Documente Academic

Documente Profesional

Documente Cultură

Riser Inspection Methods

Încărcat de

Anonymous OWeqgODrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Riser Inspection Methods

Încărcat de

Anonymous OWeqgODrepturi de autor:

Formate disponibile

Recommended Practice DNV-RP-F206, April 2008

Page 62

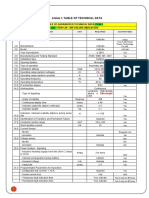

G.8 Riser Inspection Technologies

A summary of Riser Inspection Methods and Techniques and

its applicability is described in the following tables.

G.8.1 Summary of Methods and Techniques

Table G-1 Summary of Methods and Techniques

Pipe wall

Use on Use on Use on Used under See through See through Max. length

Technology thickness

Steel? Titanium? composites? water? coatings? insulation? of inspection

range?

Visual general Yes Yes Yes Yes No No N/A N/A

Visual detailed Yes Yes Yes Yes No No N/A N/A

Geometric tools Yes Yes Yes Yes No No N/A N/A

Short range ultrasonics Yes Yes No Yes Yes < 6 mm No 1 - 40 mm N/A

(manual point by point with

measurements, single marinised

echo or echo to echo equipment

Short range ultrasonics Yes Yes No Yes No No 1 – 40 mm N/A

(permanently bonded Limited

array, single echo or experience

echo to echo)

Short range ultrasonics Yes Yes No Yes No No 6 mm + N/A

(semi-AUT – TOFD) Limited

experience

Short range ultrasonics Yes Yes No Yes No No 1 mm + N/A

(AUT mapping with Limited

single/multiple experience

focussed probes or PA)

Short range ultrasonics Yes Yes No Yes No No 6 mm + N/A

(AUT pigging with sin- Extensive

gle/multiple L- or SV- experience

waves probes or PA)

Long range ultrasonics Yes Yes No Yes Yes Yes 1 mm + <30mm

Limited

experience

ET conventional Yes Yes Yes –R Yes Yes No 1 mm + N/A

RFEC Yes Yes No Yes Yes No 1 mm + N/A

Extensive

experience

Pulsed Eddy current Yes Yes No Yes Yes 6 mm N/A

MFL Yes No Yes –R Yes No No 12 mm N/A

Extensive

experience

ACFM Yes Yes No Yes Yes No 1 mm + N/A

Extensive

experience

FSM Yes Yes No Yes Yes No 1 mm + N/A

Extensive

experience

Digital Radiography Yes Yes Yes –R Yes Yes Yes 1 mm + N/A

Tangential Radiography Yes Yes No Yes Yes Yes 1 mm + N/A

AE Yes Yes Yes –R Yes Yes Yes 1 mm + N/A

Magnetic Particle Yes No No Yes No No 1 mm + N/A

inspection Extensive

experience

G.9 Monitoring System Details verted into digital format using an A/D converter. The dig-

ital communication is done as per the recommended

G.9.1 Data Logging and Transmission Methods standards of the Electronic Industries Association (EIA)

Data logging and acquisition methods can provide response using RS232, RS422 and RS485.

data continuously or intermittently to suit user requirements. — Fibre optic communication is similar to copper wire sys-

For monitoring equipment mounted at or near the water sur- tem with fibre optics replacing the copper wires. Fibre

face the power and data acquisition is generally controlled optic cable connectors are required for this purpose. The

from the vessel. For subsea equipment, the methods of storing electronic data is coded into light pulses which are trans-

and transmitting data generally fall into the following catego- mitted along the fibre-optic medium with a decoder at the

ries: data acquisition end to convert it back to digital data. The

dispersion and scattering of light inside the fibre optic

— Online data logging consists of a hardwired link between cable and the loss of signal strength at the receiving end

the sensors and the data controller at the topsides data should be considered. Signal refreshing units are required

acquisition systems. An electrical cable link is typically at the receiving end.

used for data transfer from the analogue instruments con- — Acoustic data logging consists of the subsea sensors

DET NORSKE VERITAS

S-ar putea să vă placă și

- The Fast Track to Your General Class Ham Radio License: Comprehensive Preparation for All FCC General Class Exam Questions July 1, 2023 through June 30, 2027De la EverandThe Fast Track to Your General Class Ham Radio License: Comprehensive Preparation for All FCC General Class Exam Questions July 1, 2023 through June 30, 2027Încă nu există evaluări

- Spesifikasi Siemens MRI AERA 1,5 TDocument2 paginiSpesifikasi Siemens MRI AERA 1,5 TDr.gendjutÎncă nu există evaluări

- 022516-501A Trimble C3 C5 C5HP ProductComparison USL 0320 LRsecDocument2 pagini022516-501A Trimble C3 C5 C5HP ProductComparison USL 0320 LRsecJulian JonesÎncă nu există evaluări

- Comparative FM MonitorDocument1 paginăComparative FM MonitorMPIMLACÎncă nu există evaluări

- LAMBDA 265, 365, 465: UV/Visible SpectrosDocument2 paginiLAMBDA 265, 365, 465: UV/Visible SpectrosUswatul Hasanah100% (1)

- WaveDocument4 paginiWaveCrystal HayesÎncă nu există evaluări

- Tabel Perbandingan UsgDocument4 paginiTabel Perbandingan UsgpaulaavissaÎncă nu există evaluări

- Spesifikasi Acuson P500Document2 paginiSpesifikasi Acuson P500KurniaBagusÎncă nu există evaluări

- Cardiac - Vascular Ultrasonic Scanning SystemsDocument54 paginiCardiac - Vascular Ultrasonic Scanning SystemsGino F. Musso SavageÎncă nu există evaluări

- Compare Oticon Opn OpnS Siya RubyDocument2 paginiCompare Oticon Opn OpnS Siya RubyDEAÎncă nu există evaluări

- Spec Comparison - SuperMark 1.5T PDFDocument4 paginiSpec Comparison - SuperMark 1.5T PDFsergeÎncă nu există evaluări

- Vibration Analyzer ComparisonDocument4 paginiVibration Analyzer ComparisonJuanVargasÎncă nu există evaluări

- Tech & Rigger Tools & PPEDocument2 paginiTech & Rigger Tools & PPESathiyaseelan VelayuthamÎncă nu există evaluări

- Jenway 74 76 Series BrochureDocument6 paginiJenway 74 76 Series BrochureSadik OunisÎncă nu există evaluări

- HF Entry Level Radio Selection Chart: Full-Featured Radios Icom Has The Right Radio For The Right JobDocument1 paginăHF Entry Level Radio Selection Chart: Full-Featured Radios Icom Has The Right Radio For The Right JobBien TranÎncă nu există evaluări

- HF Entry Level Radio Selection Chart: Full-Featured Radios Icom Has The Right Radio For The Right JobDocument1 paginăHF Entry Level Radio Selection Chart: Full-Featured Radios Icom Has The Right Radio For The Right JobBien TranÎncă nu există evaluări

- HF Entry Level Radio Selection Chart: Full-Featured Radios Icom Has The Right Radio For The Right JobDocument1 paginăHF Entry Level Radio Selection Chart: Full-Featured Radios Icom Has The Right Radio For The Right Jobelena daneshÎncă nu există evaluări

- Vis Uvvis Spectroscopy Education Solutions FL5299Document2 paginiVis Uvvis Spectroscopy Education Solutions FL5299BenitoÎncă nu există evaluări

- Spec Compare DP20T and KemenkesDocument4 paginiSpec Compare DP20T and KemenkesRiyandÎncă nu există evaluări

- SMART VTS Wireless Solutions: Features SVTS-500 SVTS-600 SVTS-700 SVTS-900 SVTS-1200Document6 paginiSMART VTS Wireless Solutions: Features SVTS-500 SVTS-600 SVTS-700 SVTS-900 SVTS-1200Sri KanthÎncă nu există evaluări

- Optical Spectrum Analyzer AP2050A - APEX TechnologiesDocument2 paginiOptical Spectrum Analyzer AP2050A - APEX TechnologiesAPEX TechnologiesÎncă nu există evaluări

- ESM Receiver AntennasDocument5 paginiESM Receiver AntennasPark Sung100% (1)

- B3. Noise Level Meter - Testo - 816-1Document2 paginiB3. Noise Level Meter - Testo - 816-1Harshvardhan ShahÎncă nu există evaluări

- 7 Spesifikasi USG Acuson S1000 USG Obgyn 4D UltraPremium W 3 Probes FINAL PDFDocument95 pagini7 Spesifikasi USG Acuson S1000 USG Obgyn 4D UltraPremium W 3 Probes FINAL PDFipungÎncă nu există evaluări

- Test & Inspection: OPM5 Optical Power MeterDocument4 paginiTest & Inspection: OPM5 Optical Power MeterMark Louie BerbaÎncă nu există evaluări

- Excite Live Vario Tech SpecsDocument2 paginiExcite Live Vario Tech SpecsosmannikovÎncă nu există evaluări

- Brother Fax 2600, 8060p, mfc-4300, 4600, 9060 Service Manual PDFDocument177 paginiBrother Fax 2600, 8060p, mfc-4300, 4600, 9060 Service Manual PDFdoraemon007Încă nu există evaluări

- BSWA Impedance Tube Systems Scantek Brochure v121530Document9 paginiBSWA Impedance Tube Systems Scantek Brochure v121530Teo Keng KaiÎncă nu există evaluări

- Hardwired Indoor Motion Detectors Quick Reference Guide - 042319 - R1 PDFDocument2 paginiHardwired Indoor Motion Detectors Quick Reference Guide - 042319 - R1 PDFRamon Mendoza PantojaÎncă nu există evaluări

- Datasheet Fault IndicatorDocument3 paginiDatasheet Fault IndicatorCesarÎncă nu există evaluări

- Leica Nova TS60 Total StationDocument3 paginiLeica Nova TS60 Total Stationkesuma surveyingÎncă nu există evaluări

- Spesifikasi Teknis RTI Piranha X-Ray Multimeter Multi PremiumDocument3 paginiSpesifikasi Teknis RTI Piranha X-Ray Multimeter Multi PremiumNuky ArdiniÎncă nu există evaluări

- E1 ComparisonofMetersDocument1 paginăE1 ComparisonofMetersJestonie OrdonezÎncă nu există evaluări

- Elearning134 1469625825846Document8 paginiElearning134 1469625825846Ala'a AbdullaÎncă nu există evaluări

- GeM Bidding 1352783 PDFDocument5 paginiGeM Bidding 1352783 PDFStrike infotech0% (1)

- Fiber Testing: The Right Thresholds and Why They Matter: Christian TillDocument33 paginiFiber Testing: The Right Thresholds and Why They Matter: Christian TillCamilo Restrepo CroÎncă nu există evaluări

- Spesifikasi SOMATOM Go - NowDocument2 paginiSpesifikasi SOMATOM Go - NowLoredano QuagliaÎncă nu există evaluări

- A.3 Environmental Tests: Feature Conventional Phased ArrayDocument1 paginăA.3 Environmental Tests: Feature Conventional Phased ArrayJorge Manuel GuillermoÎncă nu există evaluări

- OLP 34-35-38 Smartpocket Datasheet ViaviDocument4 paginiOLP 34-35-38 Smartpocket Datasheet ViaviIbadullah BilgenÎncă nu există evaluări

- Piranha Specs v2021.10bDocument5 paginiPiranha Specs v2021.10bsalesandservices.partoazmaÎncă nu există evaluări

- Disto X4Document3 paginiDisto X4suparman scieveÎncă nu există evaluări

- Duet Digital Comp MatrixDocument1 paginăDuet Digital Comp MatrixcrimperÎncă nu există evaluări

- Excite Live Top Tech SpecsDocument1 paginăExcite Live Top Tech SpecsVăn Thế NamÎncă nu există evaluări

- RUCKUS Indoor Wireless Access Points - CommScopeDocument2 paginiRUCKUS Indoor Wireless Access Points - CommScopeHayder KedirÎncă nu există evaluări

- WAVE - Interactive Flaw Detector: Ultrasonic NDT ReinventedDocument4 paginiWAVE - Interactive Flaw Detector: Ultrasonic NDT ReinventedDeyvi ChambillaÎncă nu există evaluări

- OSP6UDocument3 paginiOSP6UBethsy WinÎncă nu există evaluări

- Sound Level Meter: Testo 816-1 - Sound Level Measurement With Integrated Data StorageDocument2 paginiSound Level Meter: Testo 816-1 - Sound Level Measurement With Integrated Data StoragePras WiwinÎncă nu există evaluări

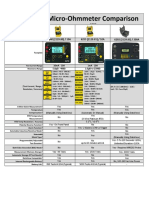

- Micro-Ohmmeter Comparison: 5A - 200A 0.10 - 1.0 10ma - 10A 5.0 - 400 1ma - 10A 1.0 To 2500Document1 paginăMicro-Ohmmeter Comparison: 5A - 200A 0.10 - 1.0 10ma - 10A 5.0 - 400 1ma - 10A 1.0 To 2500Alvaro PerezÎncă nu există evaluări

- r8085 DatasheetDocument2 paginir8085 DatasheetdanielÎncă nu există evaluări

- SIEMENS - Catalogo Seccionadoras - JUN-12 - NetDocument8 paginiSIEMENS - Catalogo Seccionadoras - JUN-12 - NetCarlos SilvaÎncă nu există evaluări

- Jabra Engage 65 Tech Spec Letter 100921 WEBDocument2 paginiJabra Engage 65 Tech Spec Letter 100921 WEBIbnuÎncă nu există evaluări

- 18 TOEC Appendix A Rev 02Document2 pagini18 TOEC Appendix A Rev 02alameerlogÎncă nu există evaluări

- Estación Total PENTAX V227 Spec - Func.listDocument2 paginiEstación Total PENTAX V227 Spec - Func.listFederico BianchiÎncă nu există evaluări

- RTS/OTS810 Series Total StationDocument2 paginiRTS/OTS810 Series Total StationMonehoi ZechalyÎncă nu există evaluări

- W3011 PDFDocument8 paginiW3011 PDFMiguel Andres VanegasÎncă nu există evaluări

- Murr Network Technology11-20Document42 paginiMurr Network Technology11-20AMÎncă nu există evaluări

- Techincal - Guide MotorolaDocument2 paginiTechincal - Guide MotorolaJhonattann EscobarÎncă nu există evaluări

- Spesifikasi SOMATOM Perspective 128 PDFDocument2 paginiSpesifikasi SOMATOM Perspective 128 PDFhermawan dwi saputro100% (1)

- Capacitance Level MeasurementDocument2 paginiCapacitance Level MeasurementBrandonÎncă nu există evaluări

- 500 ISTQB Sample Papers - Answers - Istqb - Guru PDFDocument13 pagini500 ISTQB Sample Papers - Answers - Istqb - Guru PDFTheRocket ShowÎncă nu există evaluări

- Motor Protection 7SK82 - 7SK85. Technical Data. Extract From Manual C53000-G5040-C024-7, Chapter 11. Energy AutomationDocument182 paginiMotor Protection 7SK82 - 7SK85. Technical Data. Extract From Manual C53000-G5040-C024-7, Chapter 11. Energy AutomationDrafter Technical SupportÎncă nu există evaluări

- Technical English - Lesson N°01Document4 paginiTechnical English - Lesson N°01Hadj Ben Aichouche Maroua C1 B1Încă nu există evaluări

- 6305ele-S1l5 - DCDocument25 pagini6305ele-S1l5 - DCJianguo WangÎncă nu există evaluări

- Ad4329 ManualDocument54 paginiAd4329 ManualHasan KendekÎncă nu există evaluări

- Updates To ANSI-EASA AR100 2015 0Document3 paginiUpdates To ANSI-EASA AR100 2015 0VILLANUEVA_DANIEL2064Încă nu există evaluări

- Rancang Bangun Prototipe Sistem Kendali Iron Removal Filter (Irf) Pada Unit Pengolahan Air Bersih Berbasis PLCDocument8 paginiRancang Bangun Prototipe Sistem Kendali Iron Removal Filter (Irf) Pada Unit Pengolahan Air Bersih Berbasis PLCaulyaakmala24Încă nu există evaluări

- What Is A Phase SequenceDocument5 paginiWhat Is A Phase SequencedanielÎncă nu există evaluări

- Three Improvements To The Reduceron: Matthew Naylor and Colin Runciman University of YorkDocument50 paginiThree Improvements To The Reduceron: Matthew Naylor and Colin Runciman University of YorkaldeghaidyÎncă nu există evaluări

- Cab x2 Manual enDocument24 paginiCab x2 Manual enjesus carranzaÎncă nu există evaluări

- U-WAS 2000 UserManualDocument106 paginiU-WAS 2000 UserManualEstetÎncă nu există evaluări

- Fara Dimensiuni Transformator 2D 3D NatasaDocument30 paginiFara Dimensiuni Transformator 2D 3D NatasaFazacas DanielÎncă nu există evaluări

- Abs EdgeDocument39 paginiAbs Edgecorporacion corprosinfro100% (3)

- Fingerprint-Authentication Using BiometricDocument59 paginiFingerprint-Authentication Using BiometricDebashishParidaÎncă nu există evaluări

- SWP-33 A Frame Machine For Soil Investigation WorkDocument1 paginăSWP-33 A Frame Machine For Soil Investigation WorkHassan AbdullahÎncă nu există evaluări

- BJT Cross ReferenceDocument7 paginiBJT Cross ReferenceNoel BalugoÎncă nu există evaluări

- QUESTION:Why in Computer 1024 Bytes Equals ToDocument2 paginiQUESTION:Why in Computer 1024 Bytes Equals Toanadeem_87Încă nu există evaluări

- RPP HeeDocument2 paginiRPP HeeJonni Maruli Tua SitorusÎncă nu există evaluări

- Wide Band RF TransformersDocument13 paginiWide Band RF Transformerskbdstl1Încă nu există evaluări

- Intro To Operating SystemDocument38 paginiIntro To Operating Systemmarc johansenÎncă nu există evaluări

- An Analog Front End For Self Capacitance Touch Sensing With EnvironmentalDocument3 paginiAn Analog Front End For Self Capacitance Touch Sensing With EnvironmentalMeer Zafarullah NoohaniÎncă nu există evaluări

- RSL DisconnectedDocument2 paginiRSL DisconnectedGunawan HendroÎncă nu există evaluări

- SerialsDocument7 paginiSerialsapi-3708126Încă nu există evaluări

- Electrical Circuits Multiple Choice QuestionsDocument7 paginiElectrical Circuits Multiple Choice QuestionsTaniyaÎncă nu există evaluări

- Smart HelmetDocument5 paginiSmart HelmetIJARSCT JournalÎncă nu există evaluări

- CBSE Class 12 Physics Sample Paper-01: Material Downloaded From - 1 / 20Document20 paginiCBSE Class 12 Physics Sample Paper-01: Material Downloaded From - 1 / 20ANUP KUMARÎncă nu există evaluări

- Grounding Rod Catalog Socome PDFDocument3 paginiGrounding Rod Catalog Socome PDFedy yusufÎncă nu există evaluări

- ML4824 Power Factor Correction and PWM Controller Combo: General Description FeaturesDocument16 paginiML4824 Power Factor Correction and PWM Controller Combo: General Description FeaturesTaras100% (1)

- Electronic Snap Kit Deluxe Snap RoverDocument48 paginiElectronic Snap Kit Deluxe Snap RoverScience HouseÎncă nu există evaluări

- Tig 3001 Spare PartsDocument12 paginiTig 3001 Spare PartsJesus Pedro CarvalhoÎncă nu există evaluări