Documente Academic

Documente Profesional

Documente Cultură

Amendment - I Dated 04.04

Încărcat de

mantu044Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Amendment - I Dated 04.04

Încărcat de

mantu044Drepturi de autor:

Formate disponibile

VARDHMAN FABRICS, UNIT: BUDHNI, M.

P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

AMENDMENT – I DATED 04.04.2018 TO TURBO GENERATOR & AUXILIARIES PACKAGE

Reference :

i) Request for Quotation (RFQ) for Turbo Generator and Auxiliaries : Doc. No. 4-16287-600-0014, Rev. 0 dated 17.01.2018

Volume / Chapter / Clause

No. Bid Description Amendment Description

Reference

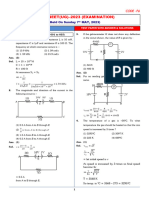

1) Volume – II / Chapter 4 : Generation Voltage : 415V ± 10 % Generation Voltage : 11 kV ± 10 %

Equipment Design Basis and Fault Level : 50 kA for 1 Sec Fault Level : 40 kA for 1 Sec

selection Basis / 4.6.2 Control Supply : 230 V AC Control Supply : 110 V AC

2) Volume – II / Chapter 4 : Generator and its Auxiliaries : The alternator Generator and its Auxiliaries : The generator

Equipment Design Basis and shall be of Synchronous Generator type rated for shall be of Induction Generator type rated for

selection Basis / 4.6.3 415V. 11 kV. Attached Annexure – A shall be referred

to for the Specification for Induction Generator.

3) Volume – II / Chapter 4 : Generator Control and Relay Panel Generator Control and Relay Panel : Attached

Equipment Design Basis and Annexure – A shall be referred to.

selection Basis / 4.6.4

4) Volume – II / Chapter 4 : LT Switchboard Power Plant Switchboard (PCC) is deleted from

Equipment Design Basis and the BIDDER’s scope.

selection Basis / 4.6.5

5) Volume – II / Chapter 4 : LT Busduct LT Busduct is deleted from the BIDDER’s

Equipment Design Basis and scope.

selection Basis / 4.6.6

TURBO GENERATOR & AUXILIARIES Page 1 of 2 AVANT-GARDE

PACKAGE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

Volume / Chapter / Clause

No. Bid Description Amendment Description

Reference

6) Volume – II / Chapter 4 : Protection, Interlock and Inter Tripping Protection, Interlock and Inter Tripping

Equipment Design Basis and Requirements Requirements : Attached Annexure – A shall be

selection Basis / 4.6.7 referred to.

Enclosure :

a) Annexure – A (Specification for various items.)

b) Single Line Diagram for TG : Drg. No. 2-16287-900-0454, Rev. 01.

TURBO GENERATOR & AUXILIARIES Page 2 of 2 AVANT-GARDE

PACKAGE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

ANNEXURE – A

4.6.3 SPECIFICATION FOR INDUCTION GENERATOR

4.6.3.1 Schedule of Equipment

4.6.3.1.1 The equipment shall include one (1) number horizontal shaft three phase

alternating current induction generator to have MCR to deliver the maximum

output of the turbine at 0.8 PF, 11 kV, 50 Hz, 1500 rpm at site condition of 50

Deg. C ambient with all accessories, spares and special tools that will be required

for satisfactory erection and efficient operation of the system. The equipment

shall be supplies as per the requirement of latest revision of IS 325 / IS 8789.

4.6.3.1.2 The generator to be coupled to the turbine shall match in respect of speed, over

speed, moment of inertia, overload capacities, coupling and other relevant

requirements.

4.6.3.1.3 The generator shall be equipped with the following:

a) Stator assembly - 1 No.

b) Rotor assembly - 1 No.

c) End shield mounted bearings - 1 No. each for DE and NDE

d) Sole plate and holding down - 1 Set.

bolts etc.

e) Forced oil lubrication system - One number each of working and

standby in addition to DC Pump

f) Stator winding RTDs (duplex) - 2 per phase.

g) Stator winding temperature - 2 Nos.

Dial type indicator

h) Bearing RTDs (duplex) - 1 No. each for DE and NDE

i) Bearing temperature dial type - 1 No. each for DE and NDE

indicator

4.6.3.1.4 Adequately rated capacitor to maintain power factor of 0.95 at the generator

terminal shall be provided. The capacitor shall be of 12 kV class with surge

arrestor and required fuses. Suitable provision for detecting the fuse blown off

condition through open delta PT and neutral displacement relay shall be provided.

The capacitor shall be sized for not less than 25% of the generator kVA. It shall

ANNEXURE - A PAGE 1 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

be the responsibility of the bidder to substantiate the rating selected with suitable

calculations, without affecting the generator performance. The capacitor shall be

mounted in a separate panel and not in the terminal box.

4.6.3.2 Design Requirement

4.6.3.2.1 The generator shall be designed so as to be capable of running at over speed of the

turbine, and all parts of the generator and other equipment shall fully and safely

withstand stresses resulting from over speed operation. The rotor shall be tested at

1.2 times the rated speed for two (2) minutes.

4.6.3.2.2 The generator shall be provided with efficiency of not less than 98%.

4.6.3.2.3 Generator shall be suitable for being switched on to a solid main even at phase

opposition at a maximum residual voltage of 50% i.e. the generator shall be

capable of withstanding 150% of the rated voltage.

4.6.3.2.4 The generator shall be provided with insulated bearing on NDE side to prevent

the circulation of shaft currents.

4.6.3.2.5 Pull-out torque shall be atleast three times the rated torque.

4.6.3.3 Stator

4.6.3.3.1 The stator shall consist of a frame which may be of cast iron, cast steel or

fabricated from mild steel plate to have the necessary rigidity both for normal and

abnormal operating conditions. The stator core shall consist of low loss magnetic

sheet steel punching securely clamped and fixed in the stator frame to provide a

solid structure for the stator winding. The clamping arrangement shall be such

that during the life of the generator, core looseness shall not set in due to frequent

start/stop thermal cycles.

4.6.3.4 Stator Winding

ANNEXURE - A PAGE 2 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

4.6.3.4.1 The stator winding shall be made out of fully insulated interchangeable coils

suitable for the class of voltage adopted. The insulation shall conform to Class F

material which shall include that of coils, wedges, separators and other winding

materials. However, the stator winding temperature rise shall be limited to class B

values as measured by resistance type embedded temperature detectors when

delivering full load at rated operating conditions with an ambient temperature not

exceeding 50 Deg. C. The winding shall be suitable for operation at 100 percent

humidity conditions. The insulation for the stator winding shall be of the VPI type

insulation system.

4.6.3.4.2 The generator shall be suitable for +10 % to -20% voltage variation (on rated

voltage) and 50 Hz ± 5% frequency variation with maximum temperature rise

limited to limits of ‘Class-B’ insulation.

4.6.3.5 Rotor

4.6.3.5.1 The rotor core shall also be made out of low loss magnetic sheet steel punchings

suitably clamped to withstand the centrifugal forces. The rotor shaft shall be made

out of forged steel having sufficient mechanical strength so as to give minimum

deflection due to static weight and dynamic forces due to normal and abnormal

running conditions. Squirrel cage rotor winding shall be made out of electrolytic

grade copper/copper alloys. The design of the squirrel cage winding shall be such

that a 10 % unbalance in load current shall not cause overheating of the squirrel

cage winding due to negative sequence currents.

4.6.3.5.2 The complete rotor shall be designed to withstand the centrifugal forces under the

maximum run away speed conditions with a factor of safety of not less than 1.5

reckoned on yield point of the material. The critical speed of the shaft system

shall be designed to be atleast 20% more than the maximum runaway speed of the

turbine.

4.6.3.6 Enclosure

4.6.3.6.1 The enclosure shall be of CACA (closed air circuit air cooled) or TETV (totally

enclosed tube ventilated) type.

4.6.3.7 Terminals

4.6.3.7.1 The terminal box shall be phase segregated type.

4.6.3.8 Bearings

ANNEXURE - A PAGE 3 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

4.6.3.8.1 The generator shall be provided with end shield mounted anti-friction bearings of

long life for continuous use. However, where necessary, sleeve type bearings

mounted in end shield are also acceptable.

4.6.3.9 Base Plate

4.6.3.9.1 The generator supplied shall be complete with fabricated / cast base plate for

mounting the generator.

4.6.3.10 Testing

4.6.3.10.1 The generator shall be completely assembled at works and tests as specified

below shall be conducted on the assembled unit and auxiliaries, as per the latest

edition of IS 325. Detailed test reports shall be furnished.

4.6.3.10.2 The following tests shall be carried out on the machine:

a) Measurement of DC resistance of stator and rotor windings.

b) Insulation resistance of stator winding (before and after high voltage tests),

bearings and embedded temperature detectors.

c) High voltage test of stator at power frequency.

d) Polarization Index.

e) Phase sequence measurement.

f) Determination of open circuit characteristics.

g) Determination of short circuit characteristics.

h) Determination of efficiency by separation of losses methods.

i) Vibration measurement.

j) Over speed at 120% for 2 minutes and measurement of vibration there of.

k) Runaway speed test for 15 minutes.

l) Shaft voltage measurement.

m) Shaft vibration measurement.

n) Noise test.

o) Air gap measurement.

p) Mechanical run test for temperature rise.

q) Temperature rise test at iron loss, copper loss with equivalent method

r) Momentary over current test for 150% of rated current for 30 Secs.

s) Stator winding capacitance and tan delta measurement.

4.6.3.11 Make

4.6.3.11.1 The make of generator shall be ABB / CGL / SIEMENS.

ANNEXURE - A PAGE 4 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

4.6.4 GENERATOR CONTROL AND RELAY PANEL

4.6.4.1 The colours for various voltages in the mimic diagram shall be as below:

Voltage Level Mimic Colour Shade as per IS:5

11 V Signal Red 537

4.6.4.2 Trip annunciations shall be provided for the following:

- Differential protection operated.

- Directional Earth Fault

- Non directional instantaneous / IDMT over current.

- Low forward power

- Reverse active / reactive Power

- Non directional instantaneous / IDMT earth fault

- Accidental energisation protection

- Local breaker backup

- Negative phase sequence : stage - II

- Under voltage

- Over voltage

- Under frequency

- Over frequency

- Master trip operated (Dedicated windows for heavy, medium and light

faults, as applicable)

- Emergency trip

- EOP trip

- Generator trip due to turbine trip.

- Turbine tripped due to mechanical fault (Feedback generated from DCS)

- Winding temperature trip

- Bearing temperature trip

4.6.4.3 Alarm annunciations shall be provided for the following:

- Negative phase sequence : stage - I

- TCS of master trip relay unhealthy

- Gen CB trip coil unhealthy

- GCP PT fuse fail

- GRP PT fuse fail

- GPR out of service

- DC fail

- UPS fail

- Winding temperature alarm

ANNEXURE - A PAGE 5 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

- Bearing temperature alarm

4.6.4.4 Trivector / power measurement metering

4.6.4.4.1 Integrating meters of the Trivector or equivalent types capable of indicating all

phase instantaneous parameters and recording kWH, kVARH and kVAH directly

shall be provided. They shall be capable of record / display of harmonic data upto

51st harmonics for PQM. kWHR meters shall also be capable of indicating the

total harmonic levels upto 25th harmonic in the system for current as well as in

voltage parameters, ie VTHD and ITHD.

4.6.4.4.2 These should be suitable for 3 phase, 4 wire 50 Hz circuits with unbalanced

loading and with two sets of elements connected to current and potential

transformers of specified ratio.

4.6.4.4.3 The meter shall be of digital type, class 0.2 or better with communication port,

RS485 interface - MODBUS RTU protocol, for hooking up to PC / DCS.

Necessary softwares for downloading of stored parameters and analysis shall also

be supplied. The meters shall have data retention facility in the event of supply

source failure for a month period. The meter shall also have digital and analog

outputs.

4.6.4.4.4 Meters for frequency, power factor and MW should be of digital type.

4.6.4.5 Dedicated TBs for DCS connectivity as below shall be provided.

- GPR - 1, 2 Out Of Service (DI)

- DC Fail (DI)

- Master Trip Relay Operated (Dedicated TBs for heavy, medium and light

faults, as applicable, shall be provided.) (DI)

- Trip Circuit Unhealthy (Dedicated TBs as above shall be provided)

- Breaker Trip Coil - 1, 2 Healthy (95/52) (DI)

- Voltage (AI)

- Current (AI)

- Frequency (AI)

- Mega Watt (AI)

4.6.4.6 Connection configuration of the protective relays shall be as shown in the tender

Single Line Diagram.

4.6.4.7 The SUPPLIER shall provide a common PC / Laptop, loaded with necessary

software and interface units to receive signals from RS 485 and RS 232

communication ports, along with A4 laser colour printer. The PC shall be of

latest configuration available in the market with a minimum configuration of Intel

ANNEXURE - A PAGE 6 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

core-I7 processor, 8GB DDR3 SD RAM, 500 GB SATA Hard disk, DVD R/W

Drive, optical scroll mouse, 1 serial, 1 parallel, 4 USB ports with 17” LED

monitor. This system shall be suitable for processing & displaying the signals

from the generator digital relays & meters, from the RS485 communication ports

with MODBUS RTU protocol. The PC / Laptop shall be provided with Windows

– 7 OS and latest version of antivirus, MS office and Adobe reader / writer

software. All softwares shall be of life time licensed versions.

4.6.7 PROTECTION, INTERLOCK AND INTER TRIPPING REQUIREMENTS

4.6.7.1 Following Protections shall be planned for the TG System:

4.6.7.1.1 Protection of the generator shall be achieved through microprocessor based,

composite protective digital relays, with one as primary and the other as back-up.

Both the relays shall include the following minimum protective functions:

- Accidental energisation protection

- Over & Under voltage

- Under & Over frequency

- Over Current & Earth Fault

- Directional Earth Fault

- Reverse Power

- Low forward power

- Generator differential

- Local breaker back-up / struck-up

- Negative sequence

- Voltage balance / PT fuse failure

- Over speed protection (from Governor)

4.6.7.1.2 Both the generator protection relays shall have the following minimum features:

- Communication port, RS485 interface - MODBUS protocol, for hooking-

up to DCS / PC, for down loading & parameter settings

- Necessary software, for processing of data.

- Event recording facility, for a minimum of 32 events.

- Disturbance recording & analysis facility

- All the events, disturbances and the fault records, generated both internally

and externally with time stampings, shall be stored in the internal memory

of the generator protection relays and shall be capable of being

downloaded when required. It shall be responsibility of the

SUPPLIER to demonstrate this feature to the PURCHASER’s engineers,

at site.

ANNEXURE - A PAGE 7 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

- Self diagnostic facility

4.6.7.1.3 Additional static / microprocessor based discrete relays for reverse active and

reactive power protections, with settable range of 0.5% connected from Class 0.2

core CT shall be provided.

4.6.7.1.4 Additional discrete relays shall also be provided for the following auxiliary

functions:

- Master trip relay for TG Incomer Breaker

- Master trip relay for Tie Breaker

- Master trip relay for Turbine Trip

- Trip circuit supervision relays for TG Incomer circuit breaker and all

master trip relays

- DC supply failure relay

- Auxiliary relays, if required

4.6.7.2 Following Interlocks shall be planned for the TG system

4.6.7.2.1 Generator shall be switched ON only after turbine reaches 95% of its rated speed.

Accordingly, the turbine speed shall be interlocked.

4.6.7.2.2 Generator shall be switched ON only when the residual voltage is less than 25%

of rated voltage. Required time delay shall be considered during successive

switching ON. Under voltage relay and timer shall be utilised for this purpose.

4.6.7.2.3 Master trip relays healthiness and trip circuit supervision relay healthiness of CB

and its master trip relays shall be used in the closing interlock.

4.6.7.2.4 All protections shall be planned as listed in the respective sections. The trip logic

for the TG to be as per recommendation of the TG Supplier.

4.6.7.2.5 Local breaker back up protection shall trip the Tie CB i.e. LV side CB of the

Power evacuation transformer.

4.6.7.2.6 First stage of under & over voltage functions, under & over frequency functions

and first stage of negative phase sequence function shall trip the Tie CB.

4.6.7.2.7 The following external signals shall be connected to the generator protection

relays for time stamping:

- Generator master trip relays

ANNEXURE - A PAGE 8 AVANT-GARDE

VARDHMAN FABRICS, UNIT: BUDHNI, M.P

(A UNIT OF VARDHMAN TEXTILES LIMITED)

ADDITION OF STEAM CAPACITY, BACK PRESSURE TG & RICE HUSK HANDLING SYSTEM

- Generator circuit breaker status

- Tie CB status

- Status of oil pump starters.

- Turbine tripped due to mechanical fault (Feedback generated from DCS)

- Any other contacts, which are all planned for tripping GCB from panels

other than GRP.

- Four (4) numbers of additional signals for PURCHASER’s use.

4.6.7.2.8 The healthiness of MCB or fuse shall be used in the interlock circuit, wherever

the under voltage function is used.

ANNEXURE - A PAGE 9 AVANT-GARDE

A RD

-G

+

A NT

E

AV

S-ar putea să vă placă și

- 3.HT Motor SpecificationDocument18 pagini3.HT Motor SpecificationsidearthmanÎncă nu există evaluări

- Generator and Excitation SystemDocument43 paginiGenerator and Excitation Systemsandeep11789Încă nu există evaluări

- X PGNDP0464 03 ECI SPC 013 Battery Tripping Unit Specification RevADocument20 paginiX PGNDP0464 03 ECI SPC 013 Battery Tripping Unit Specification RevAgrantÎncă nu există evaluări

- 3.2 Genertaor and Excitation SystemDocument42 pagini3.2 Genertaor and Excitation Systemonur.sezerÎncă nu există evaluări

- Generators - Particular Technical SpecificationDocument96 paginiGenerators - Particular Technical SpecificationAli HEIDARIÎncă nu există evaluări

- GenSet Specification and Technical Data InformationDocument19 paginiGenSet Specification and Technical Data Informationerdananda haryosuwanditoÎncă nu există evaluări

- Guidelines For Selection of Generator For SHPDocument44 paginiGuidelines For Selection of Generator For SHPrajfabÎncă nu există evaluări

- Nigam 11 KV Shunt CapacitorDocument13 paginiNigam 11 KV Shunt CapacitorSandeep SharmaÎncă nu există evaluări

- Partbii IIIDocument388 paginiPartbii IIIsaravananÎncă nu există evaluări

- Eeam Q 014Document7 paginiEeam Q 014史海云Încă nu există evaluări

- P-46-08 - Power TransformerDocument81 paginiP-46-08 - Power TransformerNasrullahÎncă nu există evaluări

- Data Sheet-DG Set - Rev 0Document6 paginiData Sheet-DG Set - Rev 0jhakg_169712275Încă nu există evaluări

- 05 02Document7 pagini05 02arturoncÎncă nu există evaluări

- Sample Quotation For 30MWDocument6 paginiSample Quotation For 30MWS V NAGESHÎncă nu există evaluări

- 04 400 KV 50 63 80 125 MVAr Shunt Reactor NGR SA R2 Jul 08Document66 pagini04 400 KV 50 63 80 125 MVAr Shunt Reactor NGR SA R2 Jul 08anjes1Încă nu există evaluări

- GBT 7894-2001fundamental Technical Requirements For Hydro-GeneratorsDocument20 paginiGBT 7894-2001fundamental Technical Requirements For Hydro-Generatorsaji.isramboÎncă nu există evaluări

- Comments On Volume 07 - Electrical DBR Rev (1) 0702 (Final) - ADocument188 paginiComments On Volume 07 - Electrical DBR Rev (1) 0702 (Final) - AdipakkupatelÎncă nu există evaluări

- Specifications: ModelDocument9 paginiSpecifications: ModelGeiler Benitez PiñaÎncă nu există evaluări

- VFDDocument9 paginiVFDVenkatesh RaoÎncă nu există evaluări

- 50 TMSS 02 R0Document0 pagini50 TMSS 02 R0renjithas20050% (1)

- Technical Specification: Page 1 / 8Document8 paginiTechnical Specification: Page 1 / 8Ahmed AbdulnaimÎncă nu există evaluări

- AutoTransformers P-169:09 WAPDADocument58 paginiAutoTransformers P-169:09 WAPDArzor100% (3)

- Technical Specification For 110V, 80A Auto and Manual Float-Cum-Boost Battery Charger, 110V, 500 Ah Battery & DCDBDocument25 paginiTechnical Specification For 110V, 80A Auto and Manual Float-Cum-Boost Battery Charger, 110V, 500 Ah Battery & DCDBAchu DeepuÎncă nu există evaluări

- Plasma C MDocument9 paginiPlasma C Mhiren1206Încă nu există evaluări

- Chapter 2 Generator and AccessoriesDocument43 paginiChapter 2 Generator and AccessoriesAnonymous nwByj9LÎncă nu există evaluări

- Combined CTPT Set - JVVNLDocument18 paginiCombined CTPT Set - JVVNLManish PareekÎncă nu există evaluări

- Teci NTPC HFTR Rev 00 1422605653Document19 paginiTeci NTPC HFTR Rev 00 1422605653Maya MenanÎncă nu există evaluări

- 11KV Motor Technical Annexure1Document15 pagini11KV Motor Technical Annexure1halder_kalyan9216Încă nu există evaluări

- Generator Technical Excitation System SpecificationDocument20 paginiGenerator Technical Excitation System SpecificationjdanastasÎncă nu există evaluări

- Elect - Generator SetDocument20 paginiElect - Generator SetDom PouchÎncă nu există evaluări

- 43TMSS01R1 Shunt Capacitor Bank, 13.8kV Through 380kVDocument16 pagini43TMSS01R1 Shunt Capacitor Bank, 13.8kV Through 380kVMohamed NasrÎncă nu există evaluări

- 03-Part C3-5 Spec Electrical MotorsDocument7 pagini03-Part C3-5 Spec Electrical MotorsThandabantu MagengeleleÎncă nu există evaluări

- E01 GeneratorDocument28 paginiE01 GeneratorvenkateshbitraÎncă nu există evaluări

- Da-6000ss (60H 110V)Document15 paginiDa-6000ss (60H 110V)Geiler Benitez PiñaÎncă nu există evaluări

- Transformer ManualDocument783 paginiTransformer ManualDorababu MutyalaÎncă nu există evaluări

- General Specifications For Power TransformersDocument18 paginiGeneral Specifications For Power Transformers54045114Încă nu există evaluări

- Data Sheet-DG Set - Rev 0Document6 paginiData Sheet-DG Set - Rev 0jhakg_169712275Încă nu există evaluări

- 43 TMSS 01 R0Document0 pagini43 TMSS 01 R0renjithas2005Încă nu există evaluări

- Ni 2403Document14 paginiNi 2403buboÎncă nu există evaluări

- Technical Specification - Part-Ii: (A) (B) (A) (C)Document27 paginiTechnical Specification - Part-Ii: (A) (B) (A) (C)Octavianus HarahapÎncă nu există evaluări

- Common Motor Requirement ForDocument3 paginiCommon Motor Requirement ForChinith012Încă nu există evaluări

- Reactors - Specification: Indian StandardDocument9 paginiReactors - Specification: Indian StandardAustindaniel JoelsimeonÎncă nu există evaluări

- Specification For Cathodic Protection System Equipment and MaterialsDocument24 paginiSpecification For Cathodic Protection System Equipment and Materialsg1kumar04100% (1)

- Spec Automatic Reactive Power CompensationDocument7 paginiSpec Automatic Reactive Power CompensationDolyÎncă nu există evaluări

- Technical Specification For 110V, 45A Auto Float-Cum-Boost Battery Charger, 110V, 150 Ah Battery & DCDBDocument24 paginiTechnical Specification For 110V, 45A Auto Float-Cum-Boost Battery Charger, 110V, 150 Ah Battery & DCDBkajale.shrikantÎncă nu există evaluări

- TS 110V 150AH Batterry Charger Battery DCDBDocument24 paginiTS 110V 150AH Batterry Charger Battery DCDBkajale.shrikantÎncă nu există evaluări

- SPEC 0021 2005 (Rev.2)Document18 paginiSPEC 0021 2005 (Rev.2)Surendra BajpaiÎncă nu există evaluări

- Application Engineering Bulletin: 1.0 Summary of Installation RequirementsDocument30 paginiApplication Engineering Bulletin: 1.0 Summary of Installation RequirementsDiego Castañeda SantaÎncă nu există evaluări

- DG Set - Rev 0Document30 paginiDG Set - Rev 0jhakg_169712275Încă nu există evaluări

- JTS02 01 01ver9Document25 paginiJTS02 01 01ver9Rafat ThongÎncă nu există evaluări

- 15-5 (Part 4) Electrical Power SupplyDocument17 pagini15-5 (Part 4) Electrical Power SupplytalabizÎncă nu există evaluări

- Terms of Reference MotorsDocument4 paginiTerms of Reference MotorsLevi FondaÎncă nu există evaluări

- HTD02 Series Rectifier Module ManualDocument34 paginiHTD02 Series Rectifier Module ManualJohn SimancaÎncă nu există evaluări

- 4.VFD Spec. Rev.1Document35 pagini4.VFD Spec. Rev.1wado11100% (1)

- Power Electronics Design Handbook: Low-Power Components and ApplicationsDe la EverandPower Electronics Design Handbook: Low-Power Components and ApplicationsEvaluare: 4 din 5 stele4/5 (2)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDe la EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesÎncă nu există evaluări

- Offshore Electrical Engineering ManualDe la EverandOffshore Electrical Engineering ManualEvaluare: 4 din 5 stele4/5 (9)

- Protection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsDe la EverandProtection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsÎncă nu există evaluări

- GuideDocument2 paginiGuidemantu044Încă nu există evaluări

- Heat Cost Calculation enDocument9 paginiHeat Cost Calculation enNurani Legahati LimbongÎncă nu există evaluări

- Service /experience Certificate: LR No: VFB/HRM/2021/0018Document1 paginăService /experience Certificate: LR No: VFB/HRM/2021/0018mantu044Încă nu există evaluări

- Estimation of Power Generation Potential of Agricultural Based Biomass Spiceis and Coal-Biomass Mixed BriquettesDocument57 paginiEstimation of Power Generation Potential of Agricultural Based Biomass Spiceis and Coal-Biomass Mixed Briquettesmantu044Încă nu există evaluări

- Annexure-8.2 - Progress (S) Curves - Procure JB1063Document1 paginăAnnexure-8.2 - Progress (S) Curves - Procure JB1063mantu044Încă nu există evaluări

- HP LP CostDocument1 paginăHP LP Costmantu044Încă nu există evaluări

- Annexure-8.4 - Progress (S) Curves - Site JB1063Document1 paginăAnnexure-8.4 - Progress (S) Curves - Site JB1063mantu044Încă nu există evaluări

- Annexure-2 DRG Doc ScheduleDocument14 paginiAnnexure-2 DRG Doc Schedulemantu044Încă nu există evaluări

- Comparing Boiler Efficiency Calculation MethodsDocument21 paginiComparing Boiler Efficiency Calculation Methodsวรศิษฐ์ อ๋องÎncă nu există evaluări

- Annexure-6-Bought Out ItemsDocument2 paginiAnnexure-6-Bought Out Itemsmantu044Încă nu există evaluări

- Annexure-8.5 - Progress (S) Curves - Ovel All JB1063 PDFDocument1 paginăAnnexure-8.5 - Progress (S) Curves - Ovel All JB1063 PDFmantu044Încă nu există evaluări

- Annexure-8.3 - Progress (S) Curves - Manuf. - Dispatch JB1063Document1 paginăAnnexure-8.3 - Progress (S) Curves - Manuf. - Dispatch JB1063mantu044Încă nu există evaluări

- Biomass EnergyDocument149 paginiBiomass EnergyAnil_biztrackÎncă nu există evaluări

- 1600 9465 1 PBDocument16 pagini1600 9465 1 PBmantu044Încă nu există evaluări

- Comparing Boiler Efficiency Calculation MethodsDocument21 paginiComparing Boiler Efficiency Calculation Methodsวรศิษฐ์ อ๋องÎncă nu există evaluări

- Boilers and ThermicFluidHeatersDocument42 paginiBoilers and ThermicFluidHeatersvallamreddyÎncă nu există evaluări

- 162870116-VII Data Sheet V1 R0-1Document86 pagini162870116-VII Data Sheet V1 R0-1mantu044Încă nu există evaluări

- Amendment - I Dated 04.04Document12 paginiAmendment - I Dated 04.04mantu044Încă nu există evaluări

- USB Fast Charging ModuleDocument2 paginiUSB Fast Charging ModuleFuture is Now Amazing World VideosÎncă nu există evaluări

- GI Cable Tray & Trunking MethodDocument9 paginiGI Cable Tray & Trunking Methodrkss100% (1)

- What Are The Required Subjects To Learn To Become A VLSI Digital IC Engineer - QuoraDocument2 paginiWhat Are The Required Subjects To Learn To Become A VLSI Digital IC Engineer - Quoramahamd saiedÎncă nu există evaluări

- XO 4 ULReportDocument55 paginiXO 4 ULReportAmang GayamÎncă nu există evaluări

- LS Series: Single Output General Purpose Power SuppliesDocument2 paginiLS Series: Single Output General Purpose Power SuppliesJarfoÎncă nu există evaluări

- Power ElectronicsDocument20 paginiPower ElectronicsPuneeth SiddappaÎncă nu există evaluări

- Triumph Tr7 Tr8 Fuel Injection HandbookDocument82 paginiTriumph Tr7 Tr8 Fuel Injection Handbookjorge Angel LopeÎncă nu există evaluări

- Exp 11 Voltage Regulator Using IC 723Document5 paginiExp 11 Voltage Regulator Using IC 723Savio Pereira67% (3)

- Manual UPS RT 5 10kVA en UsDocument48 paginiManual UPS RT 5 10kVA en UsJesus GarciaÎncă nu există evaluări

- Euromatic Series - PartsDocument17 paginiEuromatic Series - Partspickitt2hbÎncă nu există evaluări

- PhysicsDocument10 paginiPhysicssatvikvishnoi0805Încă nu există evaluări

- SETEC 624 E 05-2003: - Optional-Cradle DeviceDocument1 paginăSETEC 624 E 05-2003: - Optional-Cradle DeviceBoudaoudÎncă nu există evaluări

- Arduino OscilloscopeDocument4 paginiArduino OscilloscopeRodolfoPerezEscalonaÎncă nu există evaluări

- 592 en 082 093 Compact HCFB HCBB Fid6087Document12 pagini592 en 082 093 Compact HCFB HCBB Fid6087Boyko IzoffÎncă nu există evaluări

- NK Sir Support Resistance Code For TradingviewDocument2 paginiNK Sir Support Resistance Code For TradingviewKrunal BhosaleÎncă nu există evaluări

- 1 Megabit (128 K X 8-Bit) CMOS 5.0 Volt-Only, Uniform Sector Flash MemoryDocument31 pagini1 Megabit (128 K X 8-Bit) CMOS 5.0 Volt-Only, Uniform Sector Flash MemoryzazarÎncă nu există evaluări

- ECE 5410 Lecture 1Document16 paginiECE 5410 Lecture 1DAN THE MANÎncă nu există evaluări

- Tutorial On Using Xilinx Ise Design Suite 14.6: Design Entry Using VHDL (Full Adder) For Spartan-6 (NEXYS 3 Board)Document14 paginiTutorial On Using Xilinx Ise Design Suite 14.6: Design Entry Using VHDL (Full Adder) For Spartan-6 (NEXYS 3 Board)SEIOT 2Încă nu există evaluări

- Mcqs Of: Introduction To Power QualityDocument61 paginiMcqs Of: Introduction To Power QualityHardik Mehta100% (1)

- SAMS P58SC, Funksioni Butonave, (Cile+l.sh) SERVICE AdjustementDocument55 paginiSAMS P58SC, Funksioni Butonave, (Cile+l.sh) SERVICE AdjustementEnrik VillaÎncă nu există evaluări

- Gsm/Gprs/Gps Tracker Manual: PrefaceDocument14 paginiGsm/Gprs/Gps Tracker Manual: PrefaceHernan HernandezÎncă nu există evaluări

- Wireless Energy TransmissionDocument19 paginiWireless Energy TransmissionShrey Thakur100% (8)

- Electricity PDFDocument9 paginiElectricity PDFAsa KaÎncă nu există evaluări

- Microwave EngineeringDocument15 paginiMicrowave EngineeringRoshan PatrooÎncă nu există evaluări

- AMS 5200 UserManualDocument47 paginiAMS 5200 UserManualabbas dehghanÎncă nu există evaluări

- Exp05 BEC Audio AmplifierDocument3 paginiExp05 BEC Audio AmplifierSavithaGnÎncă nu există evaluări

- Emergency Release Coupling: For Marine Loading ArmDocument11 paginiEmergency Release Coupling: For Marine Loading ArmShamsul Azhar SulaimanÎncă nu există evaluări

- Miniature Circuit Breaker - Acti 9 xC60 MCBs - A9N2P10DDocument2 paginiMiniature Circuit Breaker - Acti 9 xC60 MCBs - A9N2P10DHapidz ErwinÎncă nu există evaluări

- Instrumentation (Chapter 2)Document7 paginiInstrumentation (Chapter 2)Yab TadÎncă nu există evaluări

- 1LE1011 1CJ23 4AA4 Datasheet enDocument1 pagină1LE1011 1CJ23 4AA4 Datasheet enbucek kintamaniÎncă nu există evaluări