Documente Academic

Documente Profesional

Documente Cultură

Somaloy 1000 3P 800 Feb 2016 1360HOG

Încărcat de

вадимTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Somaloy 1000 3P 800 Feb 2016 1360HOG

Încărcat de

вадимDrepturi de autor:

Formate disponibile

Somaloy® 1000 3P 800 MPa

General

Base material: Additive(s): Compaction: Heat treatment:

Somaloy 1000 3P 0.3% 3P Lube Pressure: 800 MPa Atmosphere: Steam

Die temperature: 80°C Temperature: 530°C

Mechanical properties Standards Physical properties Standards

o

Transverse rupture strength/150 C [MPa] 140/140 SS-ISO 3325 Density [g/cm3] 7.56 SS-ISO 2738

Tensile strength/Yield strength [MPa] 70/70 SS-EN 10002-1, ISO 2740 Thermal expansion [K-1] 11 e-06 ASTM E 228/MPIF 35

Compressive Strength/Yield [MPa] 470/290 ASTM E9-89a Thermal conductivity [W/m*K] 25 ISO 22007-2

Four point measurements on nom. size

Young’s modulus [GPa] 170 ASTM E 1876-99 Resistivity [μΩm] 70 OD 55mm ID 45mm Height 5mm

Poisson’s ratio - 0.23 ASTM E 1876-99

Impact Energy [J] 1.9 SS-EN 10045, SS-EN 25754 Powder properties Standards

Apparent density [g/cm3] 3.19 ISO 3923/1

Flow [s/50g] 36 ISO 4490

Magnetic properties Standards Green density [g/cm3] 7.54 ISO 3927

B@4000A/m [T] 1.42 IEC 60404-4 Green strength [MPa] 24 ISO 3995

B@10000A/m [T] 1.63 IEC 60404-4 Springback [%] 0.12 ISO 4492, ISO 2740

HC [A/m] 217 IEC 60404-4 Heat treated dim. change [%] -0.01 ISO 4492, ISO 2740

µr -max - 950 IEC 60404-4 Total dim. change [%] 0.11 ISO 4492, ISO 2740

Magnetising curve

Data adjusted for use in Finite Element modelling H[A/m] µ 0 M[T] B[T] H[A/m] µ 0 M[T] B[T]

B[T] Magnetising curve 0 0.00 0.00 11258 1.62 1.63

3.0 55 0.02 0.02 25221 1.81 1.84

2.5 83 0.04 0.04 49535 1.94 2.00

141 0.10 0.10 74535 1.99 2.08

2.0

193 0.17 0.17 99535 2.01 2.14

1.5

405 0.47 0.47 124535 2.03 2.18

1.0

565 0.63 0.63 149535 2.04 2.23

© Höganäs AB (publ.). February 2016. 1360HOG

0.5 862 0.84 0.84 189535 2.05 2.29

0.0 1355 1.04 1.04 229535 2.06 2.35

0 100 000 200 000 300 000

2352 1.24 1.24 279535 2.08 2.43

µ0M B H [A/m]

4905 1.43 1.44 304535 2.0809 2.46

Core loss

[W/kg] 50/60 Hz 100 Hz 200 Hz 300 Hz 400 Hz 500 Hz 600 Hz

0.5T 1.5/1.8 3.0 6.0 10 13 17 22

1.0T 5.0/6.1 10 21 33 46 60 75

1.5T 10/12 21 44 69 96 125 156

Measured according to CEI/IEC 60404-6:2003 on ring sample (OD55 ID45 H5 mm).

Loss model

Kh 0.098 Kep 0.000027

K h Hysterisis loss coefficient f Frequency [Hz]

Kep In particle eddy current B Field strength [T]

coefficient ρ Density [g/cm3]

B2 * f 2 * d2

Ptot = Kh * f * B1.75 + Kep * f 2 * B 2 + [W/kg] d Smallest cross section of resistivity [μΩm]

1.8 * ρ * resistivity * 1000 component [mm]

Model is verified up to 1.5T and 2000Hz.

www.hoganas.com/somaloy

S-ar putea să vă placă și

- External Corod Product Specification Sheet R4Document1 paginăExternal Corod Product Specification Sheet R4Ronald LlerenaÎncă nu există evaluări

- Total Seriola 32 - Product Data SheetDocument3 paginiTotal Seriola 32 - Product Data Sheetjihad jamarei100% (1)

- Industeel: A 22Cr DuplexDocument8 paginiIndusteel: A 22Cr DuplexJoaoÎncă nu există evaluări

- Butylglycol solvent technical data sheetDocument5 paginiButylglycol solvent technical data sheetxibs2009Încă nu există evaluări

- Analysis of Fe by Visible SpectrophotometryDocument1 paginăAnalysis of Fe by Visible SpectrophotometryAnnaReyesÎncă nu există evaluări

- C10200 (Cu-OF) : ) Incl. AgDocument2 paginiC10200 (Cu-OF) : ) Incl. AgJosue Crespo GonzalezÎncă nu există evaluări

- Sag & Tension (GAP Conductor)Document1 paginăSag & Tension (GAP Conductor)Subodh SontakkeÎncă nu există evaluări

- Brosur TAL JEC 3406 - Rev27Document1 paginăBrosur TAL JEC 3406 - Rev27Muhammad Yusuf100% (2)

- Mineral Heat Transfer Fluid SERIOLA 1510Document2 paginiMineral Heat Transfer Fluid SERIOLA 1510ahmetÎncă nu există evaluări

- VDM Alloy K-500: Nicorros AlDocument11 paginiVDM Alloy K-500: Nicorros AlIon PopescuÎncă nu există evaluări

- Seriola 1510Document2 paginiSeriola 1510nicolasÎncă nu există evaluări

- Ware House 20-70-8 Crane 10 Ton Structural ReportDocument34 paginiWare House 20-70-8 Crane 10 Ton Structural ReportHayman AhmedÎncă nu există evaluări

- Seriola-1510 TDS v180724Document2 paginiSeriola-1510 TDS v180724Thiago MolverstetÎncă nu există evaluări

- Haynes AlloysDocument2 paginiHaynes AlloysanshumanÎncă nu există evaluări

- Gas Dynamics LabDocument4 paginiGas Dynamics Labomar atefÎncă nu există evaluări

- Dewpoint Copper DPC-0521-DDocument4 paginiDewpoint Copper DPC-0521-DTengku MunzirÎncă nu există evaluări

- c11000 Cu Etp UsDocument2 paginic11000 Cu Etp UsjurreijndersÎncă nu există evaluări

- NyaDocument1 paginăNyaahmat kharisÎncă nu există evaluări

- Reservoir Fluid Study Report GulfaksDocument10 paginiReservoir Fluid Study Report GulfaksAngelo Kristoff MacarioÎncă nu există evaluări

- Syltherm XLT: Property SI Units English UnitsDocument3 paginiSyltherm XLT: Property SI Units English UnitsArifÎncă nu există evaluări

- TC - 115630Document1 paginăTC - 115630THPÎncă nu există evaluări

- Kuat Hantar Arus Aac Ec 1350 Jis C 3109Document1 paginăKuat Hantar Arus Aac Ec 1350 Jis C 3109Muhamad ZainudinÎncă nu există evaluări

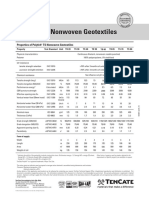

- TenCate Polyfelt TS Nonwoven GeotextilesDocument6 paginiTenCate Polyfelt TS Nonwoven GeotextilesChee Soon LeeÎncă nu există evaluări

- Flow Characteristics in a PipeDocument7 paginiFlow Characteristics in a PipeKevin Rivera GarciaÎncă nu există evaluări

- Insulating Firebrick SpecificationsDocument1 paginăInsulating Firebrick SpecificationsJackÎncă nu există evaluări

- Product Specifications Product Specifications: Ldf4 LDF4 - 50A 50ADocument3 paginiProduct Specifications Product Specifications: Ldf4 LDF4 - 50A 50ALuis Roca GalvánÎncă nu există evaluări

- NipsilR Precipitated Silica Grades for Paints, Papers and MoreDocument16 paginiNipsilR Precipitated Silica Grades for Paints, Papers and MoreDewiÎncă nu există evaluări

- Kanthal-A-1-En-V2021-02-04 13 - 30 Version 1Document3 paginiKanthal-A-1-En-V2021-02-04 13 - 30 Version 1BerchtoldÎncă nu există evaluări

- Material KG/M Dim. I Dim. II Dim. III Tip ProfilDocument21 paginiMaterial KG/M Dim. I Dim. II Dim. III Tip ProfilDanutÎncă nu există evaluări

- TDS Thermo 32Document2 paginiTDS Thermo 32Boris Popov100% (1)

- Oil and Gas Properties Analysis for Reservoir EvaluationDocument8 paginiOil and Gas Properties Analysis for Reservoir EvaluationolaseyeÎncă nu există evaluări

- NAYADocument1 paginăNAYAhenry_gtÎncă nu există evaluări

- Kanthal-D-En-V2021-02-04 13 - 31 Version 1Document3 paginiKanthal-D-En-V2021-02-04 13 - 31 Version 1Eduardo Campos RoblesÎncă nu există evaluări

- Thermal Aluminium Conductor: Technical PropertiesDocument1 paginăThermal Aluminium Conductor: Technical Propertiesabd salam100% (1)

- Condensate Specs and TBP 1Document1 paginăCondensate Specs and TBP 1asad razaÎncă nu există evaluări

- Datasheet-Kanthal-A-1-En-V2018-07-06 12 - 16 Version 1Document3 paginiDatasheet-Kanthal-A-1-En-V2018-07-06 12 - 16 Version 1putrastevanofyÎncă nu există evaluări

- Insulating Brick Example PDFDocument1 paginăInsulating Brick Example PDFpsaayoÎncă nu există evaluări

- Find similar insulating brick to SkamolDocument1 paginăFind similar insulating brick to SkamolpsaayoÎncă nu există evaluări

- FT Sifer 950iDocument2 paginiFT Sifer 950iAshik M RasheedÎncă nu există evaluări

- 4JB1 Calibration Data PDFDocument2 pagini4JB1 Calibration Data PDFHendrian ArdyÎncă nu există evaluări

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 paginiChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanÎncă nu există evaluări

- Flash Data and PVT Analysis of Gas Oil MixtureDocument41 paginiFlash Data and PVT Analysis of Gas Oil MixtureMario HuasasquicheÎncă nu există evaluări

- Nextel Ceramic Fiber Typical Properties: 3M Property Units Nextel™ 312 Nextel™ 440 Nextel™ 550Document2 paginiNextel Ceramic Fiber Typical Properties: 3M Property Units Nextel™ 312 Nextel™ 440 Nextel™ 550ninatenaÎncă nu există evaluări

- TDS - Nimrod C276KSDocument1 paginăTDS - Nimrod C276KSImmalatulhusnaÎncă nu există evaluări

- C7025 (英文) ver1 6Document11 paginiC7025 (英文) ver1 6顏健軒Încă nu există evaluări

- Grand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsDocument1 paginăGrand Pacific Petrochemical Corp: Grade: Gramid N200GP Typical Properties of GPPC Pa66-N200Gp ResinsPhuoc Thinh TruongÎncă nu există evaluări

- BoilerDocument29 paginiBoilerhonchoabhiÎncă nu există evaluări

- Nya Sni IecDocument1 paginăNya Sni IecekasandiawanÎncă nu există evaluări

- Density (Mol/L) Vs Pressure (Mpa) : Carbon Dioxide at 50 CDocument6 paginiDensity (Mol/L) Vs Pressure (Mpa) : Carbon Dioxide at 50 CbobÎncă nu există evaluări

- ChainDocument2 paginiChainmyusuf_engineerÎncă nu există evaluări

- Airpollution LATESTDocument1 paginăAirpollution LATESTSyifa'aSyamimieAmirÎncă nu există evaluări

- PEEKDocument2 paginiPEEKHugorong WongÎncă nu există evaluări

- Ceramic Fiber Blanket CatalogDocument7 paginiCeramic Fiber Blanket Catalogevelyn reksaÎncă nu există evaluări

- Tugas 1 Tekprodgas Cheasar Septian Dwi Cahyo071002200065Document21 paginiTugas 1 Tekprodgas Cheasar Septian Dwi Cahyo071002200065Cheasar SeptianÎncă nu există evaluări

- National Institute of Technology SrinagarDocument14 paginiNational Institute of Technology SrinagarAlex HustleÎncă nu există evaluări

- ANKRAL R1 Zement ISO PTDocument1 paginăANKRAL R1 Zement ISO PTWalysson JohnathasÎncă nu există evaluări

- ASTM Grades For Insulating Fire BrickDocument2 paginiASTM Grades For Insulating Fire BrickrajachemÎncă nu există evaluări

- AC Fans Static Calculation Final-1Document20 paginiAC Fans Static Calculation Final-1Hendrias A.SÎncă nu există evaluări

- Principal Stresses: Minor Principal Stress (Mpa)Document7 paginiPrincipal Stresses: Minor Principal Stress (Mpa)Muhammad IqbalÎncă nu există evaluări

- 0 Proposal Form Top Up SUBMITTED BY Markandeya Raju PDFDocument3 pagini0 Proposal Form Top Up SUBMITTED BY Markandeya Raju PDFHOD (MVGR Civil)Încă nu există evaluări

- Lecture 3 - Evolution of Labour Laws in IndiaDocument13 paginiLecture 3 - Evolution of Labour Laws in IndiaGourav SharmaÎncă nu există evaluări

- Jmeter Performance Testing Your Webapp 1203622239433273 3Document12 paginiJmeter Performance Testing Your Webapp 1203622239433273 3pallavi91Încă nu există evaluări

- Nca Lahore Nca Lahore Nca LahoreDocument1 paginăNca Lahore Nca Lahore Nca LahoreSalman QaiserÎncă nu există evaluări

- Fmi-Hd BR PDFDocument16 paginiFmi-Hd BR PDFmin thantÎncă nu există evaluări

- ERACS JournalDocument8 paginiERACS Journalmahasiswaprofesi2019Încă nu există evaluări

- Solaris 10 Service - (Management Facility (SMF: Oz Melamed E&M Computing Nov 2007Document18 paginiSolaris 10 Service - (Management Facility (SMF: Oz Melamed E&M Computing Nov 2007Anonymous 4eoWsk3100% (3)

- Good Story Company Submission Cheat SheetDocument28 paginiGood Story Company Submission Cheat SheetRoseÎncă nu există evaluări

- Business Process Reengineering and Performance Improvement in The BankDocument12 paginiBusiness Process Reengineering and Performance Improvement in The BankYakut Rumani SultanÎncă nu există evaluări

- Marie Campbell: Web DesignerDocument1 paginăMarie Campbell: Web DesignerAli hossain AkashÎncă nu există evaluări

- RTC Ruling on Land Ownership Upheld by CADocument12 paginiRTC Ruling on Land Ownership Upheld by CAGladys BantilanÎncă nu există evaluări

- PSK Lab ManualDocument4 paginiPSK Lab ManualSakshi DewadeÎncă nu există evaluări

- Huntersvsfarmers 131204084857 Phpapp01Document1 paginăHuntersvsfarmers 131204084857 Phpapp01Charles BronsonÎncă nu există evaluări

- Chapter 10Document28 paginiChapter 10ahmedÎncă nu există evaluări

- 12V Laptop ChargerDocument12 pagini12V Laptop ChargerSharon Babu0% (1)

- (OBIEE11g) Integrating Oracle Business Intelligence Applications With Oracle E-Business Suite - Oracle Bi SolutionsDocument11 pagini(OBIEE11g) Integrating Oracle Business Intelligence Applications With Oracle E-Business Suite - Oracle Bi SolutionsVenkatesh Ramiya Krishna MoorthyÎncă nu există evaluări

- Comparison Between India and ChinaDocument92 paginiComparison Between India and Chinaapi-3710029100% (3)

- Simple Mortgage DeedDocument6 paginiSimple Mortgage DeedKiran VenugopalÎncă nu există evaluări

- Brushed Axial Fans: VA85-A101-96A Performance DiagramDocument3 paginiBrushed Axial Fans: VA85-A101-96A Performance DiagramJaskaran SinghÎncă nu există evaluări

- Group analyzes Sunsilk brand auditDocument49 paginiGroup analyzes Sunsilk brand auditinkLLL0% (1)

- Financial Management Toolkit For Recipients of Eu Funds For External ActionsDocument12 paginiFinancial Management Toolkit For Recipients of Eu Funds For External ActionsGeorge BekatorosÎncă nu există evaluări

- ElasticityDocument27 paginiElasticityJames Baryl GarceloÎncă nu există evaluări

- Understanding ProbabilityDocument14 paginiUnderstanding ProbabilityKajaraiÎncă nu există evaluări

- Flygt 3202 PDFDocument137 paginiFlygt 3202 PDFEduardo50% (2)

- Image Processing Toolbox - FunctionsDocument16 paginiImage Processing Toolbox - Functionsabcd efghÎncă nu există evaluări

- Mohamed Khaled CVDocument2 paginiMohamed Khaled CVMohamed KhaledÎncă nu există evaluări

- Defining Yourself As A LeaderDocument1 paginăDefining Yourself As A Leaderrosli2503Încă nu există evaluări

- PW Trail Beaver Valley Oct 25Document63 paginiPW Trail Beaver Valley Oct 25Pennywise PublishingÎncă nu există evaluări

- Winter 2011Document128 paginiWinter 2011baoHVLABÎncă nu există evaluări

- Kokichi OmaSprite Gallery Danganronpa Wiki FDocument3 paginiKokichi OmaSprite Gallery Danganronpa Wiki Fmzcvxf9fwpÎncă nu există evaluări