncă nu există evaluări

- Filter CalculationDocument4 paginiFilter CalculationRashmi RanjanÎncă nu există evaluări

- Tank Agitator Data Sheet Engineering Procurement Project ManagementDocument10 paginiTank Agitator Data Sheet Engineering Procurement Project ManagementAliZenatiÎncă nu există evaluări

- ETHANOL (6.0D X 8.825 H), Rev. 0Document26 paginiETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaÎncă nu există evaluări

- Design of Tall Vessels for Chemical IndustriesDocument18 paginiDesign of Tall Vessels for Chemical IndustrieskurniahidayatÎncă nu există evaluări

- Flange Mawp Reduction PV Elite PDFDocument8 paginiFlange Mawp Reduction PV Elite PDFDarshan PanchalÎncă nu există evaluări

- Nozzle Check Top Head: Input ParametersDocument2 paginiNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 paginiSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRIÎncă nu există evaluări

- US Units Heat Exchanger Specification SheetDocument1 paginăUS Units Heat Exchanger Specification SheetDwi PutraÎncă nu există evaluări

- Air Exchanger TDDocument9 paginiAir Exchanger TDRajput PratiksinghÎncă nu există evaluări

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 paginiShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharÎncă nu există evaluări

- Calculation of Heat and Mass BalanceDocument16 paginiCalculation of Heat and Mass BalanceHEMANTÎncă nu există evaluări

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocument2 paginiE-03.0) General Static-Mixing Customer Specification QuestionnaireimyourscinÎncă nu există evaluări

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 paginăHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgÎncă nu există evaluări

- Inigneers India Lltvilteid: ElevationDocument7 paginiInigneers India Lltvilteid: ElevationSandip SurÎncă nu există evaluări

- Open TankDocument27 paginiOpen Tankhgagselim2012Încă nu există evaluări

- Process Design of Solid-Liquid Separators (Project Standards and Specifications)Document10 paginiProcess Design of Solid-Liquid Separators (Project Standards and Specifications)nabilaÎncă nu există evaluări

- Compress EvaluateDocument23 paginiCompress EvaluateVishalDhiman100% (1)

- 50T TANK EXTERNAL HEATING COIL CALCDocument7 pagini50T TANK EXTERNAL HEATING COIL CALCArjunÎncă nu există evaluări

- Pressure Vessel Design Old (Eugyene F Megysey)Document31 paginiPressure Vessel Design Old (Eugyene F Megysey)David FonsecaÎncă nu există evaluări

- 09 SpargerDocument17 pagini09 SpargerWeb LogueandoÎncă nu există evaluări

- PV Elite 2008Document3 paginiPV Elite 2008laleye_olumideÎncă nu există evaluări

- Flat HeadsDocument11 paginiFlat HeadsToniÎncă nu există evaluări

- PV Newsletter - Skirt Connections PDFDocument5 paginiPV Newsletter - Skirt Connections PDFDivyesh PatelÎncă nu există evaluări

- He SelectionDocument7 paginiHe SelectionKaizerÎncă nu există evaluări

- Vessel 2 Is To 1 Ellipsoidal VesselDocument3 paginiVessel 2 Is To 1 Ellipsoidal VesselHoang-Vu BuiÎncă nu există evaluări

- Dish End Weight CalculationDocument5 paginiDish End Weight CalculationAniket royÎncă nu există evaluări

- AES Floating HeadDocument8 paginiAES Floating HeadArjun Singh AroraÎncă nu există evaluări

- Mechanical Design and Material Selection for Process EquipmentDocument26 paginiMechanical Design and Material Selection for Process EquipmentibicengÎncă nu există evaluări

- Jet Mixing CalculationDocument3 paginiJet Mixing CalculationRachel FloresÎncă nu există evaluări

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 paginiHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeÎncă nu există evaluări

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 paginăElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanÎncă nu există evaluări

- Dowtherm Vent CondenserDocument1 paginăDowtherm Vent Condensersushant_jhawerÎncă nu există evaluări

- Blower Datasheet SpecsDocument2 paginiBlower Datasheet Specspramod_tryÎncă nu există evaluări

- Flare Stack Calculation Sheet by Erwin ADocument8 paginiFlare Stack Calculation Sheet by Erwin AaltruismÎncă nu există evaluări

- API 650 Baseplate DesignDocument3 paginiAPI 650 Baseplate DesignmjlazoÎncă nu există evaluări

- PLN CNG Process CalculationDocument14 paginiPLN CNG Process CalculationViqiÎncă nu există evaluări

- Boiler Feedwater Treating Systems: Design PracticesDocument96 paginiBoiler Feedwater Treating Systems: Design PracticesAleem QureshiÎncă nu există evaluări

- Output Summary: SI UnitsDocument42 paginiOutput Summary: SI UnitsAkhil JoseÎncă nu există evaluări

- TUBESHEETDocument5 paginiTUBESHEETMehta MehulÎncă nu există evaluări

- Half Pipe Coil AgitatedDocument1 paginăHalf Pipe Coil AgitatedNITINÎncă nu există evaluări

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocument127 paginiPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresÎncă nu există evaluări

- Double FdexchangerDocument8 paginiDouble FdexchangerBoško IvanovićÎncă nu există evaluări

- Volume Calculation For Pressure Vessel TankDocument2 paginiVolume Calculation For Pressure Vessel Tanksai srikarÎncă nu există evaluări

- Mist EliminatorDocument90 paginiMist EliminatordhurjatibhuteshÎncă nu există evaluări

- TubesheetDocument8 paginiTubesheetVaibhavÎncă nu există evaluări

- Arz 104 Wood 125141Document1 paginăArz 104 Wood 125141youcef islaÎncă nu există evaluări

- Pressure Vessel-Tank Sizing: Engineer's Aide Reference GuideDocument27 paginiPressure Vessel-Tank Sizing: Engineer's Aide Reference GuideUsman ArifÎncă nu există evaluări

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocument2 paginiAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanÎncă nu există evaluări

- Vessel Weight CheckDocument8 paginiVessel Weight ChecknileshÎncă nu există evaluări

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeDocument3 paginiThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaÎncă nu există evaluări

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 paginiLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiÎncă nu există evaluări

- Method of Heat Exchanger Sizing Kern MethodDocument10 paginiMethod of Heat Exchanger Sizing Kern Methodvazzoleralex6884Încă nu există evaluări

- Demister SizingDocument3 paginiDemister SizingD K SÎncă nu există evaluări

- Air Cooled ExchangerDocument4 paginiAir Cooled Exchangermayurjannu100% (1)

- Grand - L07-L19 Scut Roa 20201129Document1 paginăGrand - L07-L19 Scut Roa 20201129Ricardo Alejandro Oyarce ArmijoÎncă nu există evaluări

- 180 R Iso 46000 001 - RCDocument8 pagini180 R Iso 46000 001 - RCvigneshÎncă nu există evaluări

- Grand l21 Scut Roa 20201209Document1 paginăGrand l21 Scut Roa 20201209Ricardo Alejandro Oyarce ArmijoÎncă nu există evaluări

- Instalación Eléctrica 3Document4 paginiInstalación Eléctrica 3Alda MarínÎncă nu există evaluări

- P01 SCUT 20200624 - RevDocument1 paginăP01 SCUT 20200624 - RevRicardo Alejandro Oyarce ArmijoÎncă nu există evaluări

- Push in Push To Connect Brass Tube Fittings Web - Pdf#page 2Document7 paginiPush in Push To Connect Brass Tube Fittings Web - Pdf#page 2MarakanaMaheshÎncă nu există evaluări

- Process Industry Practices Piping: PIP PNFS0001 Pipe Supports DetailsDocument167 paginiProcess Industry Practices Piping: PIP PNFS0001 Pipe Supports DetailsromerobernaÎncă nu există evaluări

- Reference List ACHE PDFDocument8 paginiReference List ACHE PDFMarakanaMaheshÎncă nu există evaluări

- Chain and SprocketDocument1 paginăChain and SprocketMarakanaMaheshÎncă nu există evaluări

- PIPE SHOE SUPPORT-Model PDFDocument1 paginăPIPE SHOE SUPPORT-Model PDFMarakanaMaheshÎncă nu există evaluări

- LPG VesselDocument1 paginăLPG VesselMarakanaMaheshÎncă nu există evaluări

- Is 6911 1992Document18 paginiIs 6911 1992RINJUÎncă nu există evaluări

- Sizing An Air CompressorDocument1 paginăSizing An Air CompressorMarakanaMaheshÎncă nu există evaluări

- Argus International LPGDocument18 paginiArgus International LPGMarakanaMaheshÎncă nu există evaluări

- Cable ScheduleDocument36 paginiCable ScheduleMarakanaMaheshÎncă nu există evaluări

- OHH OHHL SingleStageEndSuctionProcessPumps E00697Document5 paginiOHH OHHL SingleStageEndSuctionProcessPumps E00697MarakanaMaheshÎncă nu există evaluări

- OHH OHHL SingleStageEndSuctionProcessPumps E00697Document5 paginiOHH OHHL SingleStageEndSuctionProcessPumps E00697MarakanaMaheshÎncă nu există evaluări

- SPLDocument1 paginăSPLMarakanaMaheshÎncă nu există evaluări

- Rotary Lobe Pump ModelDocument1 paginăRotary Lobe Pump ModelMarakanaMaheshÎncă nu există evaluări

- India NewsDocument68 paginiIndia NewsMarakanaMaheshÎncă nu există evaluări

- Gas CompressorDocument48 paginiGas CompressorAnonymous 1VhXp1100% (1)

- Java MCQ QuestionsDocument11 paginiJava MCQ QuestionsPineappleÎncă nu există evaluări

- Joyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Document11 paginiJoyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Raja Subramaniyan100% (1)

- Biomechanics of Advanced Tennis: January 2003Document7 paginiBiomechanics of Advanced Tennis: January 2003Katrien BalÎncă nu există evaluări

- StsDocument10 paginiStsSamonte, KimÎncă nu există evaluări

- Desarme Del ConvertidorpdfDocument7 paginiDesarme Del ConvertidorpdfDiego Orlando Santos BuitragoÎncă nu există evaluări

- MVJUSTINIANI - BAFACR16 - INTERIM ASSESSMENT 1 - 3T - AY2022 23 With Answer KeysDocument4 paginiMVJUSTINIANI - BAFACR16 - INTERIM ASSESSMENT 1 - 3T - AY2022 23 With Answer KeysDe Gala ShailynÎncă nu există evaluări

- Korba - BAH Online Temp MonitoringDocument7 paginiKorba - BAH Online Temp Monitoringrama jenaÎncă nu există evaluări

- Panasonic TC-P42X5 Service ManualDocument74 paginiPanasonic TC-P42X5 Service ManualManager iDClaimÎncă nu există evaluări

- Principles of Cost Accounting 1Document6 paginiPrinciples of Cost Accounting 1Alimamy KamaraÎncă nu există evaluări

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Document1 paginăASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihÎncă nu există evaluări

- 153C Final Exam Study Guide-2Document6 pagini153C Final Exam Study Guide-2Soji AdimulaÎncă nu există evaluări

- Lab ReportDocument5 paginiLab ReportHugsÎncă nu există evaluări

- Storytelling ScriptDocument2 paginiStorytelling ScriptAnjalai Ganasan100% (1)

- My16-Td My16-AtDocument6 paginiMy16-Td My16-AtRodrigo ChavesÎncă nu există evaluări

- WA Beretta M92FS Parts ListDocument2 paginiWA Beretta M92FS Parts ListDenis Deki NehezÎncă nu există evaluări

- ChE 135 Peer Evaluation PagulongDocument3 paginiChE 135 Peer Evaluation PagulongJoshua Emmanuel PagulongÎncă nu există evaluări

- Analysis of VariancesDocument40 paginiAnalysis of VariancesSameer MalhotraÎncă nu există evaluări

- Chetan Bhagat's "Half GirlfriendDocument4 paginiChetan Bhagat's "Half GirlfriendDR Sultan Ali AhmedÎncă nu există evaluări

- Aircraft ChecksDocument10 paginiAircraft ChecksAshirbad RathaÎncă nu există evaluări

- Levels of Attainment.Document6 paginiLevels of Attainment.rajeshbarasaraÎncă nu există evaluări

- Write 10 Lines On My Favourite Subject EnglishDocument1 paginăWrite 10 Lines On My Favourite Subject EnglishIrene ThebestÎncă nu există evaluări

- Bitcoin MambaDocument17 paginiBitcoin MambaJean MilenixÎncă nu există evaluări

- Electrophoresis and Fractionation of Wheat GlutenDocument14 paginiElectrophoresis and Fractionation of Wheat GlutensecucaÎncă nu există evaluări

- The Slave Trade and The British Empire An Audit of Commemoration in WalesDocument133 paginiThe Slave Trade and The British Empire An Audit of Commemoration in WaleslegoarkeologÎncă nu există evaluări

- JR Hydraulic Eng. Waterways Bed Protection Incomat BelfastDocument2 paginiJR Hydraulic Eng. Waterways Bed Protection Incomat Belfastpablopadawan1Încă nu există evaluări

- K Series Parts List - 091228Document25 paginiK Series Parts List - 091228AstraluxÎncă nu există evaluări

- Practical LPM-122Document31 paginiPractical LPM-122anon_251667476Încă nu există evaluări

- Vintage Style Indonesian Geography Lesson For High School by SlidesgoDocument56 paginiVintage Style Indonesian Geography Lesson For High School by Slidesgoohd InstalasicontrolÎncă nu există evaluări

- HU675FE ManualDocument44 paginiHU675FE ManualMar VeroÎncă nu există evaluări

- Keberhasilan Aklimatisasi Dan Pembesaran Bibit Kompot Anggrek Bulan (Phalaenopsis) Pada Beberapa Kombinasi Media TanamDocument6 paginiKeberhasilan Aklimatisasi Dan Pembesaran Bibit Kompot Anggrek Bulan (Phalaenopsis) Pada Beberapa Kombinasi Media TanamSihonoÎncă nu există evaluări